Preparation method of NiO/gamma-Al2O3 composite ceramic nanofiber

A technology of nanofibers and composite ceramics is applied in the field of preparation of composite ceramic nanofibers to achieve the effects of high catalytic activity, good flexibility and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

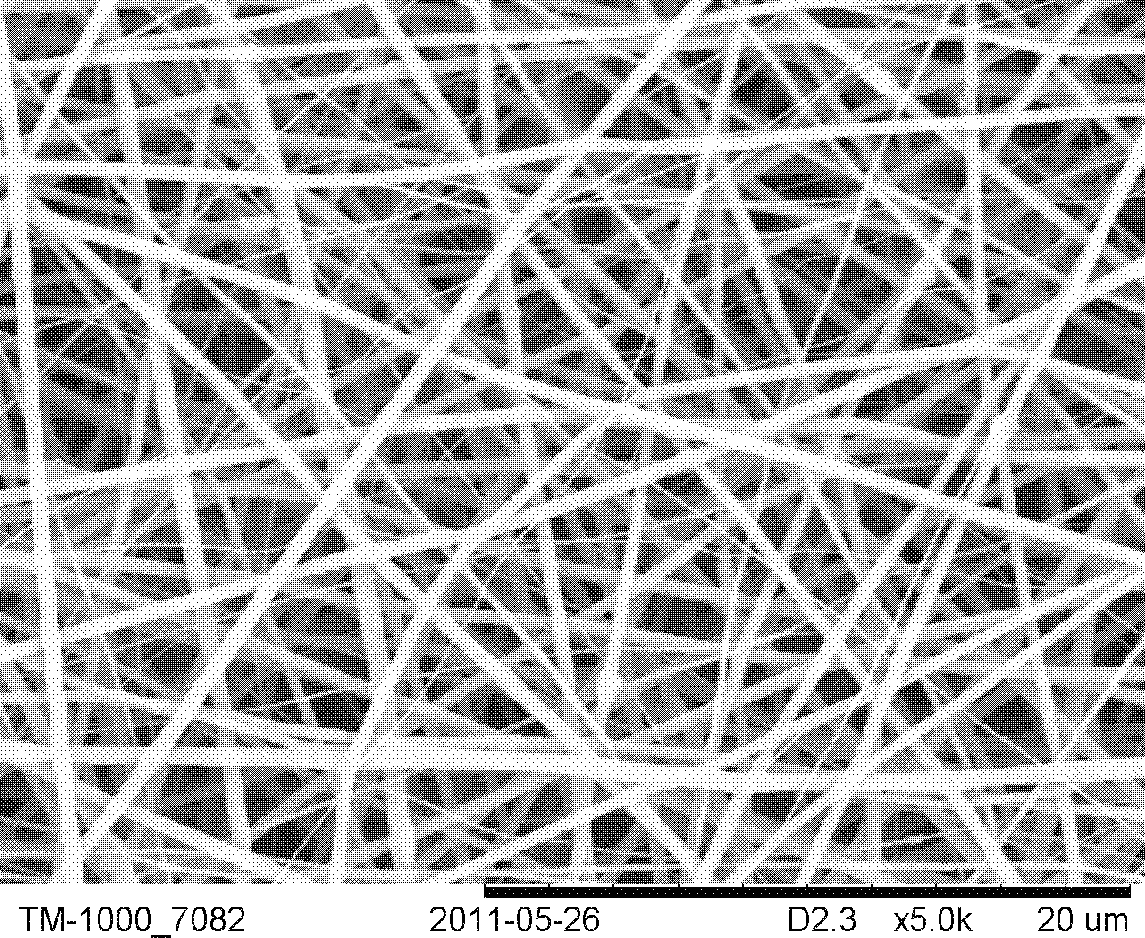

[0029] Mix and stir 0.3g aluminum acetate and 6g methanol in a weight ratio of 1:20 to fully dissolve the components to obtain Al(CH 3 COO) 3 solution, then add 4g of nickel acetate solid into the above aluminum acetate solution, stir fully to obtain uniformly dispersed Ni(CH 3 COO) 2 / Al(CH 3 COO) 3 Mix the solution, fully dissolve the PVP solid of 2g and the ethanol of 20g by weight ratio 1:10 to obtain the PVP solution, and the PVP solution is added to the above-mentioned Ni(CH) with a mass ratio of 2:1 3 COO) 2 / Al(CH 3 COO) 3 in the mixed solution, and then stirred uniformly to obtain Ni(CH 3 COO) 2 / Al(CH 3 COO) 3 / PVP precursor solution for electrospinning. The electrospinning parameters are: voltage 9kv, silk liquid supply rate 1.0ml / h, distance between the spinneret and the receiving plate 15cm, ambient temperature 25°C, and ambient humidity 30%. figure 1 The precursor nanocomposite fiber membrane shown is finally calcined at 600°C to obtain the following...

Embodiment 2

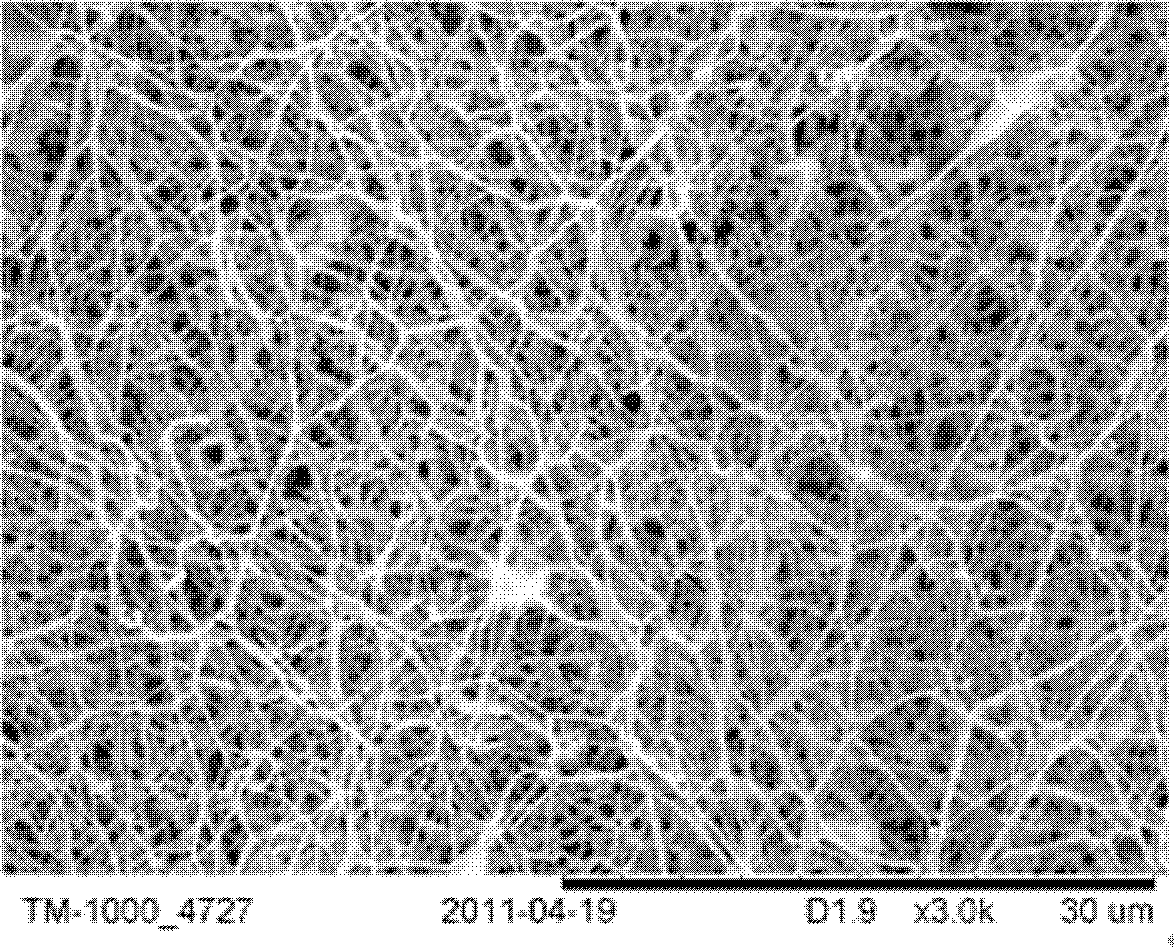

[0031] Mix and stir 0.3g aluminum acetate and 6g methanol in a weight ratio of 1:20 to fully dissolve the components to obtain Al(CH 3 COO) 3 solution, and then 4g nickel acetate solid was added to the aluminum acetate solution, fully stirred to obtain uniformly dispersed Ni(CH 3 COO) 2 / Al(CH 3 COO) 3 Mixed solution, the PVP solid of 2g and the ethanol of 18g are fully dissolved to obtain PVP solution by weight ratio 1: 9, and the PVP solution mass ratio is 1: 1 and joins above-mentioned Ni (CH 3 COO) 2 / Al(CH 3 COO) 3 in the mixed solution, and then stirred uniformly to obtain Ni(CH 3 COO) 2 / Al(CH 3 COO) 3 / PVP precursor solution for electrospinning. The electrospinning parameters are: voltage 10kv, silk liquid supply rate 1.0ml / h, distance between the spinneret and the receiving plate 15cm, ambient temperature 25°C, ambient humidity 40%, and the precursor nanocomposite fiber membrane is obtained , and finally calcined at 700°C to obtain image 3 Ceramic nanofi...

Embodiment 3

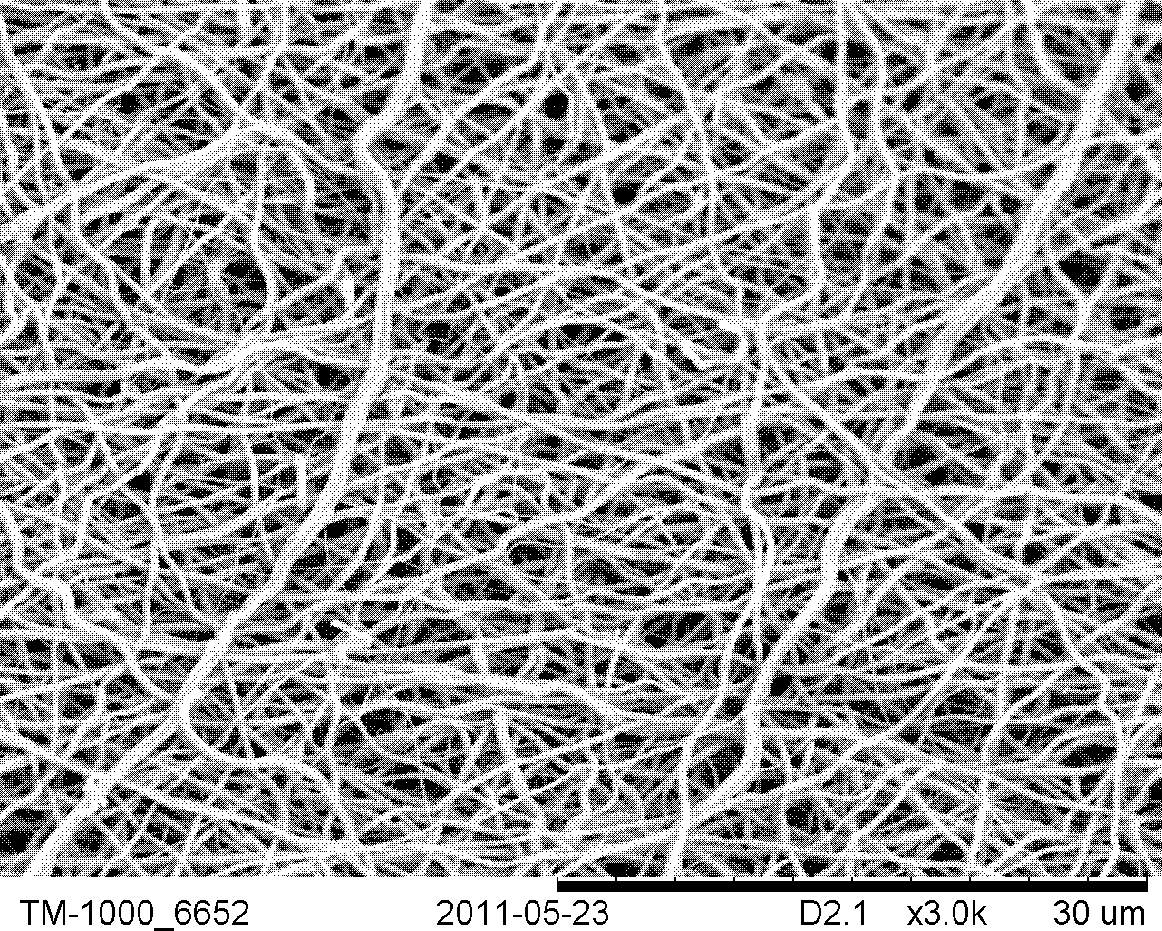

[0033] Mix and stir 1g aluminum acetate and 20g methanol in a weight ratio of 1:20 to fully dissolve the components to obtain Al(CH 3 COO) 3 solution, and then 1g of nickel acetate solid was added to the above aluminum acetate solution, fully stirred to obtain uniformly dispersed Ni(CH 3 COO) 2 / Al(CH 3 COO) 3 Mixed solutions; 2g of PVP solids and 18g of ethanol are fully dissolved in a weight ratio of 1:9 to obtain a PVP solution, and the PVP solution mass ratio is 1:1 added to the above-mentioned Ni (CH 3 COO) 2 / Al(CH 3 COO) 3 in the mixed solution, and then stirred uniformly to obtain Ni(CH 3 COO) 2 / Al(CH 3 COO) 3 / PVP precursor solution for electrospinning. Electrospinning parameters are: voltage 11kv, silk liquid supply rate 1.0ml / h, distance between spinneret and receiving plate 15cm, ambient temperature 25°C, ambient humidity 50%, and the precursor nanocomposite fiber is obtained film, and finally calcined at 800°C to obtain Figure 4 Ceramic nanofibers s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com