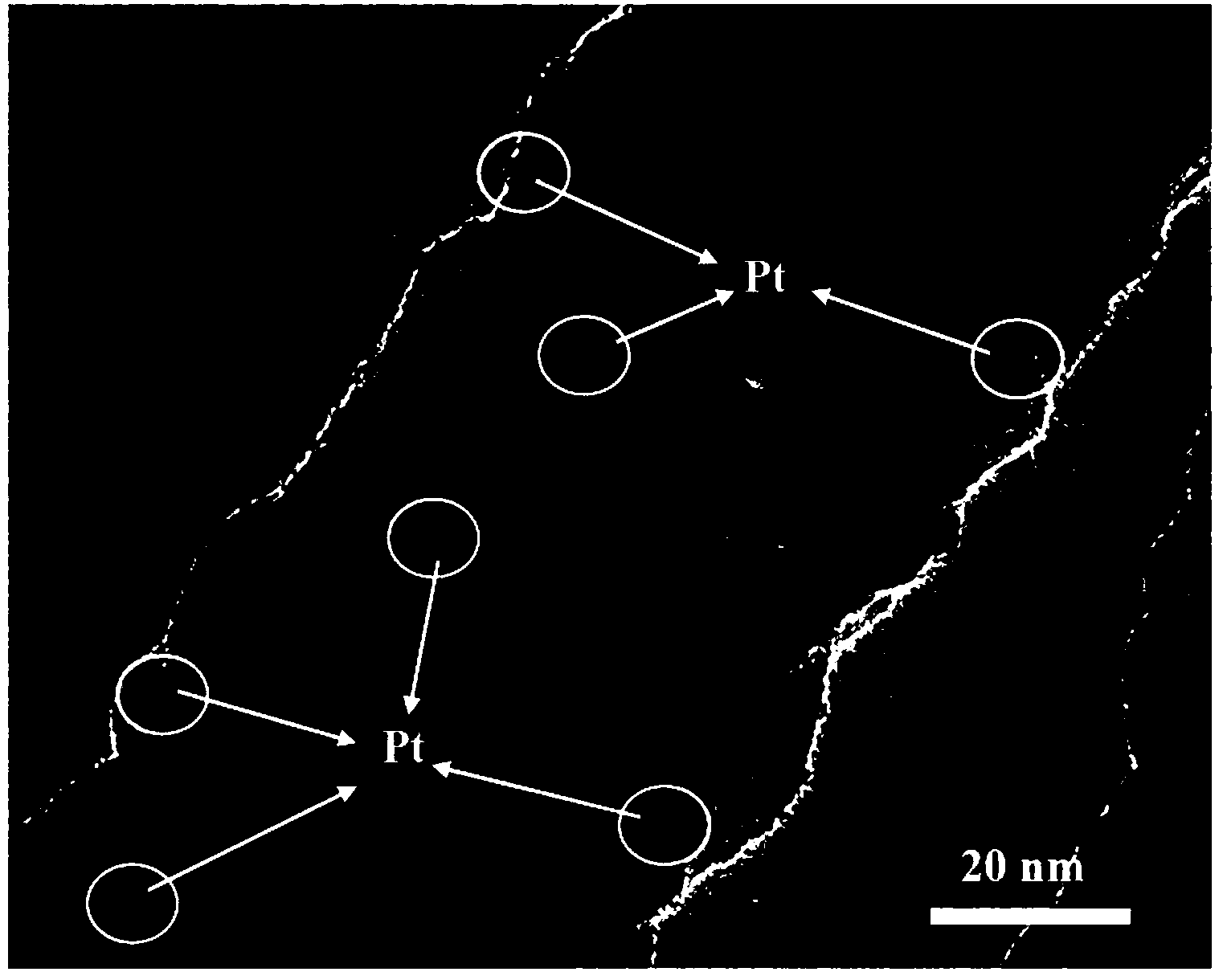

Porous TiO2 fiber loaded noble metal formaldehyde room-temperature oxidation catalyst and preparation method thereof

A technology for oxidizing catalysts and precious metals, which is applied in the field of indoor air purification, can solve the problems of easy detachment of catalysts, large air resistance, complicated process, etc., and achieve the effects of small air resistance, good dispersion and high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) First dissolve 0.5g of polyvinylpyrrolidone in absolute ethanol to prepare an absolute ethanol solution of polyvinylpyrrolidone with a mass content of 6wt%. Under stirring, add glacial acetic acid as inhibitor and CTAB and urea to make Pore agent, then add tetraisopropyl titanate, continue to stir for 12h, wherein the molar ratio of absolute ethanol, CTAB, glacial acetic acid, urea and tetraisopropyl titanate is 1:0.05:0.29:0.1:0.03; add Electrospinning is carried out in the electrospinning device, the flow rate of the electrospinning solution is 1.5mL / h, the diameter of the spinning needle is 0.75mm, and the working voltage intensity is 1.3kV / cm to obtain TiO 2 / Polymer composite fiber;

[0029] (2) The TiO obtained in step (1) 2 / Porous TiO is obtained by placing the polymer composite fiber in the air for 2 hours and then roasting at a temperature of 500°C and a roasting time of 3 hours 2 fiber.

[0030] (3) The porous TiO obtained in step (2) 2 The fiber is disperse...

Embodiment 2

[0033] Example 2 Preparation of formaldehyde room temperature oxidation catalyst

[0034] (1) First dissolve 0.5g of polyvinylpyrrolidone in absolute ethanol to prepare an absolute ethanol solution of polyvinylpyrrolidone with a mass content of 6wt%. Under stirring, add glacial acetic acid as inhibitor and CTAB and urea to make Pore agent, then add tetraisopropyl titanate, continue to stir for 24h, wherein the molar ratio of absolute ethanol, CTAB, glacial acetic acid, urea and tetraisopropyl titanate = 1:0.05:0.29:0.1:0.03; add Electrospinning is carried out in the electrospinning device, the flow rate of the electrospinning solution is 1.5mL / h, the diameter of the spinning needle is 0.75mm, and the working voltage intensity is 1.3kV / cm to obtain TiO 2 / Polymer composite fiber;

[0035] (2) The TiO obtained in step (1) 2 / Porous TiO is obtained by placing the polymer composite fiber in the air for 2 hours and then roasting at a temperature of 600℃ and a roasting time of 2 hours....

Embodiment 3

[0037] Example 3 Preparation of formaldehyde room temperature oxidation catalyst

[0038] (1) First dissolve 0.5g of polyvinylpyrrolidone in absolute ethanol to prepare an absolute ethanol solution of polyvinylpyrrolidone with a mass content of 6wt%. Under stirring, add glacial acetic acid as inhibitor and CTAB and urea to make Pore agent, then add tetraisopropyl titanate, continue to stir for 18h, wherein the molar ratio of absolute ethanol, CTAB, glacial acetic acid, urea and tetraisopropyl titanate = 1:0.1:0.4:0.1:0.03; add Electrospinning is carried out in the electrospinning device, the flow rate of the electrospinning solution is 2.5mL / h, the diameter of the spinning needle is 1.25mm, and the working voltage intensity is 1.8kV / cm to obtain TiO 2 / Polymer composite fiber;

[0039] (2) The TiO obtained in step (1) 2 / Porous TiO is obtained by placing the polymer composite fiber in the air for 2 hours and then roasting at a temperature of 450°C and a roasting time of 6 hours 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com