Slide rail mechanism and refrigerator with same

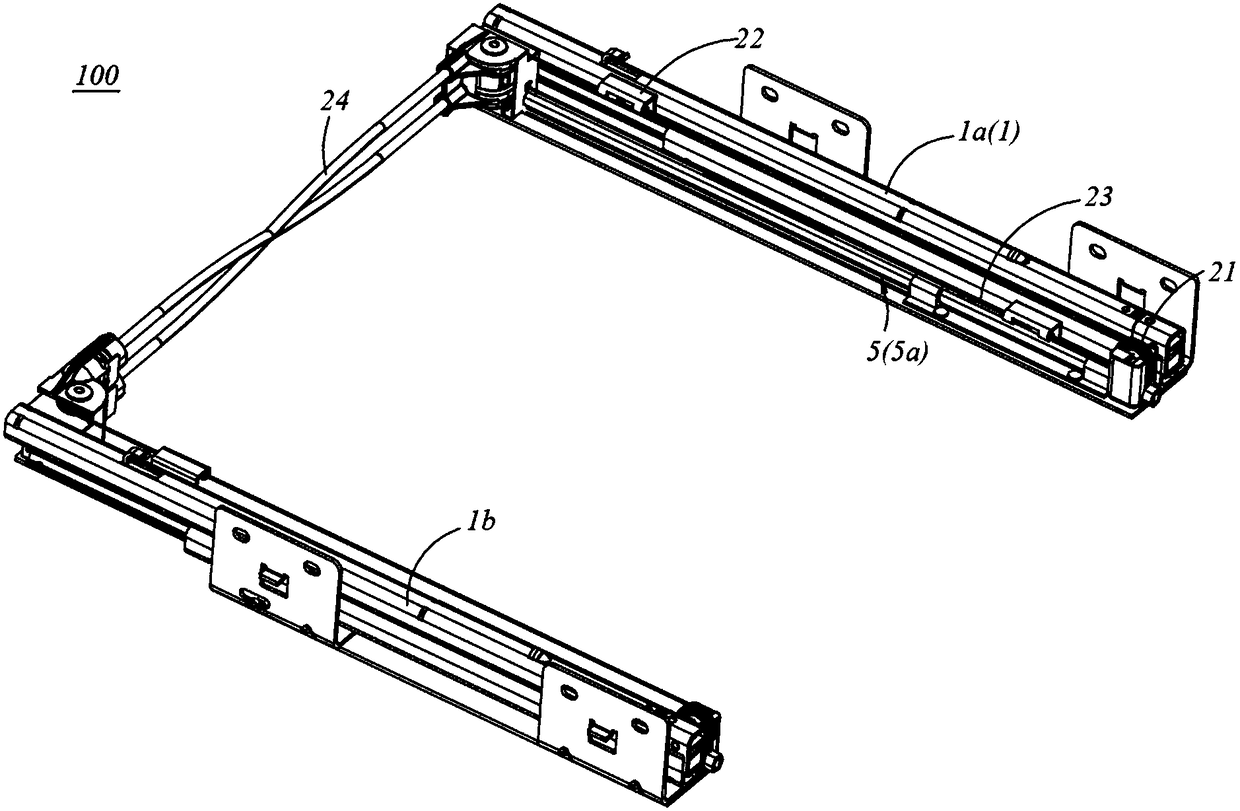

A technology of slide rails and cabinets, which is applied in the field of slide rail mechanisms and refrigerators equipped with them, which can solve problems such as easy wear, easy damage to synchronous mechanisms, and poor user experience, and achieve the effect of convenient use and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

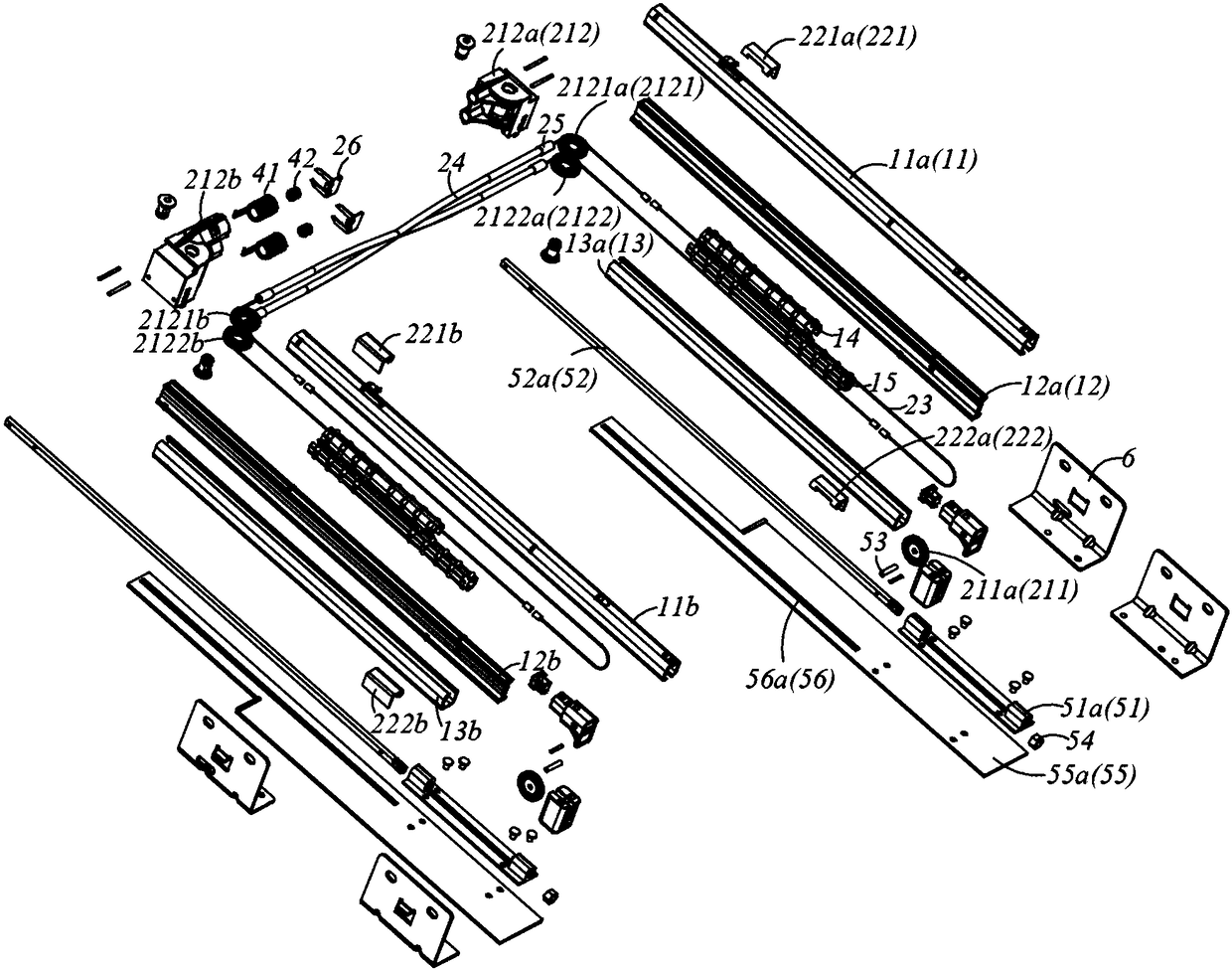

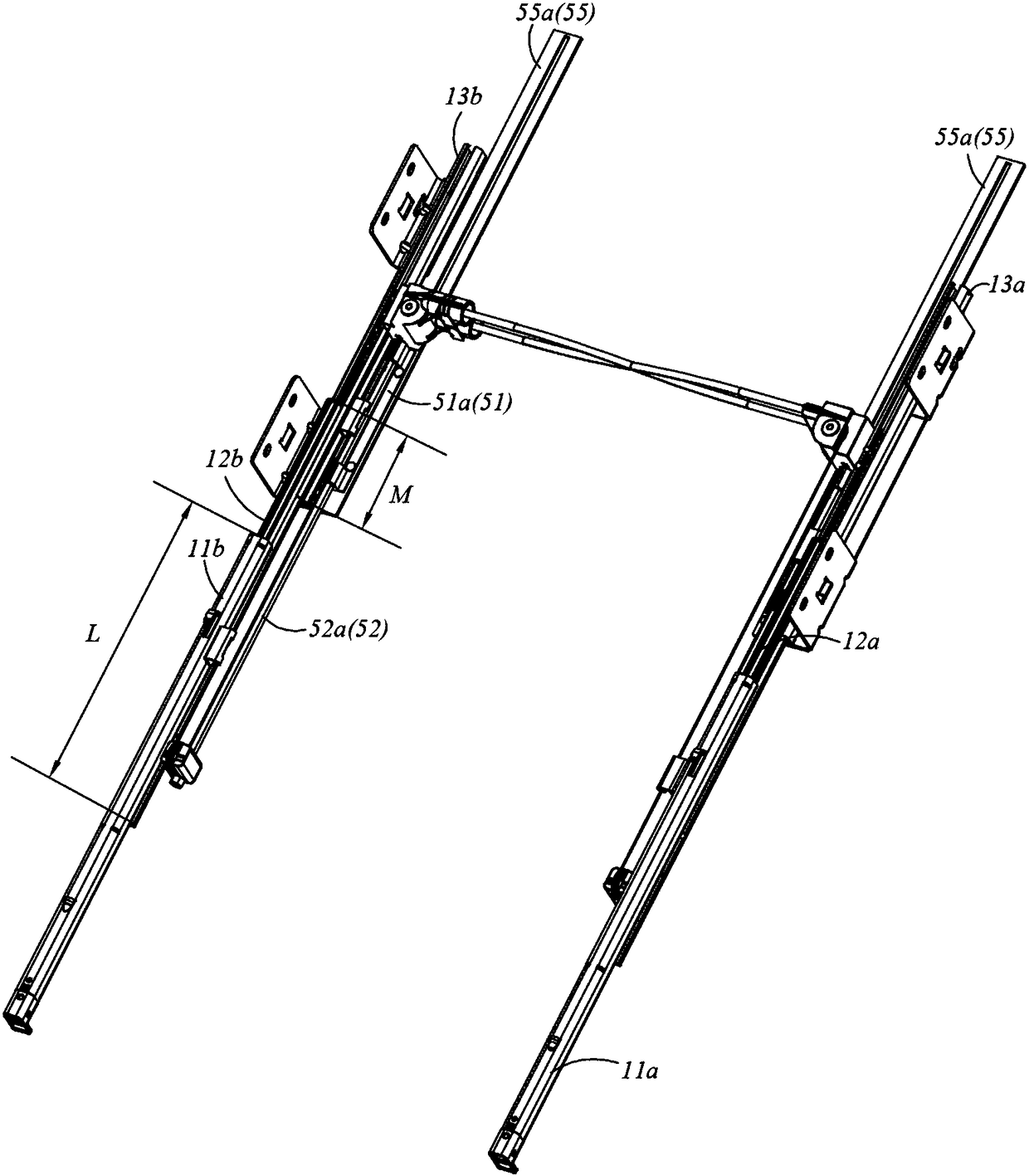

[0068]Here, on the basis of the three-section slide rail in the prior art, the auxiliary middle rail assembly 5b is added, and the steering piece 21 of the synchronous mechanism 2 is arranged on the auxiliary middle rail assembly 5b, and the steering piece 21 and the three-section slide rail are not connected to each other. Contact, that is to say, at this time, the moving tracks of the steering member 21 and the tension member 23 do not overlap with the sliding tracks of the three-section slide rails, even if the gap between the upper rail 11 and the lower rail 13 is reduced due to wear, it does not overlap. It will affect the normal operation of the steering member 21 in the synchronous mechanism 2, and can effectively solve the problem of interference between the steering member 21 and the upper rail 11 and / or the lower rail 13 in the prior art. In addition, this embodiment can utilize the common three-section slide rail structure in the market, and only needs to cooperate w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com