Compatible thermotropic liquid crystal polymer and method and application thereof

A thermotropic liquid crystal and compatibility technology, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of in-situ fiber formation of liquid crystal phase, increased material cost, low interface adhesion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The preparation method of the above-mentioned compatible thermotropic liquid crystal polymer is formed by the uniform stirring and copolymerization reaction of the following monomers at a temperature of 80-120°C:

[0030] ① One or more imide dicarboxylic acid monomers with imide bonds and flexible spacers, the general structural formula is:

[0031]

[0032] Wherein n is an integer of 4-12;

[0033] ②One or more dihydric phenol monomers with aromatic structure, the general structural formula is HO-Ar-OH, wherein Ar is selected from:

[0034]

[0035] where X is:

[0036] ——O——,——S——, and alkyl substituted derivatives;

[0037] ③Hydroxyacid monomers containing aromatic groups, the general structural formula is OH-R-COOH,

[0038] where R is selected from

[0039] The molar percentage of the hydroxy acid monomer is 30-50%, the molar percentage of the imide dicarboxylic acid monomer is 15-45%, and the molar percentage of the dihydric phenol monomer is 15-45...

Embodiment 1

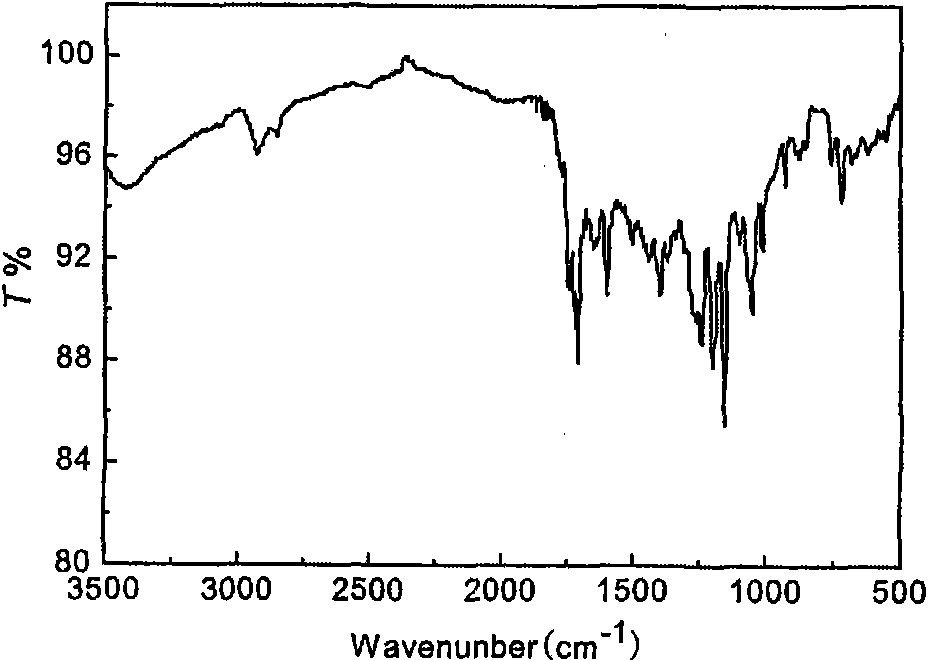

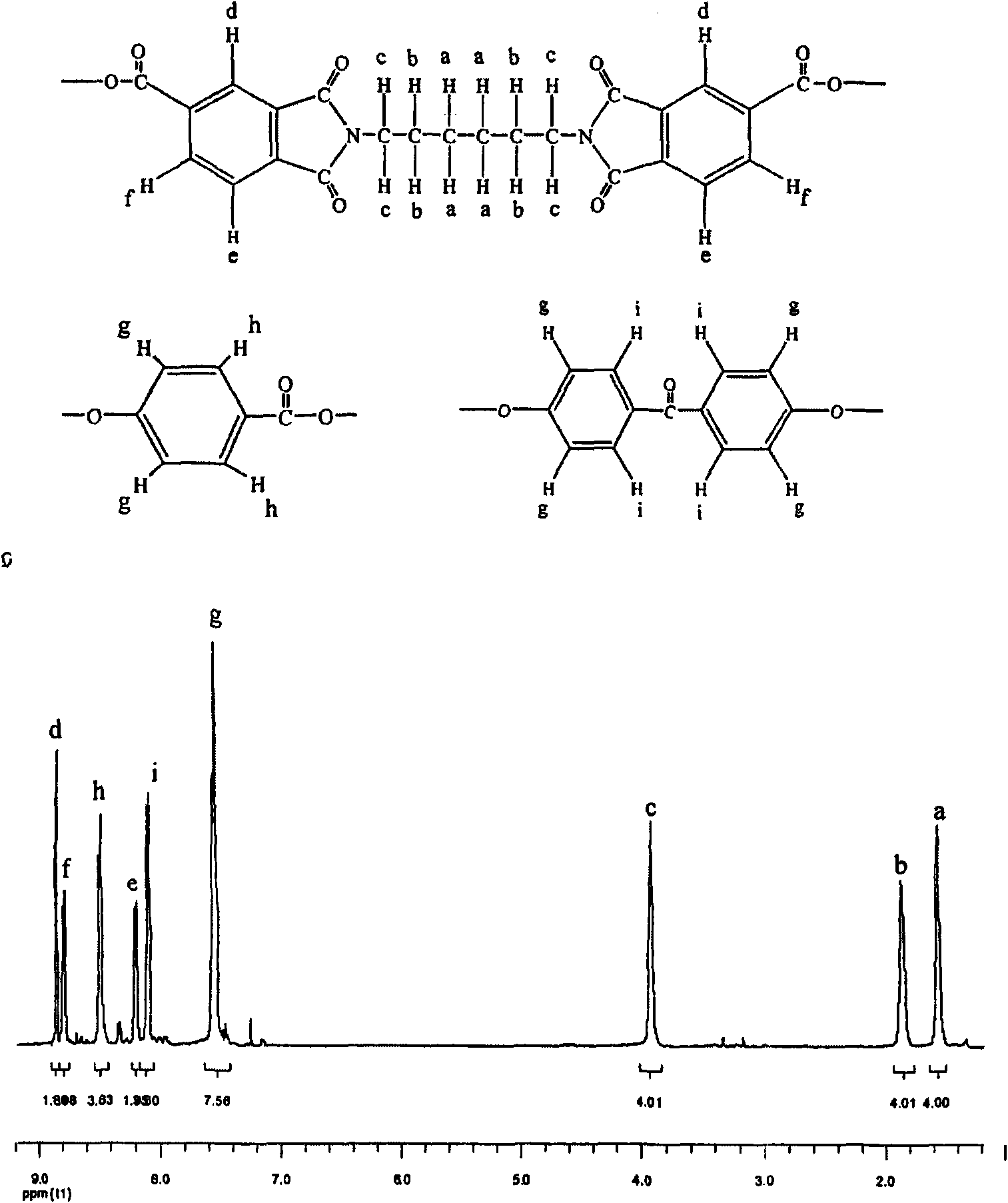

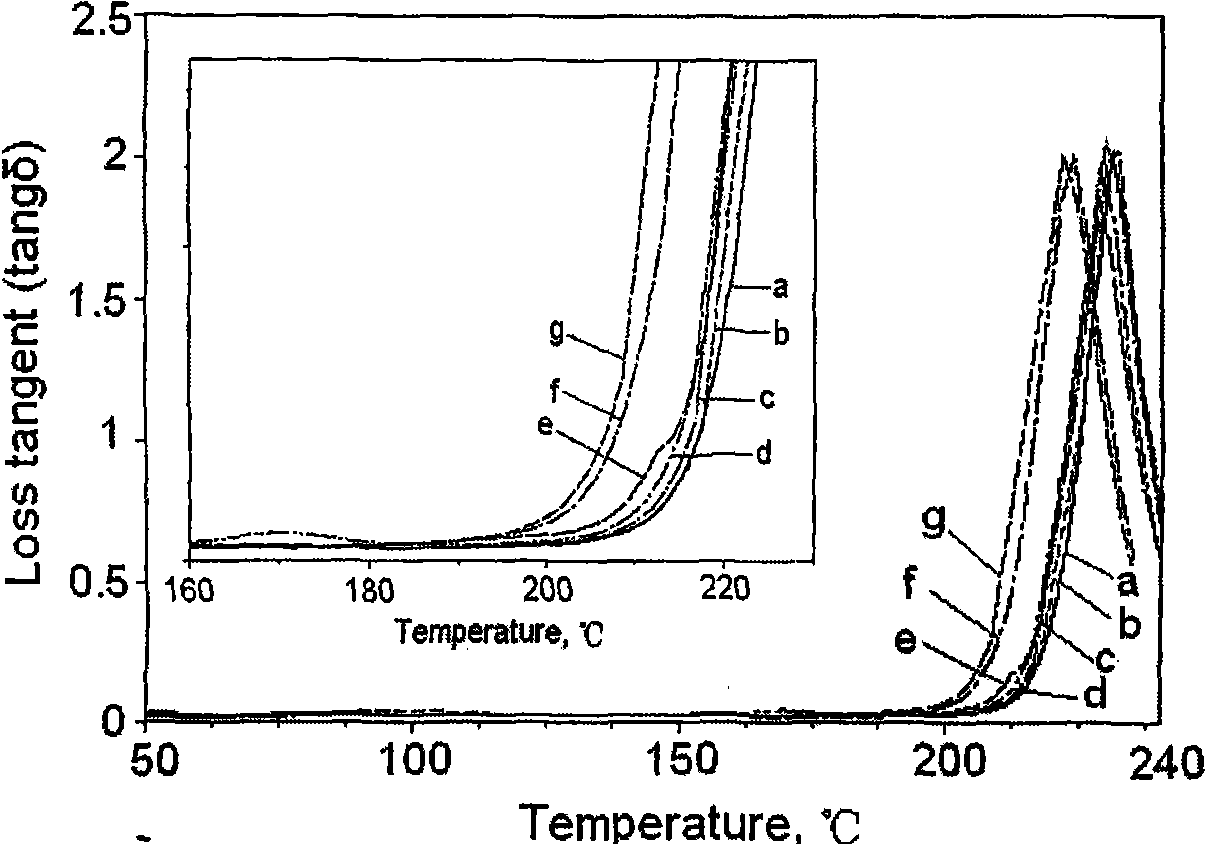

[0041] The present invention will be further described through specific implementation examples below, but the present invention is not limited to this specific example. Embodiment 1: Polymerization reaction of thermotropic liquid crystal polyesterimide (PIDB series) containing aryl ketone group

[0042] The synthesis conditions and steps of the thermotropic liquid crystal polyesterimide series products containing aryl ketones using p-hydroxybenzoic acid (p-HBA) as the monomer raw material are basically the same. Here, the synthesis of PIDB50 copolymer is taken as an example to illustrate the specific synthesis steps. PIDB50 is composed of N, N'-hexadiene-1,6-bistriphenyltrilimide diacid (IA6), p-hydroxybenzoic acid (p-HBA) and 4,4'-hydroxybenzophenone ( DHBP) The molar percentage ratio of the monomers thrown in is 1:2:1, which is the product obtained by the monomers through the copolymerization reaction. Specific steps are as follows:

[0043] Add 16.6mL (about 0.13mol) of...

Embodiment 2

[0048] Embodiment 2: Polymerization reaction of thermotropic liquid crystal polyesterimide (PIDN series) containing naphthalene ring

[0049] The synthesis conditions and steps of the thermotropic liquid crystal polyesterimide series products containing naphthalene rings using 6-hydroxy, 2-naphthoic acid (2,6-HNA) as the monomer raw material are basically the same. The following takes PIDN33 copolymer as an example to illustrate the specific synthesis steps. PIDN33 is composed of N,N'-hexadiene-1,6-diphenyltrilimide diacid (IA6), 6-hydroxy, 2-naphthoic acid (2,6-HNA) and 4,4' -Hydroxybenzophenone (DHBP) (the molar percentage ratio of the injected monomer is 1:1:1) is the copolymerization reaction product of polymerized monomers. Specific steps are as follows:

[0050] Add 16.6 mL (about 0.31 mol) of BsCl, 7.8 ML (about 0.10 mol) of DMF and 50 mL of Py into a 500 ml round bottom flask, cover the bottle with a stopper, and let stand at room temperature for 40 min. Put in a st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com