Preparation method for composite material of cellulose nanofiber and reinforced polyurethane

A technology of nanofibers and composite materials, applied in papermaking, paper recycling, processing waste paper, etc., can solve the problems that have not yet been developed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A preparation method of cellulose nanofiber / reinforced polyurethane composite material, comprising the steps of:

[0044] 1) Chemical pretreatment:

[0045] Accurately weigh 6g of newspaper debris, put it in a 600ml beaker, add 300ml of distilled water, stir at high speed for 3 minutes with a disperser, then add 2g of sodium chlorite and 1.5ml of glacial acetic acid, stir evenly, seal the mouth of the beaker with plastic wrap Heat treatment in a magnetic heating stirrer at 75°C for 1 hour; during the heating process, use a magnet to continuously stir, and after 1 hour, without waiting for the solution to cool, directly add 1.5ml of glacial acetic acid and 2.0g of sodium chlorite, shake well, and continue to heat at 75°C Heating in a stirrer for 1 hour, repeat this twice, then filter with a Buchner funnel, and wash the residue repeatedly with distilled water until the solution is neutral, remove lignin to obtain a sample; move the sample into a 600ml beaker, pour 300ml q...

Embodiment 1

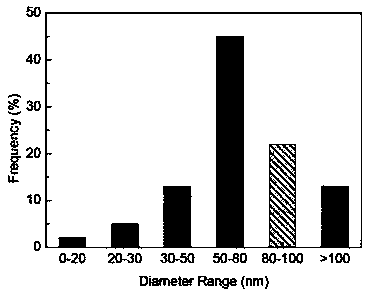

[0061] Example 1: State evolution during the preparation of newspaper cellulose nanofibers:

[0062] The morphology of newspaper cellulose nanofibers undergoes a series of changes during the preparation process. Due to the large amount of ink, impurities, etc., the newspaper pulp presents a dark gray color, but after being treated with sodium chlorite, it becomes light gray. Probably due to the bleaching action of chloride ions. After the alkali treatment, the fiber pulp became snow white, which indicated that the alkali treatment effectively removed the ink and impurities. During the chemical treatment, the fiber pulp has always settled at the bottom of the bottle, but after grinding, the fiber pulp becomes a light blue suspension state, which is due to the nanonization of the grinding disc during the grinding process, which makes the size of the fiber Significantly smaller, so that evenly dispersed in water presents a suspended state.

Embodiment 2

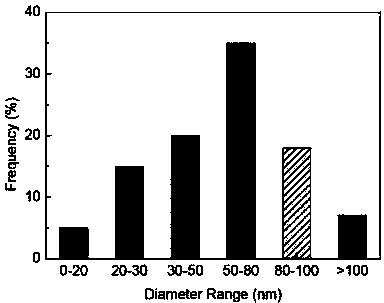

[0063] Example 2: State evolution during the preparation of wood flour cellulose nanofibers:

[0064] In the process of preparing wood flour cellulose nanofibers in this example, the morphology of wood flour fibers also undergoes a series of changes. The raw material wood flour is light yellow, which is due to the color development of wood flour containing lignin and extracts. Because of the substance, when the wood powder is extracted with benzene alcohol solution to remove the extract, and the lignin is removed with the acidic sodium chlorite solution, the wood powder presents a snow white color, which shows that the colored substance lignin, the extracted Most of the substances have been removed. In addition, the wood flour fiber at this time has a slightly smaller particle size than the raw material, which is also due to the removal of lignin and extractives. However, after alkali treatment, the size of the fiber was significantly reduced and appeared powdery. On the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com