Automatic copper pipe drawing device

A kind of drawing equipment and automatic technology, applied in the field of copper tube automatic drawing equipment, to achieve the effect of automatic drawing and fast and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

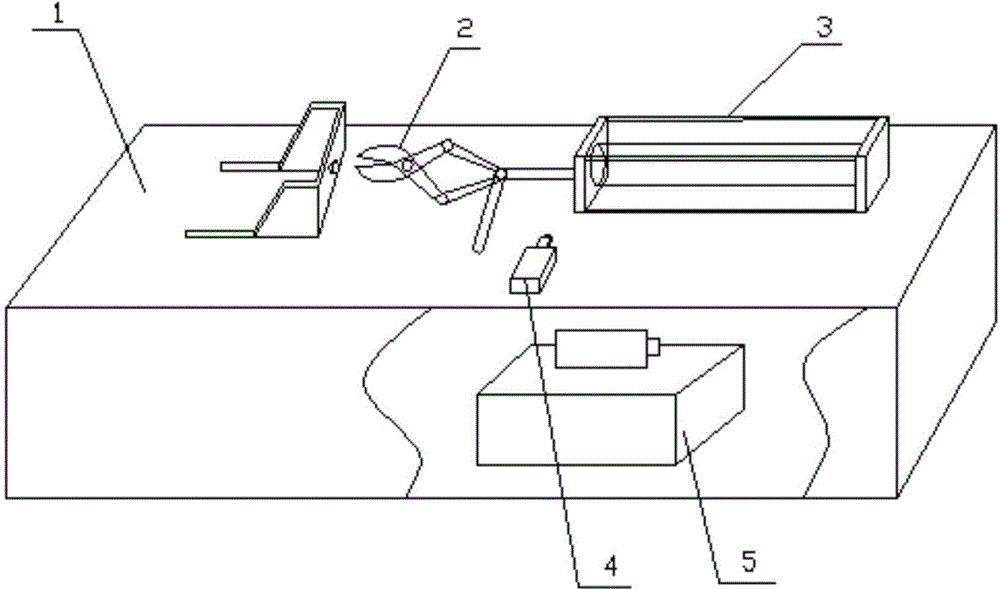

[0012] Referring to the accompanying drawings, the copper pipe automatic drawing equipment includes a fuselage 1, a hydraulic system 5, an automatic clamping pliers 2 and a drawing device, the hydraulic system 5 is installed inside the fuselage 1, and the upper surface of the fuselage 1 is installed There are automatic clamping pliers 2 and a drawing device, and the drawing device includes a drawing hydraulic cylinder 3 and a drawing length detection travel switch 4, and the proportional regulating valve adopted in the hydraulic system 5 is a pressure-balanced disc lifting adjustment, The decompression ratio was adjusted to 0.6. The shape of the automatic clamping pliers 2 is a rhombus structure, and a hydraulic cylinder 3 is connected to the end. The pressure of the drawing hydraulic cylinder 3 of the drawing device is 20Mpa. The drawing length detection travel switch 4 of the drawing device is a sick micro switch installed on the side of the drawing cylinder. Place the cop...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com