Centrifugal disc for producing glass wool

A centrifugal disc and glass wool technology, applied in the field of centrifugal discs, can solve problems such as uneven thickness of glass wool fibers, uneven coverage of glass liquid film, chaotic and disordered flow direction, etc., to achieve uniform diameter distribution and small hole flow Consistent, even diameter distribution results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

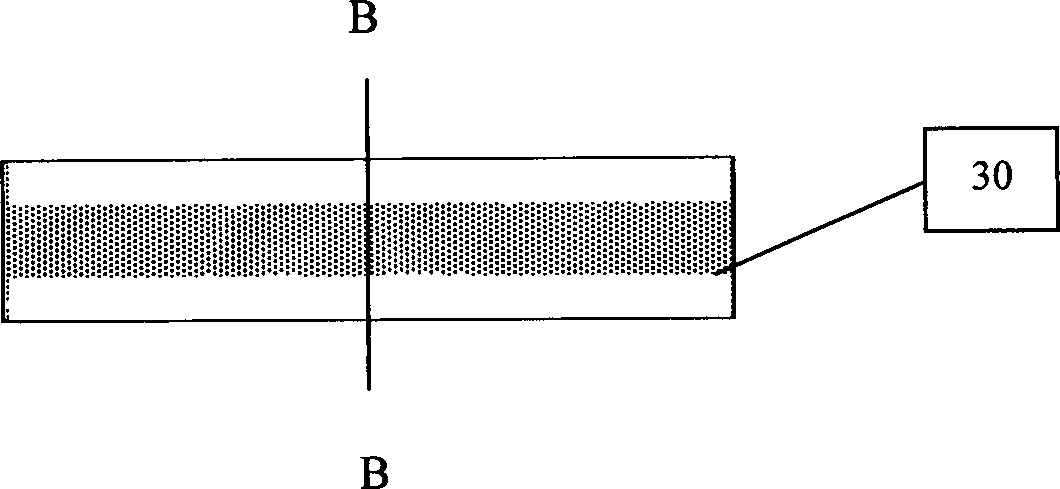

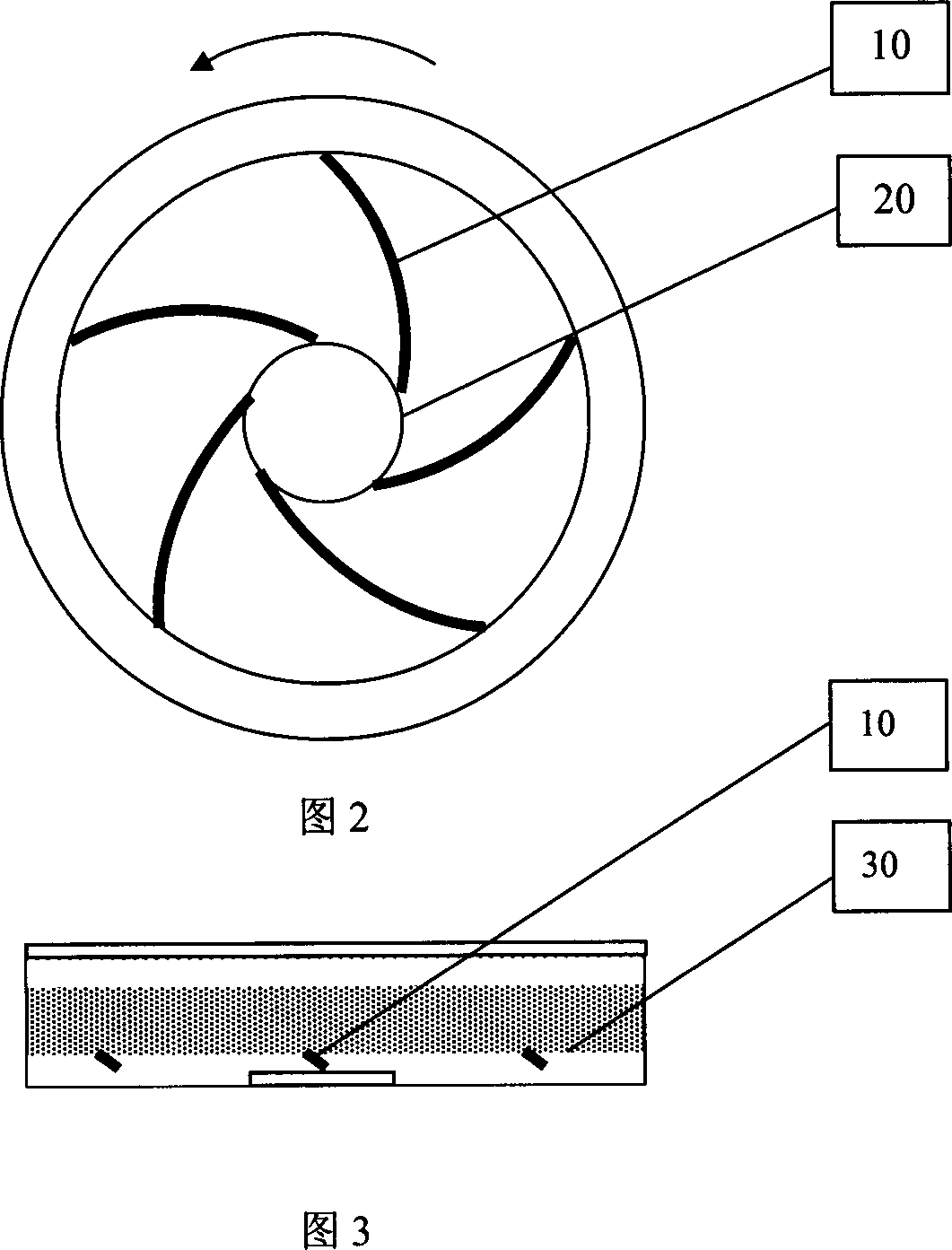

[0013] A centrifugal disk for glass wool with an inner wall diameter of 400mm, a spindle installation hole 20 diameter of 80mm, a side wall thickness of 5mm, and a bottom thickness of 7mm. The number of curved grooves 10 is 5, and the shape is an Archimedes spiral. The centrifugal disk spindle mounting hole 20 is the starting point, and the end point is the termination line 30 under the small hole on the inner wall of the centrifugal disk, with a depth of 5 mm and a width of 7 mm.

Embodiment 2

[0015] A bottom inner wall 30 with a diameter of 300 mm, a spindle installation hole 20 with a diameter of 60 mm, a side wall with a thickness of 4 mm, and a bottom with a thickness of 6 mm for a centrifugal disk for glass wool. The number of curved groove structures 10 is 7, and the shape is an Archimedes spiral Line, with the centrifugal disc spindle mounting hole 20 as the starting point, with the end line 30 under the small hole on the inner wall of the centrifugal disc as the end point, the depth is 6mm, and the width is 8mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com