Cerium oxide-doped modified lead dioxide porous electrode and preparation method thereof

A technology of lead dioxide and porous electrodes, which is applied in the fields of chemical instruments and methods, water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that the electrodeposited layer is easy to fall off, and achieve enhanced electrocatalytic oxygen capacity, Improve the effect of degradation and improve the efficiency of electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A preparation method of a modified lead dioxide porous electrode doped with cerium oxide, specifically comprising the steps of:

[0042] (1), β-PbO 2 powder preparation

[0043] Dissolve 10g of lead acetate in 20ml of water, adjust the pH to 9.0-10.0 with NaOH, then add 80ml of NaClO and stir evenly, react at 90°C for 6h, filter the obtained reaction solution, and wash the obtained filter cake repeatedly with deionized water until The filter cake is washed clean, the effluent is neutral, and then the temperature is controlled at 60-90°C for drying to obtain β-PbO 2 powder;

[0044] The above-mentioned lead acetate, water and NaClO are calculated according to the ratio of lead acetate: water: NaClO is 1g: 2mL: 8mL;

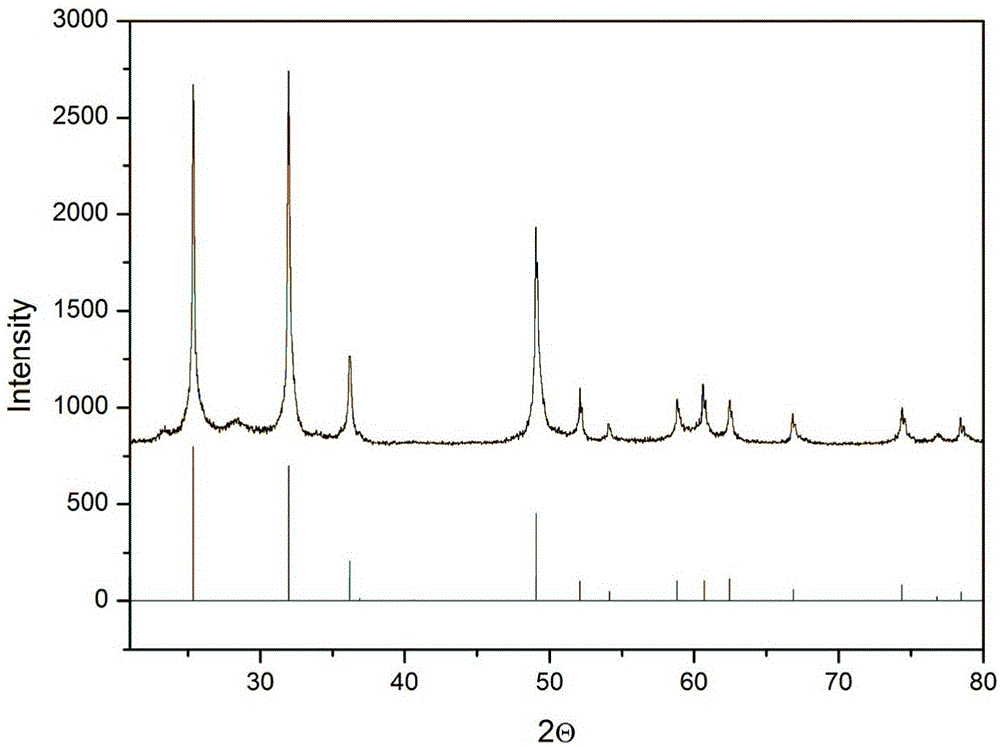

[0045] Close and look at the D / MAX2200PC pad X to test the formula for the β-PbO obtained above 2 The powder is measured, and the obtained XRD pattern is as follows figure 1 As shown, the diffraction peaks of the control JCPDS Card correspond to the rut...

Embodiment 2

[0059] A preparation method of a modified lead dioxide porous electrode doped with cerium oxide, specifically comprising the steps of:

[0060] (1), β-PbO 2 powder preparation

[0061] Dissolve 10g of lead acetate in 20ml of water, adjust the pH to 9.0-10.0 with NaOH, then add 80ml of NaClO and stir evenly, react at 90°C for 6h, filter the obtained reaction solution, and wash the obtained filter cake repeatedly with deionized water until The filter cake is washed clean, the effluent is neutral, and then the temperature is controlled at 60-90°C for drying to obtain β-PbO 2 powder;

[0062] The above-mentioned lead acetate, water and NaClO are calculated according to the ratio of lead acetate: water: NaClO is 1g: 2mL: 8mL;

[0063] (2), the β-PbO of 5.6g step (1) gained 2 Mix the powder with 0.2g of cerium oxide powder and 0.2g of carbon powder to form a mixed powder, then add 2g of polytetrafluoroethylene emulsion with a concentration of 60% by mass and mix evenly, then con...

Embodiment 3

[0070] A preparation method of a modified lead dioxide porous electrode doped with cerium oxide, specifically comprising the steps of:

[0071] (1), β-PbO 2 powder preparation

[0072] Dissolve 10g of lead acetate in 20ml of water, adjust the pH to 9.0-10.0 with NaOH, then add 80ml of NaClO and stir evenly, react at 90°C for 6h, filter the obtained reaction solution, and wash the obtained filter cake repeatedly with deionized water until The filter cake is washed clean, the effluent is neutral, and then the temperature is controlled at 60-90°C for drying to obtain β-PbO 2 powder;

[0073] The above-mentioned lead acetate, water and NaClO are calculated according to the ratio of lead acetate: water: NaClO is 1g: 2mL: 8mL;

[0074] (2), the β-PbO of 5.2g step (1) gained 2 The powder is mixed evenly with the mixed powder composed of 0.4g cerium oxide powder and 0.4g carbon powder, and then 2g of polytetrafluoroethylene emulsion with a mass percentage concentration of 60% is a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com