Electrostatic spinning equipment and method thereof for preparing one-dimensional ordered PAMPS (2-Acrylamide-2-methylpro panesulfonic acid)/PNIPAAm (Poly(N-Isoprolacrylamide)) micro-nanofibers

A technology of micro-nano fibers and electrospinning, which is applied in fiber processing, filament/thread forming, bundling of newly ejected filaments, etc. The effect of simple equipment and improved orderliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

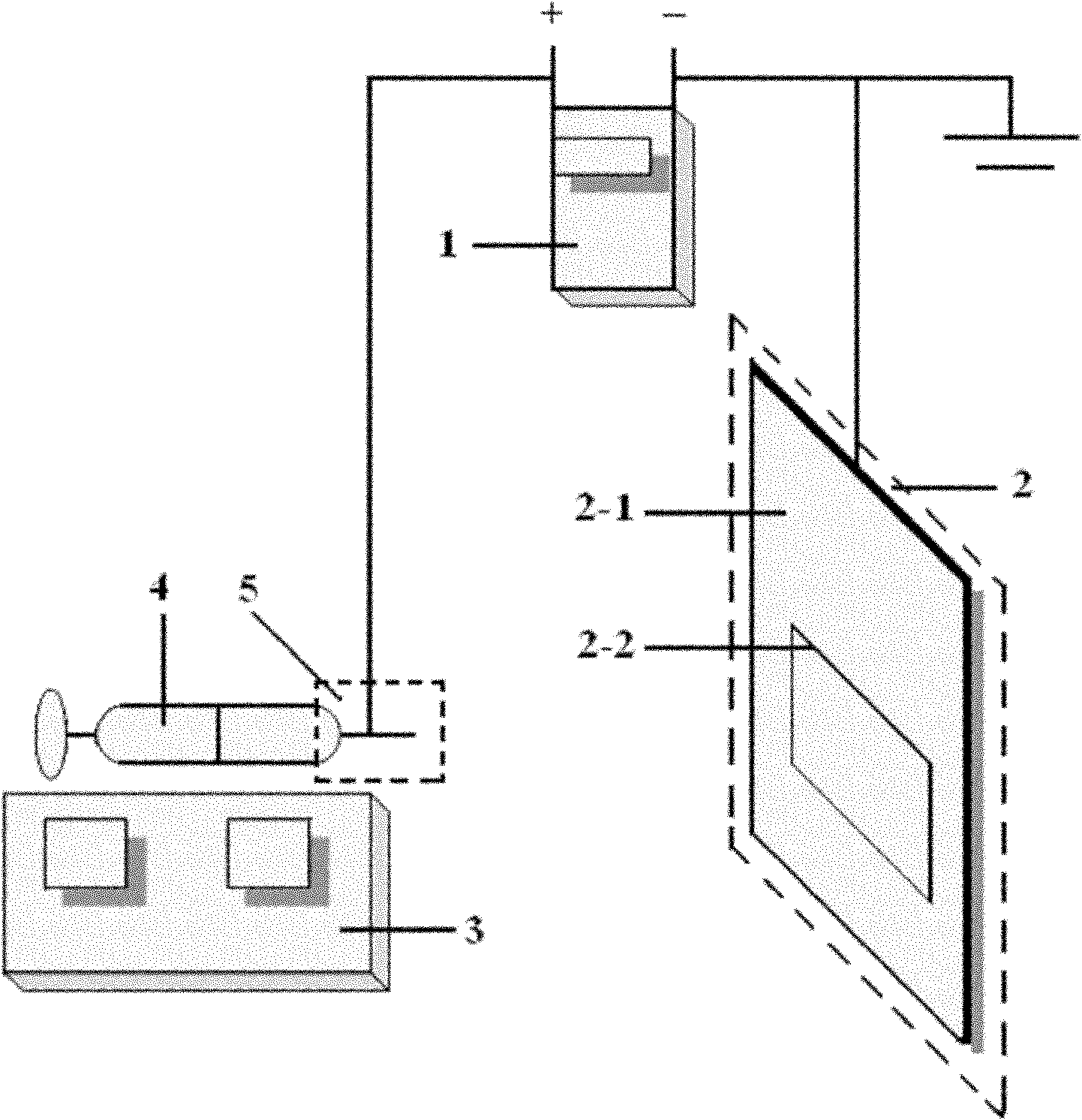

[0019] Specific embodiment one: combined with figure 1 To illustrate the electrospinning equipment of this embodiment, it includes a high-voltage power supply 1, a receiving device 2, a propulsion pump 3, a syringe 4, and a nozzle 5. The receiving device 2 consists of aluminum foil 2-1 and quartz glass arranged in parallel on the aluminum foil receiving surface The surface of the aluminum foil 2-1 is perpendicular to the spinning direction of the nozzle 5, the syringe 4 is fixed on the propulsion pump 3, the syringe 4 is connected with the nozzle 5, the inner diameter of the nozzle 5 is 0.55mm, and the nozzle 5 is connected to the high-voltage power supply. The positive pole of 1 is connected by a wire, and the receiving device 2 and the negative pole of the high-voltage power supply 1 are connected by a wire.

[0020] The electrospinning equipment of this embodiment is simple, and the quartz glass sheet is used as the receiving sheet, which can easily realize the preparation of l...

specific Embodiment approach 2

[0022] Second embodiment: This embodiment is different from the first embodiment in that the quartz glass receiving sheet 2-2 in the electrospinning equipment is pasted on the aluminum foil 2-1 in parallel by insulating tape to form the receiving device 2. The other components and connection relationships are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the center of the quartz glass receiving sheet 2-2 is located in the spinning direction of the nozzle 5. Other components and connection relationships are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com