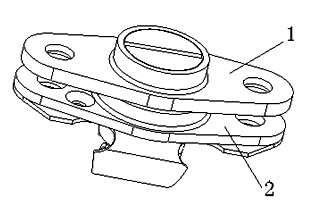

Quick release lock with spring device

A technology of spring device and lower lock, which is applied in the direction of quick action fasteners, aircraft accessories, connecting components, etc., can solve the problems of failure of small load-bearing locks, failure to open the lid, and inability to remove the curvature lock nail of the lid, etc., to achieve Avoid easy falling off and easy disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

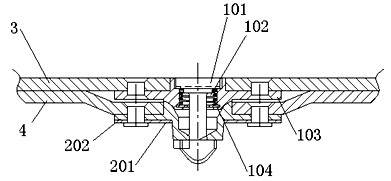

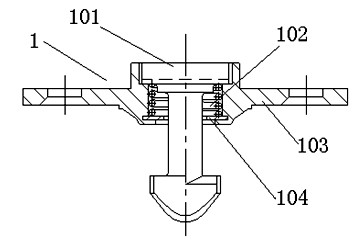

[0022] Example: The locking nail 101 is made of 30CrMnSiA-φ12, and the head of the locking nail 101 has a groove with a depth of 2mm and a width of 1mm. There is a boss under the head of locking nail 101. The lower end of the polished rod of locking nail 101 is in the shape of a frustum. cut. The lower edge of the locking nail head and the joint between the boss and the locking nail head are all chamfered, and the joint between the cone and the locking nail rod is rounded.

[0023] The material of the spring 102 is 70-E-d0.8, which is slightly larger than the frustum at the lower end of the locking nail 101 .

[0024] The material of the lock seat plate 103 is ZG35CrMnSi(R).

[0025] The material of the gasket 104 is 20-δ0.8 and notched.

[0026] When the upper lock body 1 is assembled, the spring 102 is inserted into the locking rod part from the lower end of the locking nail 101, then the washer 104 is inserted into the below of the locking rod spring 102 from the cutou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com