Halogen-free flame-proof glass fiber reinforcement epoxy molding compound

An epoxy molding compound and glass fiber technology, which is applied in the field of thermosetting molding compounds, can solve the problems such as the expansion limitation of glass fiber reinforced epoxy molding compounds, the generation of toxic and harmful gases, and the unfavorable human environment, so as to ensure the safety and protection of the human body. effects of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

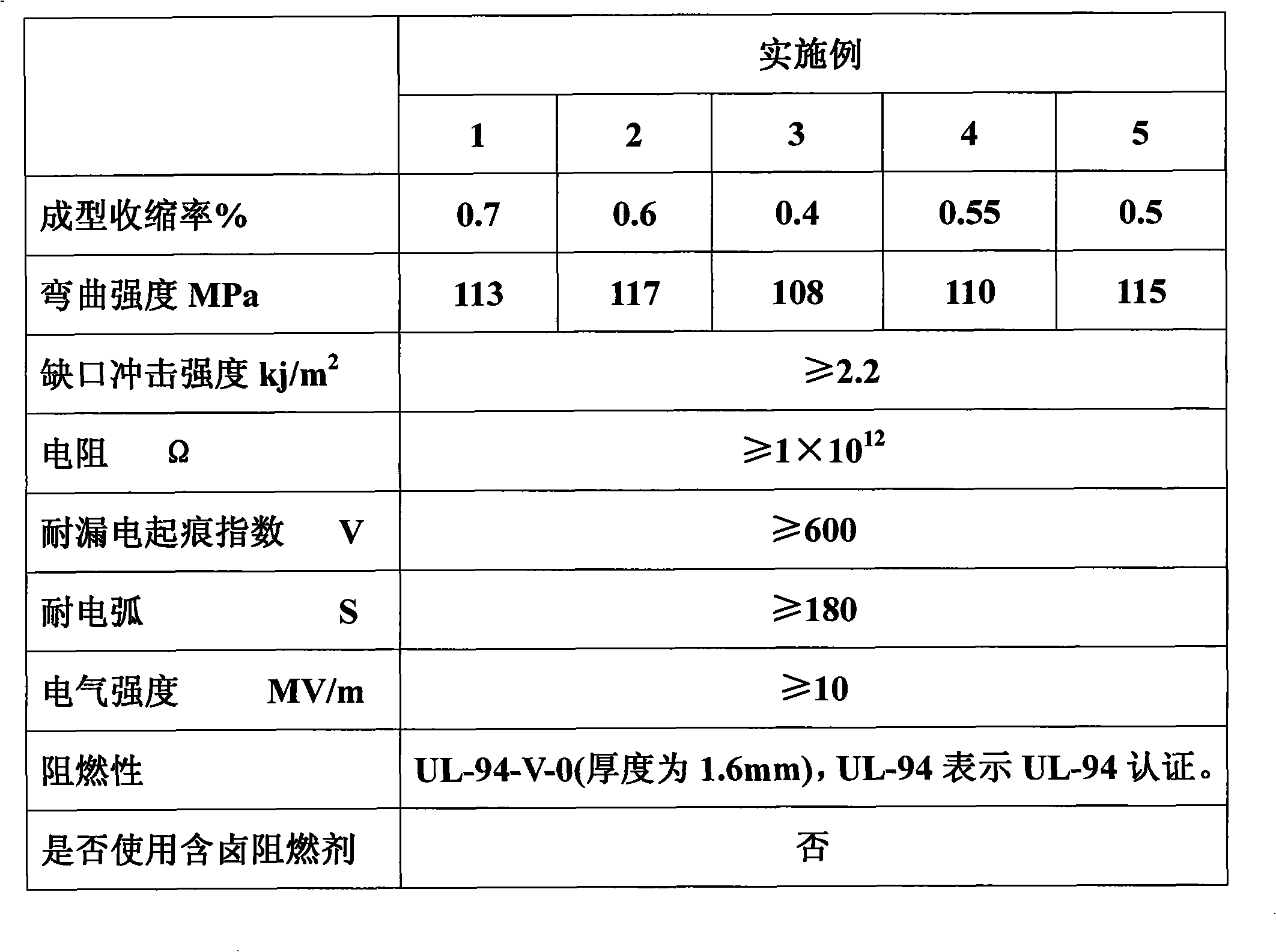

Examples

Embodiment 1

[0024] 20.2 parts of bisphenol A type epoxy resin;

[0025] 7.3 parts of novolak resin;

[0026] 2.3 parts of dicyandiamide;

[0027] 62 parts of silicon dioxide;

[0028] 6.8 parts of polyphosphate amine;

[0029] Zinc borate 0.8 part;

[0030] 1.2 parts of calcium stearate;

[0031] 0.6 parts of montan wax;

[0032] 15 parts of glass fiber;

[0033] After accurately weighing the components of bisphenol A epoxy resin, silica (42 parts) as a mineral filler, polyphosphate amine, zinc borate, calcium stearate (1 part) and montan wax (0.4 part) , adding to a kneader for heating and mixing, the mixing temperature is 100-120°C, after mixing evenly, cool and pulverize to obtain component (A);

[0034] Then novolac resin, dicyandiamide, silicon dioxide (20 parts), calcium stearate (0.2 part) and montan wax (0.2 part) components were accurately weighed, then added to the kneader for heating and mixing, After mixing evenly, cool and pulverize to obtain component (B);

[0035] ...

Embodiment 2

[0037] 21.5 parts of bisphenol A type epoxy resin;

[0038] Novolak resin 8.1 parts;

[0039] 1.5 parts of 2-methylimidazole;

[0040] 65 parts of silicon dioxide;

[0041] 7.3 parts of melamine phosphate;

[0042] 1.8 parts of antimony trioxide;

[0043] Zinc stearate 1.0 parts;

[0044] Palm wax 0.8 parts;

[0045] 0.1 parts of stearic acid;

[0046] 16 parts of glass fiber;

[0047] Everlasting Red 0.3 parts.

[0048] First accurately weigh the components of bisphenol A epoxy resin, silicon dioxide (45 parts), melamine phosphate, antimony trioxide, zinc stearate, palm wax (0.4 parts) and permanent red, then add The kneader is heated and mixed, and the mixing temperature is 100-120 ° C. After the mixing is uniform, it is cooled and pulverized to obtain component (A);

[0049] Then novolac resin, 2-methylimidazole, silicon dioxide (20 parts), stearic acid and palm wax (0.4 parts) were accurately weighed, then added to the kneader for heating and mixing, and after mix...

Embodiment 3

[0052] 22.8 parts of bisphenol A type epoxy resin;

[0053] 8.8 parts of novolac resins;

[0054] 3.2 parts of dicyandiamide;

[0055] 70 parts of aluminum hydroxide;

[0056] 5.2 parts of melamine urate;

[0057] 1.5 parts of zinc borate;

[0058] 0.5 parts of magnesium stearate;

[0059] Palm wax 0.8 parts;

[0060] 0.7 parts of montan wax;

[0061] 0.1 parts of stearic acid;

[0062] 19.5 parts of glass fiber;

[0063]Titanium cyanide blue 0.35 parts.

[0064] First accurately weigh the components of bisphenol A epoxy resin, aluminum hydroxide (50 parts) as a mineral filler, melamine urate, zinc borate, magnesium stearate, palm wax and titanium cyanide blue, then add and knead machine for heating and mixing, the mixing temperature is 100-120°C, after mixing evenly, cool and pulverize to obtain component (A);

[0065] After accurately weighing the novolac resin, dicyandiamide, aluminum hydroxide (20 parts), stearic acid and montan wax components, add them to the kn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com