Material based on bismuth oxycarbonate or bismuth oxide nano tube and preparation method thereof

A technology of bismuth oxycarbonate and nanotubes, applied in chemical instruments and methods, nanotechnology for materials and surface science, nanotechnology, etc., to achieve uniform distribution of tube diameters, large specific surface area, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] A preferred embodiment of the present invention provides a kind of preparation method based on the material of bismuth oxycarbonate or bismuth oxide nanotube, comprises the following steps:

[0035] In the first step, dissolving bismuth nitrate in dilute nitric acid or dissolving bismuth nitrate in dilute nitric acid solution dispersed with graphene oxide is stirred uniformly to obtain a first reaction solution; wherein the concentration of bismuth nitrate is 0.5-5mg / ml ;The concentration of dilute nitric acid is 0.02~0.05mol / L; the mass ratio of bismuth nitrate to graphene oxide is 50:3~200:1;

[0036] In the second step, ammonia water is added dropwise to the first reaction solution until the pH of the system formed by mixing the first reaction solution and ammonia water is adjusted to alkaline, that is, the pH value is 9 to 11, and the second mixed solution is obtained;

[0037] In the third step, the second mixed solution is contained in CO 2 Atmospheric or without...

Embodiment 1

[0041] Weigh 400mg bismuth nitrate pentahydrate [Bi(NO 3 ) 3 ·5H 2 O] and it is added in the beaker that fills 200mL, 0.02mol / L dilute nitric acid solution, stirs until fully dissolving, obtains the first reaction solution. Ammonia water was added dropwise into the first reaction solution to adjust the pH value of the reaction system to 10, and a second mixed solution containing white flocculents was obtained at this time. Place the beaker containing the second mixed solution in a constant temperature oil bath at 60°C for 12 hours and heat and stir for 12 hours, then turn off the heating and stirring to obtain a white precipitate, which is separated by centrifugation, and deionized water is used to demineralize the white precipitate. Wash and dry in an oven at 60°C to obtain the product.

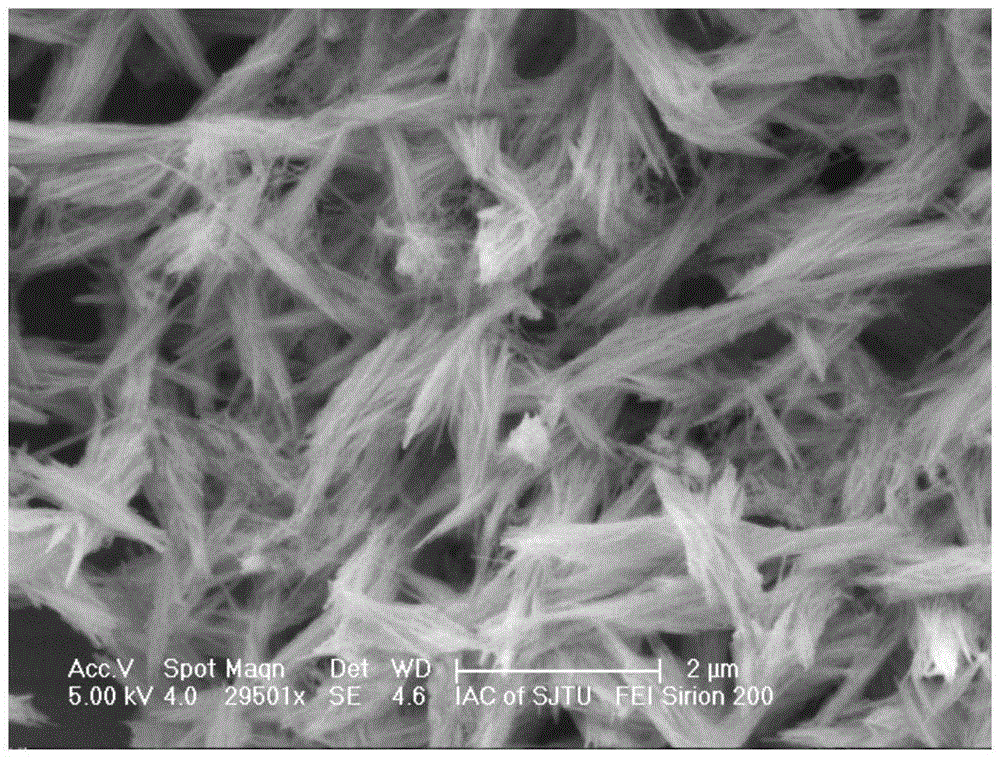

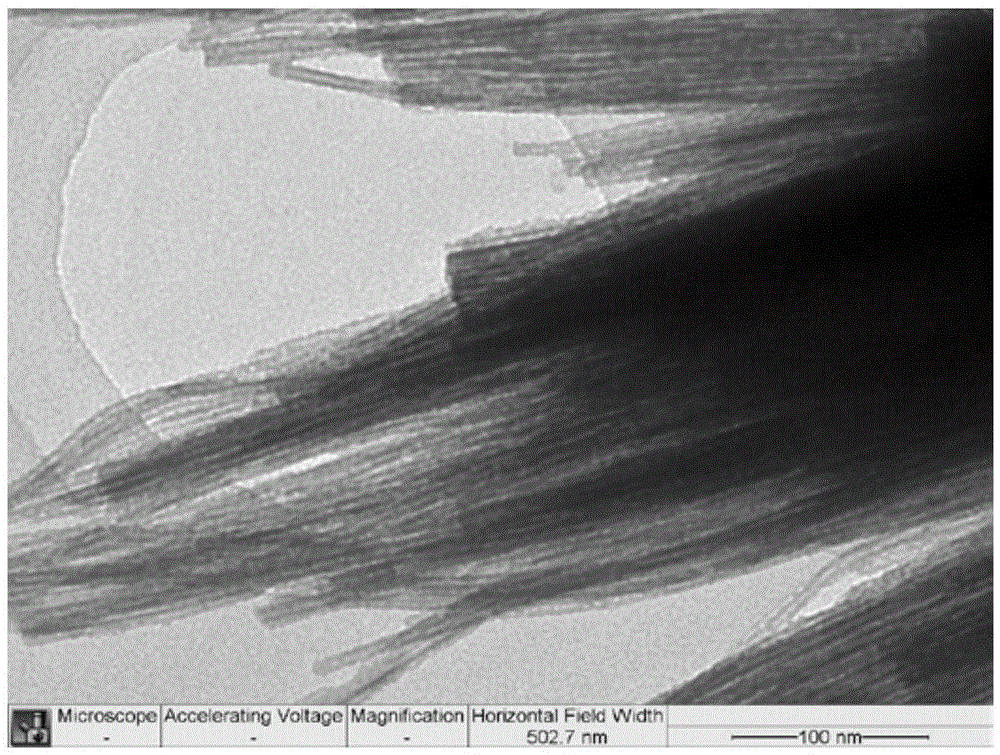

[0042] X-ray diffraction identification final product is bismuth oxycarbonate (see attached Figure 9 , the number of the corresponding standard diffraction peak is PDF:41-1488), scannin...

Embodiment 2

[0044] Weigh 800 mg of bismuth nitrate pentahydrate and add it into a round-bottomed flask containing 200 mL of 0.05 mol / L dilute nitric acid solution, and stir until fully dissolved to obtain the first reaction solution. The round bottom flask was sealed with a rubber stopper and the flask was evacuated with nitrogen sparging with stirring. Ammonia water was added dropwise into the first reaction solution to adjust the pH value of the reaction system to 11 to obtain a second mixed solution containing white flocculents. Place the flask containing the second mixed solution in a constant temperature oil bath at 60°C and heat and stir for 15 hours, then turn off the heating and stirring to obtain a white precipitate, which is separated by centrifugation, and deionized water is used to treat the white precipitate. Wash and dry in a vacuum oven at 60°C to obtain the product.

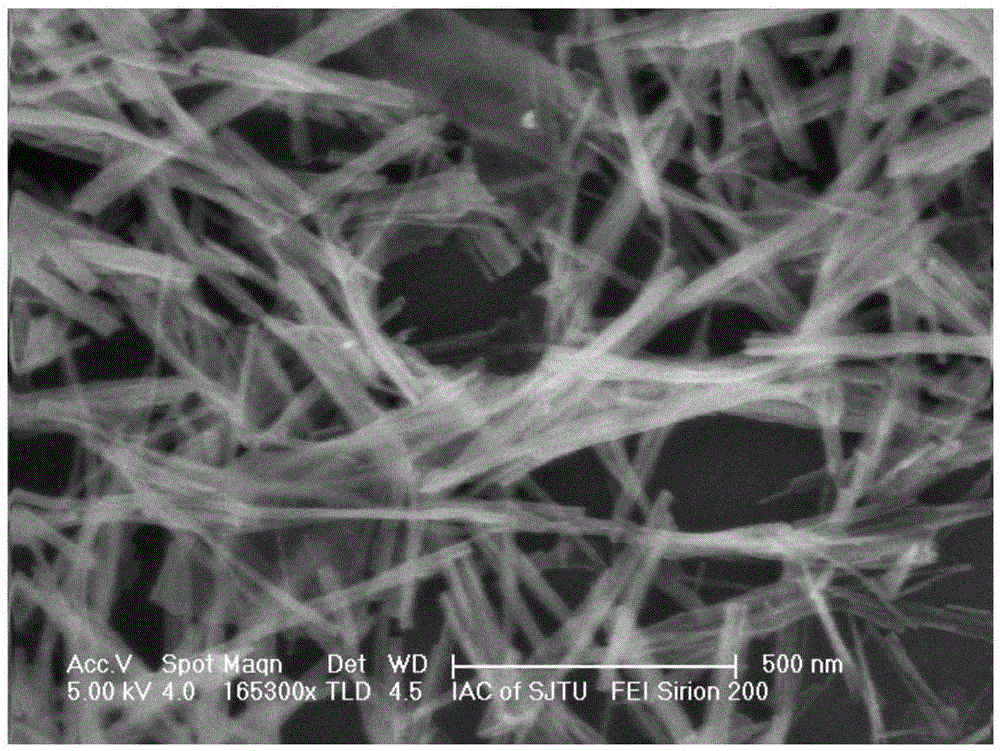

[0045] The final product was identified as bismuth oxide by X-ray diffraction (see attached Figure 10 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com