Method for preparing rice hull active carbon/silicon dioxide/titanium dioxide composite material

A silicon dioxide and titanium dioxide technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as low bonding strength, easy to fall off, poor reusability, etc., to solve environmental problems, Prevents easy falling off and improves stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

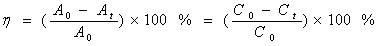

Method used

Image

Examples

Embodiment 1

[0013] First wash 1 kg of rice husk with clean water, dry, crush, pass through a 250-mesh sieve, add 10 kg of hydrochloric acid solution with a concentration of 3% by mass, stir at 85°C for 7 hours, wash with water until neutral, and obtain pickling Rice husk powder. Add 16.7 liters of 3 mol / L NaOH solution to the pickled rice husk powder, under constant stirring, maintain the alkali boiling temperature at 95°C, and keep the alkali boiling for 8 hours to obtain a mixed slurry composed of rice husk and sodium silicate. Then, under constant stirring, add 3.5mol / L TiCl to the mixed slurry composed of the obtained rice husk and sodium silicate. 4 solution, the reaction temperature is maintained at 90°C, and then the pH value of the reaction system is adjusted. When the pH value of the reaction system is adjusted to 5.5, TiCl 4 After the solution is added, continue to stir, heat-preserve and mature for 3 hours, filter, wash repeatedly with deionized water until the conductivity of...

Embodiment 2

[0015] First wash 1 kg of rice husk with clean water, dry, crush, pass through a 100-mesh sieve, add 1 kg of hydrochloric acid solution with a concentration of 10% by mass, stir at 40°C for 1 hour, wash with water until neutral, and obtain pickling Rice husk powder. Add 25 liters of 0.5 mol / L NaOH solution to the pickling rice husk powder, under constant stirring, maintain the alkali boiling temperature at 50°C, and keep the alkali boiling for 2 hours to obtain a mixed slurry composed of rice husk and sodium silicate. Then, under constant stirring, add 0.5 mol / L of TiCl to the mixed slurry composed of the obtained rice husk and sodium silicate 4 solution, the reaction temperature was kept at 45°C, and then the pH value of the reaction system was adjusted. When the pH of the reaction system was adjusted to 7.5, TiCl 4 After the solution is added, continue to stir, heat-preserve and mature for 0.5 hours, filter, wash repeatedly with deionized water until the conductivity of the...

Embodiment 3

[0017] First wash 1 kg of rice husk with clean water, dry, crush, pass through a 200-mesh sieve, add 5 kg of hydrochloric acid solution with a concentration of 5% by mass, stir at 70°C for 5 hours, wash with water until neutral, and obtain pickling Rice husk powder. Add 12.5 liters of 2 mol / L NaOH solution to the pickled rice husk powder, under constant stirring, maintain the alkali boiling temperature at 80°C, and keep the alkali boiling for 6 hours to obtain a mixed slurry composed of rice husk and sodium silicate. Then, under constant stirring, add 2.5mol / L of TiCl to the mixed slurry composed of the obtained rice husk and sodium silicate 4 solution, the reaction temperature is maintained at 75°C, and then the pH value of the reaction system is adjusted. When the pH of the reaction system is adjusted to 7, TiCl 4 After the solution is added, continue to stir, heat-preserve and mature for 2 hours, filter, wash repeatedly with deionized water until the conductivity of the fi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com