Consumable electrode arc-welding machine

A technology for arc welding machines and consumable electrodes, which is applied to arc welding equipment, welding equipment, electrical components, etc., and can solve problems such as arc instability, uncontrollability, and droplet hypertrophy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

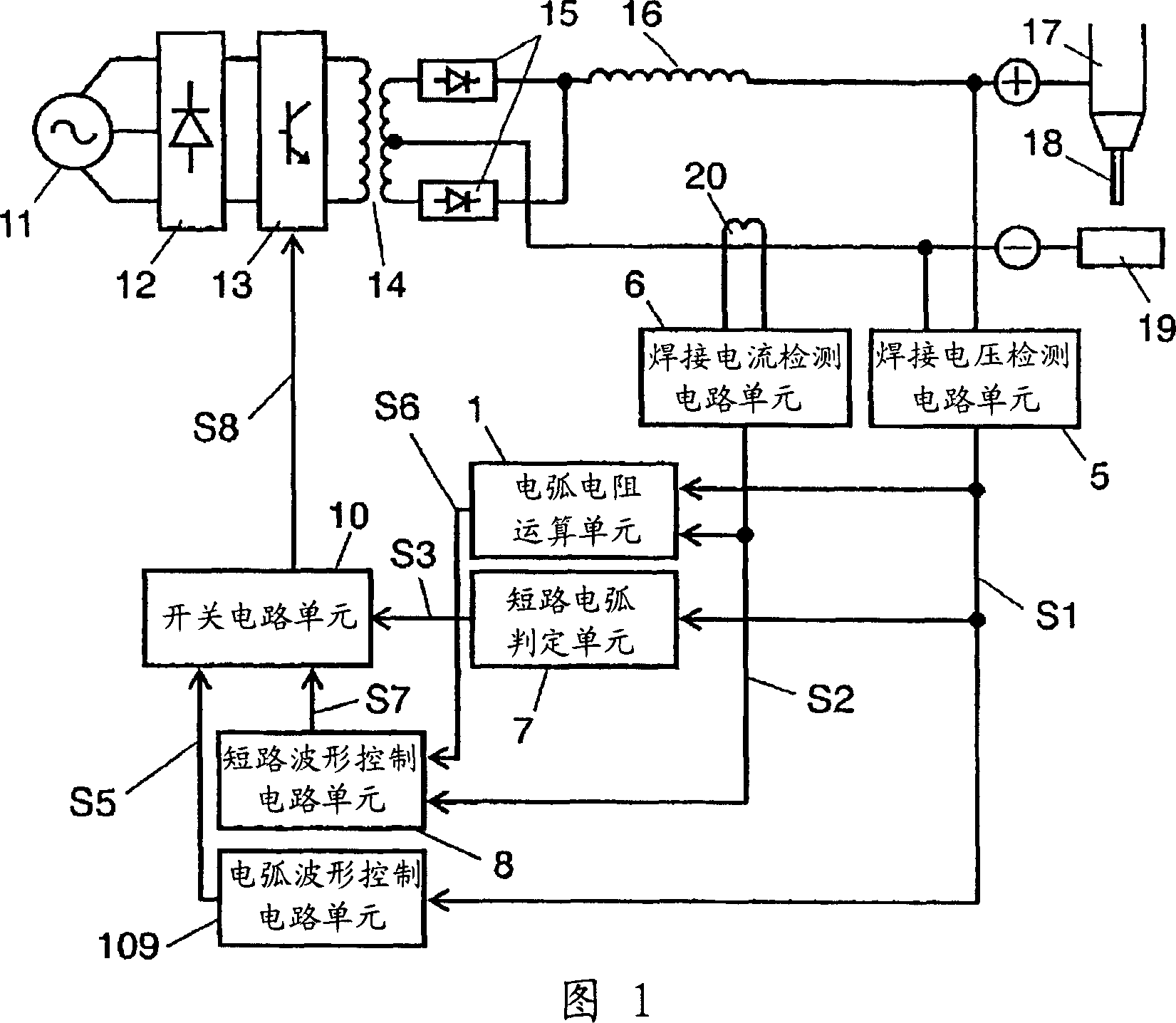

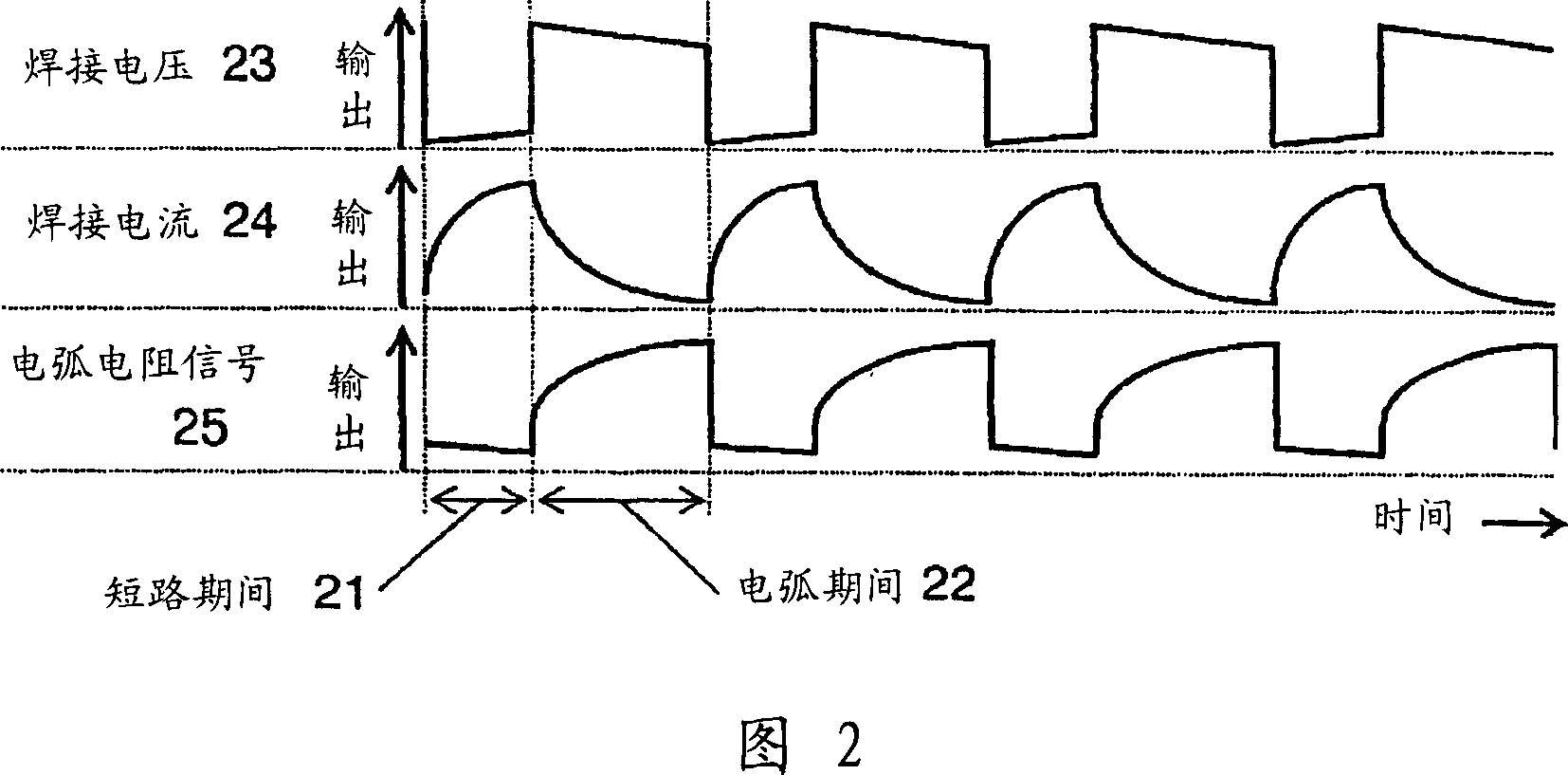

[0049] A consumable electrode type arc welding machine in Embodiment 1 will be described with reference to FIGS. 1 and 2 . The same reference numerals are assigned to the same constituent elements as those of the conventional consumable electrode type arc welding machine described in the background art, and detailed description thereof will be omitted. Furthermore, the main difference between the consumable electrode type arc welding machine of the first embodiment and the conventional one is that the short-circuit waveform control circuit unit 8 is different, and the arc resistance calculation unit 1 described later is newly installed.

[0050]In FIG. 1, the welding voltage detection circuit unit 5 detects a welding voltage and outputs a welding voltage detection signal S1. The welding current detection circuit unit 6 detects a welding current and outputs a welding current detection signal S2. The arc resistance calculation unit 1 receives a welding voltage detection signal ...

Embodiment approach 2

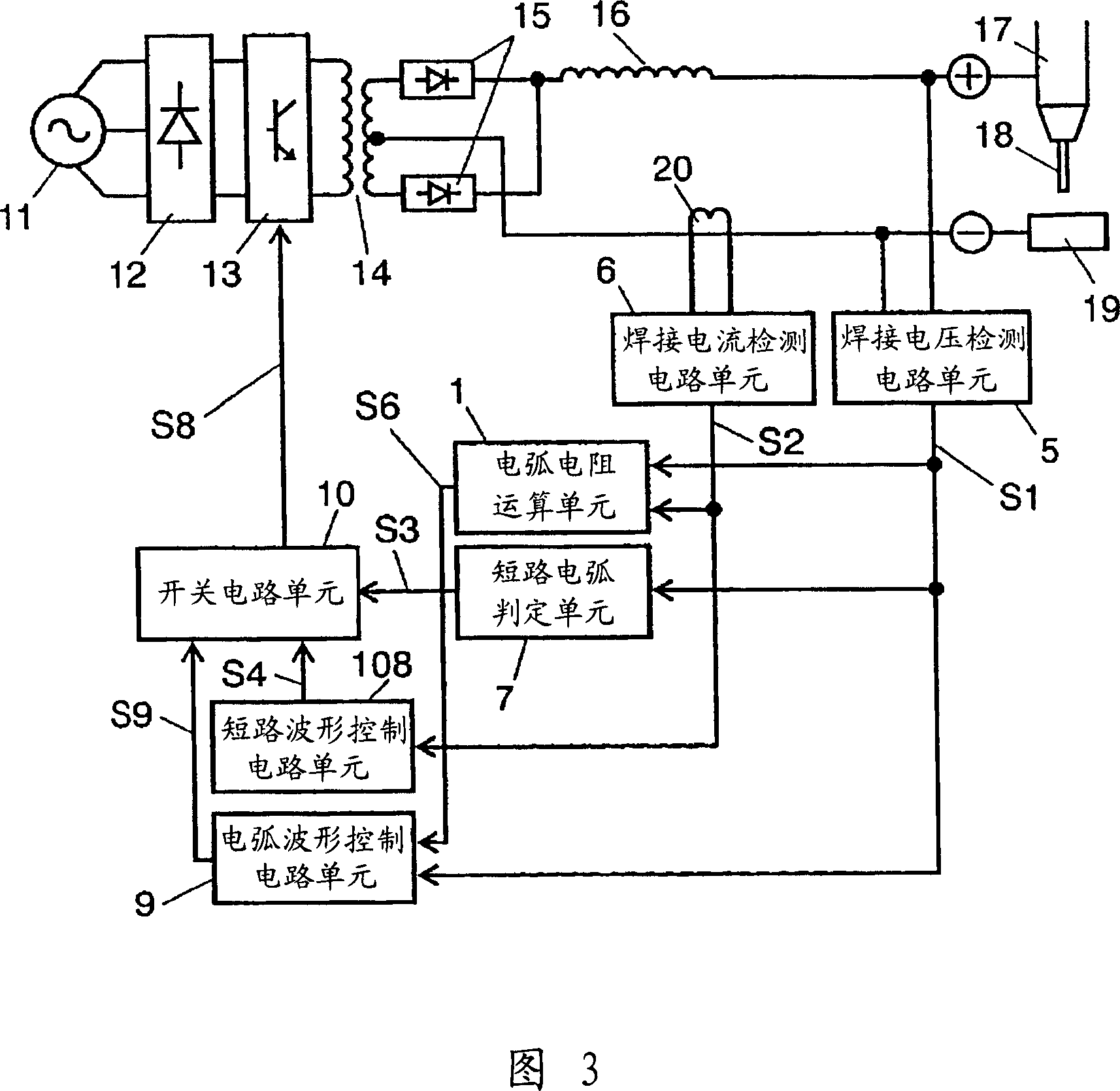

[0054] 3 is a block diagram showing a schematic configuration of a consumable electrode type arc welding machine according to Embodiment 2 of the present invention. In FIG. 3 , the same components as those in Embodiment 1 are assigned the same reference numerals, and detailed description thereof will be omitted. The difference from Embodiment 1 is that the short-circuit waveform control circuit unit 108 is different from the arc waveform control circuit unit 9, and the output of the arc resistance calculation unit 1 is not input to the short-circuit waveform control circuit unit 108 but to the arc waveform control circuit Unit 9 on this.

[0055] In FIG. 3 , arc resistance calculation unit 1 receives welding voltage detection signal S1 from welding voltage detection circuit unit 5 and welding current detection signal S2 from welding current detection circuit unit 6 as inputs. Then, the arc resistance calculation unit 1 calculates an arc resistance value based on these input s...

Embodiment approach 3

[0061] In this embodiment, the same reference numerals are assigned to the same configurations as those in Embodiments 1 and 2, and detailed descriptions are omitted. The main difference between Embodiment 1 and Embodiment 2 is that a constant current control circuit unit 2, a constant current control period setting unit 3, and a second switch circuit unit 4, which will be described later, are provided to perform constant current control when the welding current decreases during the arc period. flow control, thereby preventing arc interruption.

[0062] In Fig. 4, the arc resistance calculation unit 1 calculates the arc resistance value according to the welding voltage detection signal S1 and the welding current detection signal S2, and outputs the calculation result as the arc resistance signal S6 to the constant current control period setting unit 3 and the short circuit waveform control unit 3. The circuit unit 8 and the arc waveform control circuit unit 9 . In the short-c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com