Glass carbon nanometer fiber preparation method

A nanofiber and glassy carbon technology, which is applied in fiber processing, fiber chemical characteristics, heating/cooling fabrics, etc., can solve problems that have not been reported yet, and achieve the effects of uniform diameter distribution, abundant output, and low pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

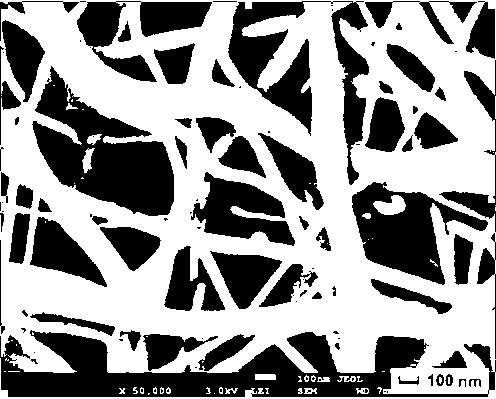

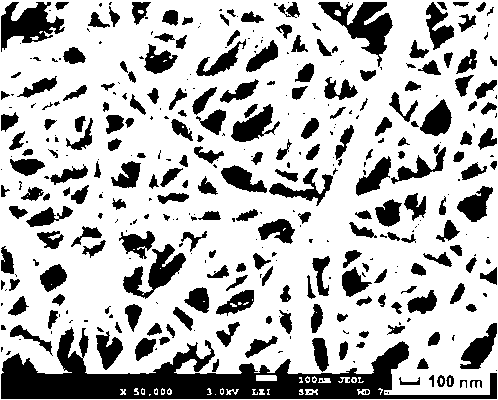

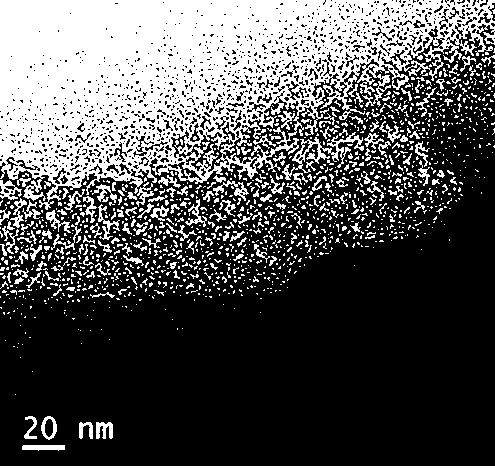

Image

Examples

Embodiment 1

[0022] 1. Dissolve 3 g of cellulose acetate in 17 g of acetone and N,N -In the mixed solvent of dimethylacetamide, be configured into the cellulose acetate spinning solution that mass fraction is 15%. of which acetone and N,N - The mass ratio of dimethylacetamide is 2:1.

[0023] 2. Transfer the cellulose acetate spinning dope to a 10 ml syringe, then fix the syringe on the syringe pump, control the temperature at 25 °C, humidity at 60%, electric field strength at 0.5 kV / cm, and feeding speed at 10 μL / min , and electrospun in an electrospinning device to obtain cellulose acetate nanofibers. The prepared cellulose acetate nanofibers were dried in a vacuum oven at 40 °C for 8 h.

[0024] 3. The cellulose acetate nanofibers were hydrolyzed in an ethanol solution containing 0.1 mol / L NaOH at 25°C for 24 h, then washed with distilled water until neutral, drained in the atmosphere for 8 h, and then vacuum-dried at 70°C for 12 h. Cellulose nanofibers are obtained.

[0025] 4. Th...

Embodiment 2

[0027] 1. Dissolve 5 g of cellulose acetate in 20 g of acetone and N,N -In the mixed solvent of dimethylacetamide, be configured into the cellulose acetate spinning solution that mass fraction is 20%. of which acetone and N,N - The mass ratio of dimethylacetamide is 2:1.

[0028] 2. Transfer the cellulose acetate spinning dope to a 10 ml syringe, then fix the syringe on the syringe pump, control the temperature at 30°C, humidity 70%, voltage 10 kV, needle tip diameter 1 mm, distance between the needle tip and the receiver 20 cm, the flow rate of the spinning solution was 15 μL / min, and electrospun in an electrospinning device to obtain cellulose acetate nanofibers. The cellulose acetate nanofibers were dried in a vacuum oven at 40 °C for 8 h.

[0029] 3. The cellulose acetate nanofibers were hydrolyzed in an ethanol solution containing 0.1 mol / L NaOH at 25 °C for 24 h, then washed with distilled water until neutral, drained in the atmosphere for 8 h, and then vacuum-dried a...

Embodiment 3

[0032] 1. Dissolve 2g of cellulose acetate in 18g of acetone and N,N -In the mixed solvent of dimethylacetamide, be configured into the cellulose acetate spinning solution that mass fraction is 10%. of which acetone and N,N - The mass ratio of dimethylacetamide is 2:1.

[0033] 2. Transfer the cellulose acetate spinning dope to a 10 ml syringe, then fix the syringe on the syringe pump, control the temperature at 20°C, humidity 80%, voltage 5 kV, needle tip diameter 1 mm, distance between the needle tip and the receiver 20 cm, the flow rate of the spinning solution was 5 μL / min, and electrospun in an electrospinning device to obtain cellulose acetate nanofibers. The cellulose acetate nanofibers were dried in a vacuum oven at 40 °C for 8 h.

[0034] 3. The cellulose acetate nanofibers were hydrolyzed in an ethanol solution containing 0.1 mol / L NaOH at 25 °C for 24 h, then washed with distilled water until neutral, drained in the atmosphere for 8 h, and then vacuum-dried at 70...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com