Patents

Literature

41results about How to "Good degree of graphitization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

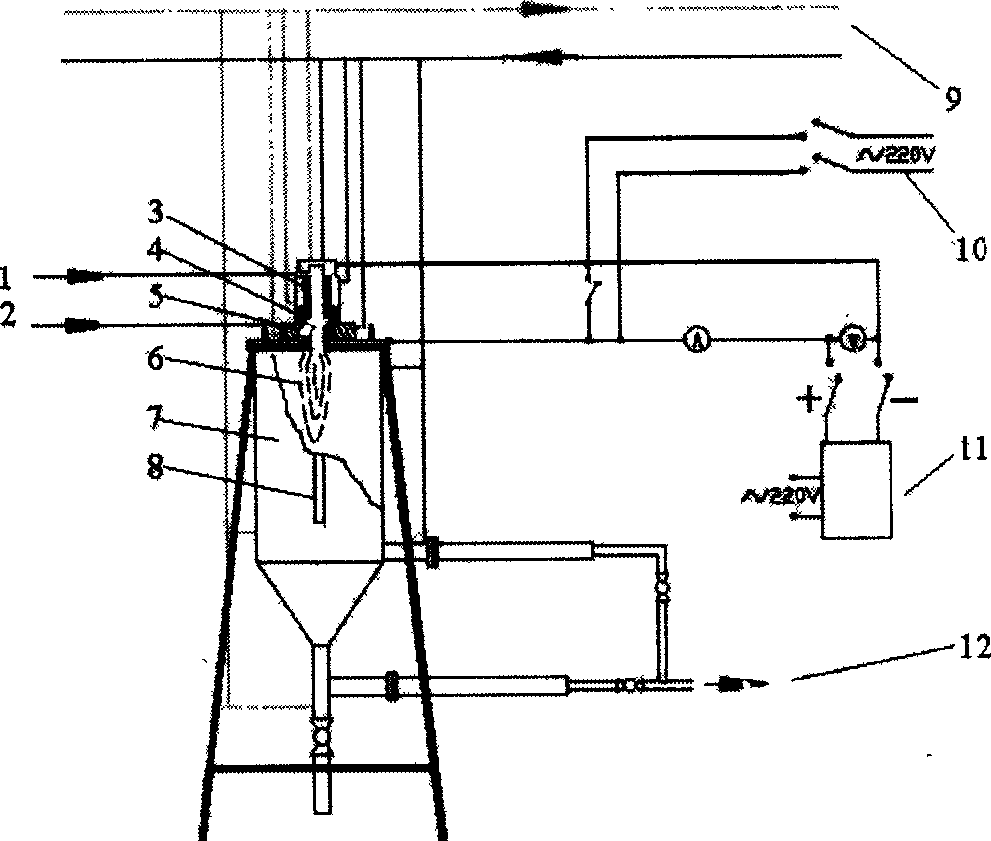

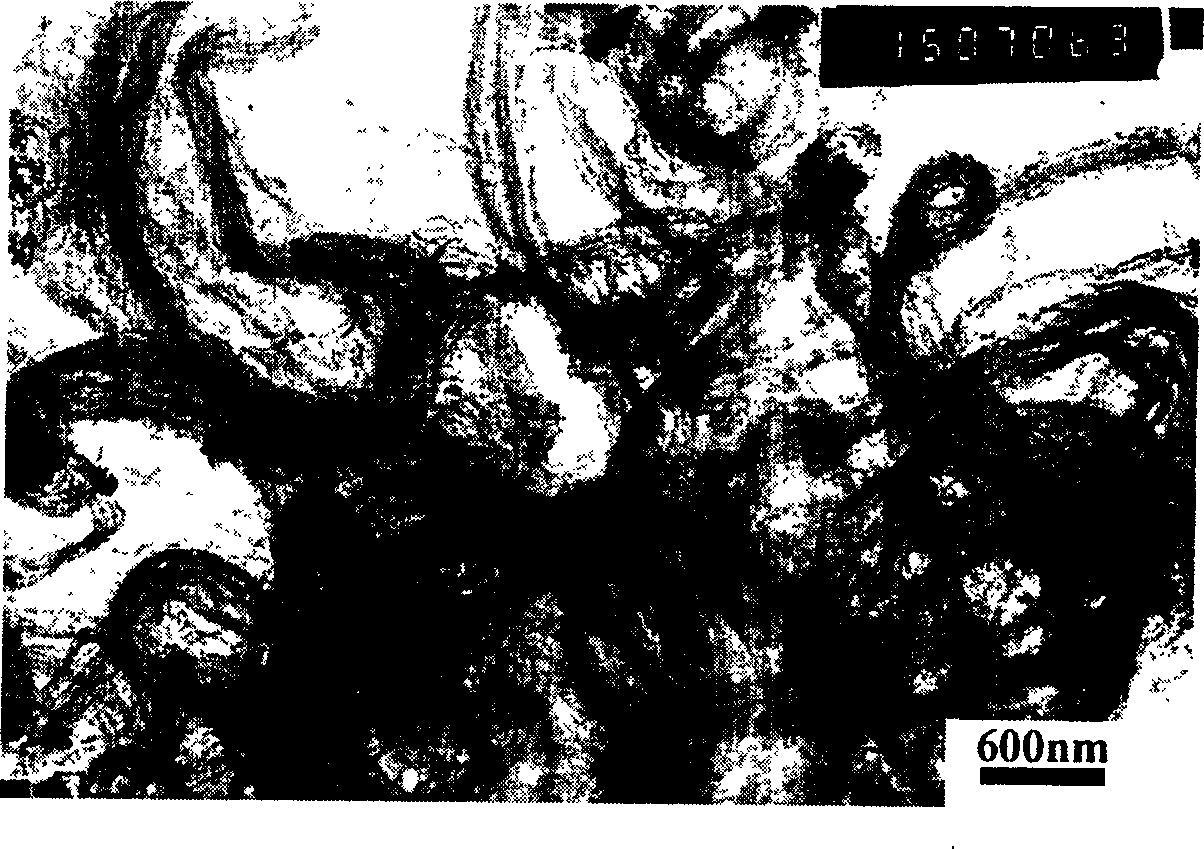

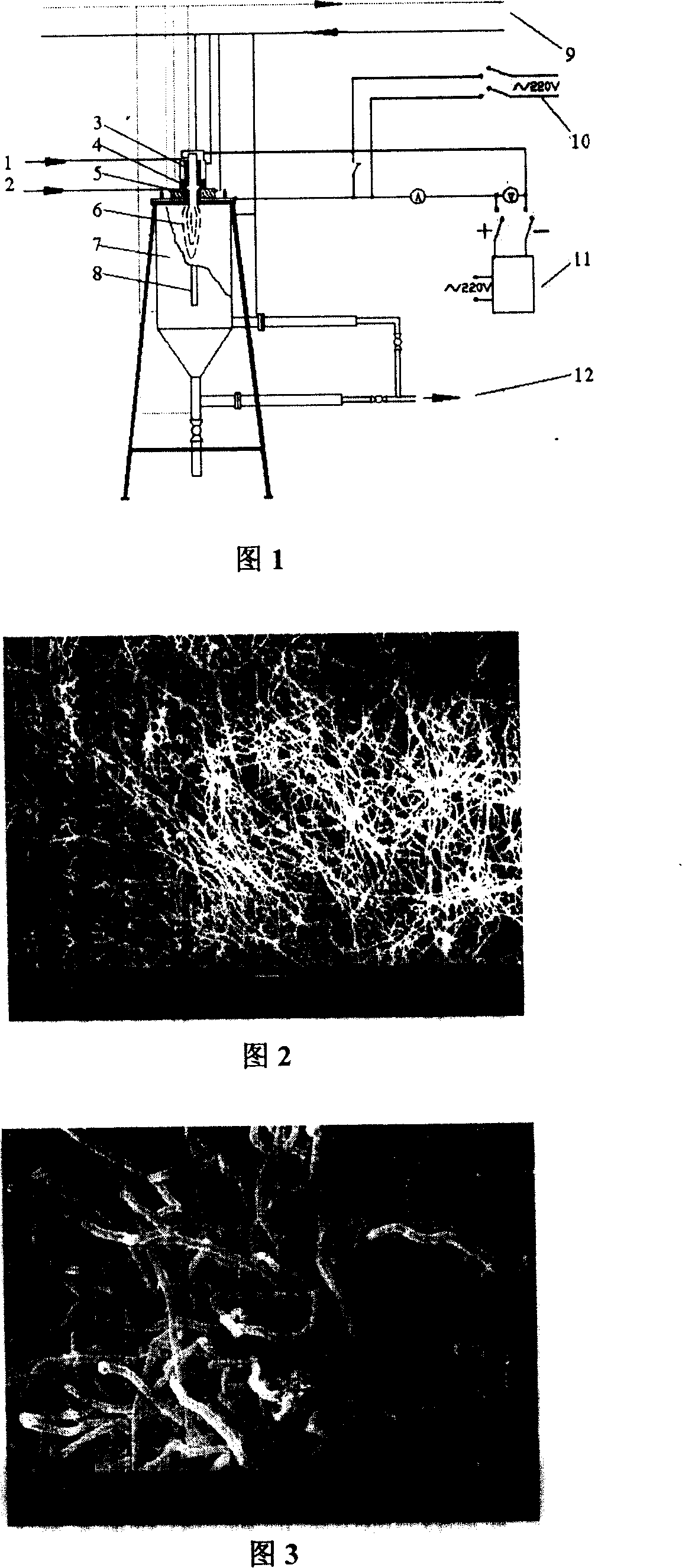

Plasma method for preparing nano carbon material using coal liquefied residue as raw material

The invention discloses an arc plasma torch preparing nanometer charcoal fibrous material method, which comprises the following steps: placing untreated leavings of liquefying coal directly in direct current arc plasma torch to carry on heat-treatment; using nitrogen for arc working gas under atmosphere pressure; getting nanometer charcoal fibrous material after 120-175 seconds, wherein there is no need to add in any activators in preparing process. The method is characterized by the following: the craft route is simple; the raw material is the waste of coal hydrogenant liquefaction craft; it's a good way to use coal liquification leavings to prepare high-added value, functional carbon material; the nanometer charcoal fibrous material can be used for accelerating agent, catalyst carrier, lithium ion secondary cell anode material, double-layer capacitor electrode, highly effective active solid, release agent and construction reinforced materials.

Owner:DALIAN UNIV OF TECH

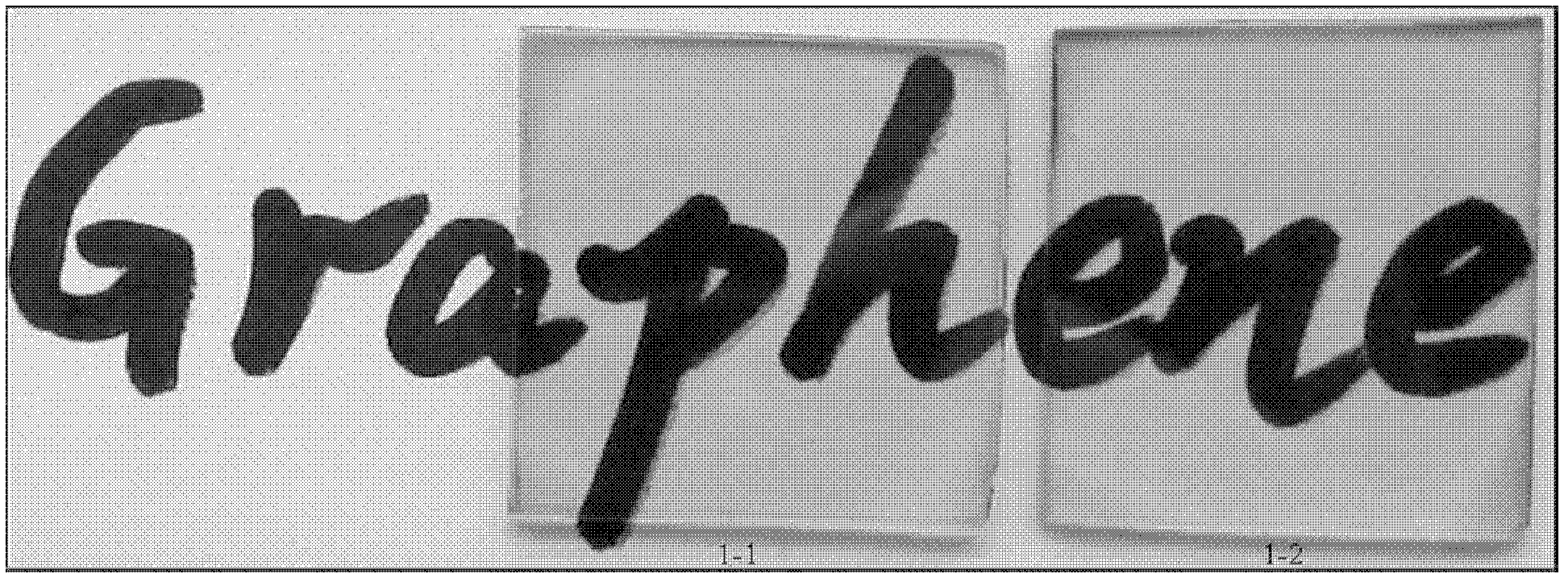

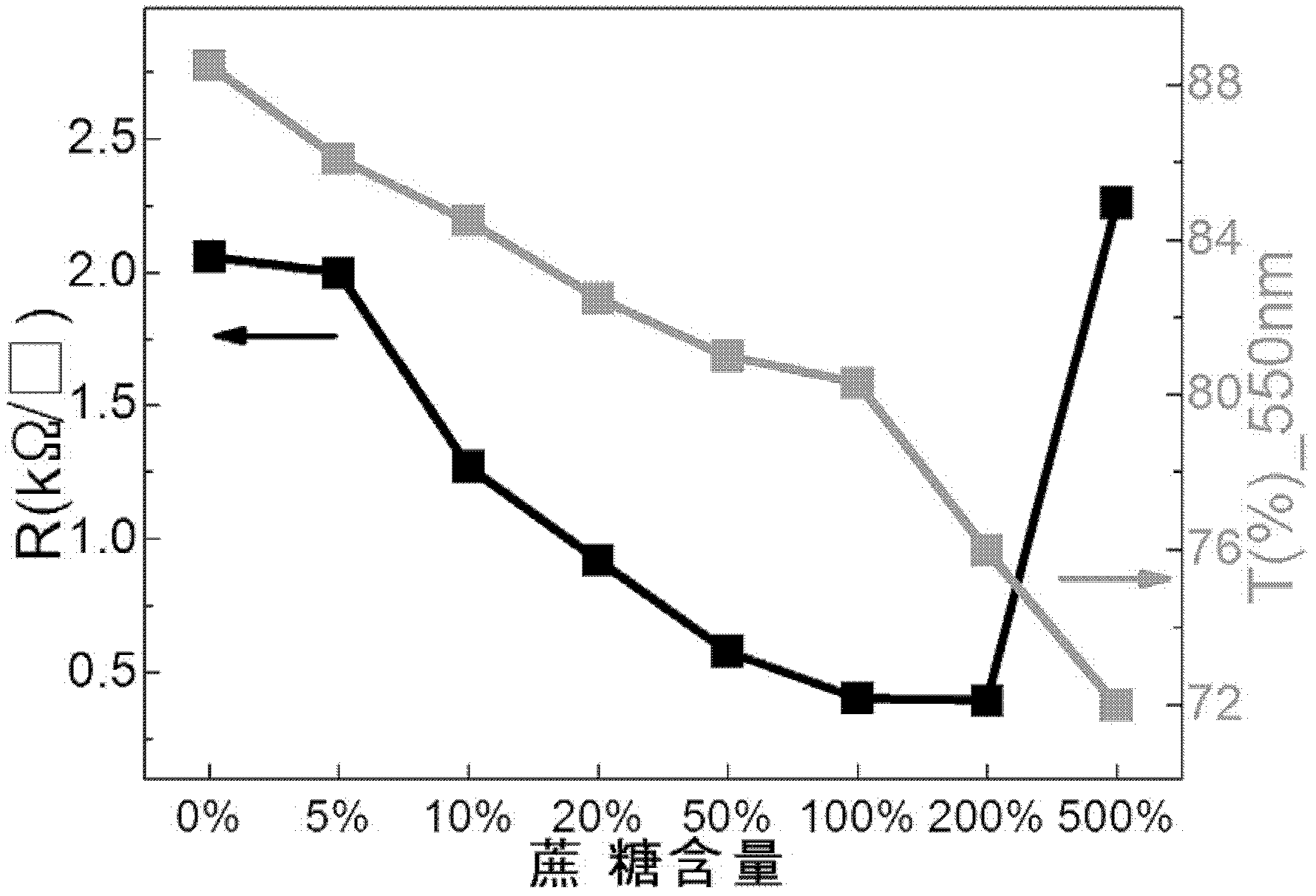

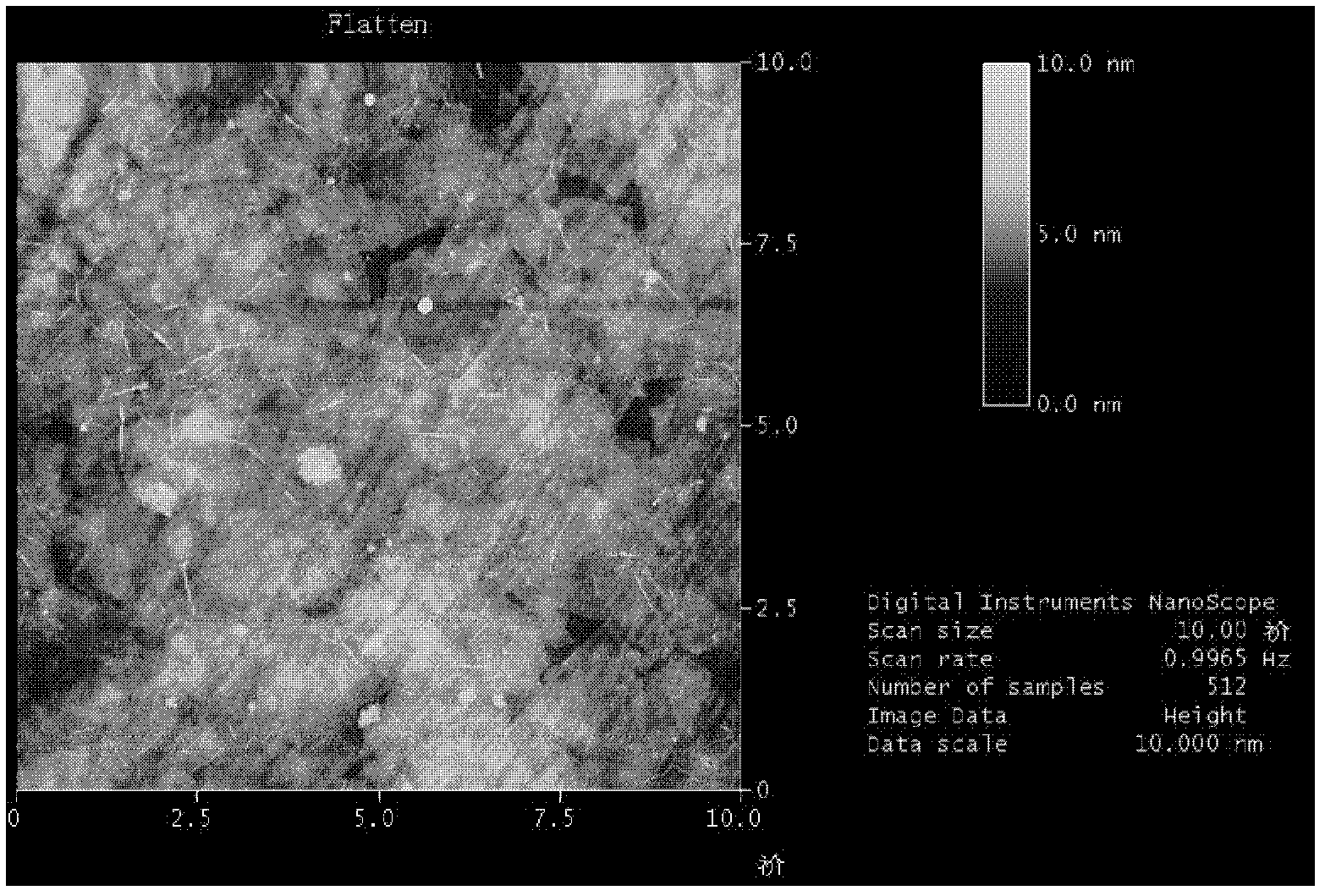

Graphene-carbon nano composite transparent conducting thin film and preparation method thereof

InactiveCN103021503AMild in natureSimple processMaterial nanotechnologyGrapheneComposite filmOptical transmittance

The invention provides a graphene-carbon nano composite transparent conducting thin film and a preparation method thereof. The graphitization degree of the graphene-carbon nano-composite thin film prepared by the steps of adding various char formation precursors to graphene oxide dispersion liquid and then carrying out thermal reduction is obviously increased, and thus the electric conduction performance of the thin film is substantially improved, and the light transmittance of the film is not affected. In addition, compared with the pure graphene thin film, the film has the advantages that the roughness is less than 0.2nm, and the evenness is high. The preparation method provided by the invention is simple in technology; reagents used in the preparation method have a mild property; and the preparation method can be applied to the large-scale production and has a very good application prospect in the field of photoelectricity such as touch screens, solar cells and light emitting diodes.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

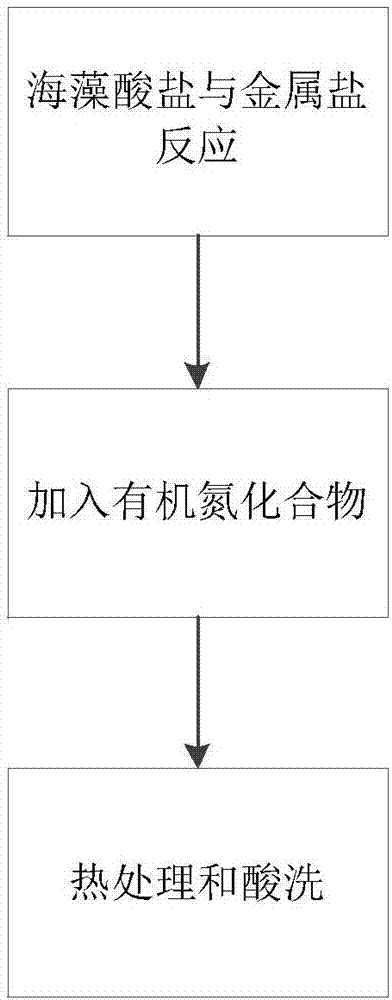

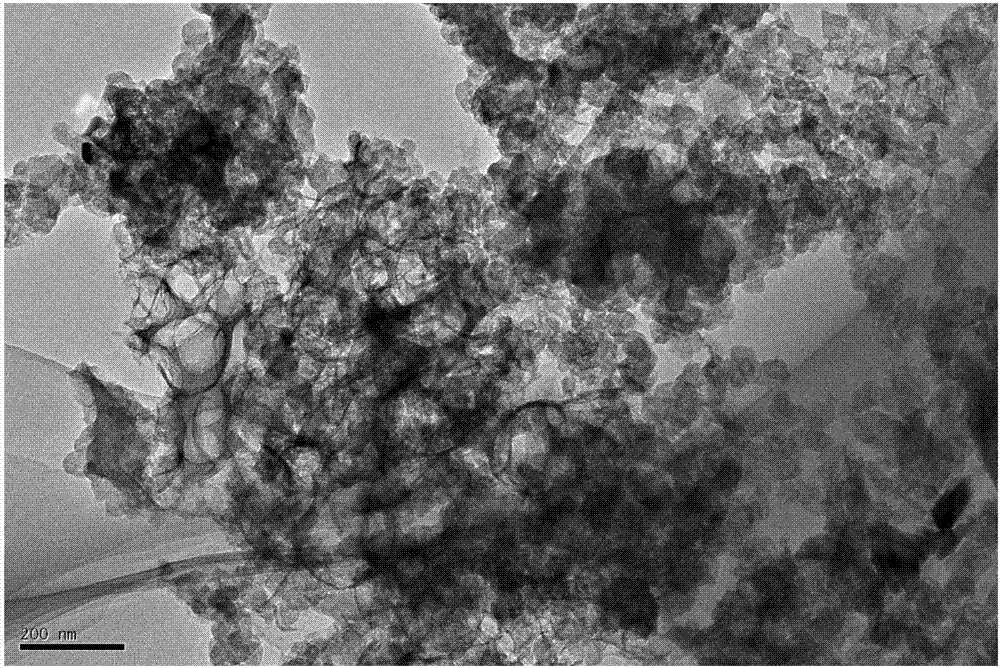

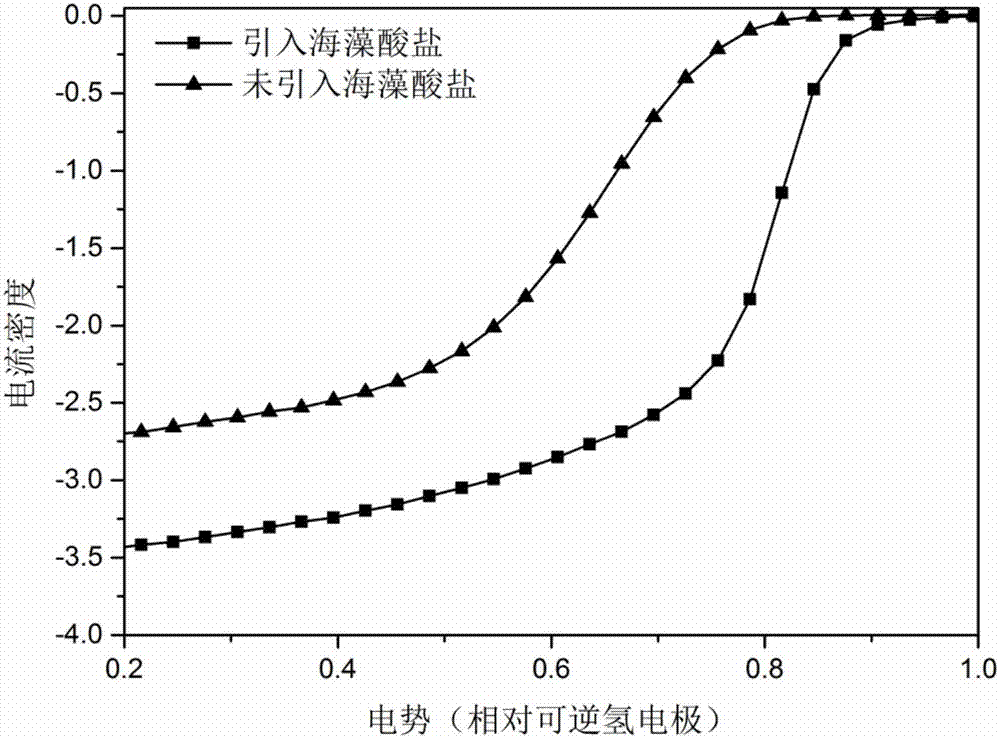

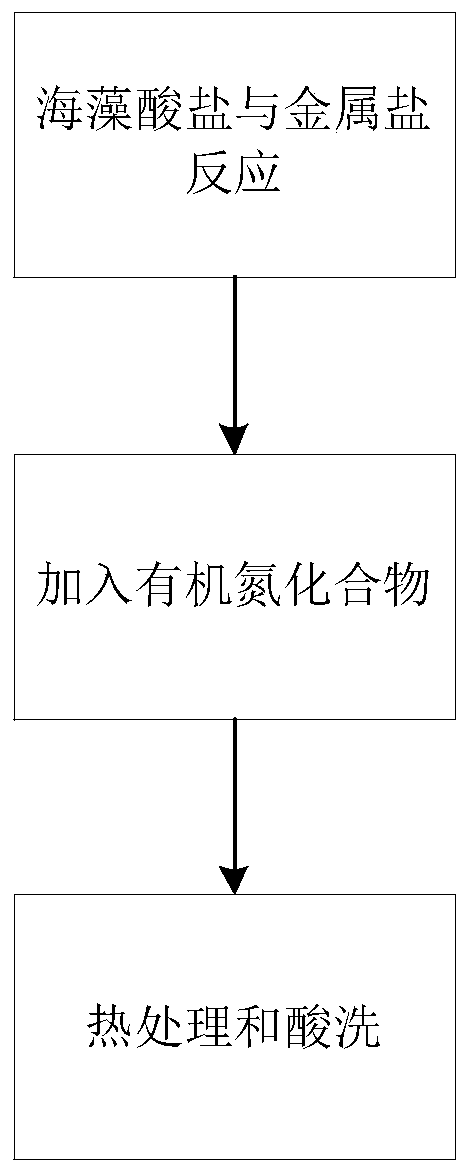

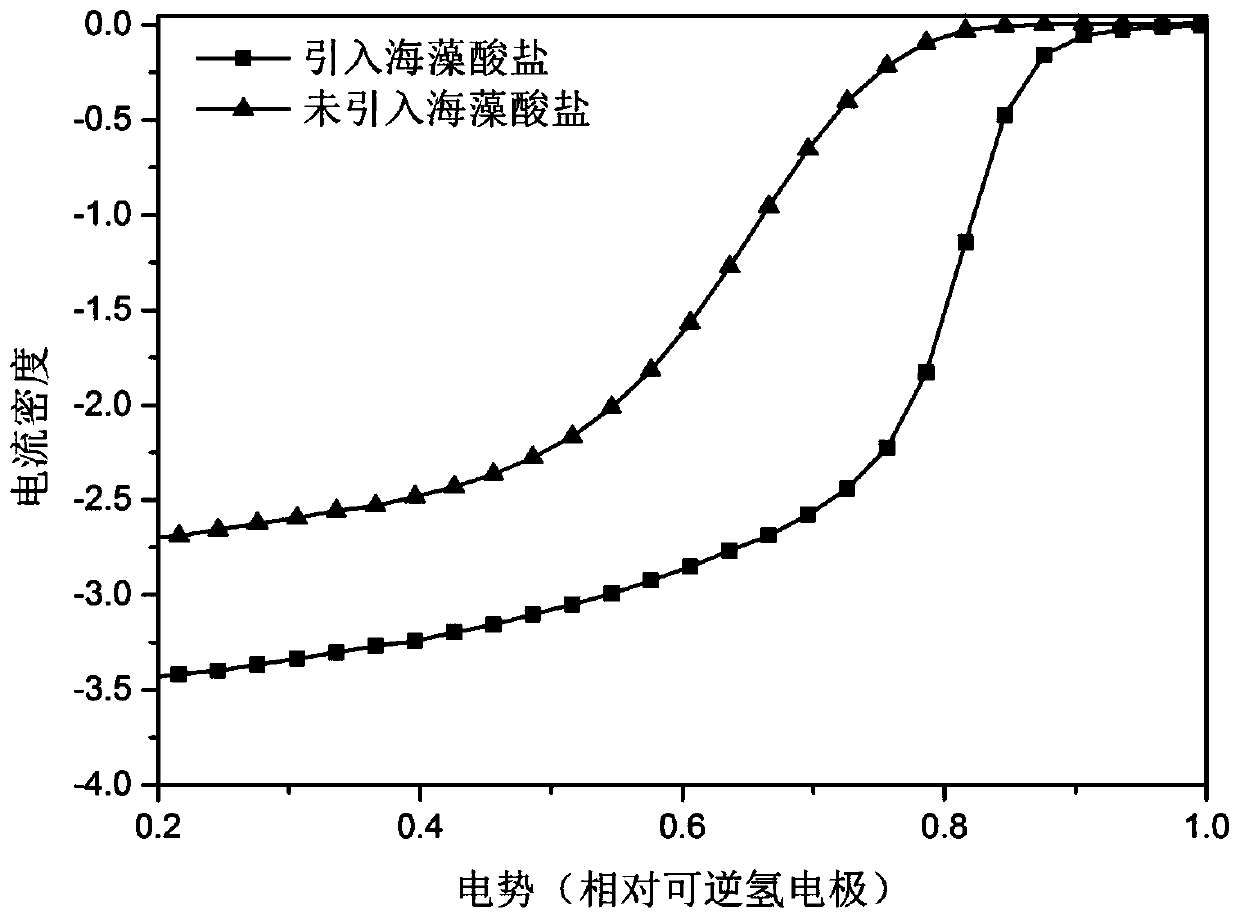

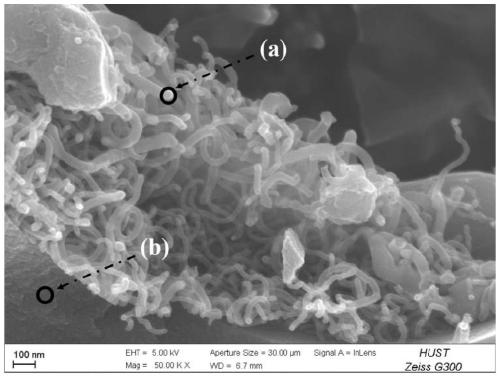

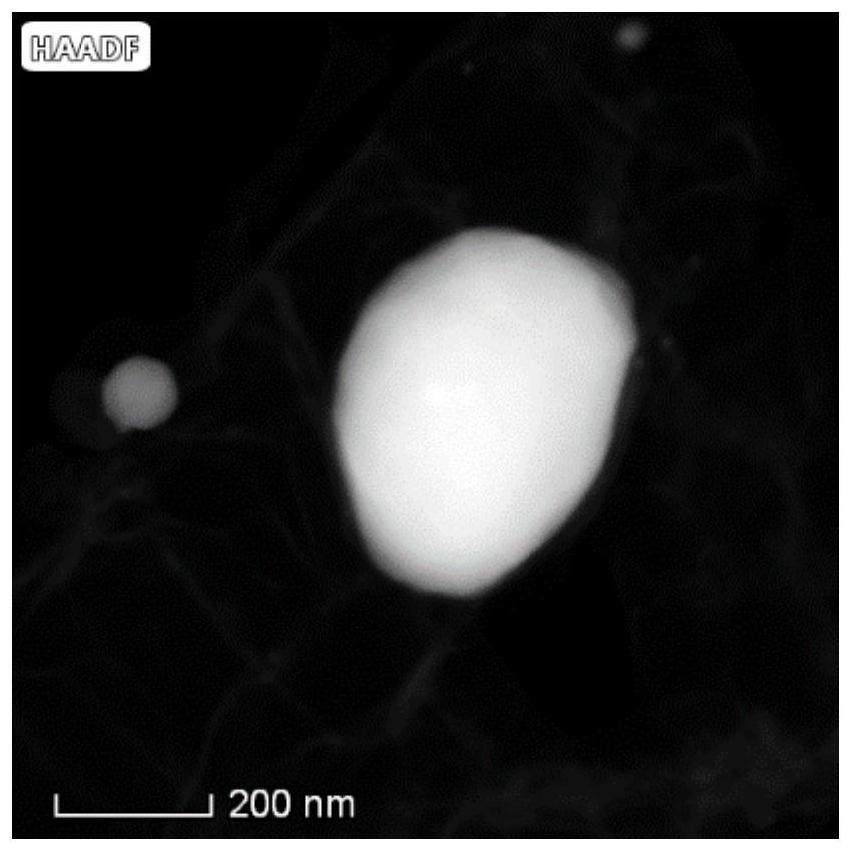

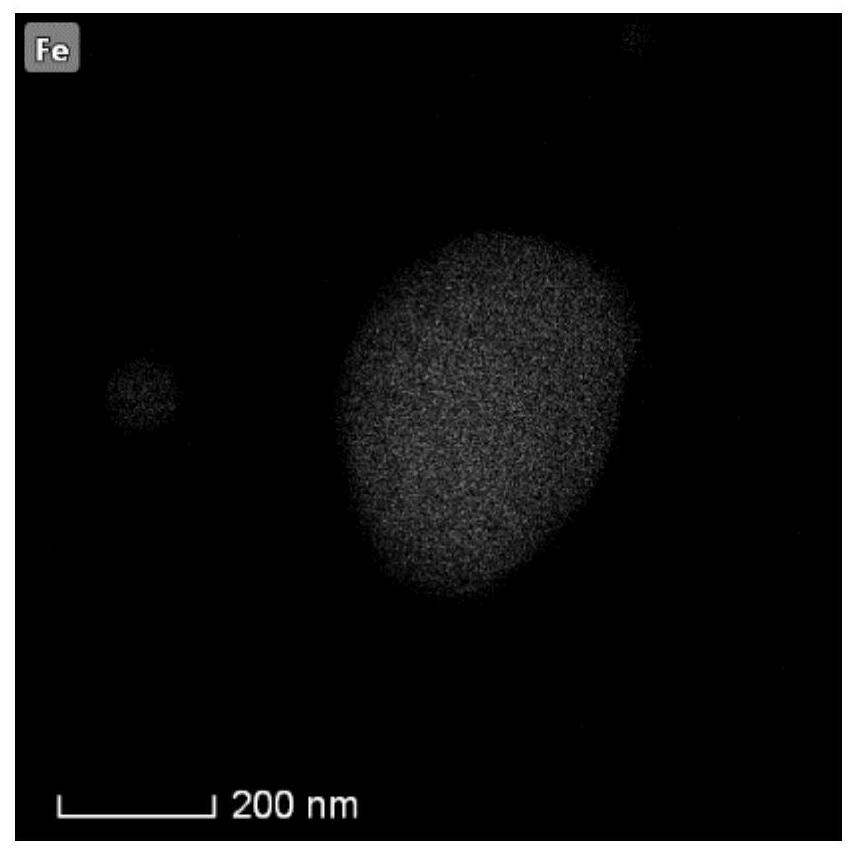

Preparation method of atomic dispersion non-noble metal fuel battery cathode catalyst

The invention belongs to the field of electrochemistry catalysis, and discloses a preparation method of an atomic dispersion non-noble metal fuel battery cathode catalyst. The method comprises the following steps: (a) heating and dissolving alginate into an alginate solution, keeping a heating temperature, adding metal salts into the alginate solution, and generating an alginate chelate solution; (b) adding organic nitride into the alginate chelate solution, enabling the organic nitride and the alginate chelate solution to react, and drying a product after reaction by steaming to obtain a powdered compound; and (c) successively performing primary heat treatment, acid pickling and secondary heat treatment on the powdered compound, thus obtaining the needed catalyst. By virtue of the preparation method, the catalyst with high activity in an acid medium is prepared, and active sites are uniformly dispersed and fixed, so that the preparation method is easy in control and regulation and suitable for large-scale production and application.

Owner:HUAZHONG UNIV OF SCI & TECH

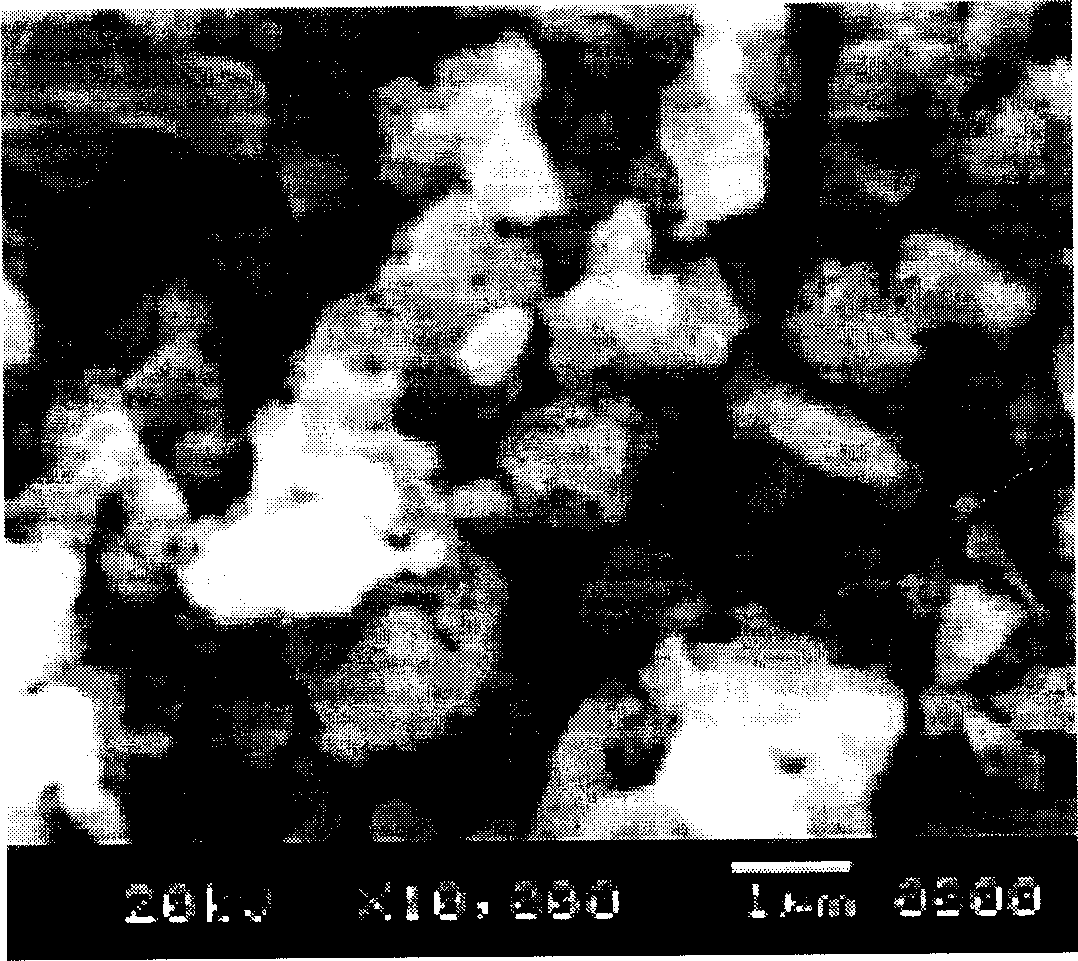

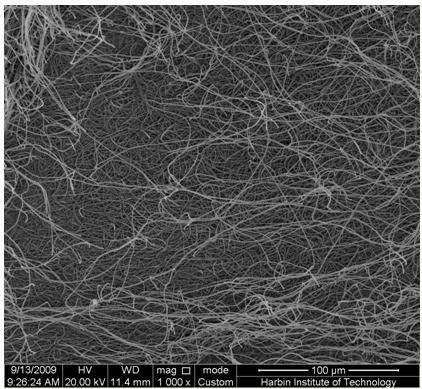

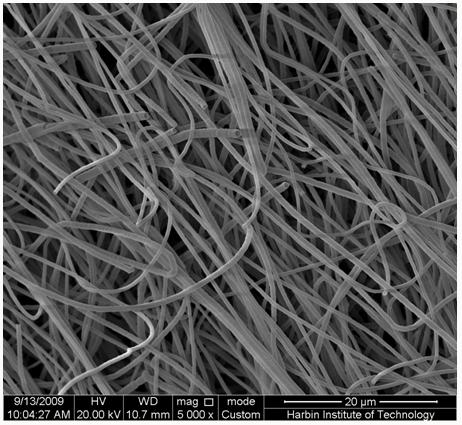

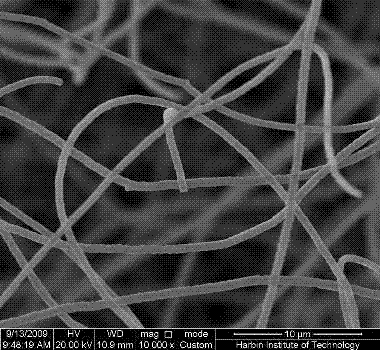

Metal oxide catalyst for preparing bundle-formed multiwall nano carbon tube, its preparation method and application

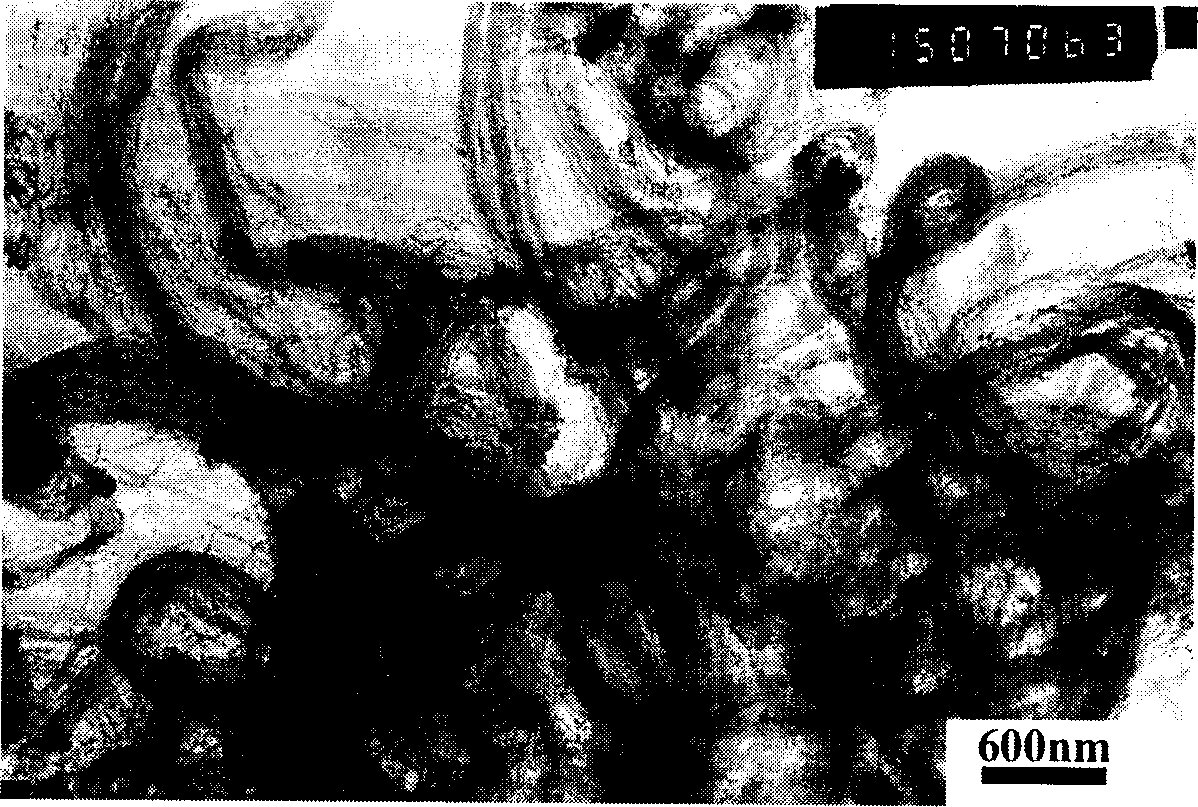

InactiveCN1477057AHigh activityIncrease profitMetal/metal-oxides/metal-hydroxide catalystsCobaltMetallic Nickel

The invented catalyst is a Fe / Mo / MgO, Co / Mo / MgO and Ni / Mo / MgO three-phase metal oxide catalyst for preparing bundled multi-wall nano carbon tube. The catalyst is made up by using oxide formed from magnesium and molybdenum as main catalyst and using iron or cobalt or nickel as co-catalyst. Its preparation method includes the following steps: firstly, according to the mole ratio of Fe or Co or Ni:Mo:Mg=0.1-1:0.5-2:0.8-3 uniformly mixing their alkoxides, combustion at 600-700 deg.C and heat-insulating for 10-40 min., cooling formed solid and grinding it or drying the formed solid at 80-150 deg.C, heat-insulating for 10-40 min., then cooling formed solid and grinding it.

Owner:ZHEJIANG UNIV

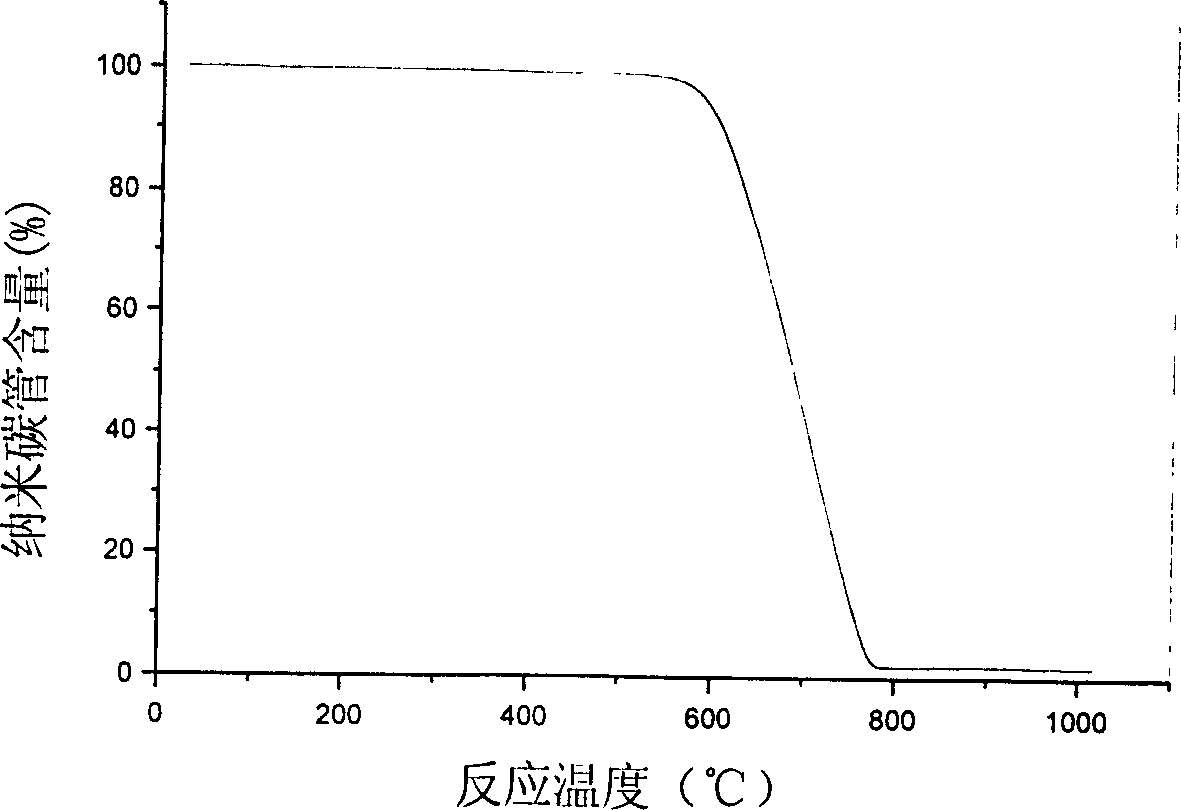

Method oxide catalyst and method for preparing bundled multiwall nano carbon tube

InactiveCN1443708AHigh activityIncrease profitMetal/metal-oxides/metal-hydroxide catalystsHydrogenFixed bed

The present invention relates to a metal oxide catalyst and a method for preparing bundled multiwall nano carbon tube by using said metal oxide catalyst and catalytic cracking methane, said metal oxide catalyst is the Fe / Mo / MgO and Ni / Mo / MgO catalyst formed from oxide of magnesium and molybdenum as main catalyst and iron or nickel as auxiliary catalyst. Said catalyst is placed in the fixed bed gas continuously-flowing reaction furnace, and the methane whose introduced flow rate is 50-1500 sccm and the hydrogen gas or nitrogen gas or inert gas whose flow rate is 50-300 sccm are reacted for 10-100 min. at 750-1200 deg.C so as to form the invented bundled multiwall nano carbon tube.

Owner:ZHEJIANG UNIV

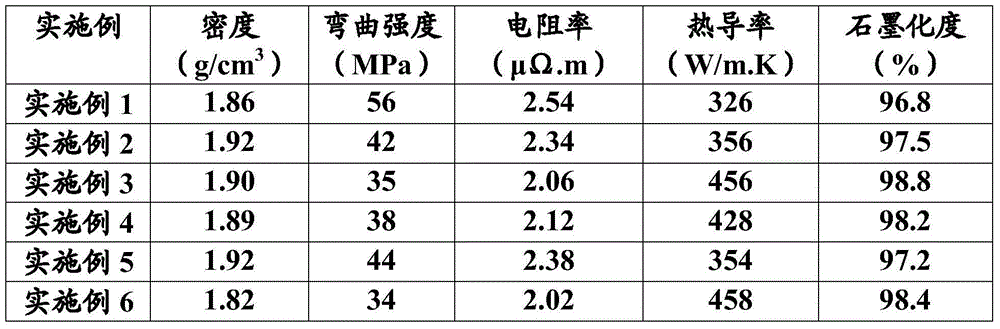

High thermal conductivity of graphite material and preparation method and application thereof

ActiveCN103979930AShort preparation cycleReduce manufacturing costElectrical batteryMaterials processing

The invention relates to a high thermal conductivity graphite material, and a preparation method and application thereof. The high thermal conductivity graphite material uses graphite tailing and ceramic components generated in the machining processes of mesocarbon microbeads and lithium ion battery anode material as the main raw materials; and the raw materials are subjected to cold compression molding and graphitization to obtain the high thermal conductivity graphite material. The graphite material provided by the invention has excellent performance, is particularly suitable as a radiating fin base material for civil high-end electronic devices, LED chip materials and heat exchangers for industrial devices. In addition, the process provided by the invention is simple and has short material preparation period, and the size of the prepared material can be enlarged; therefore, the method is easy for mass production, and greatly reduces the cost of production materials. The method also solves the problems and hidden dangers of stacking landfill and environmental pollution caused by graphite tailing, realizes the comprehensive utilization of waste resources, and decreases the comprehensive cost for the manufacturers of composite cathode material of lithium ion battery by more than 10%.

Owner:ZHANJIANG JUXIN NEW ENERGY +1

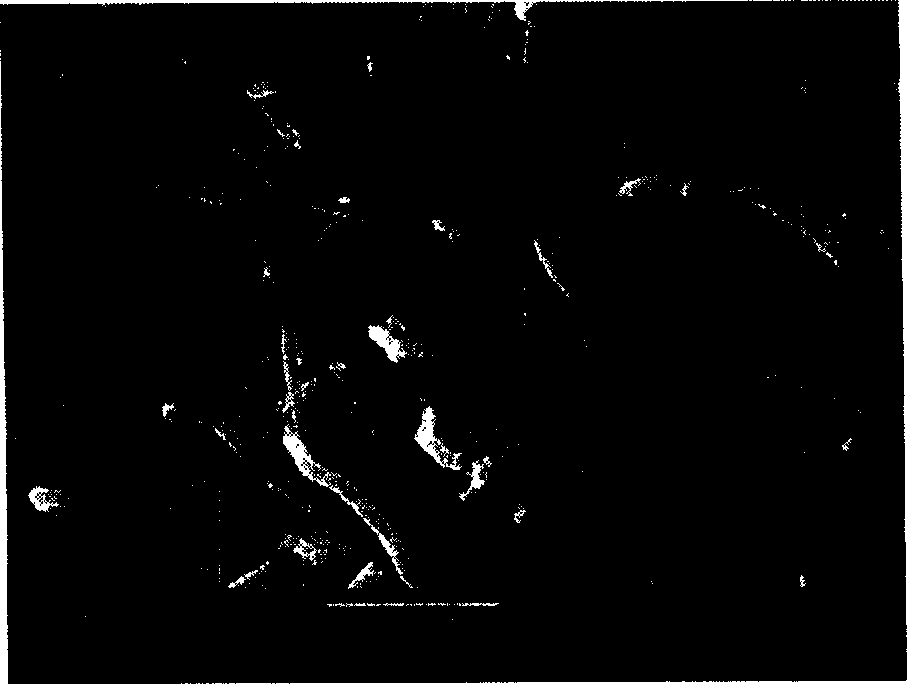

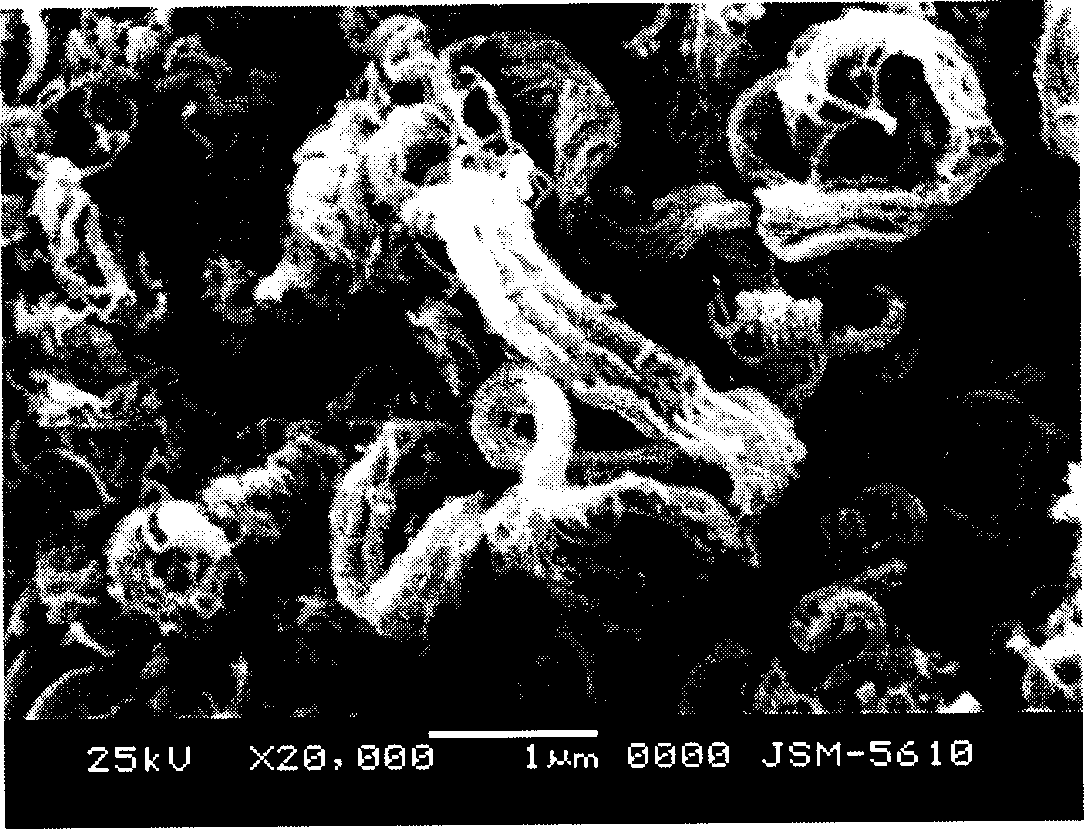

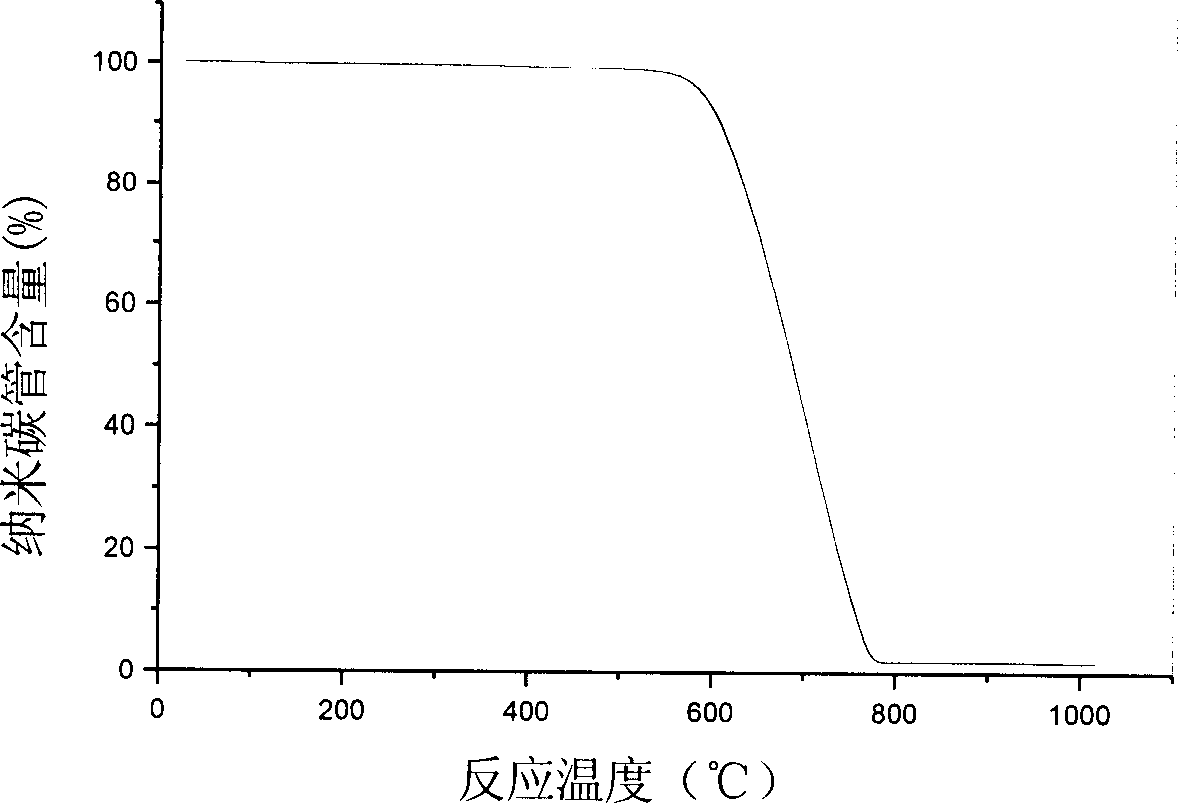

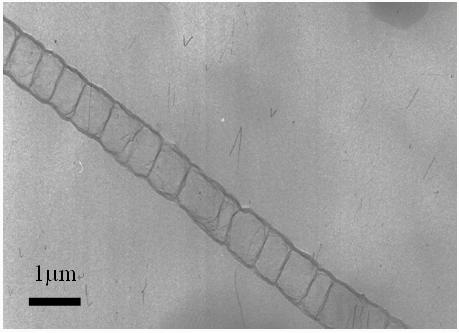

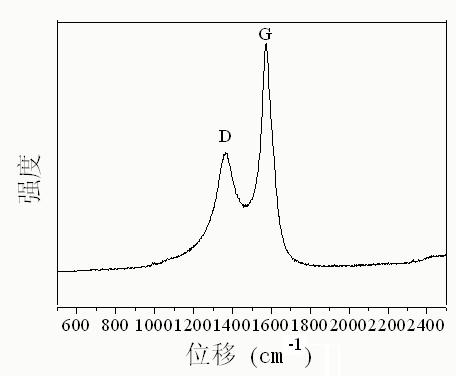

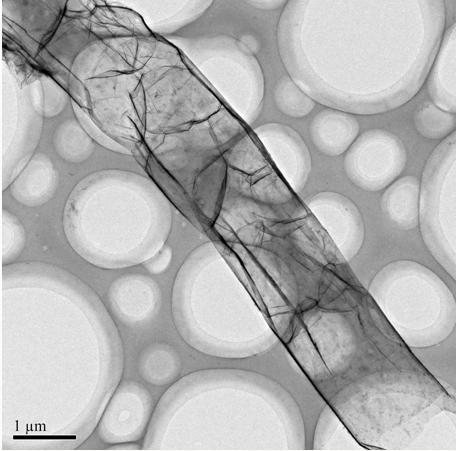

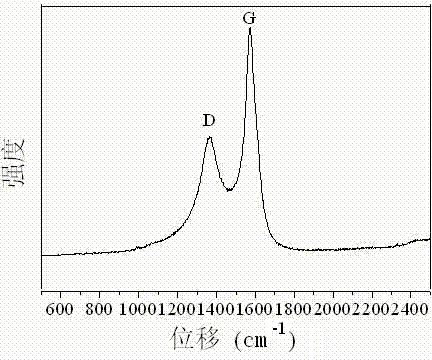

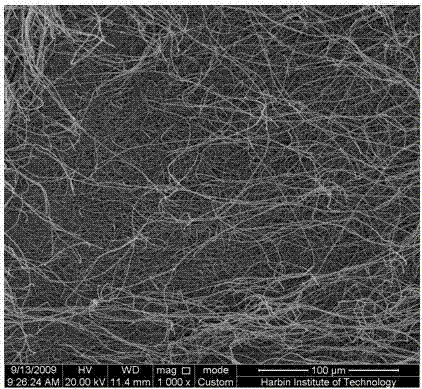

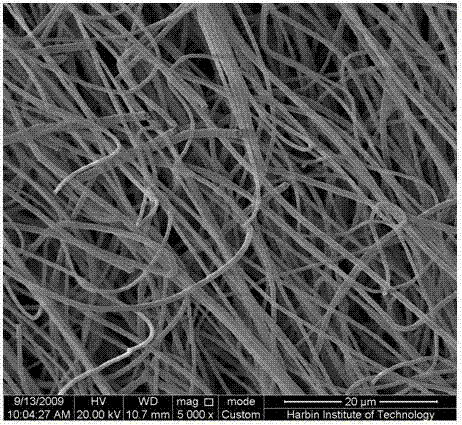

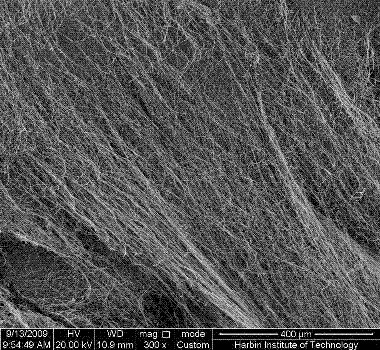

Carbon micro-tube epoxy resin wave-absorbing composite material and preparation method thereof

InactiveCN101817971AGood degree of graphitizationReduce weightNanostructure manufactureFiberCarbon fibers

The invention discloses a carbon micro-tube epoxy resin wave-absorbing composite material and a preparation method thereof, and relates to a wave-absorbing composite material and a preparation method thereof. The invention solves the problems that the existing active carbon fiber epoxy resin composite wave-absorbing material has fussy preparation process and large density, the hollow fiber prepared by a spinning method has low elastic modulus and the wave-absorbing material has poor strength. The composite material is prepared from carbon micro-tube and epoxy resin glue. The method comprises the following steps of: preparing the carbon micro-tube by using urea and ethylene glycol; preparing the epoxy resin glue by using bisphenol A epoxy resin, acetone and diethylenetriamine; and adding the carbon micro-tube into the epoxy resin glue, stirring the mixture uniformly, then adding the mixture into a die, and pressing the mixture to obtain the composite material. The elastic modulus of the material is 10 to 20GPa, the density is 1.00 to 1.05g / cm<3>, the lowest reflectivity is -13.25dB, the band width of -10dB reflectivity is 3.1GHz, and the material can be used for hiding weapons and eliminating the harm of electromagnetic wave to the organism.

Owner:HARBIN INST OF TECH

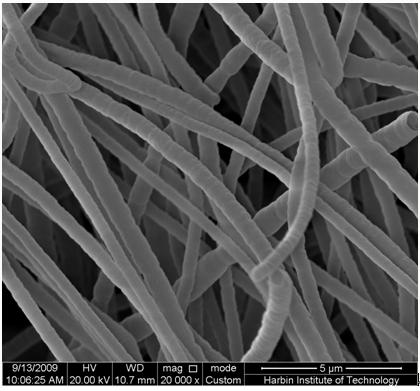

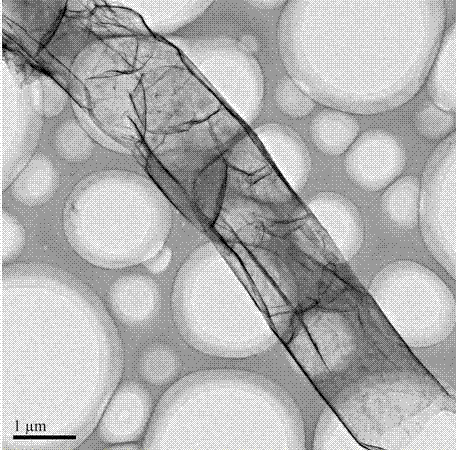

Hollow carbon fiber felt epoxy resin composite material and preparation method thereof

The invention discloses a hollow carbon fiber felt epoxy resin composite material and a preparation method thereof, relates to a carbon fiber epoxy resin composite material and the preparation method thereof, and aims to solve the problems of high density of a conventional carbon fiber epoxy resin composite material and difficult three-dimensional weaving of the carbon fiber serving as a composite material reinforcement. The hollow carbon fiber felt epoxy resin composite material is prepared from a hollow carbon fiber felt and epoxy resin adhesive; and the method comprises the following steps of: placing urea and carbon powder in a graphite crucible; preparing the hollow carbon fiber felt in an atmosphere sintering furnace; placing the hollow carbon fiber felt in a mould; sealing the mould and pouring the epoxy resin adhesive consisting of bisphenol A epoxy resin, acetone and diethylenetriamine into the mould under vacuum; and pressing the mould and drying the mould under vacuum to obtain the hollow carbon fiber felt epoxy resin composite material. The hollow carbon fiber felt is self-woven and the density of the composite material is only 0.92 to 0.94g / cm<3>, so the material can be used for spacecrafts, artificial satellites, space shuttles and missiles.

Owner:HARBIN INST OF TECH

Method for reducing carbon dioxide into porous carbon material, and porous carbon material and application thereof

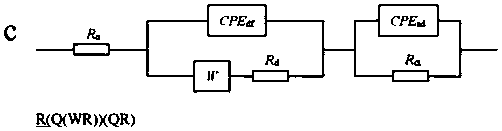

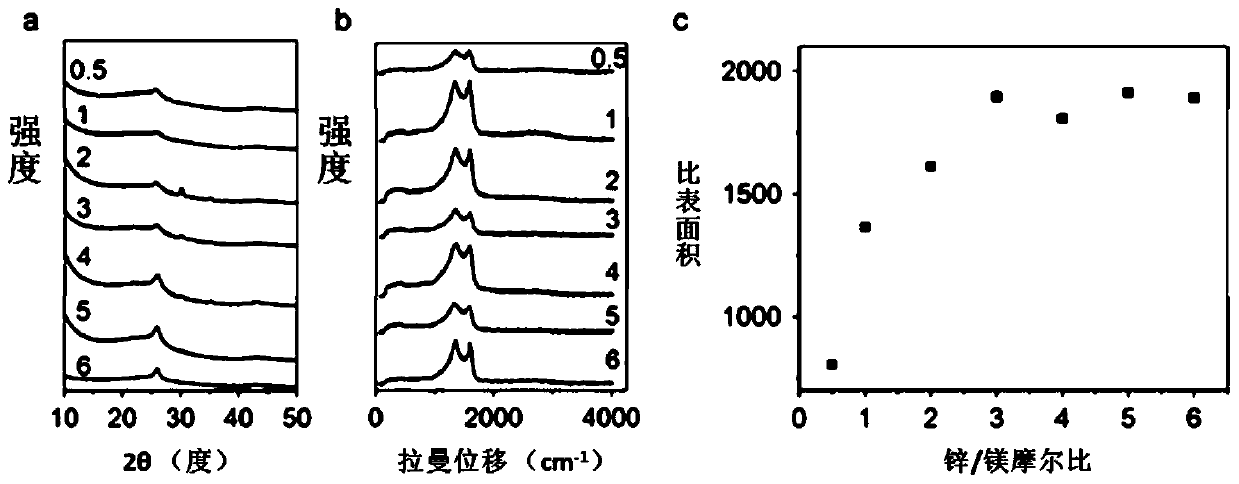

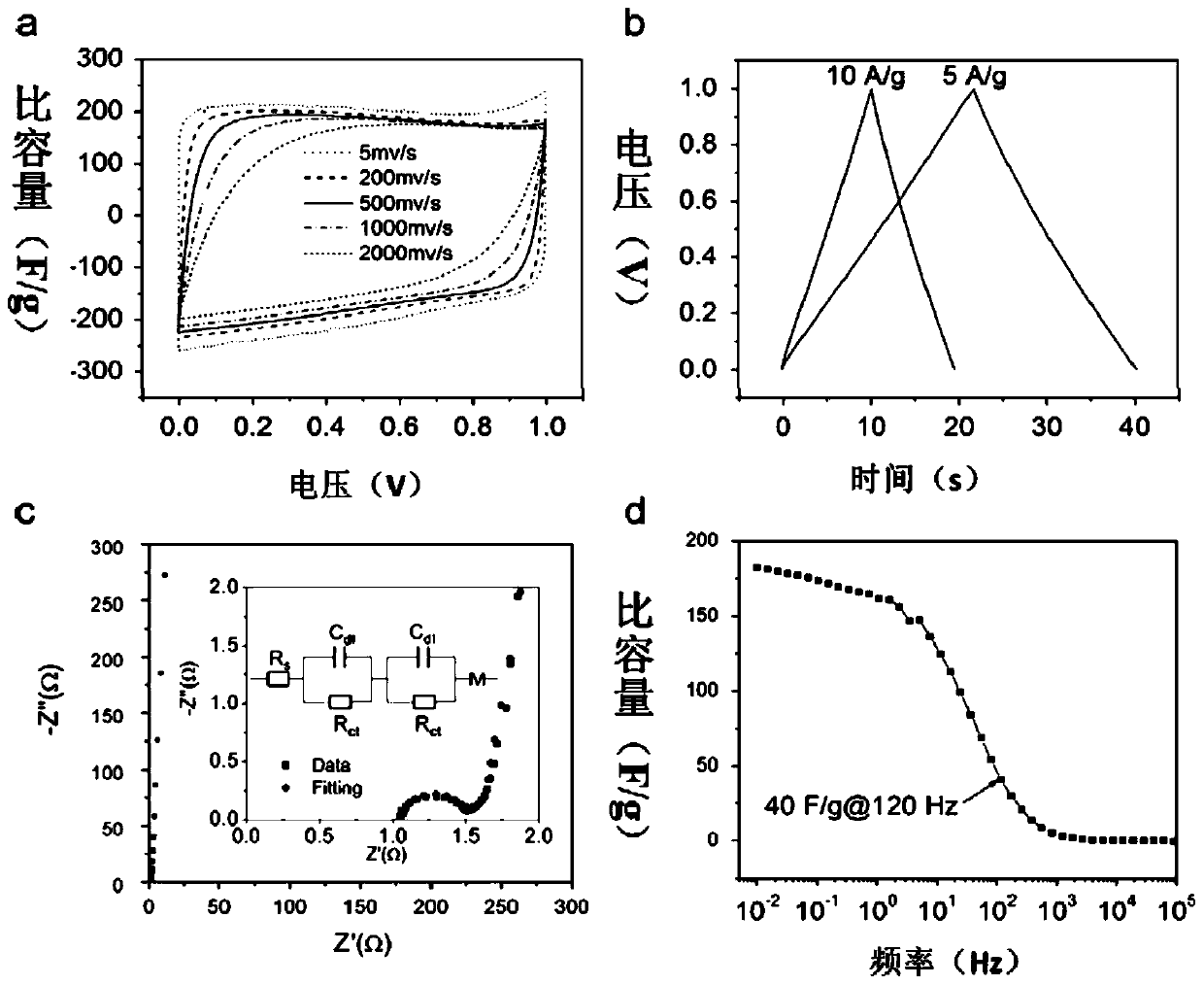

The invention belongs to the technical fields of metal thermal reduction reactions and graphene materials, and particularly discloses a method for reducing carbon dioxide into a porous carbon material, and the porous carbon material and application thereof. The method comprises the following specific steps: carrying out heat treatment on magnesium-containing metal in a CO2-containing atmosphere; after a reaction is finished, stirring an obtained product in an HCl solution; and purifying the obtained mixture, and carrying out drying overnight at room temperature to obtain the porous carbon material. The specific surface area of the porous carbon material prepared from the magnesium-zinc mixture can reach 1800-2000 m<2> / g; the conductivity of the material is as high as 1000 to 1100 S / m; thecapacitance retention rate is high; the tap density of the material is almost the same as the tap density of activated carbon and is 0.60-0.65 g / cm<3>; so the porous carbon material is an ideal material for preparing a high-power electrochemical capacitor electrode. The porous carbon material prepared from the magnesium-copper mixture has the advantages of favorable specific surface area and goodcrystallinity, and is an ideal material for preparing electrodes of microbial fuel cells.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Co-based MOFs-heteroatom doped porous carbon catalyst for oxygen reduction and preparation method thereof

InactiveCN111185218AImprove electrocatalytic activityImprove electron supply capabilityCatalyst activation/preparationPtru catalystPorous carbon

The invention relates to the technical field of oxygen reduction catalysts, and discloses a Co-based MOFs-heteroatom doped porous carbon catalyst for oxygen reduction and a preparation method thereof.The catalyst comprises the following formula raw materials: Fe-based MOFs, 1-hydroxyethane 1,1-diphosphonic acid, chitosan, glycine, an esterification catalyst, a composite base catalyst and a condensing agent. According to the catalyst and the method, N / P co-doping enables a carbon material to form rich pore channels and a large number of mesoporous structures; the formation of active sites andmedium transmission of oxygen reduction reaction are facilitated; the core-shell nanostructure of a cobalt compound coated with a porous carbon material has a richer morphological structure, so that the catalyst has better mass transfer performance; the cobalt compound formed after the cobalt-based MOFs with the nanometer structure are calcined is uniformly loaded into the pore channels of the porous carbon material, the graphitization degree of the carbon material is improved with the cobalt compound, the electrical conductivity of the carbon material is increased, and the forward oxygen reduction reaction is promoted.

Owner:朱旭烈

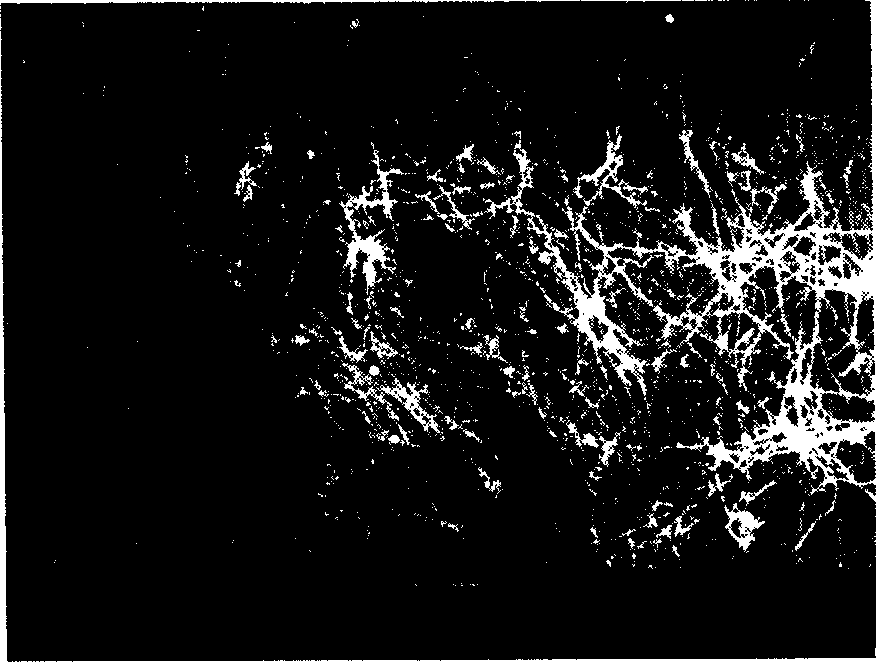

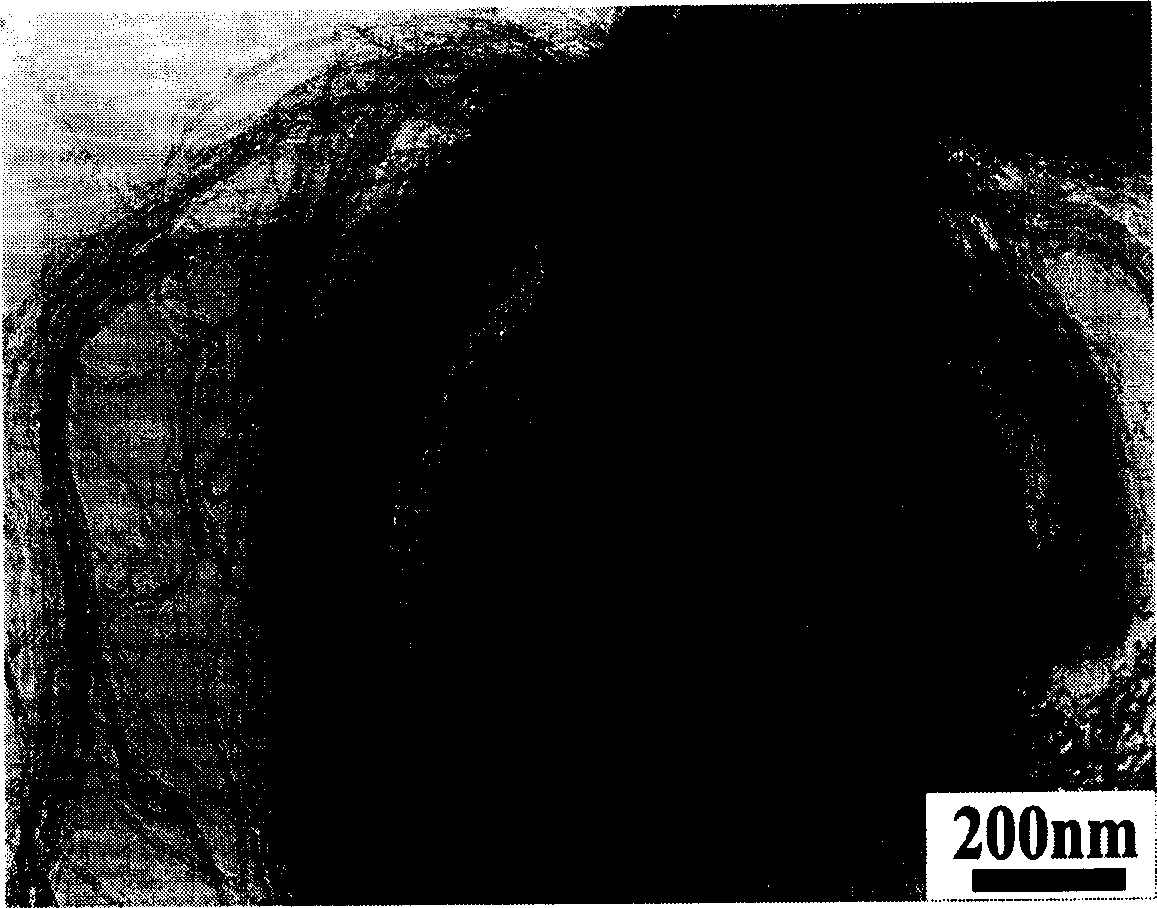

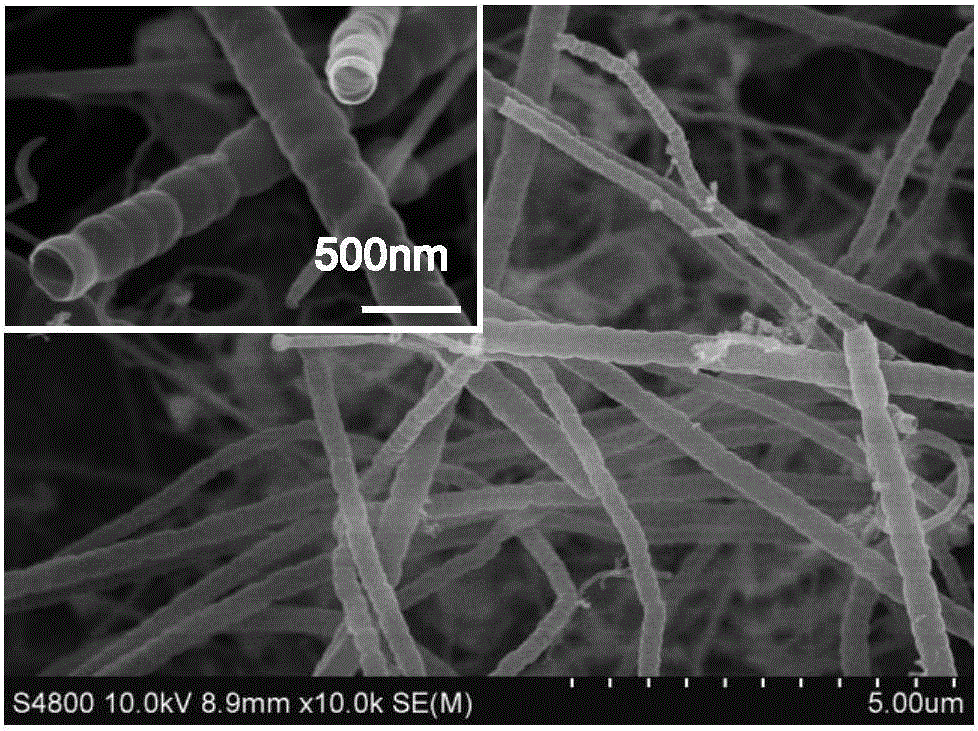

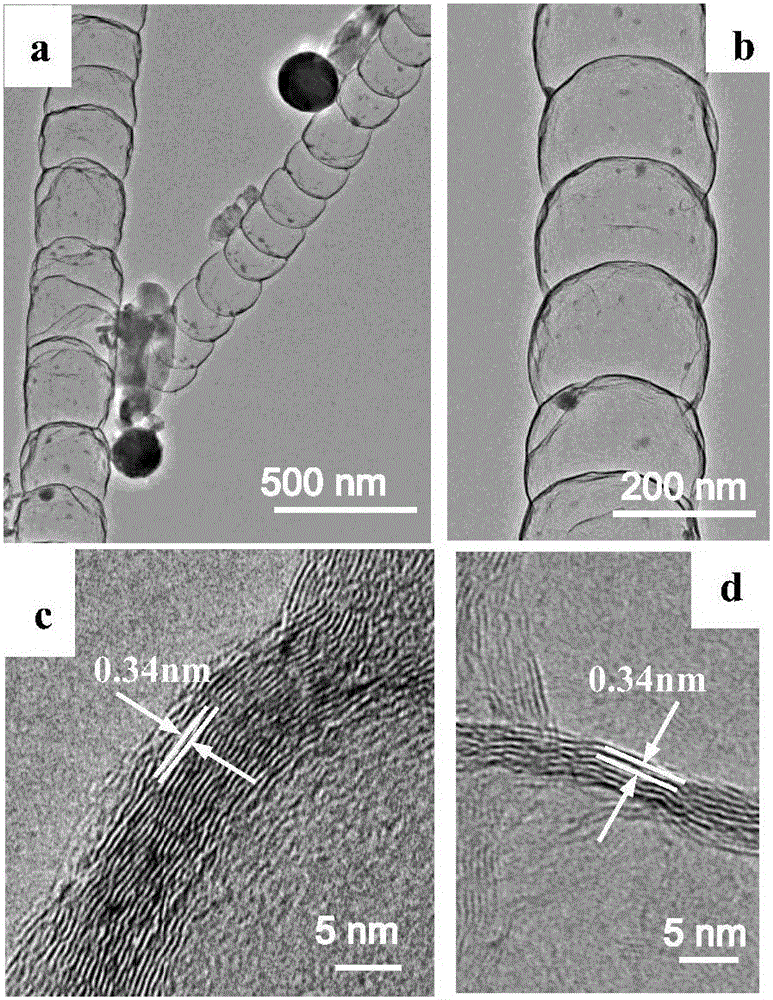

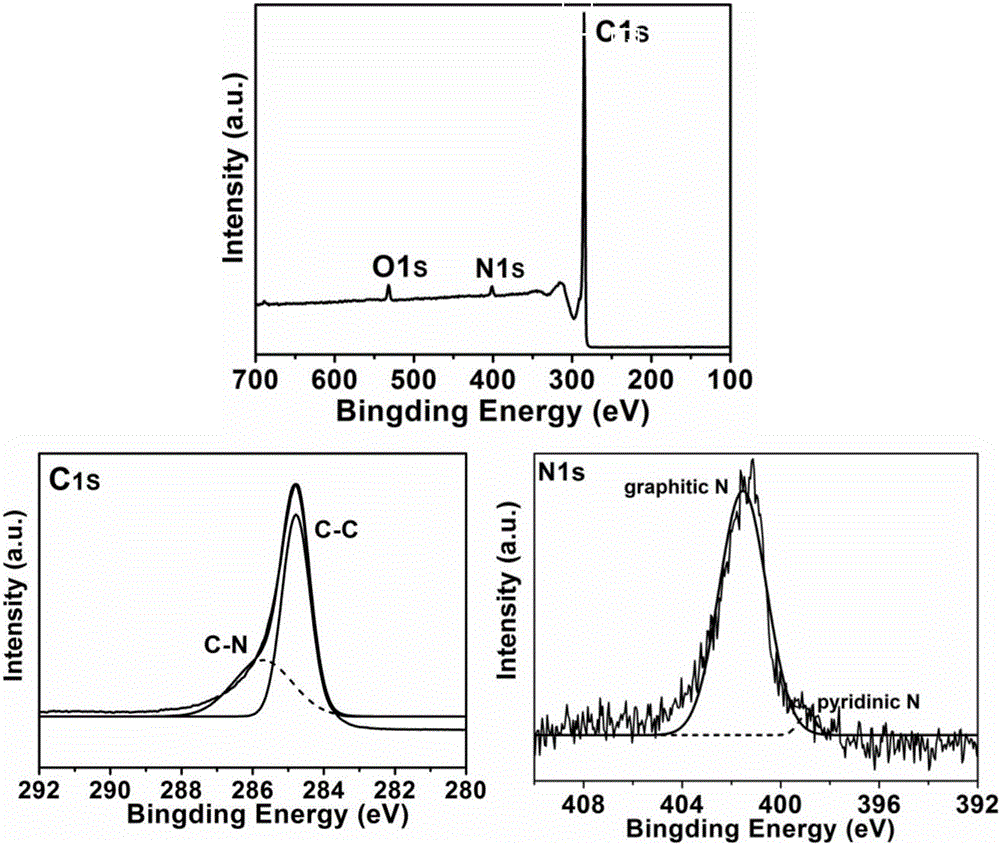

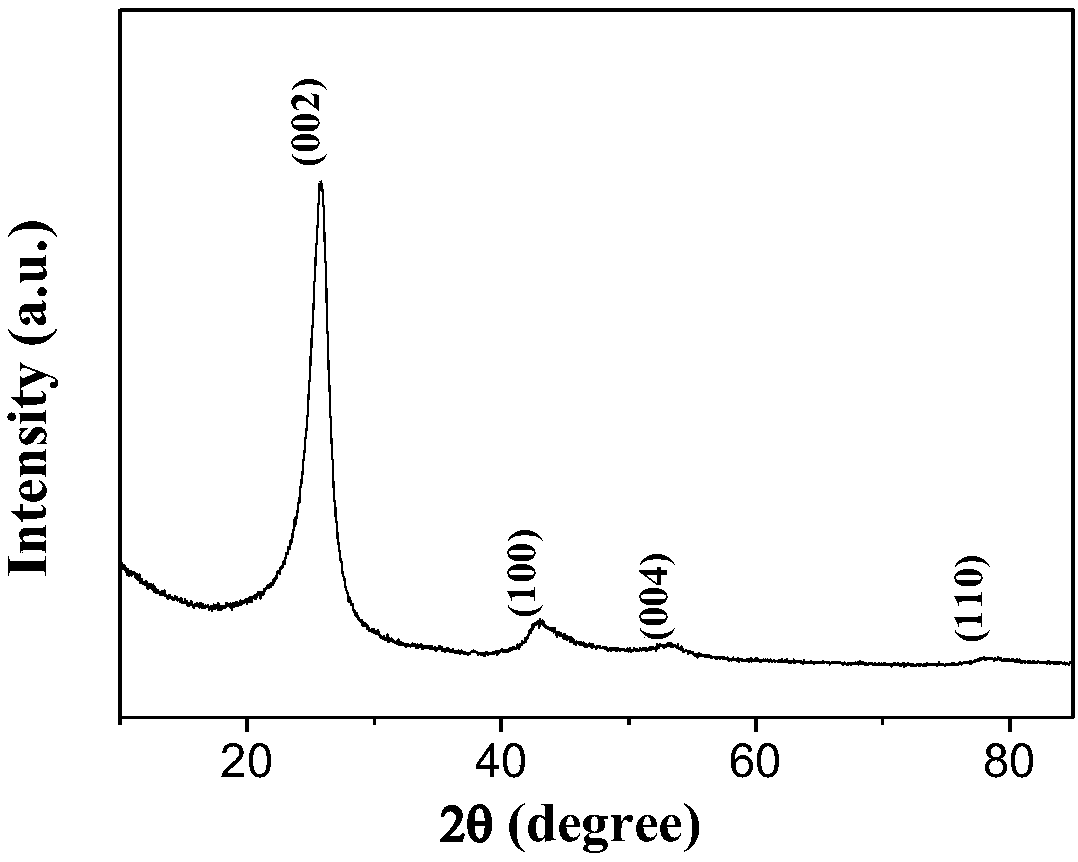

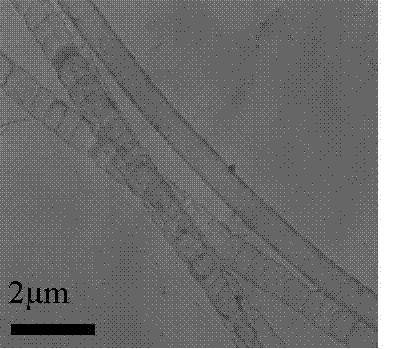

Method for preparing high-ratio graphite-type nitrogen-doped graphene tube in template-free one-step method

ActiveCN105731443AAvoid preparation removalHigh purityNanotechnologyNitrogen doped grapheneMethane gas

The invention discloses a method for preparing a high-ratio graphite-type nitrogen-doped graphene tube in a template-free one-step method. The method comprises the following steps: taking melamine as a reaction raw material, silicon powder as an auxiliary material and nickel nitrate as a catalyst, heating a vacuum atmosphere furnace to 1200 to 1250 DEG C by adopting a one-step chemical gaseous reaction method, keeping the temperature for 20 to 30 min, then introducing methane gas for 5 to 10 minutes, turning off a power supply, and cooling to the room temperature along with the furnace. The method is simple in process, easy to control, and capable of avoiding the complicated procedures of a template method and avoiding the damage on a tube structure in the template removal process; the obtained nitrogen-doped graphene tube is high in purity, uniform in structure and good in repeatability; and the tube diameter is 200 to 300 nm, the thickness of the tube wall is 6 to 8 nm, and the nitrogen-doped structure in the product is domain on the graphite-type nitrogen. The nitrogen configuration can effectively improve the electrical performance of the product and is suitable for the fields of novel vacuum micro-electronic devices, nano photoelectron devices and super capacitors.

Owner:QINGDAO UNIV OF SCI & TECH

Preparation method for biomass-based nitrogen-doped thin layer graphitized carbon material

InactiveCN108285143AGood degree of graphitizationThe synthesis method is simpleCarbon compoundsSynthesis methodsNitration

The invention relates to a preparation method for a biomass-based nitrogen-doped thin layer graphitized carbon material. The method is characterized by comprising the following steps that 1) lignin isused as a carbon source, through a nitration reaction, nitryl is introduced into lignin functional groups, then nitryl is reduced into amidogen, and nitrogen-doped lignin is obtained; 2) nitrogen-doped lignin is carbonized in an inert atmosphere; 3) the nitrogen-doped thin layer graphitized carbon material is obtained through a chemical insertion layer method. The nitrogen-doped thin layer graphitized carbon material has a high graphitized degree and a thin graphite layer, the synthesis method is easy, renewable lignin is used as the carbon source, and the material is environmentally friendlyand sustainable.

Owner:JIANGSU UNIV OF TECH

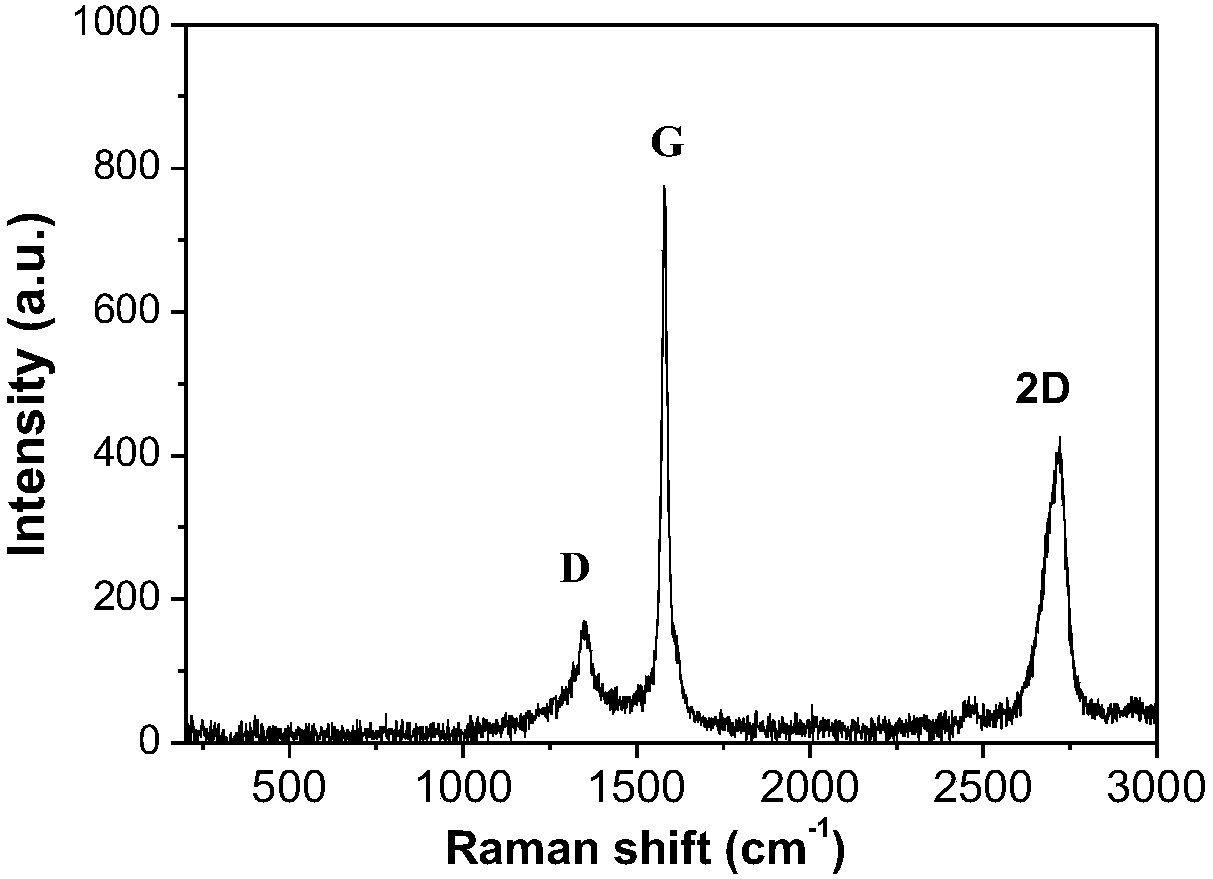

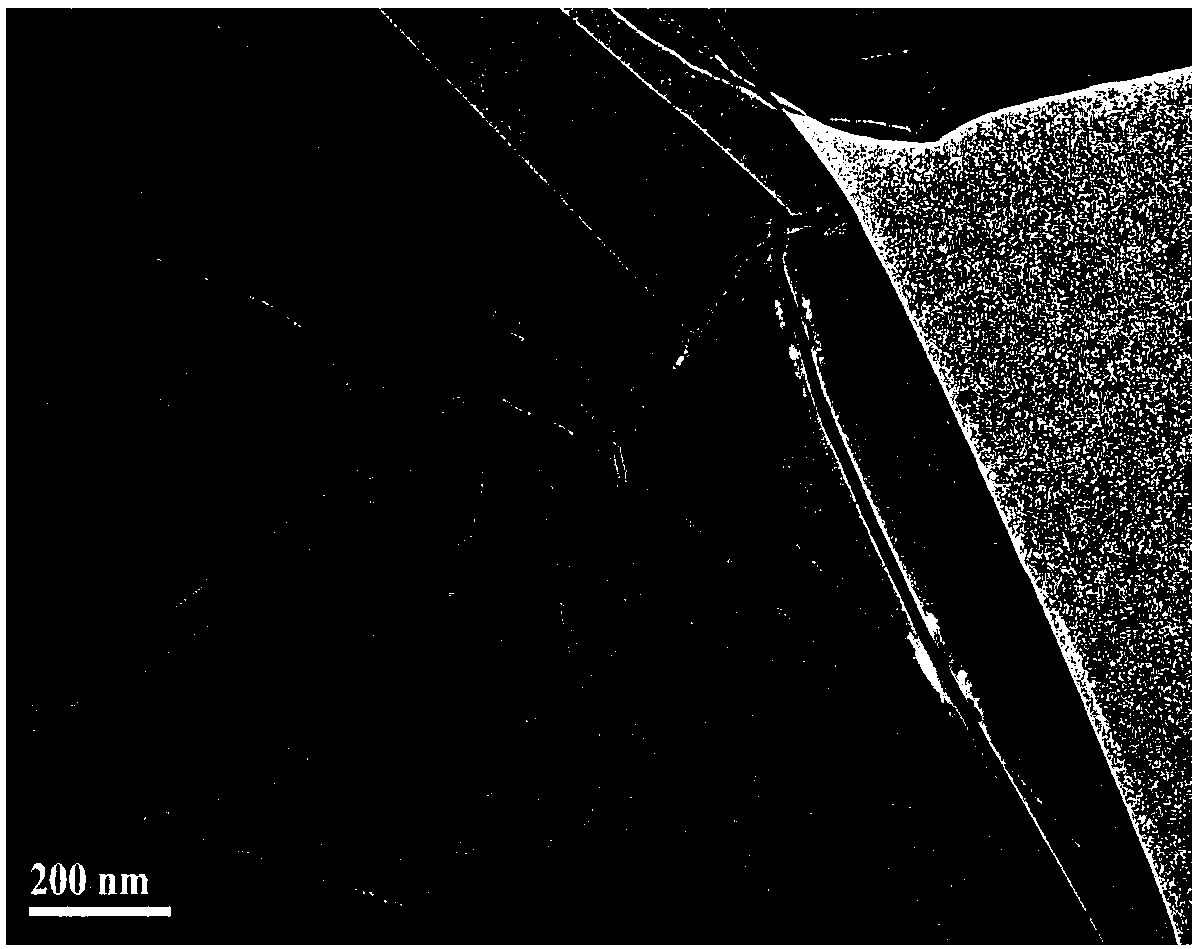

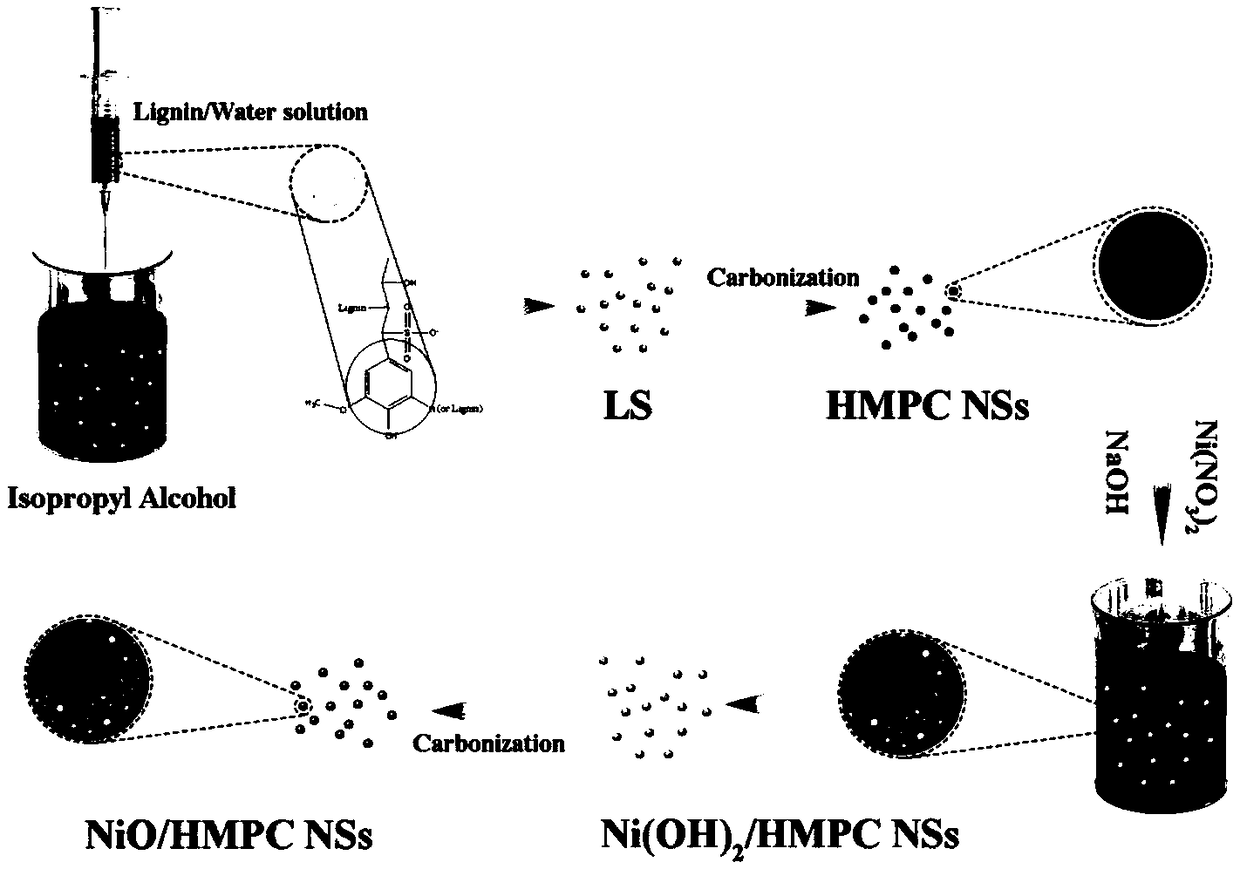

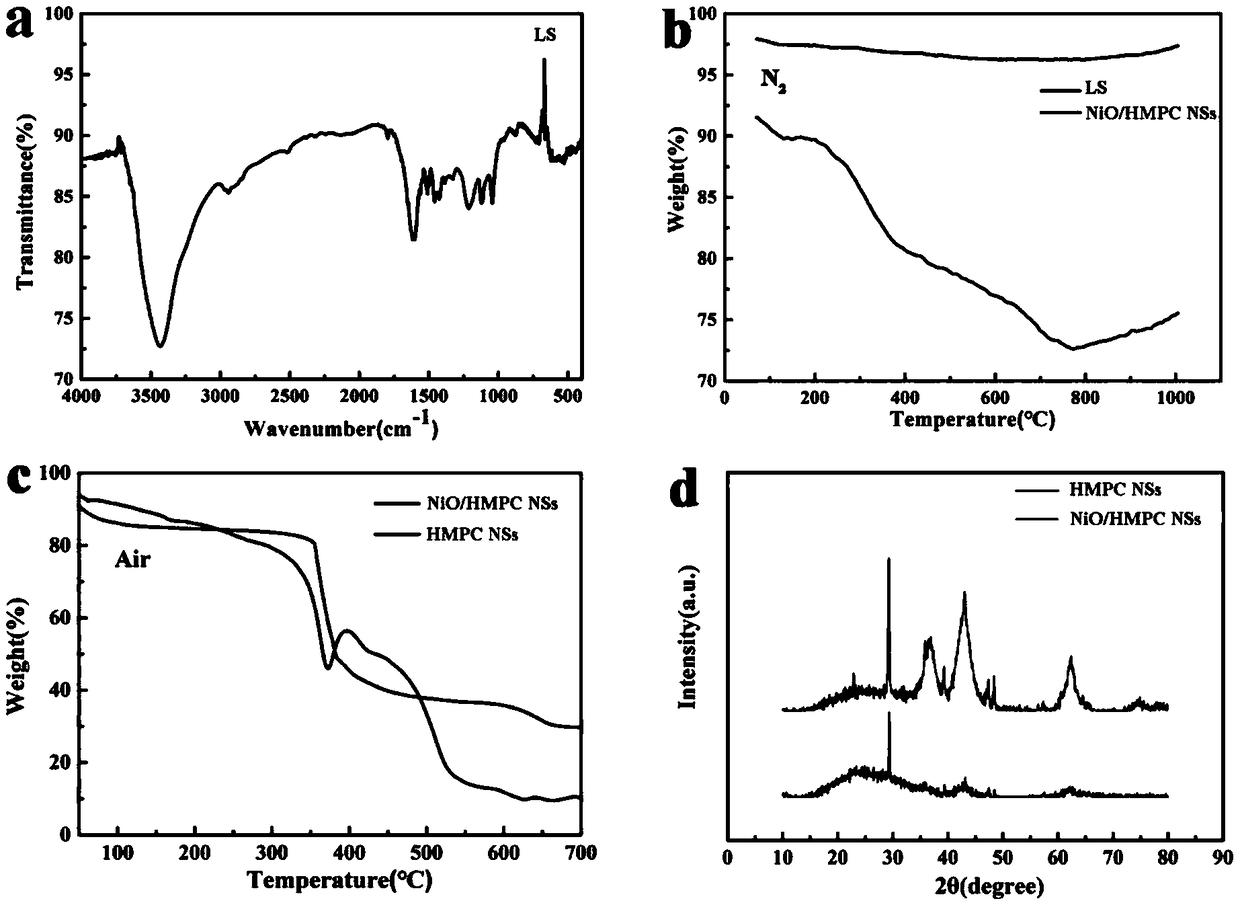

Method for preparing graded mesoporous carbon nanocomposite nickel oxide material

InactiveCN108975307AGood degree of graphitizationNano-carbonNickel oxides/hydroxidesWater bathsMicrosphere

A method for preparing a graded mesoporous carbon nanocomposite nickel oxide material includes the following steps: (1) dissolving sodium lignosulfonate in deionized water, and performing ultrasonic dissolution; (2) putting isopropanol in an ultrasonic water bath, injecting a solution obtained in step (1) into the isopropanol by means of an automatic sampler to obtain suspension liquid of lignin microspheres, and centrifugally drying a product in vacuum to obtain lignin nanosphere powder; (3) calcinating the dried lignin nanosphere powder in an N2 atmosphere in a tubular furnace to obtain graded mesoporous carbon nanospheres; (4) putting HMPC NSs into a sodium hydroxide and nickel nitrate solution for reaction to obtain HMPC NSs (Ni(OH)2 / HMPC NSs) coated with nickel hydroxide; (5) calcinating the Ni(OH)2 / HMPC NSs in an N2 atmosphere in the tubular furnace. The lignin is a graded mesoporous carbon source and has a larger specific surface area.

Owner:ZHEJIANG UNIV OF TECH

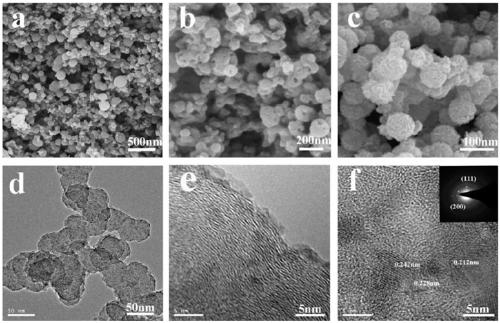

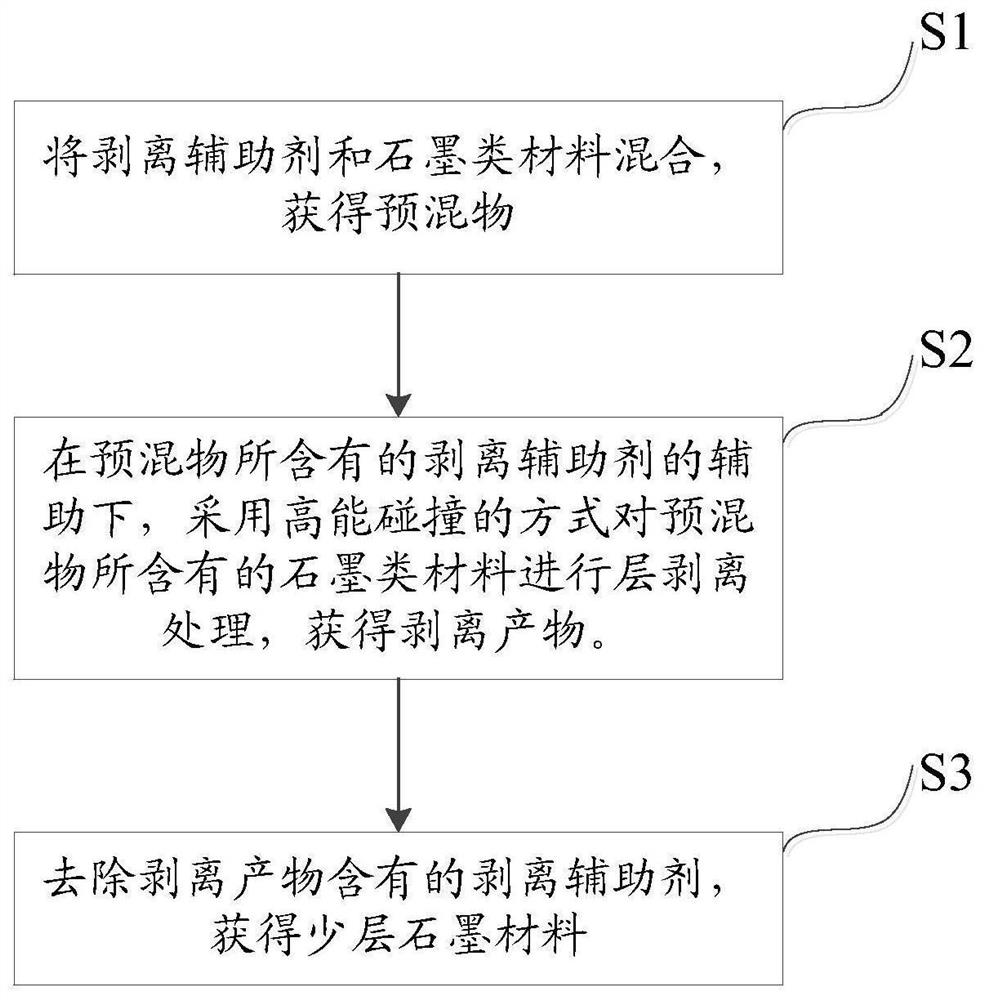

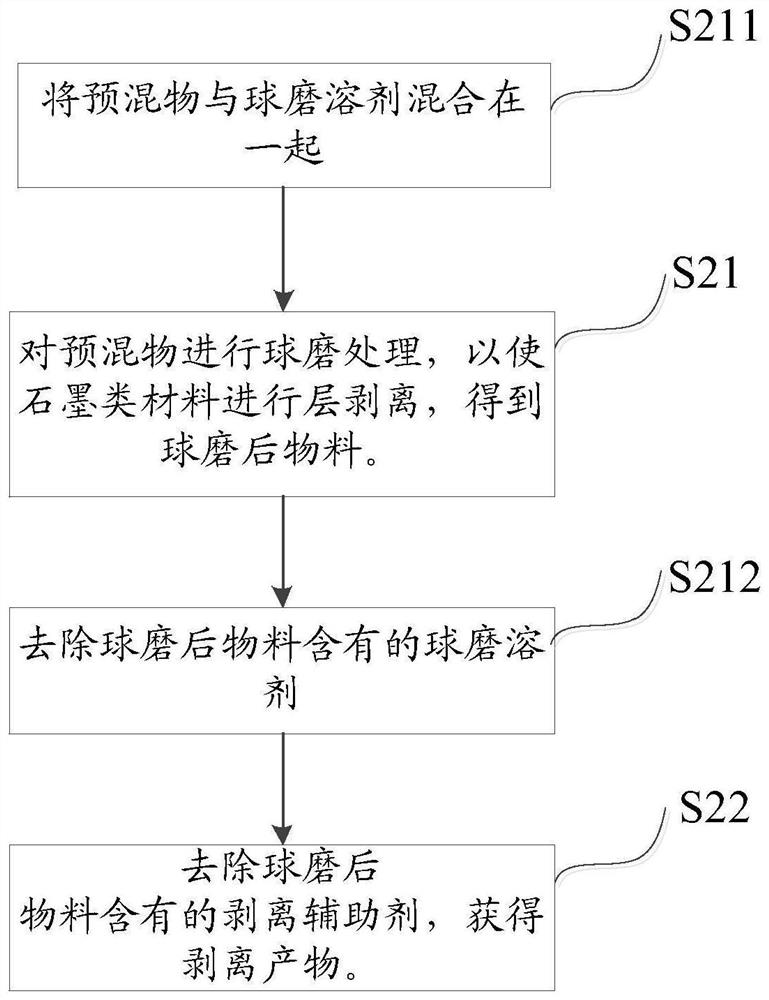

Few-layer graphite material and preparation method thereof, electrode material and battery

InactiveCN111689492AGood degree of graphitizationIncrease the active siteCarbon compoundsCell electrodesGraphiteElectric Capacitance

The invention discloses a few-layer graphite material, a preparation method of the few-layer graphite material, an electrode material and a battery, relates to the technical field of graphite materials, and aims to solve the problem of relatively low discharge capacity of a battery taking a graphite material as an electrode material. The preparation method of the few-layer graphite material comprises the step of stripping a graphite material in a high-energy collision mode to obtain the few-layer graphite material. The method is used for preparing the electrode material in the battery.

Owner:ENN SCI & TECH DEV

Carbon micro-tube epoxy resin wave-absorbing composite material and preparation method thereof

InactiveCN101817971BGood degree of graphitizationReduce weightNanostructure manufactureFiberCarbon fibers

The invention discloses a carbon micro-tube epoxy resin wave-absorbing composite material and a preparation method thereof, and relates to a wave-absorbing composite material and a preparation method thereof. The invention solves the problems that the existing active carbon fiber epoxy resin composite wave-absorbing material has fussy preparation process and large density, the hollow fiber prepared by a spinning method has low elastic modulus and the wave-absorbing material has poor strength. The composite material is prepared from carbon micro-tube and epoxy resin glue. The method comprises the following steps of: preparing the carbon micro-tube by using urea and ethylene glycol; preparing the epoxy resin glue by using bisphenol A epoxy resin, acetone and diethylenetriamine; and adding the carbon micro-tube into the epoxy resin glue, stirring the mixture uniformly, then adding the mixture into a die, and pressing the mixture to obtain the composite material. The elastic modulus of the material is 10 to 20GPa, the density is 1.00 to 1.05g / cm<3>, the lowest reflectivity is -13.25dB, the band width of -10dB reflectivity is 3.1GHz, and the material can be used for hiding weapons and eliminating the harm of electromagnetic wave to the organism.

Owner:HARBIN INST OF TECH

A preparation method of atomically dispersed non-precious metal fuel cell cathode catalyst

ActiveCN107369840BGood dispersionSolve the problem of low product yieldCell electrodesPtru catalystFuel cells

Owner:HUAZHONG UNIV OF SCI & TECH

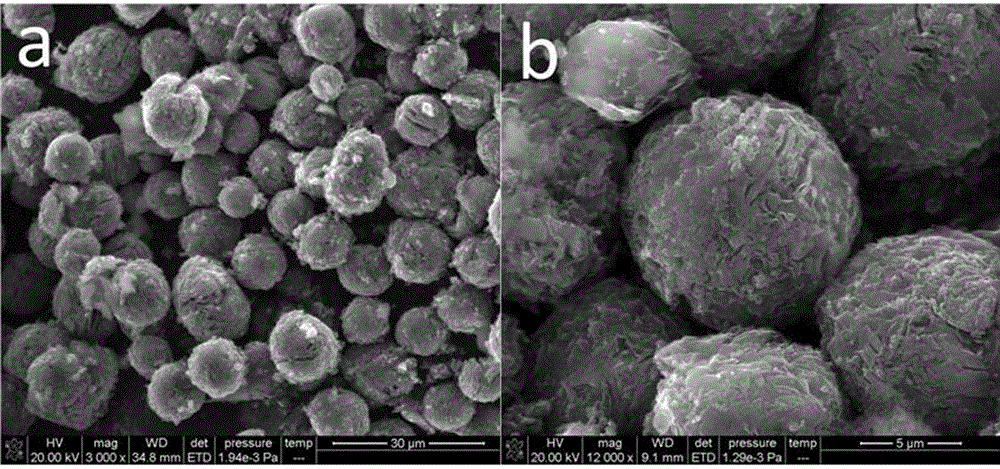

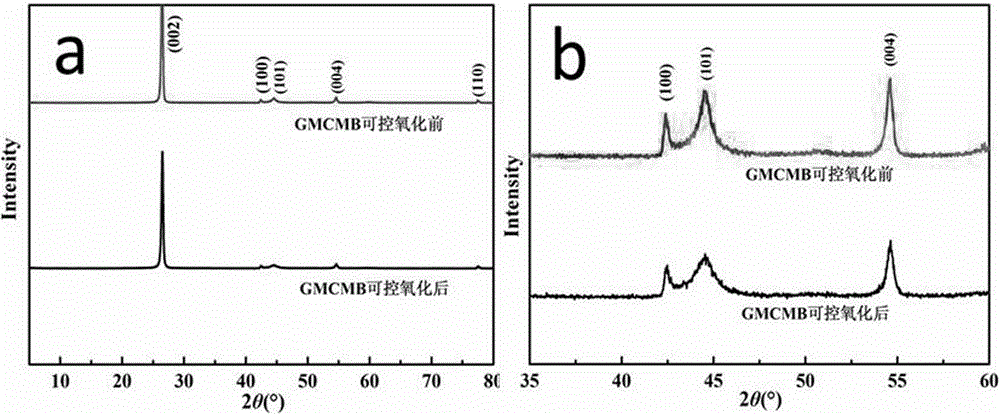

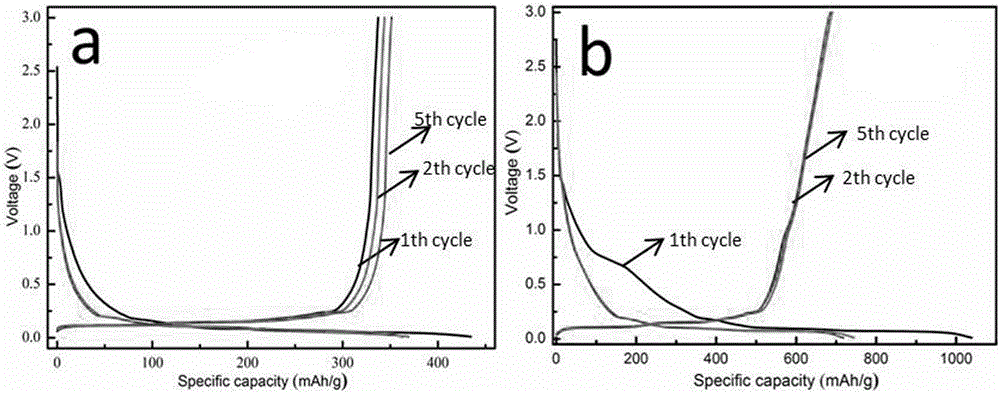

Surface controllable oxidation graphitization mesophase carbon nanosphere negative electrode material and preparation method

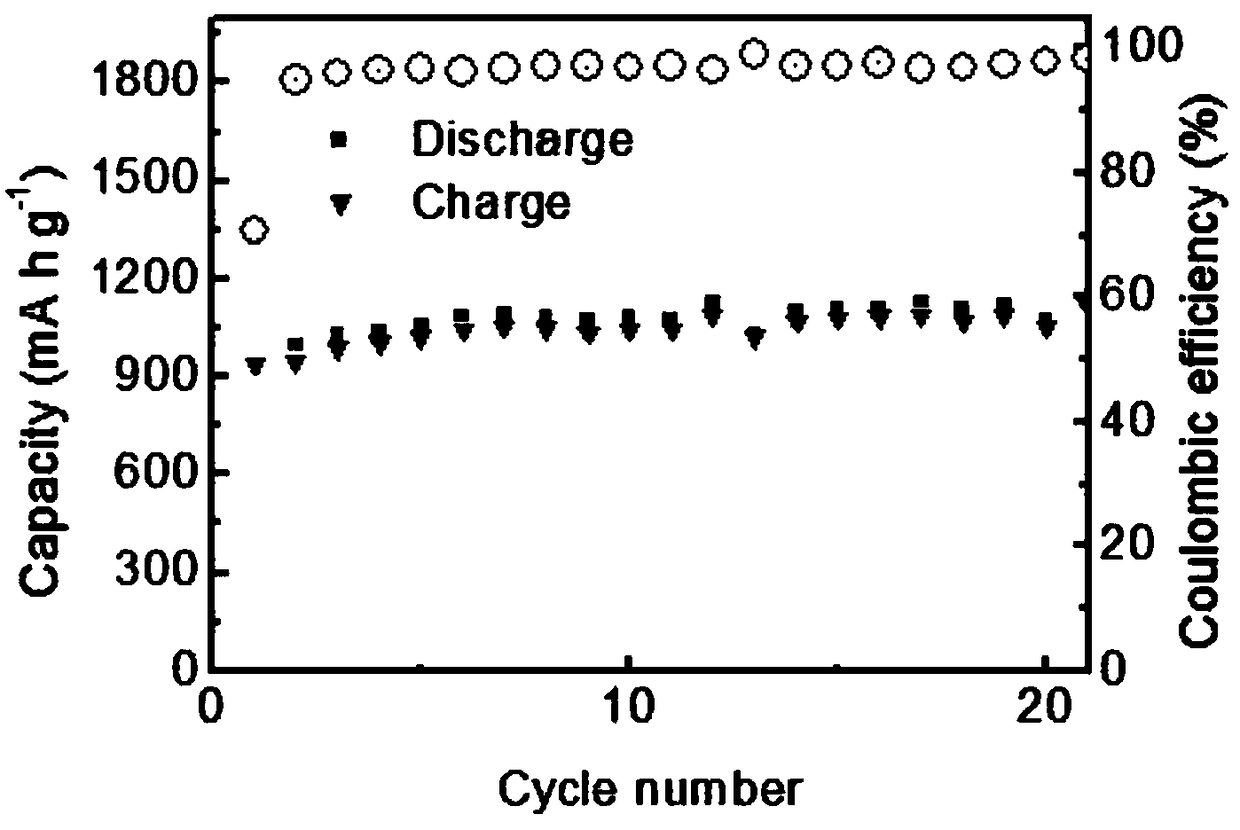

ActiveCN105336953AAvoid spherical damageImprove immersionCell electrodesSecondary cellsChromium trioxideFiltration

The present invention discloses a surface controllable oxidation graphitization mesophase carbon nanosphere negative electrode material and a preparation method. The method comprises the following steps: 1) measuring a certain volume of sulfuric acid to mix with one or more than one of nitric acid, perchloric acid and phosphoric acid, and ultrasonically processing or stirring for a certain time; 2) measuring a certain amount of graphitization mesophase carbon nanospheres to add into the mixed acid, ultrasonically processing or mechanically stirring for a certain time; 3) adding a certain amount of chromium trioxide into the liquid mixture, ultrasonically processing or mechanically stirring for oxidation for a certain time, and after completion of the reaction, filtering to obtain a black solid; 4 ) after filtration, using repeatedly washing with a certain concentration of hydrochloric acid and distilled water to clean, and drying; and 5) putting the dried solid into a tube furnace for high temperature heat treatment for some time a certain time in a protective atmosphere and cooling to room temperature. The surface controllable oxidation graphitization mesophase carbon nanosphere has lower lithium-intercalation removal platform and high platform capacity, and has a good degree of graphitization and excellent cycle performance.

Owner:广西卓能新能源科技有限公司

Hollow carbon fiber felt epoxy resin composite material and preparation method thereof

The invention discloses a hollow carbon fiber felt epoxy resin composite material and a preparation method thereof, relates to a carbon fiber epoxy resin composite material and the preparation method thereof, and aims to solve the problems of high density of a conventional carbon fiber epoxy resin composite material and difficult three-dimensional weaving of the carbon fiber serving as a composite material reinforcement. The hollow carbon fiber felt epoxy resin composite material is prepared from a hollow carbon fiber felt and epoxy resin adhesive; and the method comprises the following steps of: placing urea and carbon powder in a graphite crucible; preparing the hollow carbon fiber felt in an atmosphere sintering furnace; placing the hollow carbon fiber felt in a mould; sealing the mould and pouring the epoxy resin adhesive consisting of bisphenol A epoxy resin, acetone and diethylenetriamine into the mould under vacuum; and pressing the mould and drying the mould under vacuum to obtain the hollow carbon fiber felt epoxy resin composite material. The hollow carbon fiber felt is self-woven and the density of the composite material is only 0.92 to 0.94g / cm<3>, so the material can be used for spacecrafts, artificial satellites, space shuttles and missiles.

Owner:HARBIN INST OF TECH

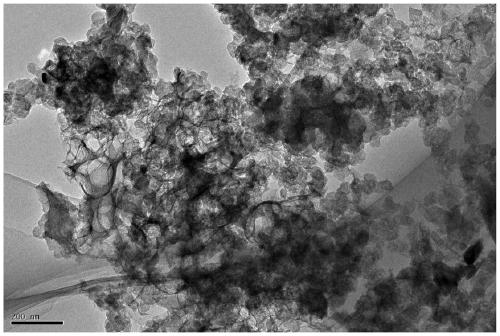

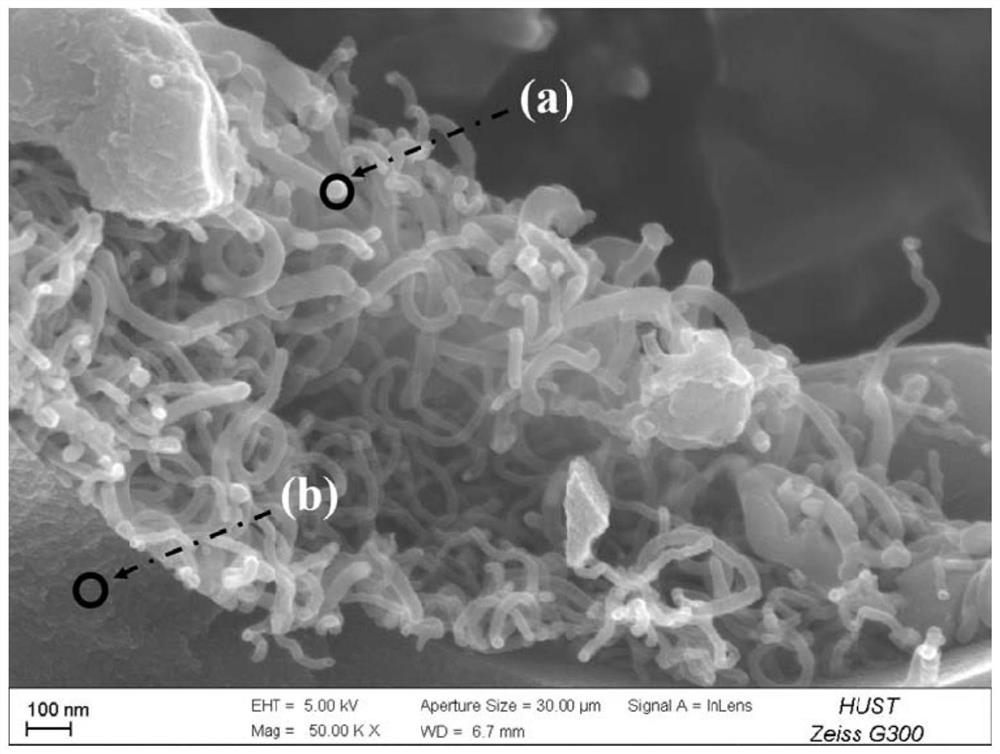

Method for preparing oxygen reduction catalyst from biomass and product

ActiveCN111193039AAchieve synthesisReasonable pyrolysis temperatureFuel and primary cellsCell electrodesCarbon layerPtru catalyst

The invention discloses a method for preparing an oxygen reduction catalyst from biomass and a product. The method comprises the following steps: S1, mixing biomass with a transition metal salt solution I, and performing freeze-drying to obtain a mixture I; S2, pyrolyzing the mixture I in an inert atmosphere to obtain a core-shell structure material with transition metal nanoparticles wrapped by agraphite carbon layer; S3, dispersing the core-shell structure material into a volatile organic solvent, adding a nitrogen-containing organic matter and a transition metal salt solution II, performing mixing and drying to obtain a mixture II; and S4, pyrolyzing the mixture II in an inert atmosphere so as to grow nitrogen-containing carbon nanofibers on the surface of the core-shell structure material, and washing, filtering and drying the nitrogen-containing carbon nanofibers to obtain the required oxygen reduction catalyst. The sea urchin-shaped oxygen reduction catalyst can be prepared, hasdeveloped porosity, high nitrogen content and stable metal active sites, and has good activity and durability in the aspect of oxygen reduction catalysis.

Owner:HUAZHONG UNIV OF SCI & TECH

Preparation method and application of novel carbon and silicon-based composite material

InactiveCN108428879AWide variety of sourcesEasy to purchase in the marketMaterial nanotechnologySecondary cellsFiberNitrogen gas

The invention discloses a preparation method and application of a novel carbon and silicon-based composite material. The method comprises the following steps: mixing saccharose and silicon powder; primarily drying for 8-12h under room temperature; roasting for 2-3h in nitrogen atmosphere under 773-1473K to obtain a primary carbon-silicon composite material; combining the primary carbon-silicon composite material and graphite fibers to obtain the carbo and silicon-based composite material. The preparation method is low in cost, simple to operate, and wide in raw material source; generation of toxic gas is avoided in the preparation processes; in addition, the prepared carbon-silicon-based composite material is stable in performance and outstanding in circulating performance when being applied to a lithium battery negative electrode material and has a god industrial application prospect.

Owner:王立勇

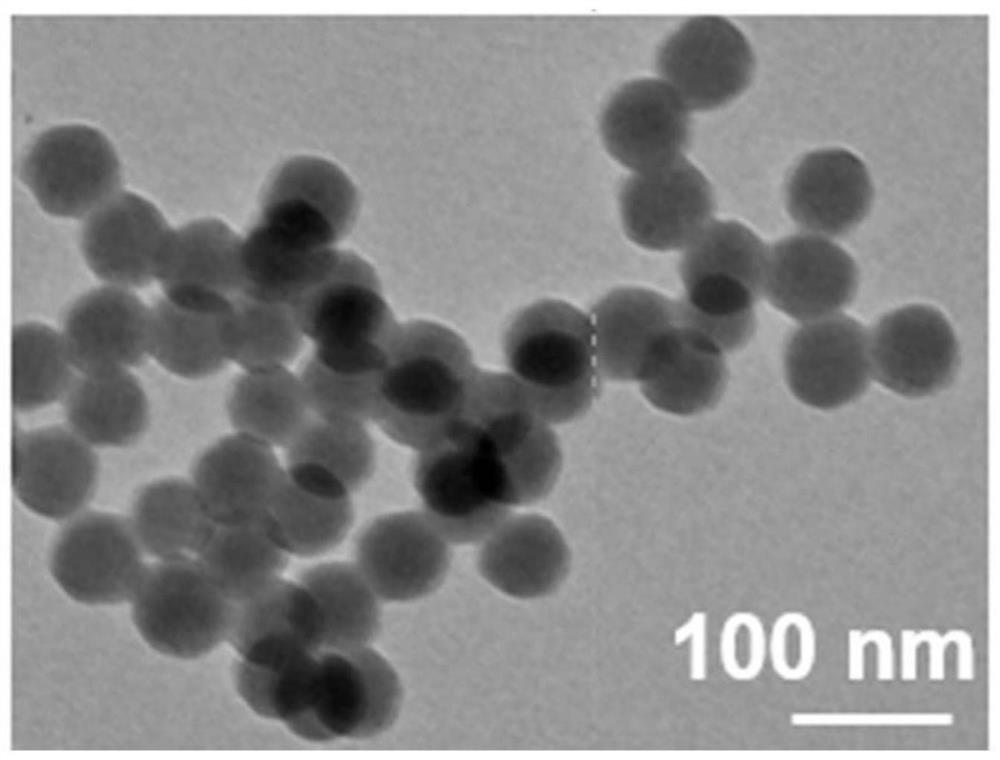

Controllable synthesis method for nitrogen and phosphorus co-doped graphitized carbon ball with hollow structure

InactiveCN103183330BLow priceEasy to recycleMaterial nanotechnologyCarbon preparation/purificationCatalytic transformationPtru catalyst

The invention relates to a controllable synthesis method for a nitrogen and phosphorus co-doped graphitized carbon ball with a hollow structure. The method comprises the following preparation steps: (1) a carbon source, soluble metal salt and a catalyst are dissolved in a solvent according to a molar ratio, the mixture is transferred to a hydrothermal reaction kettle for hydrothermal synthesis after stirred to be dissolved completely, and an obtained precipitate is cleaned, filtered and dried to obtain a primary product; (2) the obtained primary product is subjected to high-temperature reduction under the protection of gas in a high-temperature reaction furnace; and (3) the product obtained by high-temperature reduction is placed in an acid solution to be soaked, and then cleaned, filtered and dried to obtain the nitrogen and phosphorus co-doped graphitized carbon ball with the hollow structure. The nitrogen and phosphorus co-doped graphitized carbon ball with the hollow structure prepared with the method has the advantages that the appearance is uniform, a carbon shell has a cellular structure, the interior of the carbon ball has a mesoporous carbon support structure, the graphitization degree is good, and the like; and the carbon ball can be used in various fields of efficient catalytic conversion, energy storage and conversion, medicine release and control, substance adsorption and separation and the like. A template-free hydrothermal synthesis technique is simple and controllable, and can be used for mass production.

Owner:CHINA UNIV OF MINING & TECH +1

Method oxide catalyst and method for preparing bundled multiwall nano carbon tube

InactiveCN1226085CHigh activityIncrease profitMetal/metal-oxides/metal-hydroxide catalystsHydrogenFixed bed

The present invention relates to a metal oxide catalyst and a method for preparing bundled multiwall nano carbon tube by using said metal oxide catalyst and catalytic cracking methane, said metal oxide catalyst is the Fe / Mo / MgO and Ni / Mo / MgO catalyst formed from oxide of magnesium and molybdenum as main catalyst and iron or nickel as auxiliary catalyst. Said catalyst is placed in the fixed bed gas continuously-flowing reaction furnace, and the methane whose introduced flow rate is 50-1500 sccm and the hydrogen gas or nitrogen gas or inert gas whose flow rate is 50-300 sccm are reacted for 10-100 min. at 750-1200 deg.C so as to form the invented bundled multiwall nano carbon tube.

Owner:ZHEJIANG UNIV

Lanthanum doped monometallic catalyst for preparing carbon nano tube with uniform diameter and preparing process thereof

InactiveCN1302846CHigh catalytic efficiencyEvenly distributedMetal/metal-oxides/metal-hydroxide catalystsMagnesium saltCarbon nanotube

The invention discloses a method for preparing a lanthanum doping monometallic catalyst, which is used in making the uniform caliber carbon nanometer tube. The catalyst uses magnesia as the carrier, uses the oxide of cobalt, iron or nickel as the metal oxide component, uses the oxide of lanthanum as the doping component, and uses the oxide of molybdenum as the catalytic promoter. The method comprises: a) dissolving the magnesium salt in the distilled water, b) adding the metal oxide component, the lanthanum doping component salt and the catalytic promoter, making them dissolved absolutely, wherein the molar ratio of the four is: 0.5~3.0:0.1~1.0:0.01~1.0:0.5~3.0, c) drying said solution in 120-200 DEG C for 3-5 hours, calcining in 550-850 DEG C for 10-30 minutes, d) grinding them to powder and getting the catalyst, which can be used for producing the carbon nanometer tube with uniform caliber.

Owner:上海华实纳米材料有限公司

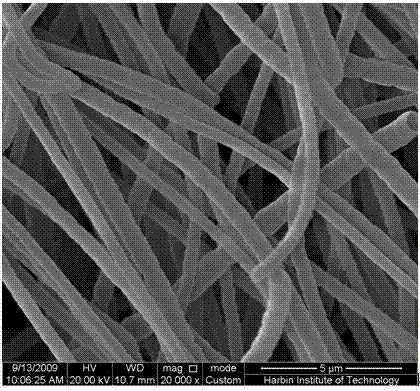

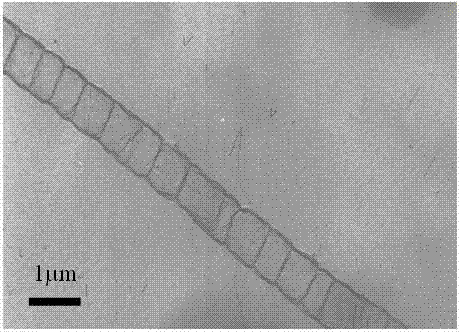

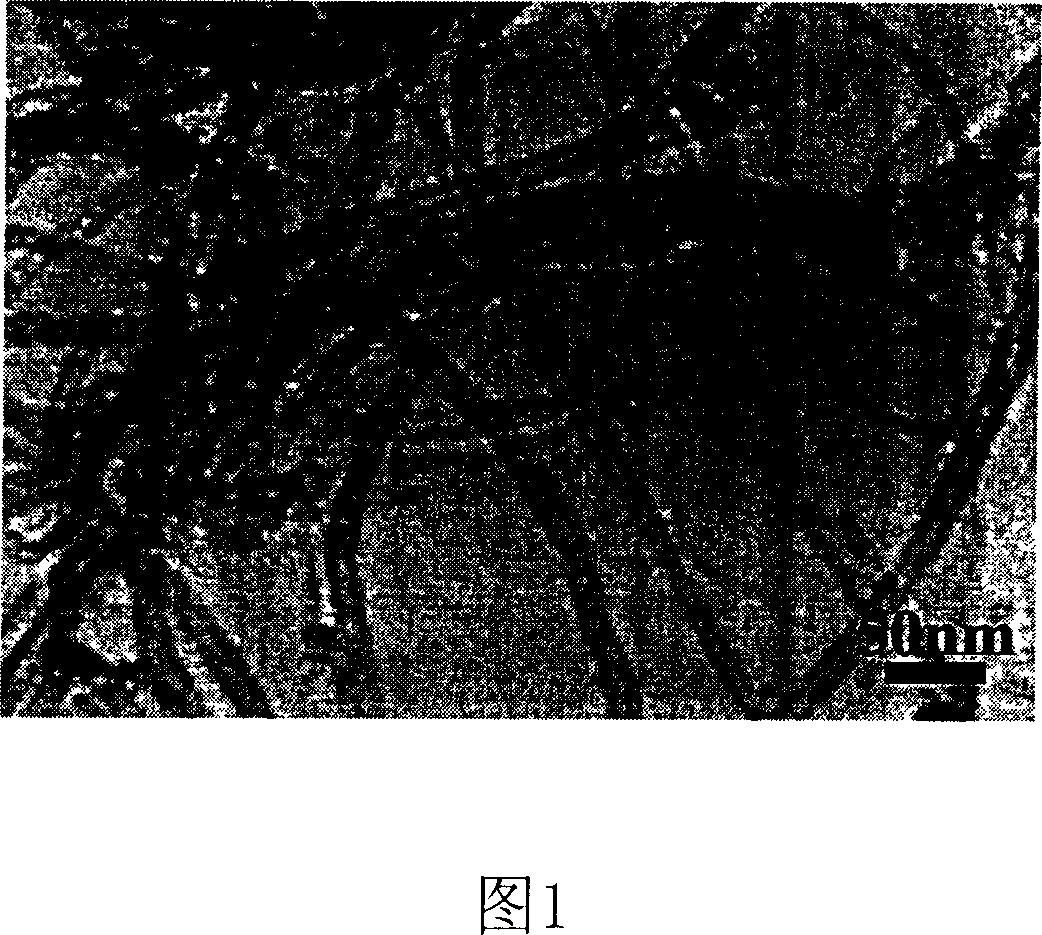

Method for producing hollow carbon fibers

InactiveCN101805943BGood degree of graphitizationLarge lumenFibre chemical featuresFiberCarbon fibers

The invention discloses a method for producing hollow carbon fibers, which relates to a method for producing carbon fibers. The invention solves the following problems of the prior spinning production process for producing hollow carbon fibers: high temperature, low elasticity modulus, impurities contained in hollow carbon fibers produced by the chemical vapor growing method and difficult synthesization of hollow carbon fibers with the caliber of hundreds of nanometers to a few microns. The method includes the following steps: (1) carbon source material is put into a graphite crucible, the graphite crucible is put into an atmosphere sintering furnace, and the atmosphere sintering furnace is vacuumized to 0.1Pa to 1Pa; (2) high-pure nitrogen or argon is filled into the furnace until pressure reaches 0.2MPa to 2.5MPa; (3) the temperature is increased to 900 DEG C to 1500 DEG C at 5 DEG C / min to 30 DEG C / min, and is then kept for one to four hours, and the furnace is then cooled to the room temperature, so that hollow carbon fibers are obtained. The reaction temperature of the method is low, catalyst is not used, the graphitization degree of the synthesized hollow carbon fibers is high, the hollow carbon fibers do not contain impurities, and the purity is 100 percent. The hollow carbon fibers are applicable to capacitors, hydrogen storage and composite materials.

Owner:HARBIN INST OF TECH

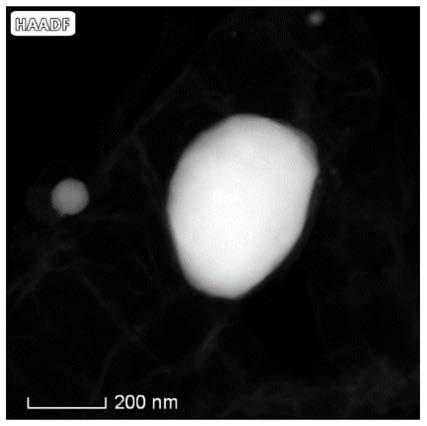

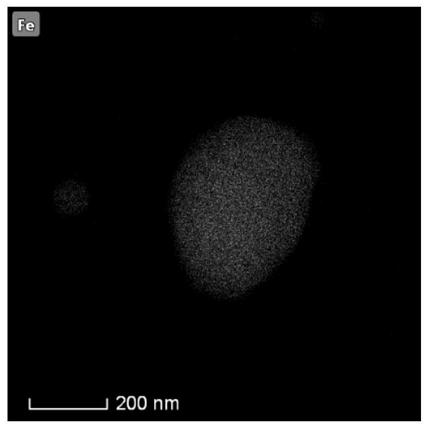

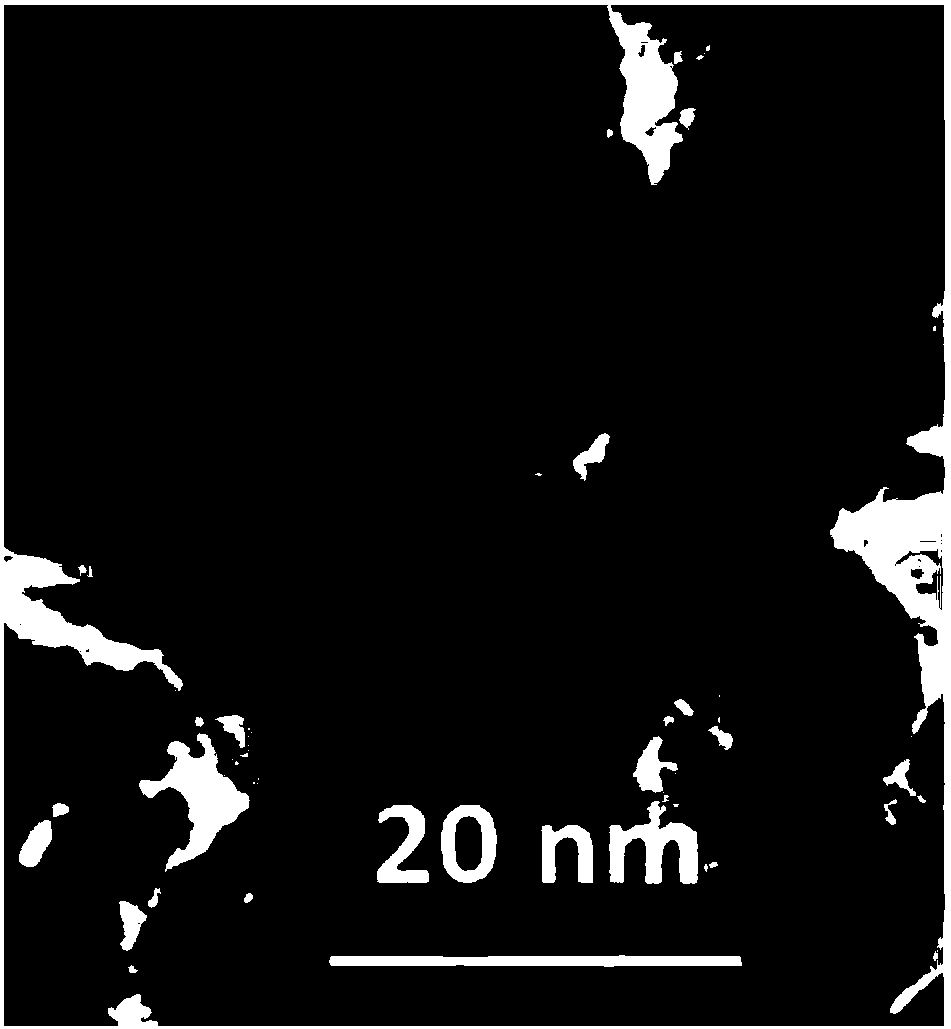

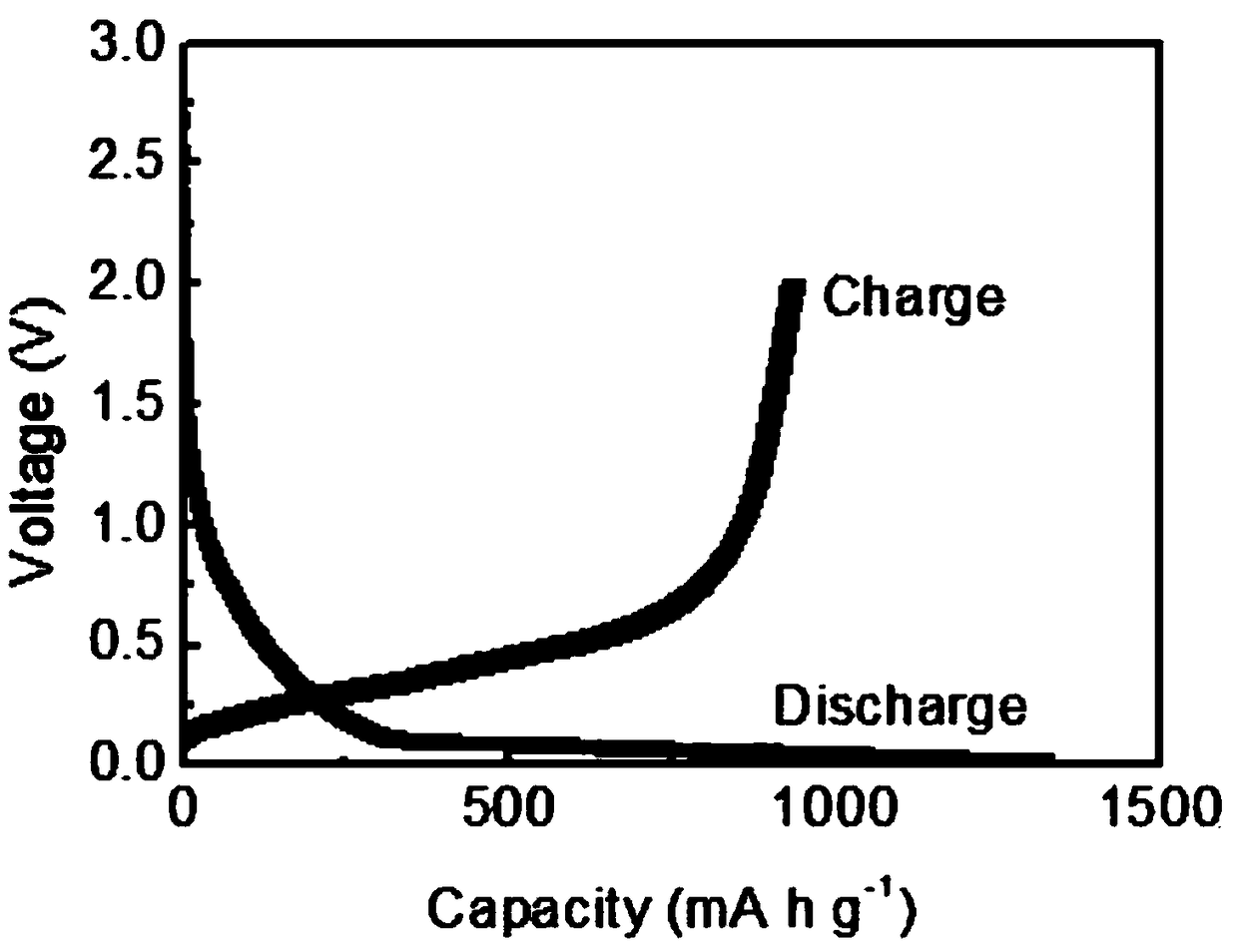

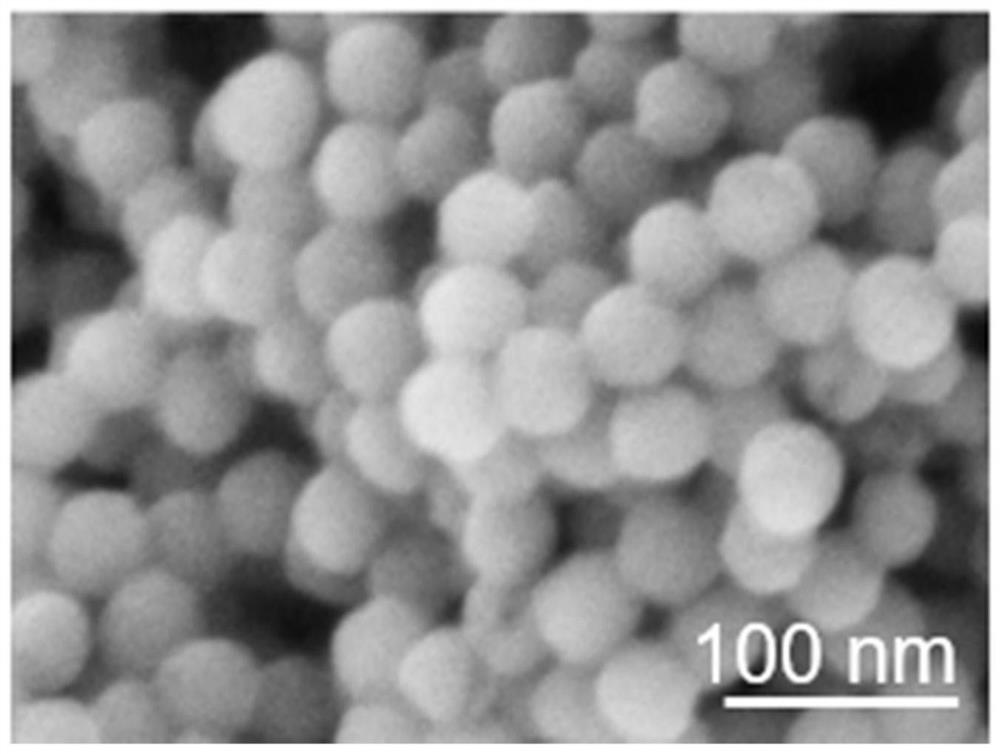

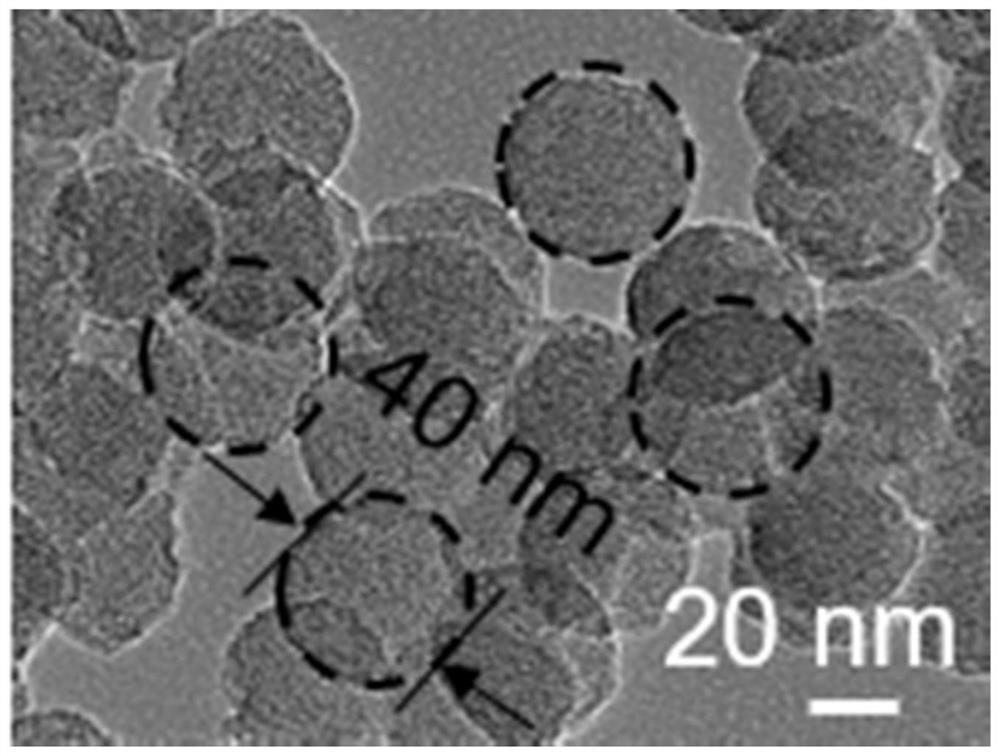

Iron-containing monatomic catalyst and application thereof

PendingCN114824329AGood degree of graphitizationImprove conductivityCell electrodesPtru catalystIron salts

The invention discloses an iron-containing monatomic catalyst and application thereof. The iron-containing monatomic catalyst is in a monodisperse spherical shape, the surface is smooth, the diameter is 40 nm + / -1 nm, and the uniform spherical shape of matrix resin is inherited, which shows that phenolic resin spheres are ideal precursors for producing carbon materials. The preparation method comprises the following steps: dispersing 3-aminophenol and hexamethylenetetramine in water, and reacting at 100 DEG C for 24 hours by taking hexadecyl trimethyl ammonium bromide as a morphology guiding agent to obtain phenolic resin spheres; and stirring the obtained phenolic resin spheres and an iron salt solution at normal temperature for 12-24 hours at the stirring speed of 200rpm, centrifuging, taking the precipitate, freeze-drying, carbonizing the freeze-dried product in an inert atmosphere, and preserving heat for 60 minutes. Compared with the prior art, the method disclosed by the invention is simple to operate and easy for large-scale production, and the prepared carbon nanosphere loaded iron monatomic material has the advantages of maximized atom utilization rate, unique electronic structure, good conductivity, high catalytic activity and the like.

Owner:NANJING NORMAL UNIVERSITY

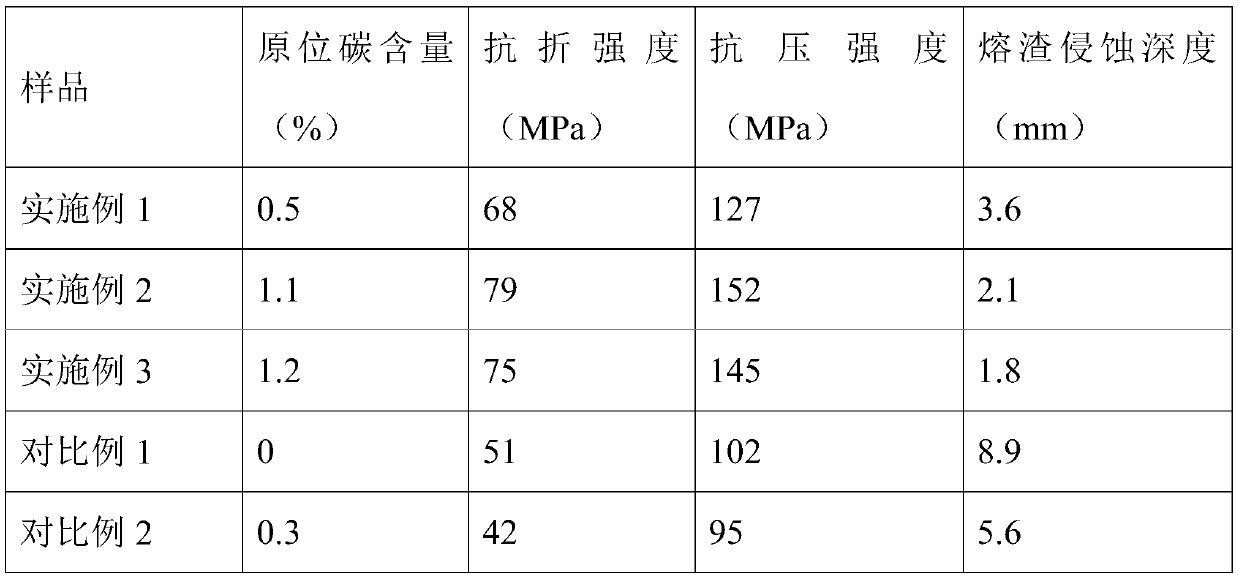

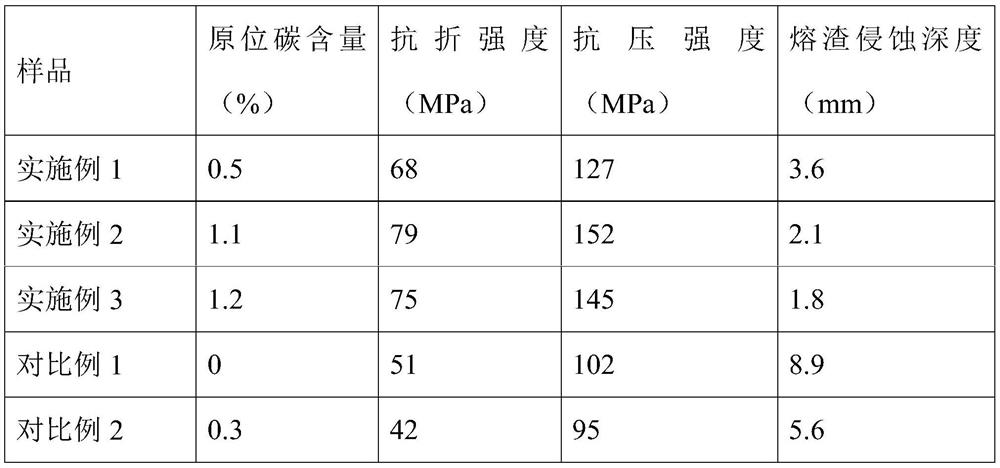

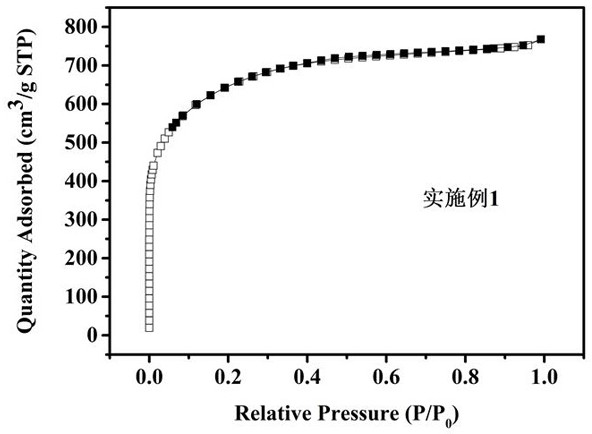

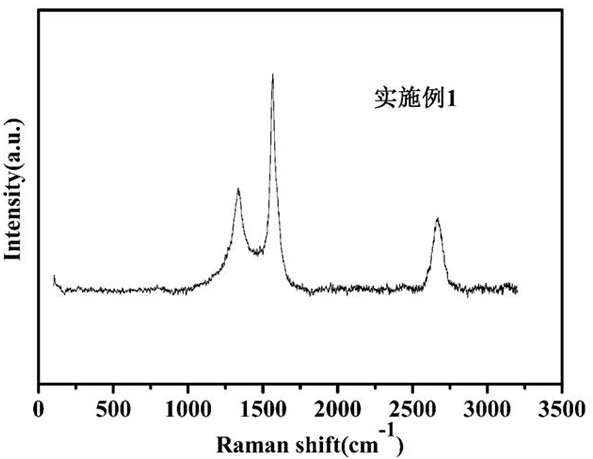

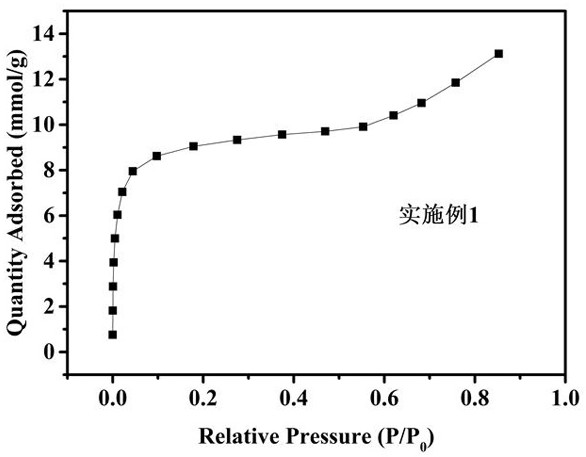

In-situ carbon-containing refractory castable and preparation method thereof

The invention discloses an in-situ carbon-containing refractory castable, which comprises a component A and a component B. The component A is composed of refractory raw material corundum particles, sintered magnesia, activated alumina micropowder, calcium aluminate cement and silica micropowder, and the component B is a transition metal in-situ doped polymer solution. The transition metal in-situdoped polymer aqueous solution is added into the raw materials, so that on one hand, the raw material mixture of the refractory castable is endowed with fluidity in the preparation process, and on theother hand, the polymer is pyrolyzed to produce a carbon material in the sintering process, the carbon material is dispersed and distributed in the castable, meanwhile, the graphitization degree of the in-situ generated carbon material is improved through transition metal, and according to the in-situ synthesis theory, the carbon material in the in-situ carbon-containing refractory castable has good dispersity, the non-wetting characteristic of carbon material slag can be brought into play, and the carbon-containing refractory castable is endowed with excellent mechanical properties and erosion resistance. The invention further provides a preparation method of the in-situ carbon-containing refractory castable, the technological process is simple, and industrial production is facilitated.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Method and product for preparing oxygen reduction catalyst from biomass

ActiveCN111193039BAchieve synthesisReasonable pyrolysis temperatureFuel and primary cellsCell electrodesCarbon layerPtru catalyst

The invention discloses a method and a product for preparing an oxygen reduction catalyst from biomass, which comprises the following steps: S1 mixing and freeze-drying the biomass and a transition metal salt solution to obtain a mixture; S2 pyrolyzing the mixture under an inert atmosphere Obtain a core-shell structure material with graphite carbon layer wrapped transition metal nanoparticles; S3 disperse the core-shell structure material in a volatile organic solvent, add nitrogen-containing organic matter and transition metal salt solution 2, mix and dry to obtain mixture 2 ; S4 Pyrolyzing the mixture two under an inert atmosphere to grow nitrogen-containing carbon nanofibers on the surface of the core-shell structure material, and obtain the required oxygen reduction catalyst after washing, filtering and drying. The invention can prepare the sea urchin-shaped oxygen reduction catalyst, has developed porosity, high nitrogen content, stable metal active sites, and has good activity and durability in oxygen reduction catalysis.

Owner:HUAZHONG UNIV OF SCI & TECH

Plasma method for preparing nano carbon material using coal liquefied residue as raw material

The invention discloses an arc plasma torch preparing nanometer charcoal fibrous material method, which comprises the following steps: placing untreated leavings of liquefying coal directly in direct current arc plasma torch to carry on heat-treatment; using nitrogen for arc working gas under atmosphere pressure; getting nanometer charcoal fibrous material after 120-175 seconds, wherein there is no need to add in any activators in preparing process. The method is characterized by the following: the craft route is simple; the raw material is the waste of coal hydrogenant liquefaction craft; it's a good way to use coal liquification leavings to prepare high-added value, functional carbon material; the nanometer charcoal fibrous material can be used for accelerating agent, catalyst carrier, lithium ion secondary cell anode material, double-layer capacitor electrode, highly effective active solid, release agent and construction reinforced materials.

Owner:DALIAN UNIV OF TECH

A kind of in-situ carbon-containing refractory castable and preparation method thereof

ActiveCN111285667BWide variety of sourcesGood degree of graphitizationPolymer solutionMaterials science

The invention discloses a refractory castable containing in-situ carbon, which comprises A component and B component, and the A component is composed of refractory raw material corundum particles, sintered magnesia, activated alumina micropowder, calcium aluminate cement and silica micropowder , B component is transition metal in-situ doped polymer solution. The present invention adds transition metal in-situ doping polymer aqueous solution to the raw material, on the one hand endows the refractory castable raw material mixture with fluidity during the preparation process; on the other hand, during the sintering process, the polymer is pyrolyzed to generate carbon materials, Realize the dispersion of carbon materials in castables, and at the same time transition metals improve the degree of graphitization of carbon materials generated in situ. According to the theory of in situ synthesis, carbon materials in refractory castables containing in situ carbon have good dispersion and can play The slag non-wetting properties of the material endow carbon-containing refractory castables with superior mechanical properties and corrosion resistance. The invention also provides a method for preparing refractory castables containing in-situ carbon, which has a simple process and is beneficial to industrial production.

Owner:ZHENGZHOU UNIVERSITY OF AERONAUTICS

Preparation and application of a glucose-based porous carbon material

ActiveCN112619608BConvenient sourceLow costGas treatmentOther chemical processesHydrofluoric acidPorous carbon

The invention provides the preparation and application of a glucose-based porous carbon material. The method comprises the following steps: dissolving glucose in deionized water and stirring to obtain solution A; dissolving iron powder and trimesic acid in deionized water, and Add hydrofluoric acid and nitric acid dropwise, stir to obtain solution B; add solution A to solution B, stir evenly, transfer the resulting mixed solution into a stainless steel high-pressure reactor, and then heat to react; the reaction product is centrifugally washed with water, soaked in ethanol and vacuum-dried; The dried product is mixed with an activator, and then activated by heating to obtain an activated product; the activated product is sequentially subjected to pickling, water washing and vacuum drying to obtain a glucose-based porous carbon material. The glucose-based porous carbon material prepared by this method has high specific surface area, rich hierarchical pore structure and good VOCs adsorption performance.

Owner:FUZHOU UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com