Intraocular lens coating with excellent biological antifouling performance and preparation method thereof

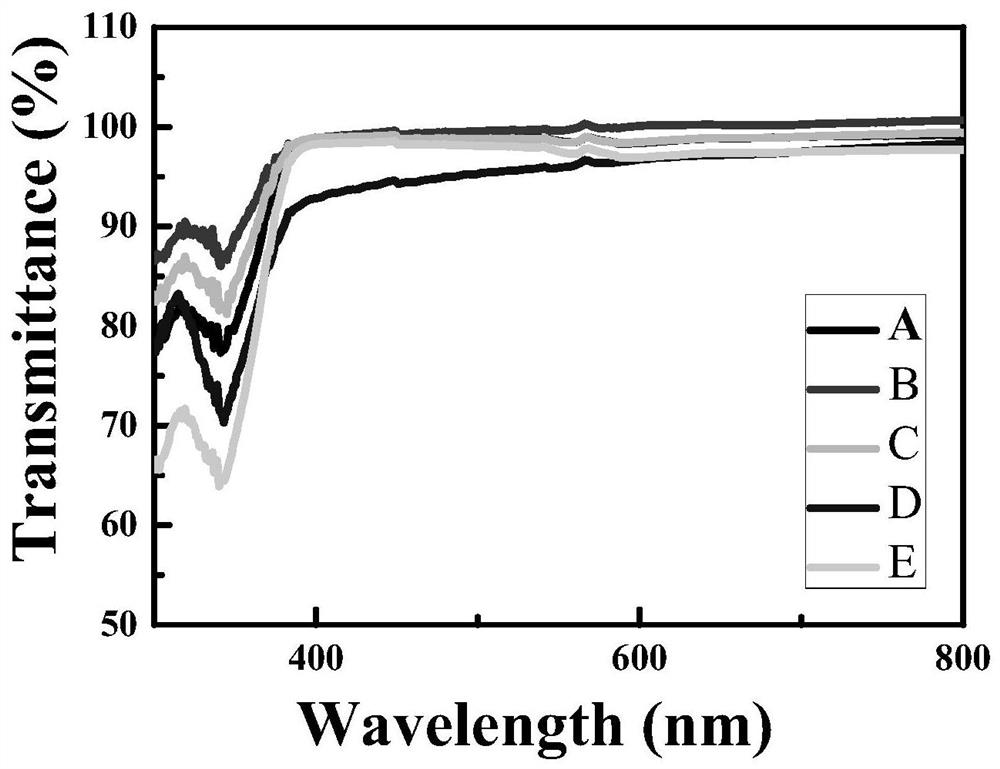

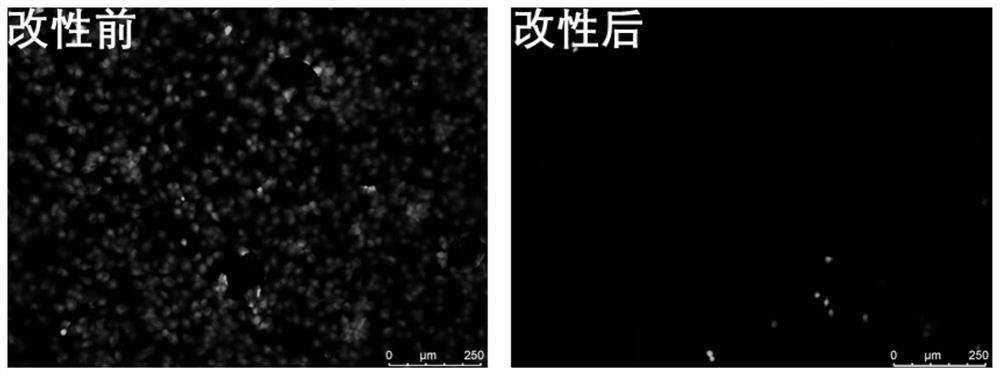

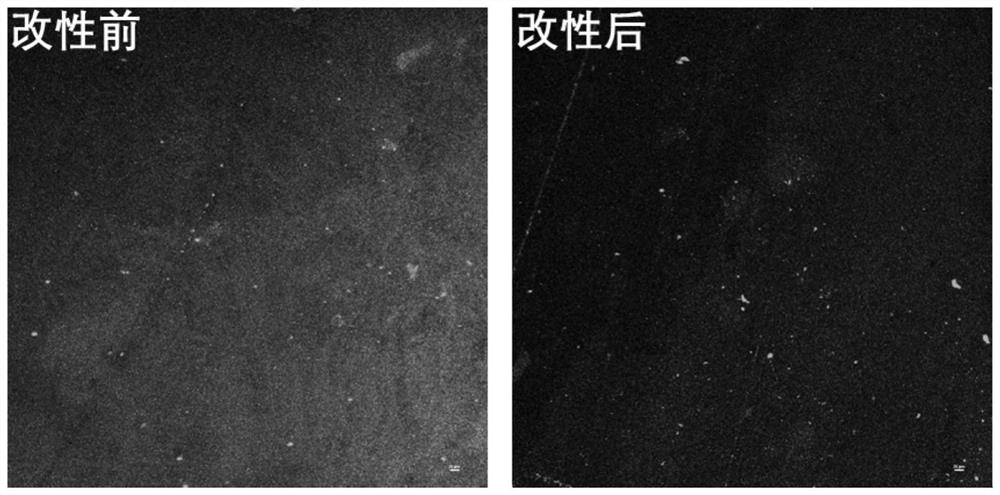

A technology for intraocular lenses and coatings, applied in coatings, prostheses, tissue regeneration, etc., to achieve the effects of easy industrialized large-area treatment, good hydrophilic and anti-fouling properties, and improved biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A method for preparing an intraocular lens coating with excellent biological antifouling performance, comprising the following steps:

[0030] (1) The rigid polymethyl methacrylate intraocular lens material is subjected to low-temperature plasma surface treatment at 50V for 40s, and then the rigid polymethyl methacrylate intraocular lens material is dipped into the epoxy resin solution for 15s , dried at a temperature of 50°C to obtain a transition layer;

[0031] (2) Prepare a polyvinyl alcohol solution with a concentration of 5 mg / ml, then place the transition layer obtained in step (1) into the polyvinyl alcohol solution and immerse it for 5 minutes, and dry it at 50°C to obtain an intraocular lens with excellent biological antifouling properties coating.

Embodiment 2

[0033] A method for preparing an intraocular lens coating with excellent biological antifouling performance, comprising the following steps:

[0034] (1) The rigid polymethyl methacrylate intraocular lens material was subjected to low-temperature plasma surface treatment at a voltage of 70V for 30s, and then the rigid polymethyl methacrylate intraocular lens material was dip-coated in an epoxy resin solution for 20s. Dry at a temperature of ℃ to obtain a transition layer;

[0035] (2) Prepare a polyoxyethylene solution with a concentration of 10mg / ml, then place the transition layer obtained in step (1) into the polyoxyethylene solution and immerse it for 5 minutes, and dry it at a temperature of 50°C to obtain an intraocular lens with excellent biological antifouling properties coating.

Embodiment 3

[0037] A method for preparing an intraocular lens coating with excellent biological antifouling performance, comprising the following steps:

[0038] (1) The poly(hydroxyethyl methacrylate) intraocular lens material was subjected to low-temperature plasma surface treatment at 80V for 90s, and then the poly(hydroxyethyl methacrylate) intraocular lens material was dip-coated in the epoxy resin solution for 10s. Dry at a temperature of ℃ to obtain a transition layer;

[0039] (2) Prepare a poly-2-methacryloyloxyethylphosphorylcholine solution with a concentration of 8 mg / ml, and then place the transition layer obtained in step (1) into the poly-2-methacryloyloxyethylphosphorylcholine solution Immerse for 15s and dry at 30°C to obtain an intraocular lens coating with excellent biological antifouling performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com