Method for preparing pure hyaluronic acid nano fiber non-woven fabric

A hyaluronic acid and nanofiber technology, which is applied in fiber treatment, fiber chemical characteristics, spinning solution preparation, etc., can solve the problems of increased equipment requirements, increased costs, troublesome post-processing of the preparation method, etc., and achieves low equipment requirements and fiber Uniform diameter distribution and easy post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) The weight-average molecular weight is Mw=400,000 hyaluronic acid powder is dissolved in the mixed solvent that the volume ratio of water, formic acid and DMF is 1:1:1, is made into the solution that weight percent is 5wt%, then the solution is fully Stir until it is completely dissolved, and place the solution in an ultrasonic wave for 1 hour so that all the bubbles are separated out to obtain a transparent hyaluronic acid solution.

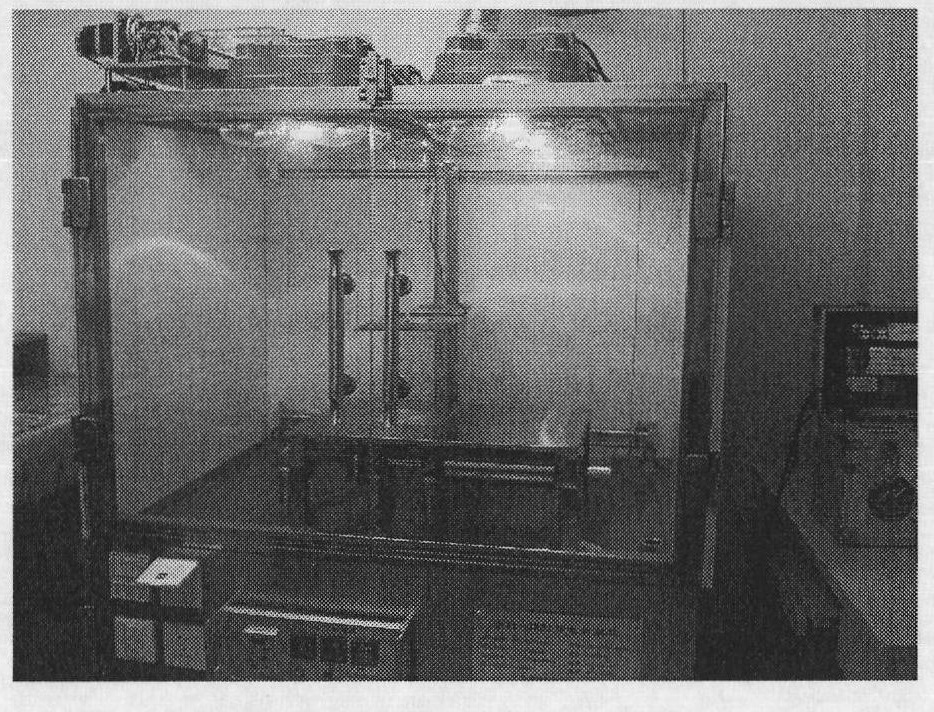

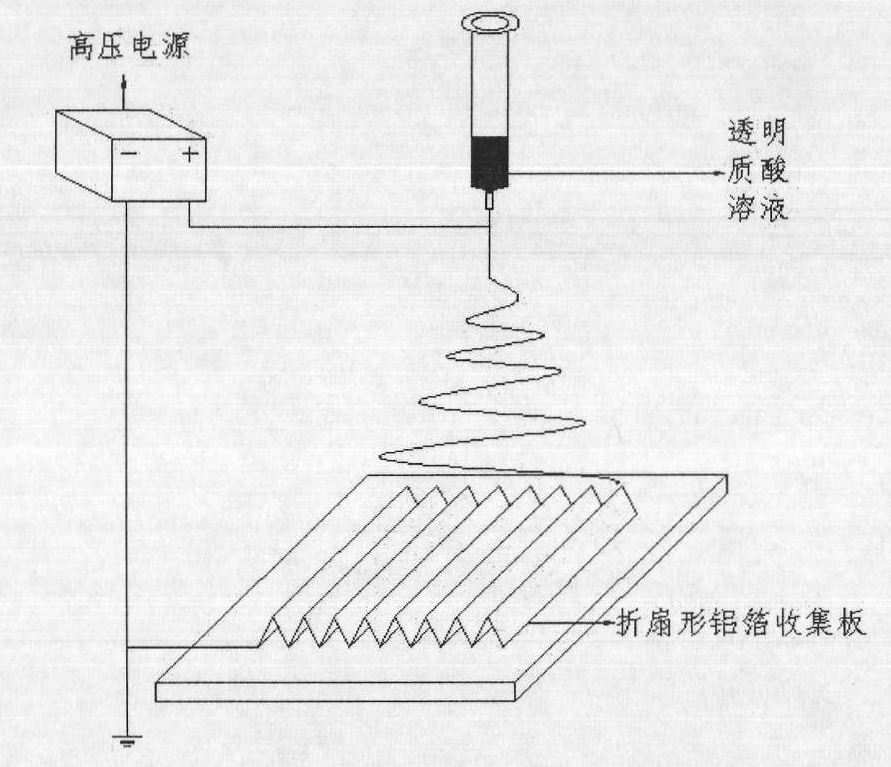

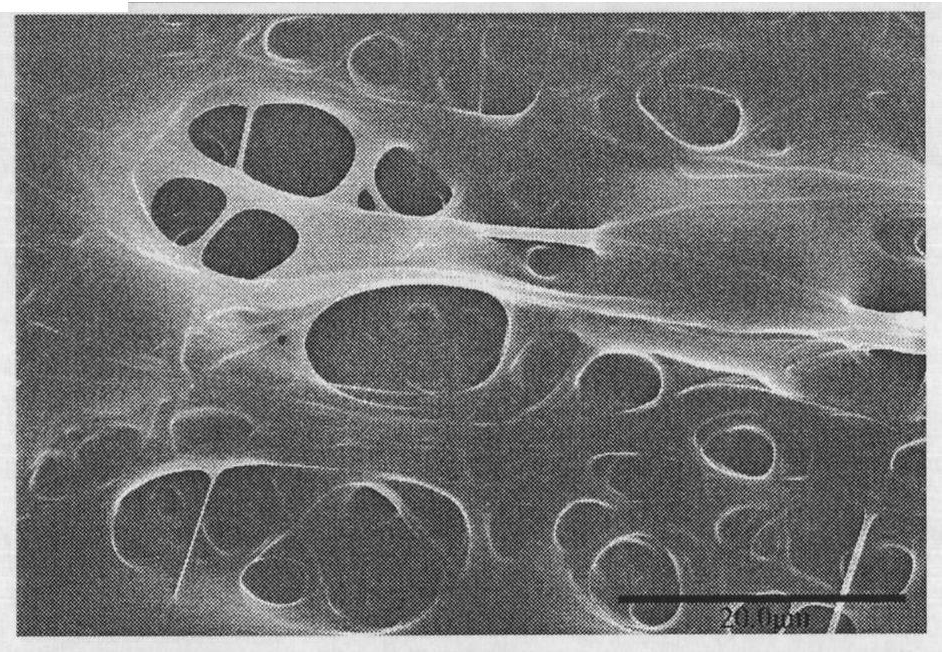

[0023] (2) Add the hyaluronic acid electrospinning solution prepared in step (1) into the syringe pump, and adjust the voltage to 20kV; the distance from the spinneret to the collecting plate is 8cm; the flow rate of the spinneret spinning solution is 1.5mL / h; the spinning environment temperature is 30°C; the collection plate is origami fan-shaped, and the device is started to perform electrospinning of hyaluronic acid, and the hyaluronic acid nanofiber non-woven fabric is obtained on the collection plate, and the fiber diameter is ev...

Embodiment 2

[0025] (1) The weight-average molecular weight is that the hyaluronic acid powder of Mw=1,000,000 is dissolved in the mixed solvent that the volume ratio of water, formic acid and DMF is 1:2:1, is made into the solution that weight percent is 1.5wt%, then the solution Thoroughly stir until it is completely dissolved, and place the solution in an ultrasonic wave for 1 hour so that all the bubbles are separated out to obtain a transparent hyaluronic acid solution.

[0026] (2) Add the hyaluronic acid electrospinning solution prepared in step (1) into the syringe pump, and adjust the voltage to 24kV; the distance from the spinneret to the collecting plate is 18cm; the flow rate of the spinneret spinning solution is 1.0mL / h; the spinning environment temperature is 20°C; the collection plate is origami fan-shaped, and the device is started to perform electrospinning of hyaluronic acid, and the hyaluronic acid nanofiber non-woven fabric is obtained on the collection plate, the fiber...

Embodiment 3

[0028] (1) The weight-average molecular weight is that the hyaluronic acid powder of Mw=2,000,000 is dissolved in the mixed solvent that the volume ratio of water, formic acid and DMF is 1:2:3, is made into the solution that weight percent is 0.5wt%, then the solution Thoroughly stir until it is completely dissolved, and place the solution in an ultrasonic wave for 1 hour so that all the bubbles are separated out to obtain a transparent hyaluronic acid solution.

[0029] (2) Add the hyaluronic acid electrospinning solution prepared in step (1) into the syringe pump, adjust the voltage to 30kV; the distance from the spinneret to the collecting plate is 20cm; the flow rate of the spinneret spinning solution is 0.5mL / h; the spinning environment temperature is 40°C; the collection plate is origami fan-shaped, and the device is started to perform electrospinning of hyaluronic acid, and the hyaluronic acid nanofiber non-woven fabric is obtained on the collection plate, and the fiber...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com