Electrochemical grinding electrode, and apparatus and method using the same

a technology of electrochemical grinding electrodes and electrodes, which is applied in the direction of manufacturing tools, metal/alloy conductors, and conductors, etc., can solve the problems of inferior abrasive properties, lower arc resistance and/or limitations of conventional electrodes for electrochemical grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Embodiments of the present disclosure will be described hereinbelow with reference to the accompanying drawings. In the following description, well-known functions or constructions are not described in detail to avoid obscuring the disclosure in unnecessary detail.

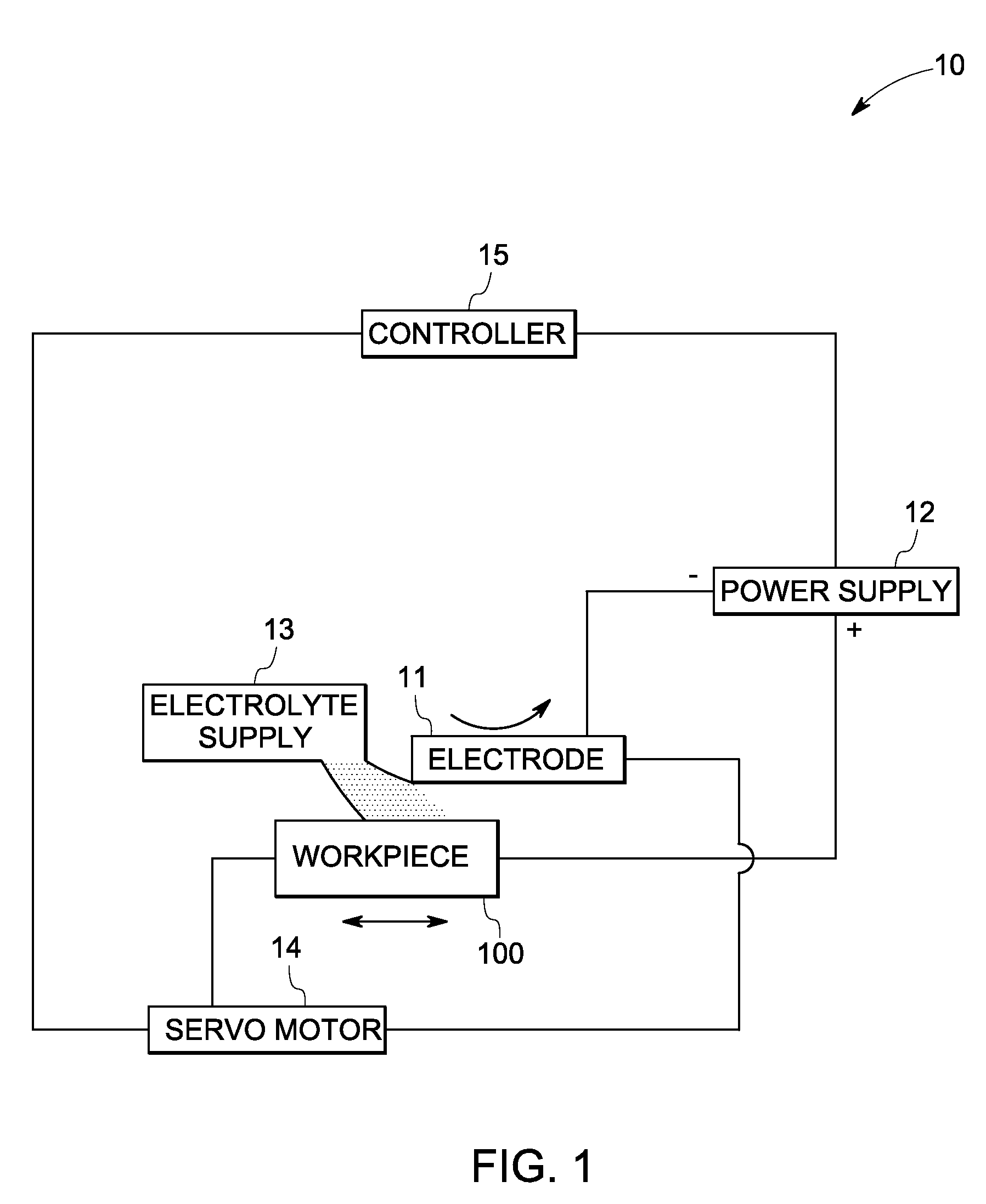

[0015]FIG. 1 illustrates a schematic diagram of an electrochemical grinding apparatus 10 in accordance with one embodiment of the invention. In embodiments of the invention, the electrochemical grinding apparatus 10 may be used to remove material from a workpiece 100 to form a desired configuration. As illustrated in FIG. 1, the electrochemical grinding apparatus 10 comprises an electrode 11, a power supply 12, an electrolyte supply 13, a servomotor 14 and a controller 15. In non-limiting examples, the electrode 11 may be in a rod, wheel or spindle shape.

[0016]In the illustrated example, the electrode 11 and the workpiece 100 are connected to negative and positive poles of the power supply 12, respectively. According...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight percent | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com