Skin-simulating function film and preparation method thereof

A functional film and skin-imitation technology, applied in skin care preparations, pharmaceutical formulations, cosmetic preparations, etc., can solve the problems of low veneer adhesion and easy falling off, and achieve high user comfort, high comfort, and restraint The effect of skin moisture evaporation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

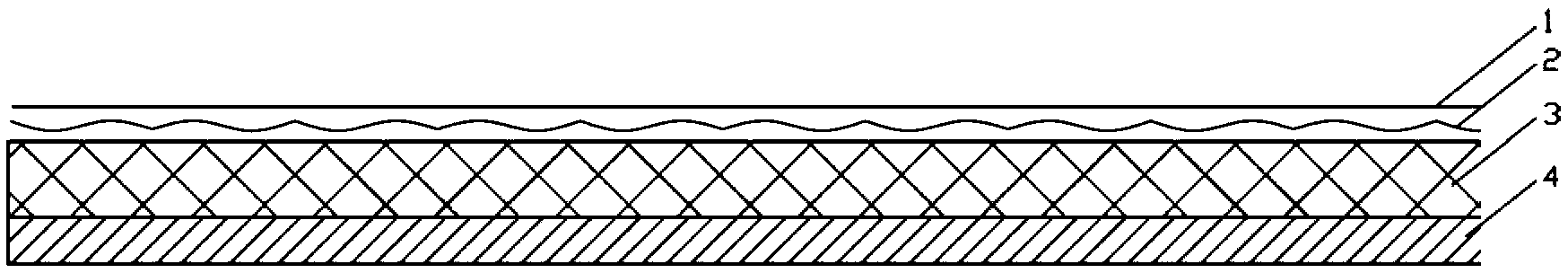

[0022] Skin-like functional film, such as figure 1 As shown, it includes imitation skin film substrate layer 3 and the pressure-sensitive adhesive layer 2 mixed with skin conditioning factors coated on the surface of the imitation skin film substrate layer, and the pressure-sensitive adhesive layer 2 mixed with skin conditioning factors is covered with Release film 1, the skin-imitating film substrate layer is provided with a PP film backing layer 4 outside. The imitation skin film substrate layer is a thermoplastic polyurethane film, and the pressure-sensitive adhesive layer mixed with skin conditioning factors is composed of 0.2% vitamin E, 2.8% vitamin C ethyl ether and alcohol-soluble polyacrylate pressure. Sensitive glue 97%. The moisture permeability of the skin-like functional film is 1000g / m 2 ·24h, air permeability ≥2000mL / m 2 ·24h·0.1Mpa, the peel strength (180 degrees) is 0.1KN / m-0.2KN / m.

[0023] The skin-imitating functional film can be die-cut into a mask acc...

Embodiment 2

[0028] The skin-imitation functional film comprises a skin-imitation film substrate layer and a pressure-sensitive adhesive layer mixed with skin conditioning factors coated on the surface of the skin-imitation film substrate layer, and the pressure-sensitive adhesive layer mixed with skin conditioning factors is covered with Release paper, the skin imitation film substrate layer is provided with a PE film backing layer. , the pressure-sensitive adhesive layer mixed with skin conditioning factors is calculated by weight percentage: 25% of seaweed oligosaccharides, 1.5% of glycerin, 73.5% of polyacrylate emulsion glue, and additionally contains an appropriate amount to adjust the viscosity of the aforementioned system to 20000mPa · s viscosity additive carbo resin. The moisture permeability of the skin-like functional film is 1500g / m 2 ·24h, air permeability ≥2000mL / m 2 ·24h·0.1Mpa, the peel strength (180 degrees) is 0.1KN / m-0.2KN / m.

[0029] The skin-imitating functional fi...

Embodiment 3

[0034] The skin-imitation functional film comprises a skin-imitation film substrate layer and a pressure-sensitive adhesive layer mixed with skin conditioning factors coated on the surface of the skin-imitation film substrate layer, and the pressure-sensitive adhesive layer mixed with skin conditioning factors is covered with Release paper, the skin imitation film substrate layer is provided with a PE film backing layer. The skin-imitating film substrate layer is a water-based polyurethane film, and the pressure-sensitive adhesive layer mixed with skin conditioning factors is calculated by weight percentage: 19% of aloe polysaccharide, 1% of hyaluronic acid and 80% of polyacrylate emulsion glue , additionally contains an appropriate amount of viscosity additive xanthan gum which can adjust the viscosity of the aforementioned system to be 18000mPa·s. Its moisture permeability is 2000g / m 2 ·24h, air permeability ≥2000mL / m 2 ·24h·0.1Mpa, the peel strength (180 degrees) is 0.1KN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Moisture permeability | aaaaa | aaaaa |

| Moisture permeability | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com