Electrostatic spinning method for polyhydroxylated polymer

A polyhydroxy polymer, polyhydroxy compound technology, applied in spinning solution preparation, single-component polyester rayon, filament/thread forming, etc., can solve the problem of uneven distribution of fiber diameter, low solvent volatilization speed, The fibers are easy to stick together and other problems, so as to achieve the effect of improving the electrospinning speed, uniform diameter distribution and product quality improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Weighed 1.6 g of polyvinyl alcohol powder with a degree of polymerization of 2400, added it to 18.4 g of deionized water, and stirred magnetically for 3 hours at 80° C. to obtain a uniform aqueous solution of polyvinyl alcohol with a mass fraction of 8%.

[0018] Add 0.32g vitamin C to the above solution, and magnetically stir at 25°C for 1-2 hours to prepare a blended spinning stock solution with a vitamin mass fraction of 20% (relative to the mass of polyvinyl alcohol).

[0019] Use a capillary nozzle tube with an inner diameter of 0.5mm as the spinneret hole, use a silver needle with a diameter of less than 1mm as the electrode, and an aluminum foil as the receiving plate. C blend solution for electrospinning.

[0020] The time required for electrospinning 5ml of 8% polyvinyl alcohol aqueous solution and 8% polyvinyl alcohol / vitamin C (20%) blended solution was measured respectively.

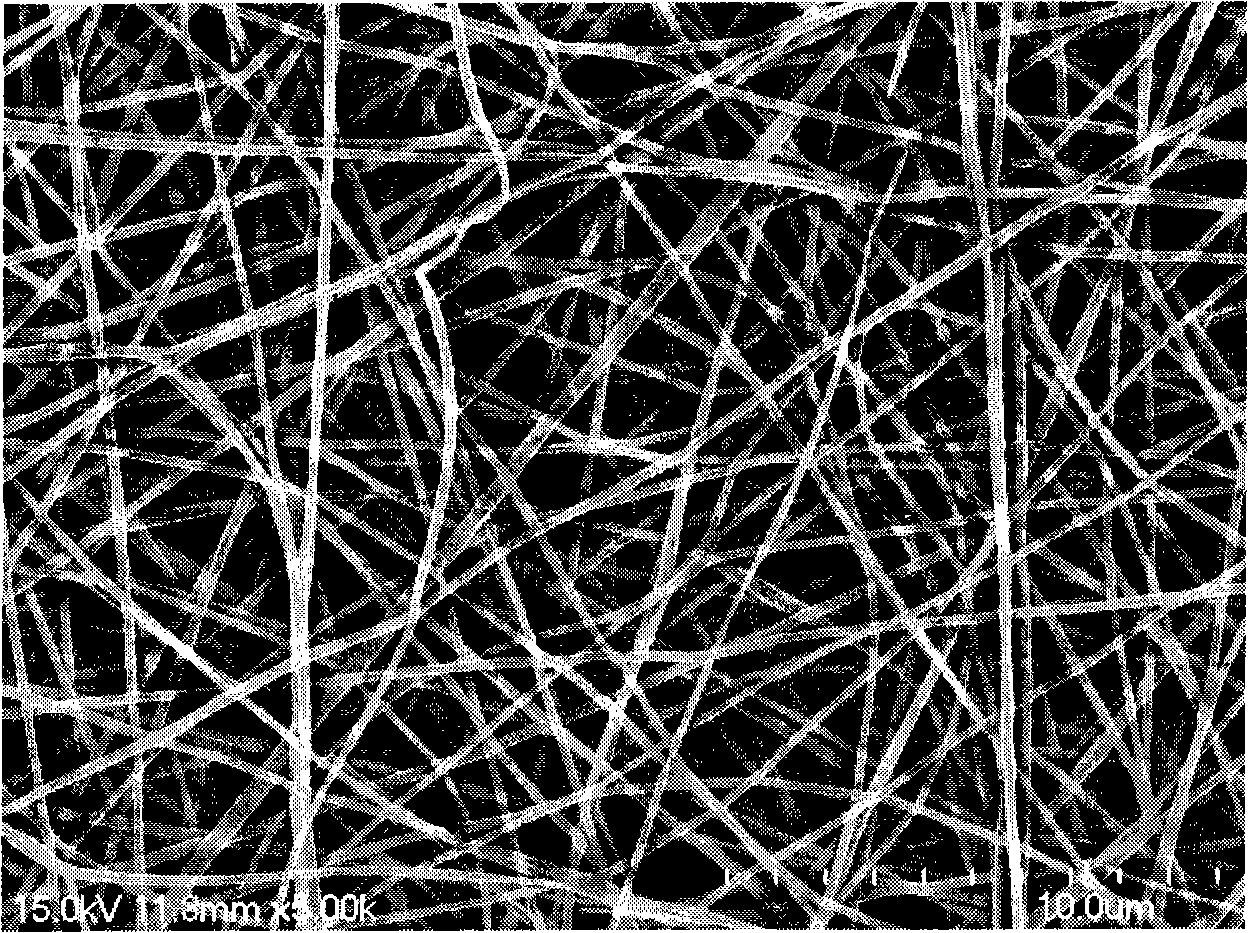

[0021] At room temperature, a nonwoven fabric with a diameter of 100-280 nm was o...

Embodiment 2

[0025] Weigh 1.4 g of polyvinyl alcohol powder with a degree of polymerization of 2400, add 18.6 g of deionized water, and stir magnetically at 80° C. for 2 hours to prepare a uniform polyvinyl alcohol aqueous solution with a mass fraction of 7%.

[0026] Add 0.14 g of saponin to the above solution, and magnetically stir at 25° C. for 1 to 2 hours to prepare a blend solution with a mass fraction of saponin of 10% (relative to the mass of polyvinyl alcohol).

[0027] Use a capillary nozzle tube with an inner diameter of 0.5mm as the spinneret hole, use a silver needle with a diameter of less than 1mm as the electrode, and an aluminum foil as the receiving plate. Under the conditions of a voltage of 15kv and a collection distance of 15cm, the polyvinyl alcohol / saponin blended spinning stock solution Perform electrospinning.

[0028] Using the same electrospinning process as above, the time required for electrospinning 5ml of polyvinyl alcohol concentration of 7% spinning stock s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com