Self-twisting graphene fiber and preparation method thereof

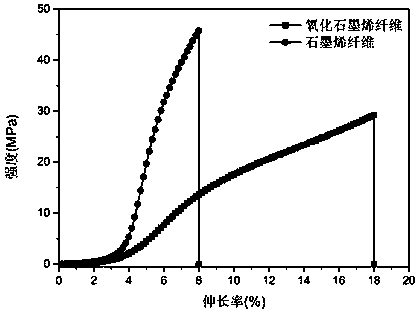

A graphene fiber and graphene technology, applied in the direction of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of low flexibility of graphene fiber and cannot meet the application requirements, so as to achieve large-scale production and application, fiber flexibility performance Prominent, large elongation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

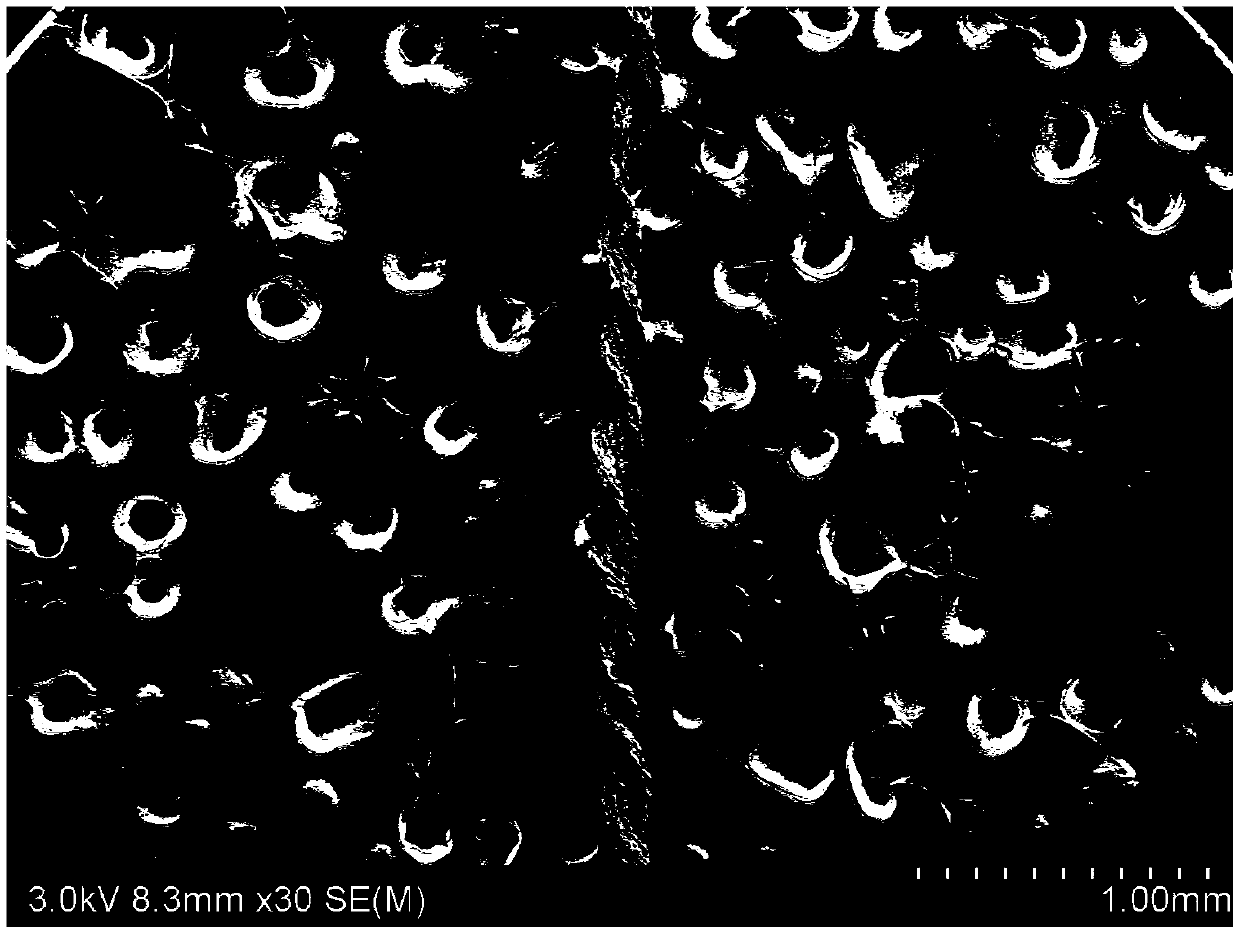

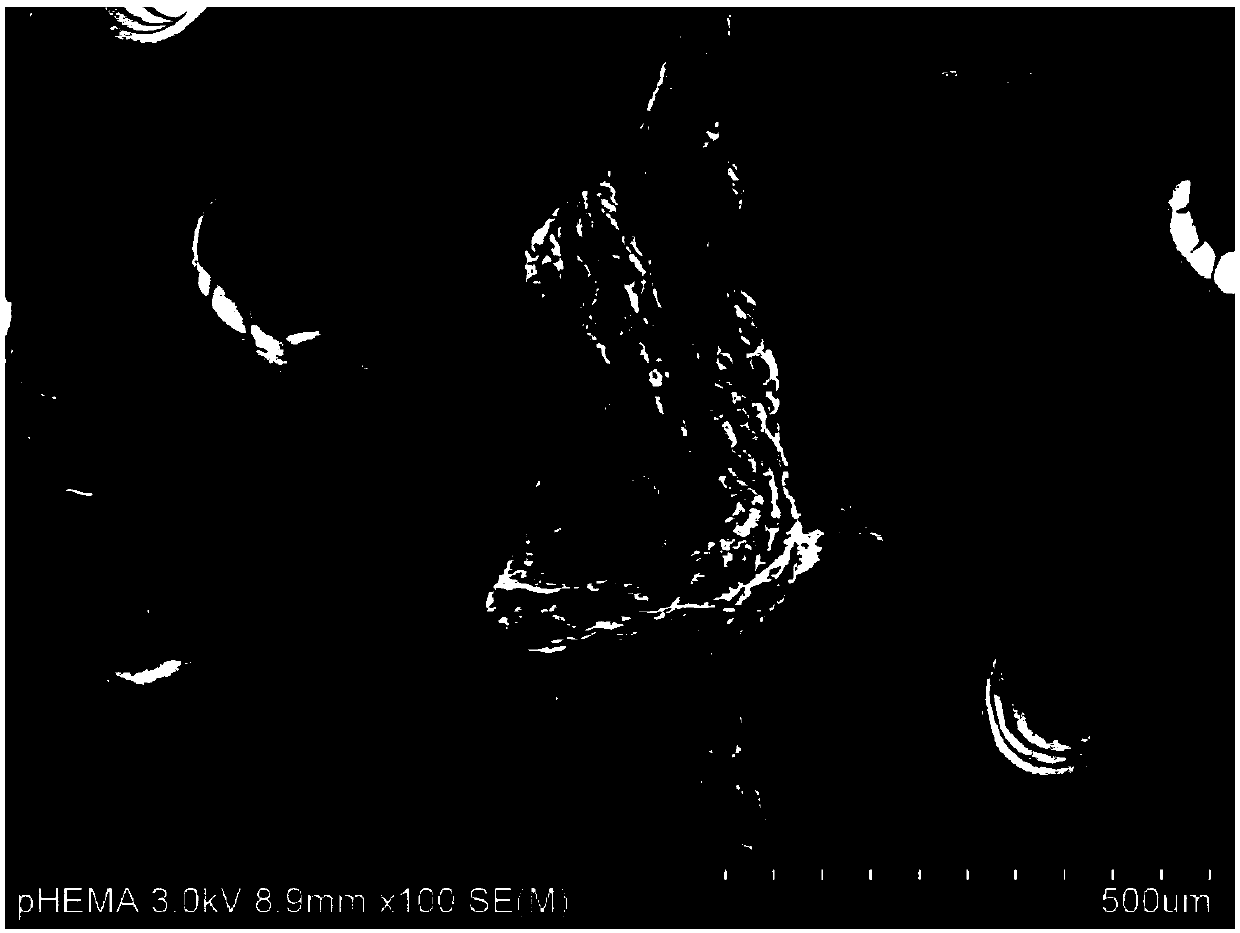

[0046]Fill the graphene oxide spinning solution into the spinner, control the spinning speed with a flow pump to be 0.5ml / h, the inner diameter of the spinning hole is 0.8mm, the temperature of the spinning shaft is 250°C, and the flow rate of the hot air The temperature is 24 l / min, the angle between the hot air flow and the spinning hole is 45°, and the prepared dry and regular self-twisted graphene oxide fiber is wound onto the bobbin at a speed of 1 r / min. The spinning solution was prepared from a graphene oxide aqueous solution with a concentration of 15 mg / ml at 40° C. and magnetically stirred at a speed of 400 r / min for 4 hours.

[0047] The prepared self-twisted graphene oxide fibers were reduced by hydroiodic acid at 100°C for 8 hours, washed with absolute ethanol and deionized water three times in sequence, and dried at 100°C to obtain self-twisted graphene fibers.

Embodiment 2

[0049] Fill the graphene oxide spinning liquid into the spinning container, control the spinning speed with a flow pump to be 1ml / h, the inner diameter of the spinning hole is 1.5mm, the temperature of the spinning shaft is 300°C, and the flow rate of hot air is 12l / min, the angle between the hot air flow and the spinning hole is 30°, and the prepared dry and regular self-twisted graphene oxide fiber is wound onto the bobbin at a speed of 2r / min. The spinning solution was prepared from a graphene oxide ethanol solution with a concentration of 5mg / ml at 60°C and magnetically stirred at a speed of 400r / min for 3h.

[0050] The prepared self-twisted graphene oxide fibers were reduced by hydroiodic acid at 100°C for 12 hours, washed with absolute ethanol and deionized water three times in sequence, and dried at 100°C to obtain self-twisted graphene fibers.

Embodiment 3

[0052] The graphene oxide spinning solution is filled into the spinning container, and the spinning speed is controlled by a flow pump to be 3ml / h, the inner diameter of the spinning hole is 2mm, the temperature of the spinning shaft is 350°C, and the flow rate of the hot air is 9l / h. min, the angle between the hot air flow and the spinning hole is 50°, and the prepared dry and regular self-twisting graphene oxide fiber is wound onto the bobbin at a speed of 3r / min. The spinning solution was prepared from a methanol solution of graphene oxide with a concentration of 10 mg / ml at 40° C. and magnetically stirred at a speed of 600 r / min for 8 hours.

[0053] The prepared graphene oxide fibers were reduced at 800°C for 3 hours under the protection of argon to obtain self-twisted graphene fibers.

PUM

| Property | Measurement | Unit |

|---|---|---|

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com