Preparation method of high-speed locomotive pantograph carbon slide plate material

A technology of pantograph carbon slides and pantograph slides, applied in the field of electric locomotives, can solve the problems of poor mechanical properties of pure carbon slides, large wire damage, short life, etc., achieve good mechanical properties, improve mechanical properties, high The effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

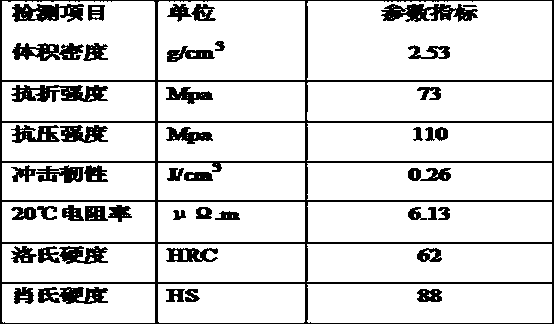

Image

Examples

Embodiment 1

[0016] Product configuration method

[0017] Raw material ratio:

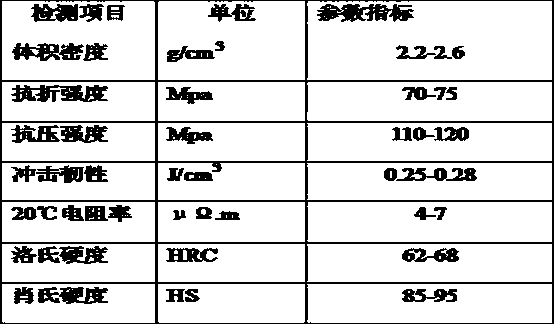

[0018] Prepare the raw materials, the raw materials are mixed according to weight percentage, graphite powder 45%, copper-coated graphite powder 20%, carbon black 3%, resin binder content 15%, impregnating agent is impregnated asphalt 17%, and then mixed at a pressure of 10Mpa Extrude strips under pressure, and roast according to the heating curve of the first roasting, roasting for 260 hours, after roasting, the pressure is 1Mpa, the temperature is 230°C, the asphalt impregnation time is 2 hours, and finally the second roasting is carried out, and the roasting temperature is 800 ℃, the time is 300 hours, and the physical and chemical indicators of the product are:

[0019]

Embodiment 2

[0021] Product configuration method

[0022] Raw material ratio:

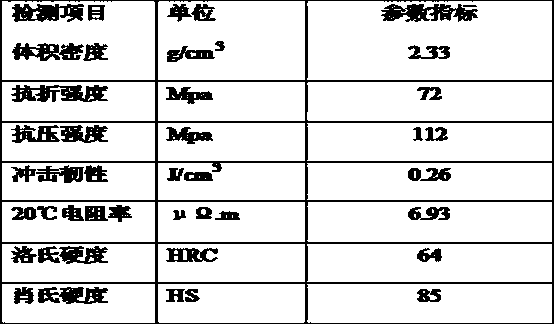

[0023] Prepare the raw materials, the raw materials are mixed according to weight percentage, graphite powder 35%, copper-coated graphite powder 30%, carbon black 3%, resin binder content 15%, impregnating agent is impregnated asphalt 17%, and then mixed at a pressure of 12Mpa Extrude strips under pressure, and roast according to the temperature rise curve of the first roasting, roasting for 260 hours, after roasting, the pressure is 1.5Mpa, the temperature is 250 ° C, the asphalt impregnation time is 2 hours, and finally the second roasting, the roasting temperature is 800℃, the time is 350 hours, the physical and chemical indicators of the product are:

[0024]

Embodiment 3

[0026] Product configuration method

[0027] Raw material ratio:

[0028] Prepare raw materials, raw materials are mixed according to weight percentage, graphite powder 30%, copper-coated graphite powder 35%, carbon black 3%, resin binder content 15%, impregnating agent is 17% impregnated asphalt, and then mixed at a pressure of 15Mpa Extrude strips under pressure, and roast according to the temperature rise curve of the first roasting, roasting for 260 hours, after roasting, the pressure is 1.5Mpa, the temperature is 280 ° C, the asphalt impregnation time is 2 hours, and finally the second roasting, the roasting temperature is 800℃, the time is 400 hours, the physical and chemical indicators of the product are:

[0029] Test items

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com