Composite coating of printed circuit board drill point and preparation method thereof

A composite coating, printed circuit technology, applied in the coating, metal material coating process, ion implantation plating and other directions, can solve the problem that a single coating is difficult to play a promoting role, the number of composite structure layers is too many, and the drill pin is worn out. Serious problems, to achieve the effect of slowing down the graphitization phase transformation trend, reducing the temperature, and improving the quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

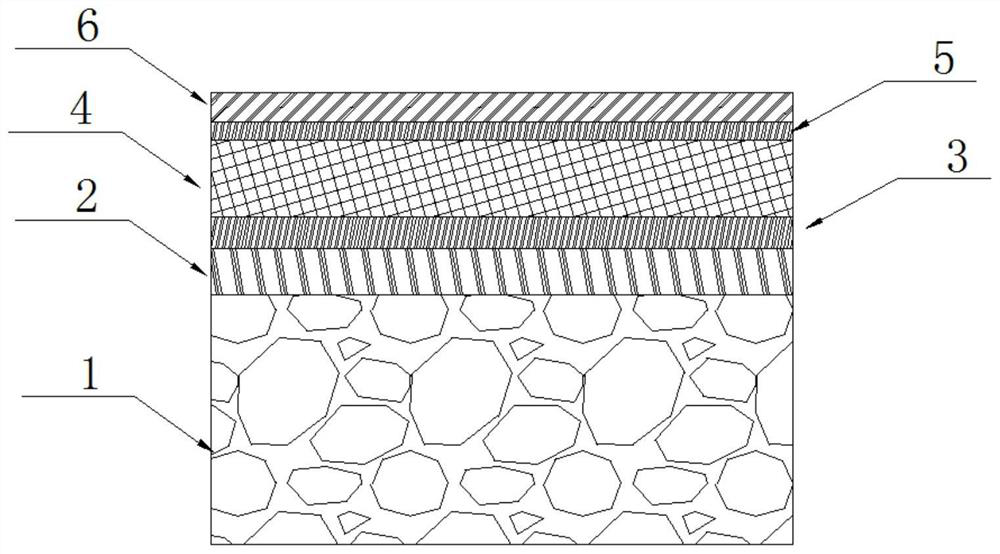

[0090] This embodiment provides a composite coating for a drill bit of a printed circuit board, and the structural schematic diagram of the composite coating is as follows figure 1 As shown, the bottom layer 2, the carbonitriding layer 3, the diamond-like coating 4 and the heat insulation layer 6 are sequentially included from the surface of the drill 1, the bottom layer 2 is a metal layer, and the heat insulation layer 6 is metal nitrogen compound ceramic layer.

[0091] The metal layer is a Ti metal layer with a thickness of 0.25 μm.

[0092] The carbonitriding layer 3 is a TiCN layer with a thickness of 0.05 μm.

[0093] The thickness of the diamond-like coating 4 is 0.5 μm.

[0094] The thermal insulation layer 6 is a TiN ceramic layer with a thickness of 0.12 μm.

[0095] The composite coating also includes a transition layer 5 located between the diamond-like coating 4 and the thermal insulation layer 6 .

[0096] The transition layer 5 is a TiCN layer with a thickne...

Embodiment 2

[0098] This embodiment provides a composite coating for a printed circuit board drill. The composite coating includes a bottom layer 2, a carbonitriding layer 3, a diamond-like coating 4 and a heat-insulating layer from the surface of the drill 1 to the outside. 6. The bottom layer 2 is a metal compound layer, and the heat insulating layer 6 is a metal nitride ceramic layer.

[0099] The bottom layer 2 is a CrN layer with a thickness of 0.5 μm.

[0100] The carbonitriding layer 3 is a CrCN layer with a thickness of 0.1 μm.

[0101] The thickness of the diamond-like coating 4 is 1.0 μm.

[0102] The heat insulating layer 6 is a CrN ceramic layer with a thickness of 0.2 μm.

[0103] The composite coating also includes a transition layer 5 located between the diamond-like coating 4 and the thermal insulation layer 6 .

[0104] The transition layer 5 is a CrCN layer with a thickness of 0.1 μm.

Embodiment 3

[0106] This embodiment provides a composite coating for a printed circuit board drill. The composite coating includes a bottom layer 2, a carbonitriding layer 3, a diamond-like coating 4 and a heat-insulating layer from the surface of the drill 1 to the outside. 6. The bottom layer 2 is a metal compound layer, and the heat insulating layer 6 is a metal nitride ceramic layer.

[0107] The bottom layer 2 is a TiN layer with a thickness of 0.05 μm.

[0108] The carbonitriding layer 3 is a TiCN layer with a thickness of 0.02 μm.

[0109] The thickness of the diamond-like coating 4 is 0.1 μm.

[0110] The thermal insulation layer 6 is a TiN ceramic layer with a thickness of 0.05 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com