Plasma method for preparing nano carbon material using coal liquefied residue as raw material

A technology of liquefied residue and plasma torch, which is applied to the chemical characteristics of fibers, textiles and papermaking, etc., can solve problems such as undiscovered, and achieve the effects of easy operation, easy control of parameters, and uniform diameter distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

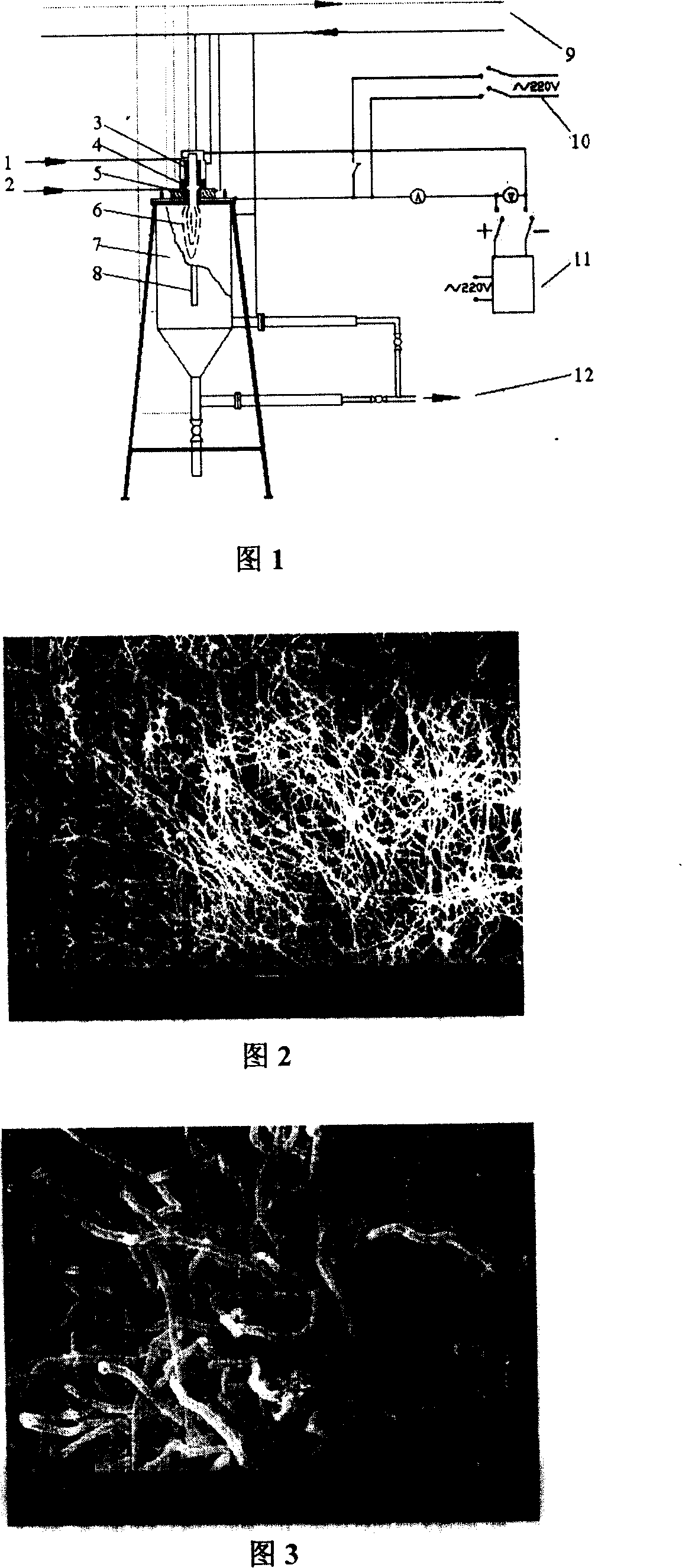

Method used

Image

Examples

Embodiment 1

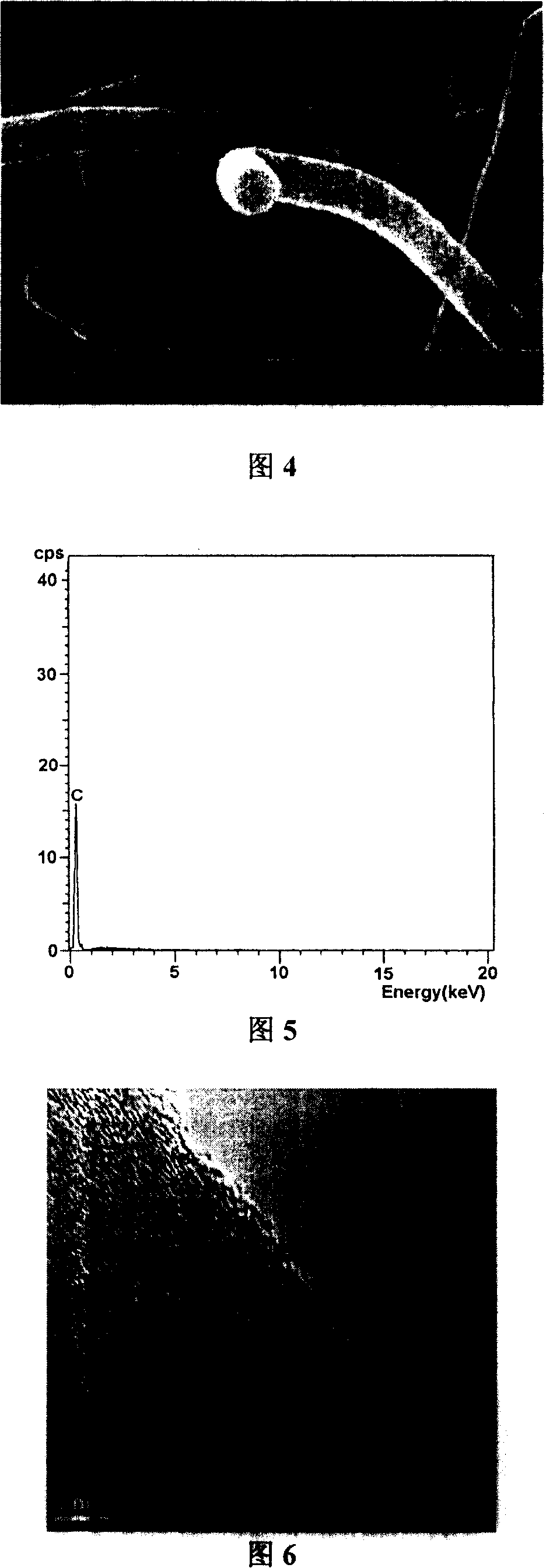

[0027] Put 20g of coal liquefaction residue without any treatment into the crucible and place it 35mm directly below the plasma torch nozzle. Cover the top cover of the reactor, and pass cooling water to the reaction system. Connect the high-frequency voltage power supply and the arc voltage power supply respectively, and then pass in the cathode carrier gas (cooling gas, nitrogen, purity 99.5%) with a flow rate of 4 m 3 / h, anode carrier gas (ionized gas, nitrogen, purity 99.5%) flow rate is 5m 3 / h; Turn on the power supply fan, start the high-frequency power supply to break down the anode ionized gas, ignite the arc, adjust the current to 220-240A, the voltage to 140-150V through the thyristor resistance, and the response time is 150s. After the reaction is over, close the electric, gas and water valves, open the reactor, and take out the product. The obtained product is detected by SEM, HRTEM and EDX, which proves that there are a large number of carbon nanofibers in the...

Embodiment 2

[0029] Put 30g of coal liquefaction residue without any treatment into the crucible and place it 35mm directly below the plasma torch nozzle. Cover the top cover of the reactor, and pass cooling water through the reaction system. Connect the high-frequency voltage power supply and the arc voltage power supply respectively, and then pass in the cathode carrier gas (cooling gas, nitrogen, purity 99.5%) with a flow rate of 4 m 3 / h, anode carrier gas (ionized gas, nitrogen, purity 99.5%) flow rate is 5m 3 / h; Turn on the power supply fan, start the high-frequency power supply to break down the anode ionized gas, ignite the arc, adjust the current to 220-240A and the voltage to 140-150V through the thyristor resistor, and keep the residence time of the reactant under the arc for 165s. After the reaction is over, close the electric, gas and water valves, open the top cover of the reactor, and take out the product. The obtained product is analyzed by SEM, HRTEM and EDX, which prov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com