Preparation method for poly-dopamine modified ceramic particle nonwoven diaphragm

A non-woven separator, ceramic particle technology, applied in electrical components, circuits, battery pack components, etc., can solve the problems of poor heat resistance of polyolefin, reduce safety risks, lose protection functions, etc., and improve adhesion. , to avoid easy falling off, the effect of improving safety performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

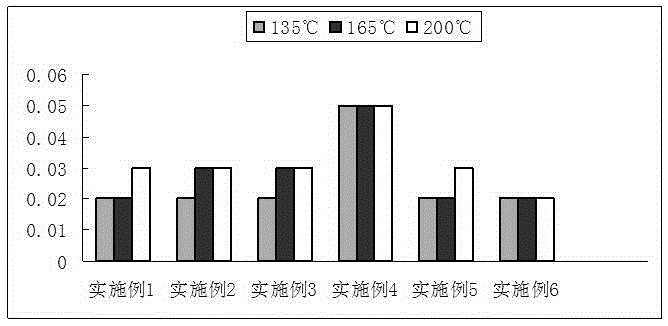

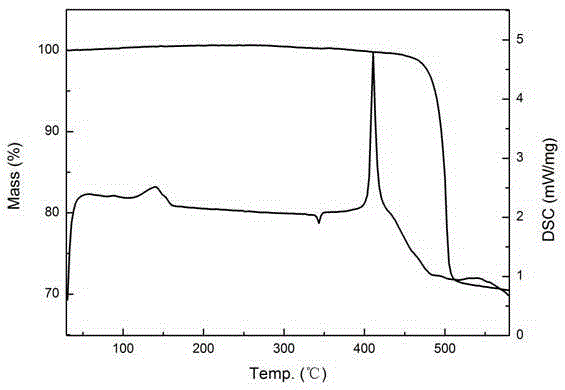

[0019] (1) 2.0g SiO with a particle size of 20nm 2 The particles were stirred in 200mL dopamine solution with a concentration of 0.5g / L, soaked for 10h, taken out, filtered and dried to obtain polydopamine modified ceramic particles SiO 2 (2) Weigh 5.0g of PVDF-HFP with a weight average molecular weight of 400,000, add 40g of DMF, stir well, then add 2.0g of modified SiO in (1) 2 , stirring at high speed for 5 hours; (3) Add 3.5g of n-butanol to (2), and continue to stir for 2 hours; (4) Cast the colloid mixture in step (3) on the non-woven fabric, and cast and scrape it into (5) Remove the membrane, roll a thick composite diaphragm to a thickness of 28 μm, and dry it in vacuum at 75°C for 8 hours to obtain polydopamine-modified SiO 2 / Non-woven separator. The diaphragm prepared in this example has good heat resistance, and the TG experimental curve is shown in figure 1 , 2 .

[0020]

Embodiment 2

[0022] (1) 2.0g Al with a particle size of 30nm 2 o 3 The particles were stirred in 200 mL of dopamine solution with a concentration of 2.0 g / L, soaked for 24 hours, taken out, filtered and dried to obtain polydopamine modified ceramic particles Al 2 o 3 (2) Weigh 5.0g of PVDF-HFP with a weight average molecular weight of 500,000, add 50g of acetone, stir well, add 16g of modified Al in (1) 2 o 3 , stirring vigorously for 6 hours; (3) Add 4.75g of absolute ethanol to (2), and continue to stir for 2 hours; (4) Cast the colloid mixture in step (3) on the non-woven fabric, and cast and scrape it into (5) Remove the membrane, roll a thick composite diaphragm to a thickness of 45 μm, and dry it in vacuum at 50°C for 2 hours to obtain polydopamine-modified Al 2 o 3 / Non-woven separator.

Embodiment 3

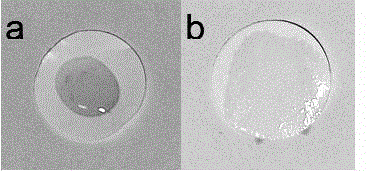

[0024] (1) 2.0g ZrO with a particle size of 120nm 2 The particles were stirred in 100 mL of dopamine solution with a concentration of 1.5 g / L, soaked for 24 hours, then taken out, filtered, and dried to obtain polydopamine-modified ceramic particles ZrO 2 ; (2) Weigh 3.0g PVDF with a weight average molecular weight of 400,000, add 20g acetone and 12gDMF to the mixed solvent, stir evenly, add 0.5g (1) modified ZrO 2 , vigorously stirred for 5 hours; (3) Add 4.0g of deionized water to (2), and continue to stir for 2 hours; (4) Cast the colloid mixture in step (3) on the non-woven fabric, cast and scrape it into (5) Remove the membrane, roll a thick composite diaphragm to a thickness of 40 μm, and dry it in vacuum at 70°C for 8 hours to obtain polydopamine-modified ZrO 2 / Non-woven separator. The diaphragm prepared in this example has better wettability, see image 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com