Reciprocating steel pipe drawer

A reciprocating, tube-extracting machine technology, applied in the field of steel rolling equipment, can solve problems such as high equipment cost, increased steel pipe manufacturing cost, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

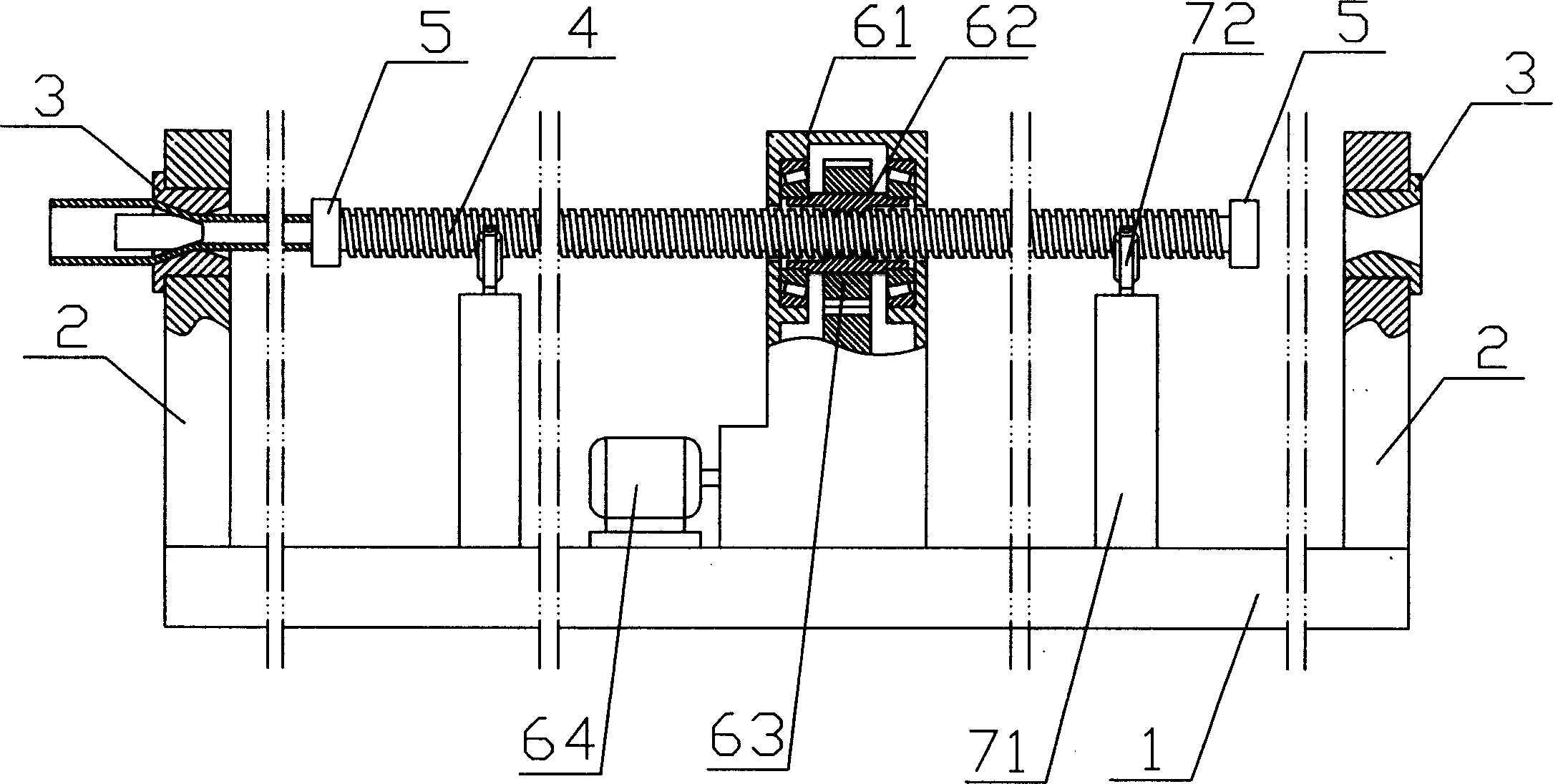

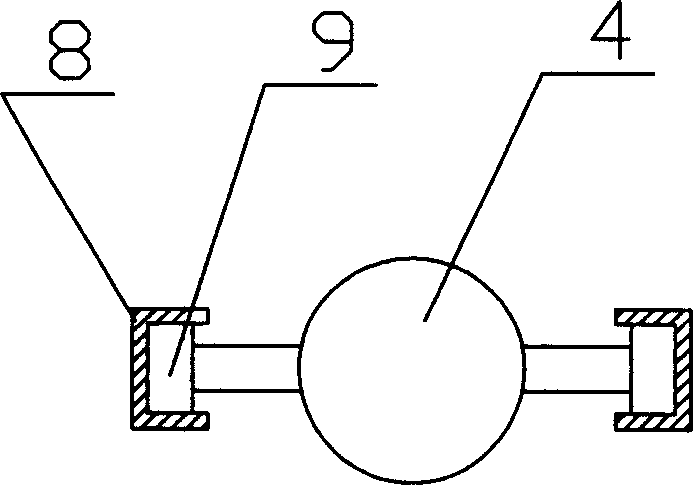

[0011] as attached figure 1 As shown, the reciprocating steel pipe pulling machine includes a frame 1, and the two ends of the frame 1 are respectively equipped with a reducing die support 2, and a reducing die 3 is installed on the reducing die support 2, which is located at the two reducing die supports. 2 is provided with an extruding lead screw 4 that can move left and right along the centerlines of the two reducing dies 3, steel pipe clamps 5 are respectively installed at both ends of the extubating lead screw 4, and are located in the middle of the two reducing die supports 2 The extubation screw drive device is installed on the frame 1.

[0012] The extubation screw driving device includes a gearbox housing 61, a nut 62 installed in the gearbox housing 61 and matched with the extubation screw 4, and a drive gear 63 fixedly connected to the nut 62, passing through the middle The gear drives the motor 64 that drives the gear 63 to rotate, and the screw nut 62 only perfor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com