Solvent-free anti-pollution flashover organic silicon coating and preparation method thereof

An organic silicon coating, anti-pollution flashover technology, applied in coatings and other directions, can solve problems such as slow curing speed, and achieve the effects of excellent hydrophobicity, excellent self-cleaning, and excellent aging performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a solvent-free antifouling flashover silicone paint, which includes the following components:

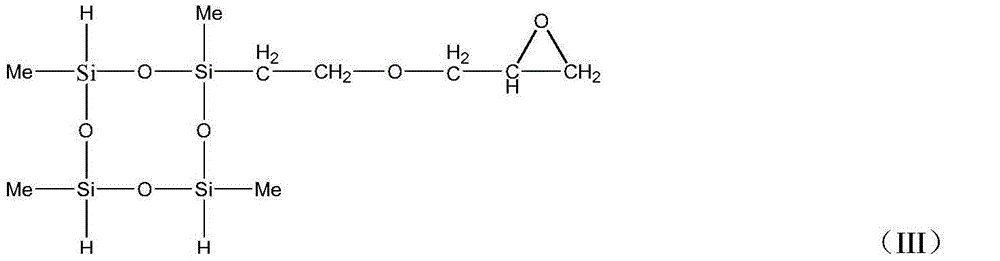

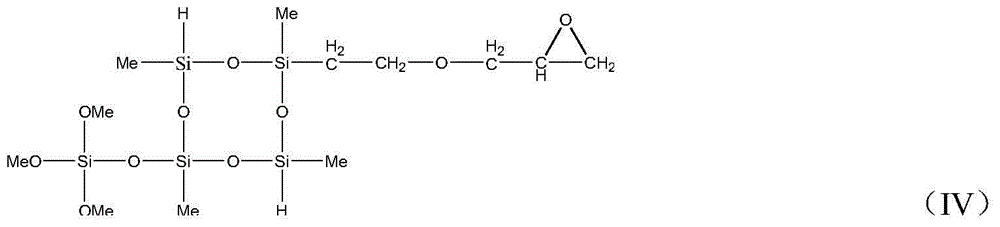

[0047]Viscosity is 1500mPa.s, 100 parts of polydimethylsiloxane containing terminal vinyl group, its vinyl group directly linked to Si can be located at the two ends of the molecular chain or in the middle of the molecular chain, and its molecular structure can be as shown in (I) Show; Viscosity is 60mPa.s 1.5 parts of polydimethylsiloxane containing terminal silicon hydrogen group, its hydrogen atom that is directly connected with Si can be positioned at the two ends of molecular chain or in the middle of molecular chain, and its molecular structure can be as (II ) shown; the structure is Me 3 SiO(Me 2 SiO) 4 (MeHSiO) 6 SiMe 3 8.5 parts of polysiloxane; 15 parts of wet-process white carbon black, whose specific surface area is 190m 2 / g, with an average particle size of 10 μm; 10 parts of aluminum hydroxide, 10 parts of decabromodiphenyl ether; ...

Embodiment 2

[0063] This embodiment provides a solvent-free antifouling flashover silicone paint, which includes the following components:

[0064] The viscosity is 2000mPa.s, 100 parts of polydimethylsiloxane containing terminal vinyl groups, the vinyl groups directly connected to Si can be located at the two ends of the molecular chain or in the middle of the molecular chain, and its molecular structure can be as shown in (I) Show; Viscosity is 80mPa.s 1.0 parts of polydimethylsiloxane containing terminal silicon hydrogen group, its hydrogen atom that is directly connected with Si can be positioned at the two ends of molecular chain or in the middle of molecular chain, and its molecular structure can be as (II ) shown; the structure is Me 3 SiO(Me 2 SiO) 4 (MeHSiO) 6 SiMe 3 8.0 parts of polysiloxane; 15 parts of wet-process white carbon black, whose specific surface area is 190m 2 / g, the average particle size is 10 μm; 15 parts of aluminum hydroxide, 5 parts of decabromodiphenyl et...

Embodiment 3

[0074] This embodiment provides a solvent-free antifouling flashover silicone paint, which includes the following components:

[0075] Viscosity is 6000mPa.s, 100 parts of polydimethylsiloxane containing vinyl end; other components are the same as in Example 1.

[0076] The preparation method of the solvent-free anti-pollution flashover silicone coating described in this embodiment is the same as that in Example 1.

[0077] The one-component solvent-free anti-fouling flash silicone coating can be stored for 3 months at a low temperature of 0-5°C. Components A and B can be stored at room temperature for more than 12 months. Solvent-free antifouling anti-fouling silicone coating formulated with components A and B, with a working time of ≧8 hours at room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com