Preparation method of high-efficiency composite attapulgite/rice hull activated carbon purified water material

A technology of attapulgite and composite materials, which is applied in chemical instruments and methods, adsorption water/sewage treatment, and other chemical processes, and can solve problems such as difficulty in meeting wastewater treatment requirements, and achieve simple steps, increased bonding performance, and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

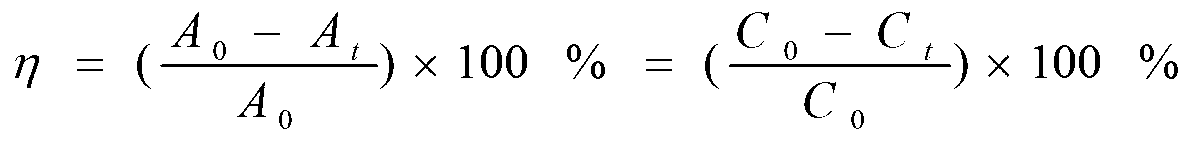

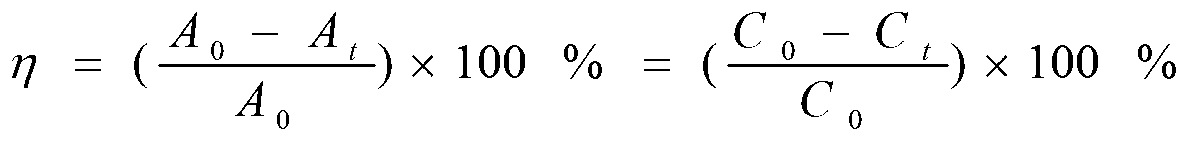

Image

Examples

Embodiment 1

[0017] 1. Pass 5 kg of rice husk and 25 kg of attapulgite mixture through a 200-mesh filter screen to obtain a uniformly mixed powder of rice husk and attapulgite; take 10 kg of mixed powder and add it to 40 kg with a molar concentration of 1.0 In a mole / liter sodium hydroxide solution, let it stand for 24 hours; under a nitrogen atmosphere, heat up to 450 ° C, and roast for 12 hours;

[0018] 2. Disperse the composite material obtained in step 1 into 66.7 kg of deionized water, heat and boil for 90 minutes, keep the system temperature at 60°C, and adjust the pH value of the system with a hydrochloric acid solution with a molar concentration of 1.0 mol / liter while stirring. 10. Suction filtration and drying to obtain the attapulgite / rice husk activated carbon composite material.

Embodiment 2

[0020] 1. Pass 16 kg of rice husk and 20 kg of attapulgite mixture through a 325-mesh filter screen to obtain a uniform mixed powder of rice husk and attapulgite; take 15 kg of mixed powder and add it to 33.3 kg with a molar concentration of 4.0 In a mol / L potassium hydroxide solution, let it stand for 8 hours; under a nitrogen atmosphere, heat up to 530 ° C, and roast for 5 hours;

[0021] 2. Add the composite material obtained in step 1 into 150 kg of deionized water, heat and boil for 30 minutes, keep the system temperature at 90°C, and while stirring, adjust the pH value of the system with a phosphoric acid solution with a molar concentration of 0.5 mol / liter 8. Suction filtration and drying to obtain the attapulgite / rice husk activated carbon composite material.

Embodiment 3

[0023] 1. Pass 10 kg of rice husk and 25 kg of attapulgite mixture through a 200-mesh filter screen to obtain a uniform mixed powder of rice husk and attapulgite; take 5 kg of mixed powder and add it to 16.7 kg with a molar concentration of 2.0 In a mol / L potassium hydroxide solution, let stand for 16 hours; under a nitrogen atmosphere, heat up to 500°C, and roast for 8.5 hours;

[0024] 2. Add the composite material obtained in step 1 into 100 kg of deionized water, heat and boil for 45 minutes, keep the system temperature at 80°C, and while stirring, adjust the pH of the system with a sulfuric acid solution with a molar concentration of 0.7 mol / liter 9. Suction filtration and drying to obtain the attapulgite / rice husk activated carbon composite material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com