Method for preparing agricultural rock wool

A manufacturing method and rock wool technology, applied in manufacturing tools, glass manufacturing equipment, etc., can solve the problems of undesired, unable to establish connection, limited effect of improving peel strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

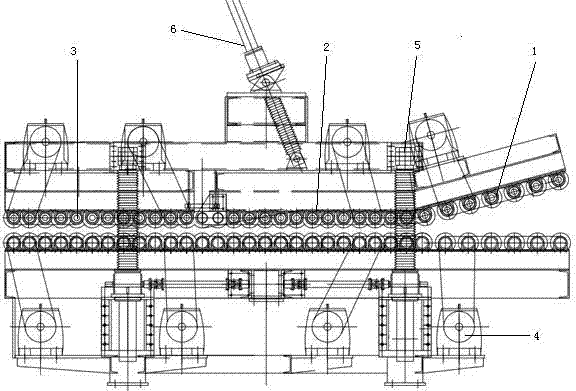

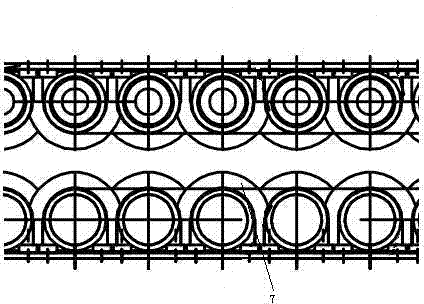

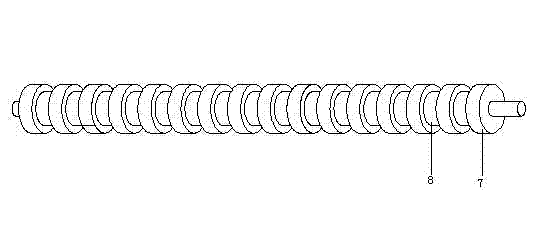

Image

Examples

Embodiment 1

[0027] Embodiment 1: 75 parts by weight of basalt, 6 parts of limestone, 5 parts of slag, 25 parts of coke, 3 parts of fluorite, and 1 part of diatomaceous earth are mixed and pulverized and added to the cupola. Enter liquid oxygen, melt, and magma is formed into fibers through a four-roller centrifuge, and the exit is sprayed with phenolic resin binder and hydrophilic agent to prepare a solution. After cotton collection and pendulum machine laying, it enters the cotton press machine and is made after solidification. Three-dimensional structure rock wool.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com