Preparation method of carbonized silicon (SiC) sub-micron fibers

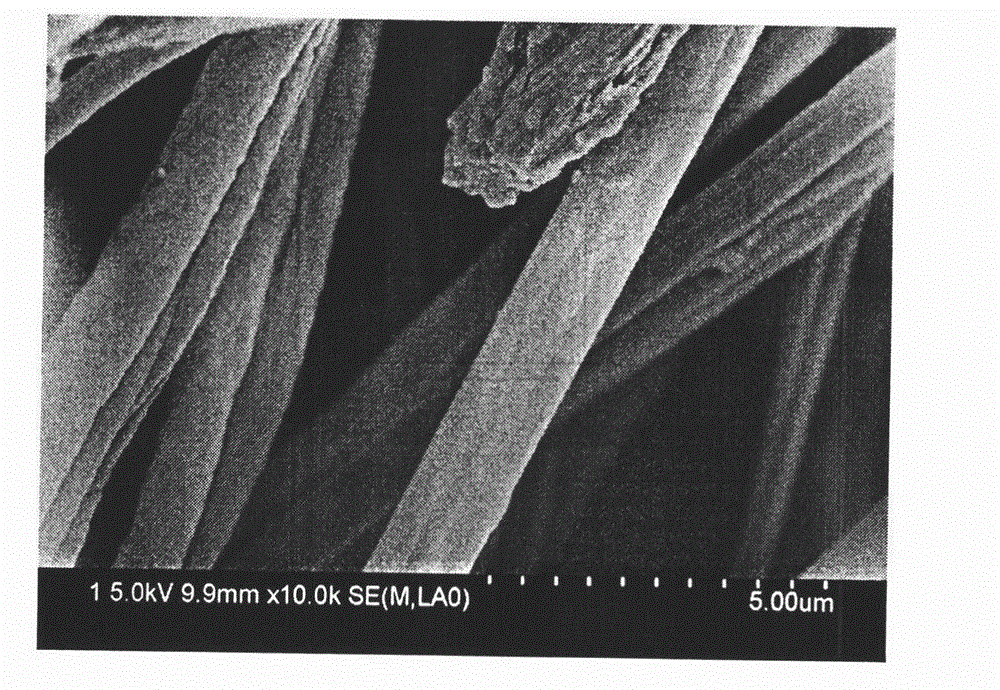

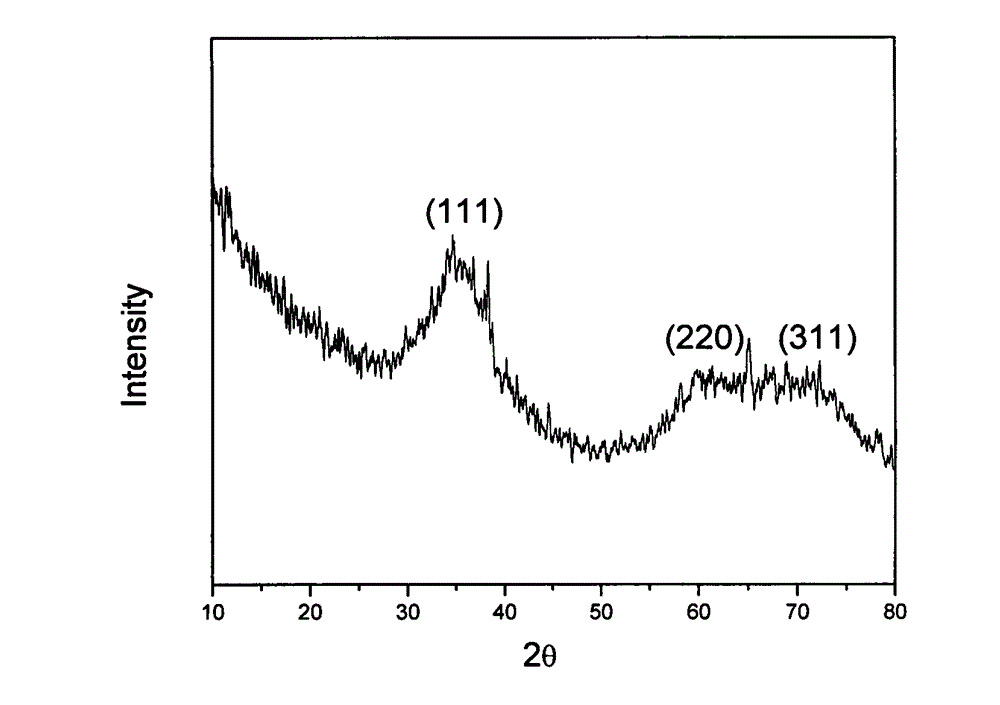

A technology of micron fiber and silicon carbide sub-technology, which is applied in the field of silicon carbide fiber preparation, can solve the problems of low fiber yield and uneven fiber diameter, etc., and achieve the effect of fine fiber diameter, good crystal form and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Preparation of spinning solution: mix polyurea silane and polymethyl methacrylate at a mass ratio of 10:5, dissolve it in tetrahydrofuran to make polyurea silane / polymethyl methacrylate spinning solution ; The concentration of the polyurea silane in the total solution is 10%;

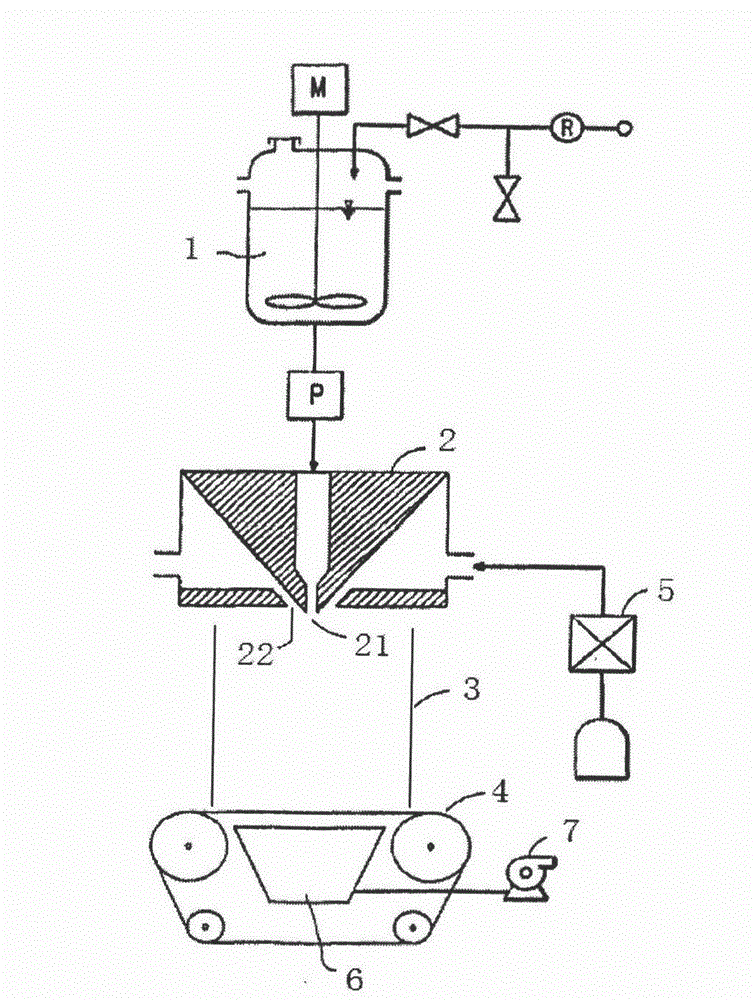

[0024] (2) Preparation of precursor fibers by solution jet spinning: the spinning solution is supplied to the spinneret die at a rate of 15mL / h / spinning hole, so that the spinning solution is extruded from the spinning hole to form a thin stream of solution ; Then utilize a high-speed jet stream (pressure is 0.50MPa, temperature is 25 ℃) to draw and thin the described fine flow of spinning solution, and make it enter the drying chamber; Under the action of the chamber, the precursor fibers are gradually formed; finally, the precursor fibers are collected on the mesh curtain by the suction airflow generated by the fan. The distance from the spinneret die to the screen curtain, that is, the re...

Embodiment 2

[0030] (1) Preparation of spinning solution: mix polycarbomethylsilane and polylactic acid / polystyrene (mass ratio 1:1) at a mass ratio of 10:10, dissolve it in a mixed solvent of toluene and tetrahydrofuran, and the solvent volume The ratio is 1: 1 to make spinning solution; the concentration of polycarbomethylsilane in the total solution is 20%;

[0031] (2) Precursor fibers are prepared by solution jet spinning: the spinning solution is supplied to the spinneret at a rate of 20mL / h / spinning hole, so that the spinning solution is extruded from the spinneret to form a thin stream of solution; Then utilize a high-speed jet stream (pressure is 1.0MPa, temperature is 45 ℃) to draw and thin the described fine stream of spinning solution, and make it enter drying chamber; Under the action of the box, the nascent fibers are gradually formed; finally, the nascent fibers are collected on the mesh curtain by the suction airflow generated by the fan. The distance from the spinneret to...

Embodiment 3

[0035] (1) Preparation of spinning solution: mix polycarbomethylsilane / polyurea silane (mass ratio 1:1) and polystyrene in a mass ratio of 10:10, dissolve it in a mixed solvent of toluene and tetrahydrofuran, The volume ratio of the solvent is 3:1 to make a spinning solution; the concentration of the polycarbomethylsilane / polyureasilane in the total solution is 30%;

[0036] (2) Preparation of precursor fibers by solution jet spinning: the spinning solution is supplied to the spinneret die at a rate of 5 mL / h / spinning hole, the air jet pressure is 0.60 MPa, the jet air temperature is 60 °C, and the mesh curtain The receiving distance is 200cm.

[0037] (3) Non-melting treatment: the above-mentioned as-spun fibers were heated in an air atmosphere at a rate of 3°C / min, kept at 200°C for 1 hour, and cooled to room temperature to obtain non-melting fibers.

[0038] (4) High-temperature calcination treatment: Under the protection of inert gas, the above-mentioned non-melting fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com