Grounding switch contact

A grounding switch and contact technology, applied in electrical switches, air switch parts, contacts, etc., can solve the problems of poor electrical contact reliability, large impact force, complex structure, etc., achieve reliable contact, reduce equipment damage, improve The effect of movement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

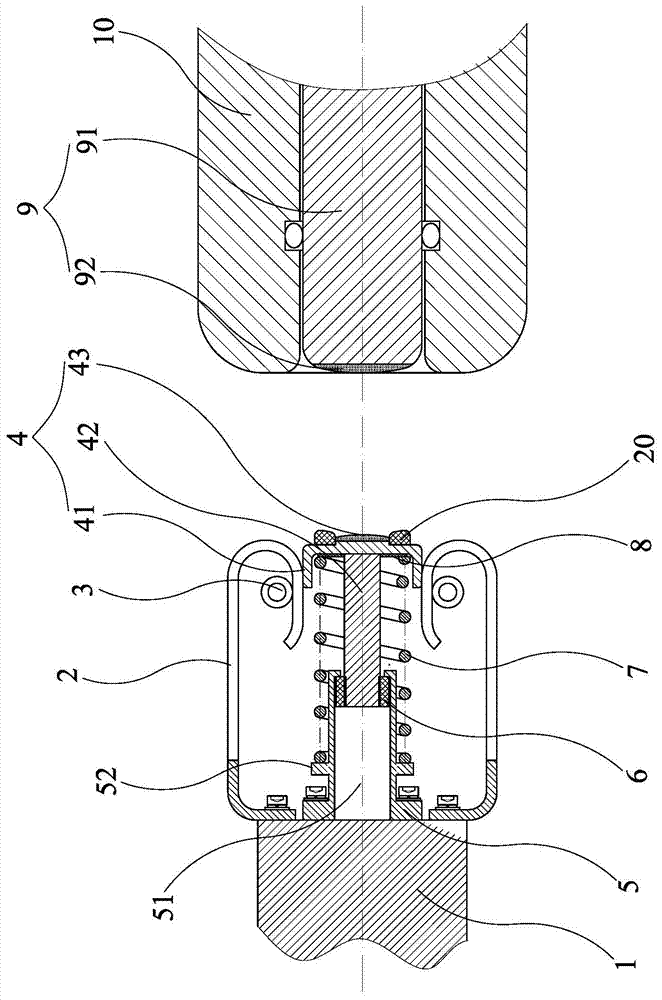

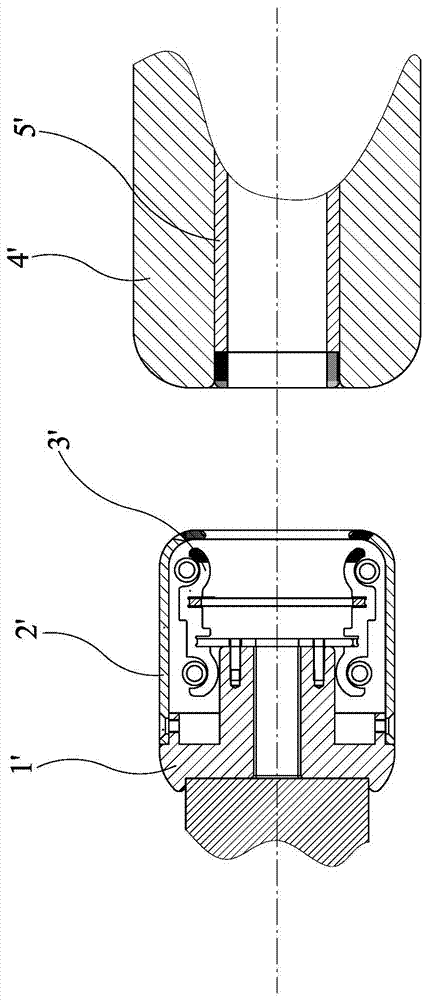

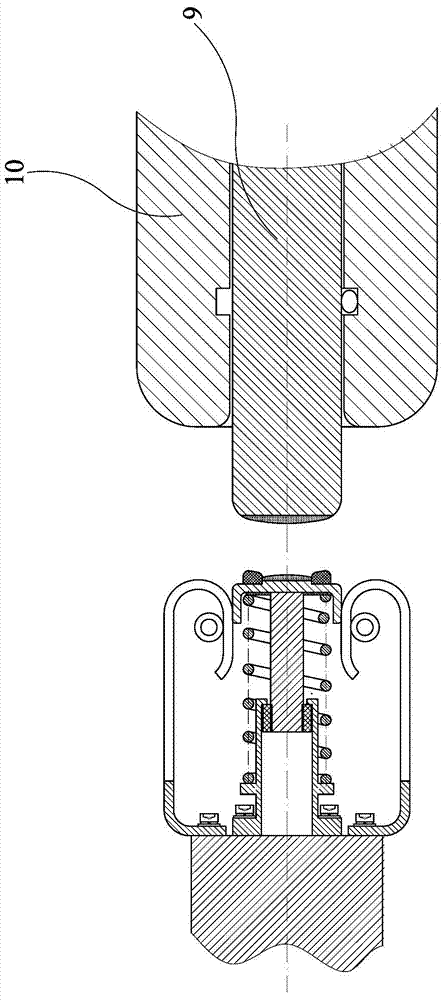

[0025] like figure 1 , Figure 5 As shown, the present invention is a grounding switch contact; including a static contact conductor 1, a shielded static contact 2, a contact spring 3, a static arcing contact 4, a guide cylinder 5, a guide block 6, and a buffer spring 7 , Insulation gasket 8, earthing switch moving contact 9, moving contact seat 10, buffer pad 20.

[0026] The static arc-leading contact 4 includes a cup-shaped conductor 41, a guide rod 42, and a static arc-leading contact arc-resistant alloy 43; the outer end of the guide rod 42 is fixed on the inner end of the cup-shaped conductor 41. On the outer end surface of the cup-shaped conductor 41 is fixed an arc-resistant alloy 43 for a static arc-starting contact.

[0027] The moving contact 9 of the grounding switch includes a conductive rod 91 and a moving contact arc-resistant alloy 92 ; the moving contact arc-resistant alloy 92 is fixed on the outer end surface of the conductive rod 91 .

[0028] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com