Three-dimensional nanoflower-like Ni-Fe composite hydroxide oxygen evolution anode used for carbonate electrolysis

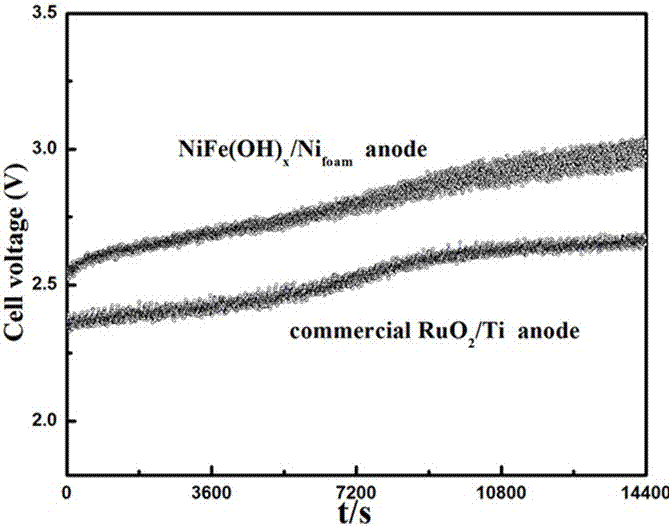

A technology of compound hydroxide and oxygen evolution, applied in electrodes, electrolysis components, electrolysis process, etc., can solve the problems of high price and unsuitable for large-scale industrial electrolysis, and achieve the effect of reducing the energy consumption of electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Mix 8 mmol L -1 NiSO 4 •6H 2 O and 8 mmol L -1 FeSO 4•7H 2 Mixed solution of O as electrodeposited NiFe(OH) x / Ni foam Precursor salt for oxygen evolution anode, 25 mmol L -1 of (NH 4 ) 2 SO 4 As a buffer solution, the solution prepared above was mixed with 1 mol L -1 h 2 SO 4 After adjusting to pH = 4, the electrodeposition solution was prepared for use.

[0027] (2) At room temperature, NiFe(OH) was prepared by electrodeposition experiment using a two-electrode system x / Ni foam Oxygen evolution anode. The blank nickel foam (10 mm × 10 mm) after degreasing the oxide film was used as the cathode, and the Pt sheet (10 mm × 10 mm) electrode was used as the auxiliary electrode. Apply 10 mA cm to the cathode -2 The current density of NiFe(OH) was made after electrodeposition for 60 s x / Ni foam electrode.

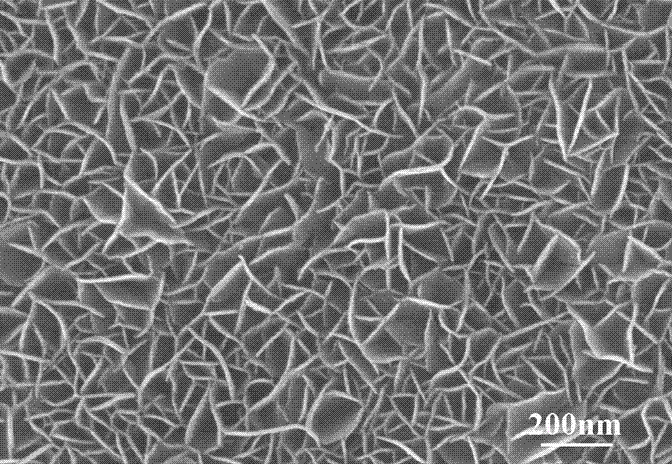

[0028] The SEM of the obtained Ni-Fe composite hydroxide is as follows figure 1 As shown in the figure, it can be seen from the figure that ...

Embodiment 2

[0031] (1) Mix 10 mmol L -1 NiSO 4 •6H 2 O and 10 mmol L -1 FeSO 4 •7H 2 Mixed solution of O as electrodeposited NiFe(OH) x / Ni foam Oxygen evolution anode precursor salt, 30 mmol L -1 of (NH 4 ) 2 SO 4 As a buffer solution, the solution prepared above was mixed with 1.5 mol L -1 h 2 SO 4 After adjusting to pH = 4, the electrodeposition solution was prepared for use.

[0032] (2) At room temperature, NiFe(OH) was prepared by electrodeposition experiment using a two-electrode system x / Ni foam Oxygen evolution anode. The blank nickel foam (10 mm × 10 mm) after degreasing the oxide film was used as the cathode, and the Pt sheet (10 mm × 10 mm) electrode was used as the auxiliary electrode. Apply 60 mA cm to the cathode -2 The current density of NiFe(OH) was made after electrodeposition for 120 s x / Ni foam electrode.

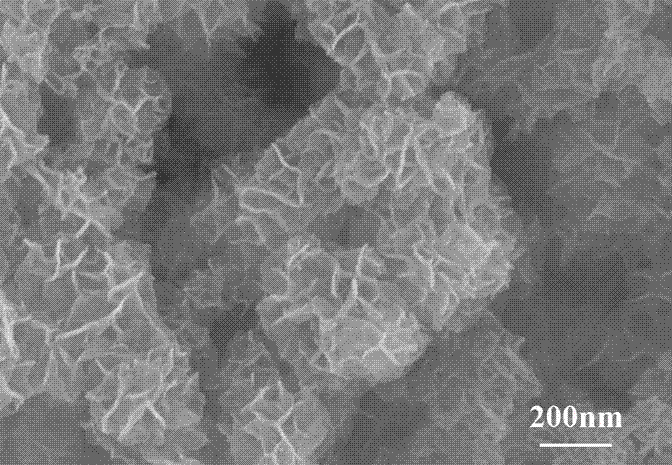

[0033] The SEM of the obtained Ni-Fe composite hydroxide is as follows image 3 As shown, it can be seen from the figure that the prepared...

Embodiment 3

[0036] (1) Mix 8 mmol L -1 NiCl 2 ▪6H 2 O, 8 mmol L -1 FeCl 2 ▪4H 2 Mixed solution of O as electrodeposited NiFe(OH) x / Ni foam Oxygen evolution anode precursor salt, 50 mmol L -1 of (NH 4 ) 2 SO 4 As a buffer solution, the solution prepared above was mixed with 1 mol L -1 HCl was adjusted to pH = 4 to make an electrodeposition solution for later use.

[0037] (2) At room temperature, NiFe(OH) was prepared by electrodeposition experiment using a two-electrode system x / Ni foam Oxygen evolution anode. The blank nickel foam (10 mm × 10 mm) after degreasing the oxide film was used as the cathode, and the Pt sheet (10 mm × 10 mm) electrode was used as the auxiliary electrode. Apply 200 mA cm to the cathode -2 The current density of NiFe(OH) made after electrodeposition for 60 s x / Ni foam electrode.

[0038] The SEM of the obtained Ni-Fe composite hydroxide is as follows Figure 4 As shown, it can be seen from the figure that the prepared composite hydroxide ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com