A method for the indirect electrosynthesis of quinones assisted by ultrasound

An ultrasonic-assisted, compound technology, applied in electrolytic components, electrolytic process, electrolytic organic production, etc., can solve the problems of low yield, high electrolytic production cost, long chemical reaction time, etc., to reduce cell pressure, facilitate circulation, The effect of improving product selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

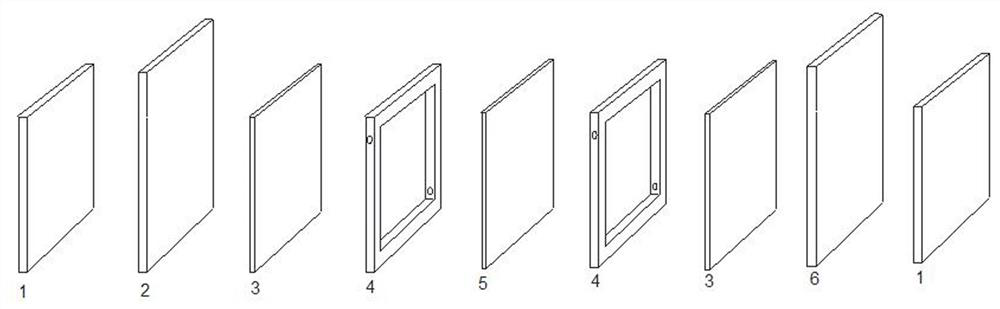

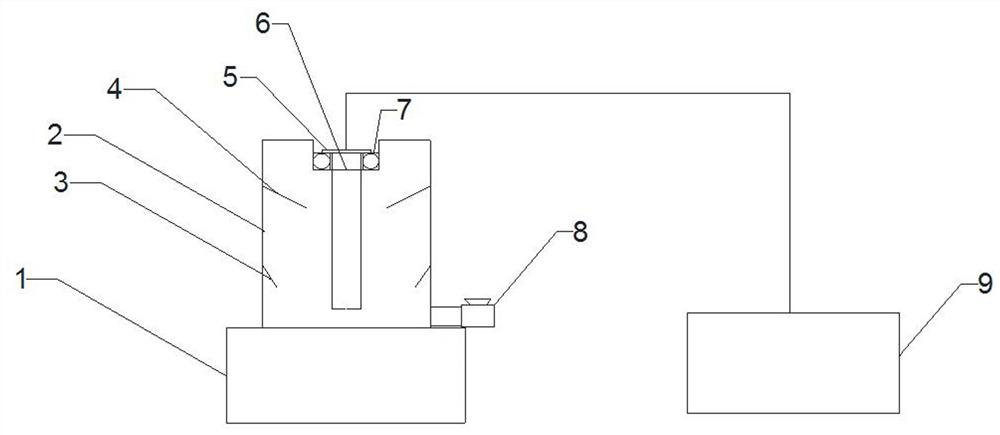

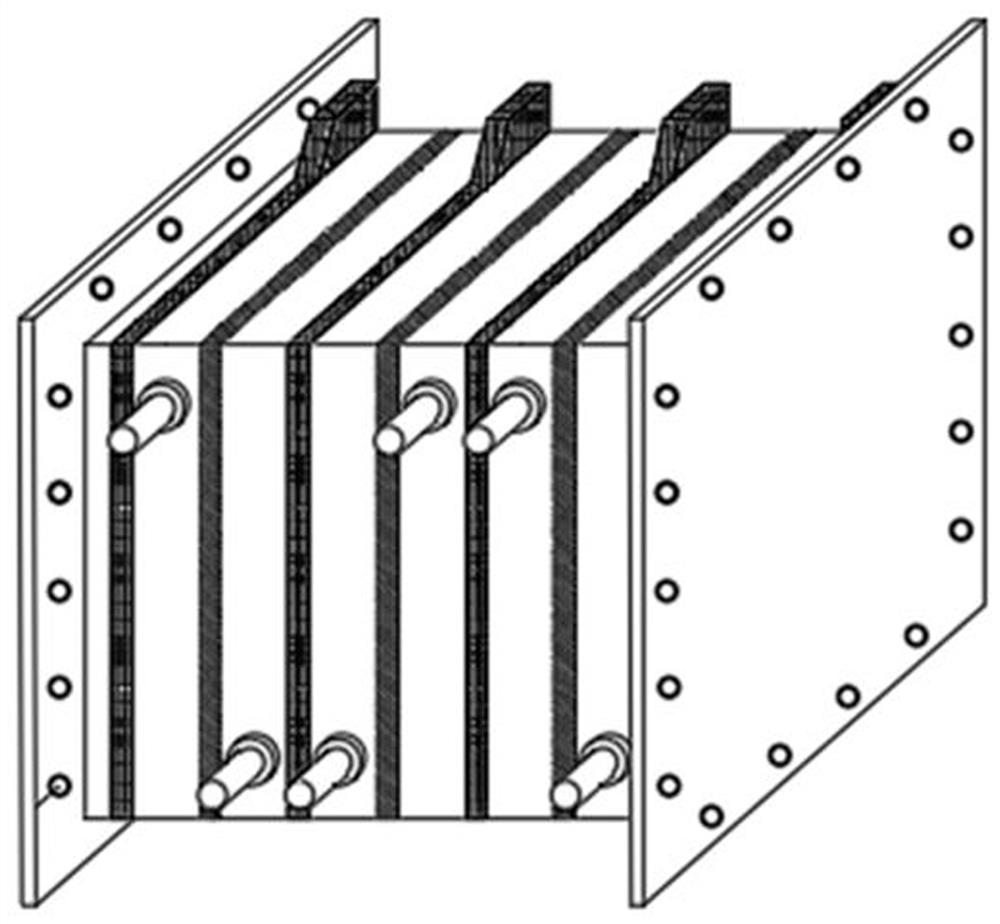

[0041] Electrolysis part: see reaction device figure 1 . The prepared 1.2L, 1mol / L Ce 3+ The mixed acid solution (methanesulfonic acid 2mol / L, sulfuric acid 0.4mol / L), the flow rate is controlled by a flow meter and a pump, and it is passed into the anode chamber for circulation, and the same operation is performed for the cathode. The electrolytic flow rate is controlled at 40L / H, and the current density is 20mA / cm 2 , the electrolysis temperature is 40°C, the electrolysis time is 7 hours and 20 minutes, and the Ce is measured by titration after the electrolysis 4+ Ion concentration, Ce 3+ The ion conversion rate is 60%, the current efficiency is 85%, and the voltage is 2.2V. After the reaction is completed, the bypass is opened, the anolyte enters the synthesis reaction chamber, the catholyte enters the anode liquid storage tank, and the liquid obtained by the synthesis reaction is passed into the cathode chamber to continue electrolysis and cycle operation.

[0042] S...

Embodiment 2

[0047] The difference with the electrolysis step of embodiment 1 is: Ce 3+ The ion concentration is 0.8mol / L, the electrolysis time of the electrolysis part is the theoretical time condition, and the rest of the steps are unchanged, using Fe 2+ Titrate to get Ce 4+ Concentration, the conversion rate is calculated to obtain a current efficiency of 69%, and a voltage of 2.1V.

Embodiment 3

[0049] The difference with the electrolysis step of Example 1 is that the current density is 60mA / cm 2 , the electrolysis time of the electrolysis part is the theoretical time condition, and the rest of the steps remain unchanged, using Fe 2+ Titrate to get Ce 4+ concentration, calculate the conversion rate to obtain a current efficiency of 66%, and a voltage of 2.6V.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com