Surface controllable oxidation graphitization mesophase carbon nanosphere negative electrode material and preparation method

A technology of mesocarbon microspheres and negative electrode materials, applied in battery electrodes, electrochemical generators, electrical components, etc., can solve the problems of reduced degree of graphitization, reduced cycle performance, reduced bulk density, etc., to promote immersion, The effect of increasing lithium storage sites and high platform capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Measure 150mLH respectively 2 SO 4 and 180mLHNO 3 Place in a round bottom flask with a volume of 500mL, stir for 5min and mix well. Weigh 8g of graphitized mesocarbon microspheres, add them into the mixed acid, and ultrasonicate for 20min. Then add 3gCrO to the mixture 3 , at 40 oC Stirring for 7h at high temperature. After the reaction was completed, it was cooled to room temperature and filtered to obtain a black solid. Use 5% hydrochloric acid solution to wash five times, then wash repeatedly with distilled water until neutral, and in a vacuum environment, 80 oC drying temperature. The dried black solid was then placed in a quartz tube furnace. Introduce argon as a protective gas, the gas flow rate is 100mL / min, with 10 o C / min heating rate from room temperature to 800 o C, keep warm for 10min, and then rapidly cool down to room temperature, so as to obtain a calcined product. The obtained calcined product is collected and set aside.

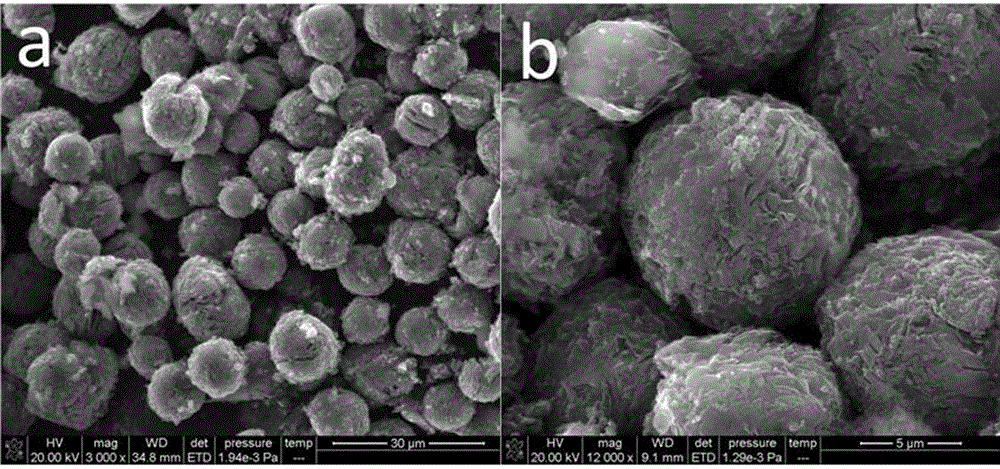

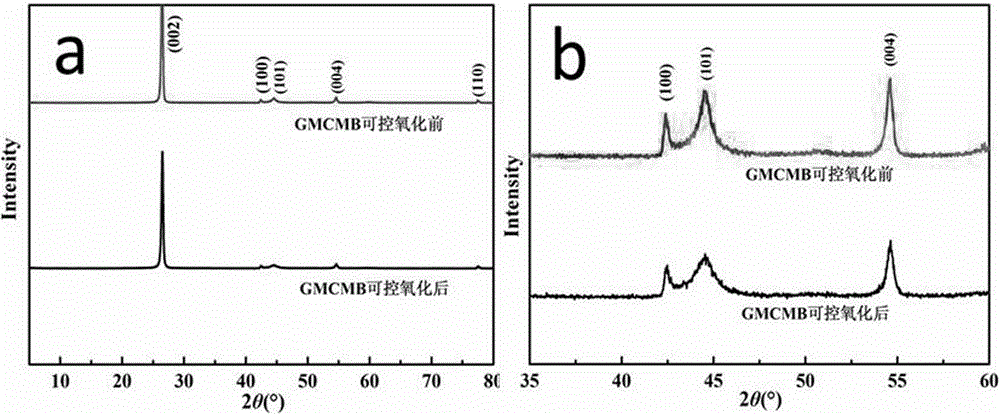

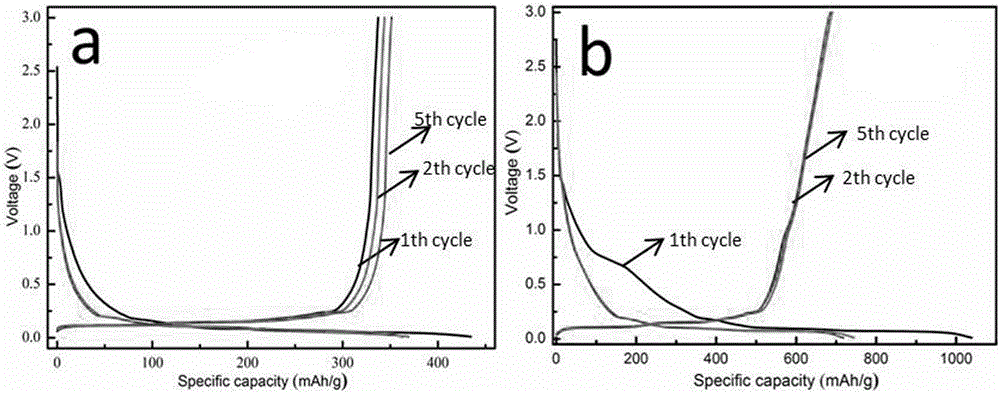

[0026] The morpholo...

Embodiment 2

[0035] Measure 130mLH respectively 2 SO 4 and 200mLHNO 3 Place in a round-bottomed flask with a volume of 500mL, and mix well by ultrasonication for 5min. Weigh 8 g of graphitized mesocarbon microspheres, add them into the mixed acid, and stir for 20 min. Then add 5gCrO to the mixture 3 , at 40 oC Stirring for 7h at high temperature. After the reaction was completed, it was cooled to room temperature and filtered to obtain a black solid. Use 5% hydrochloric acid solution to wash five times, then wash repeatedly with distilled water until neutral, and in a vacuum environment, 80 oC drying temperature. The dried black solid was then placed in a quartz tube furnace. Introduce argon as a protective gas, the gas flow rate is 200mL / min, with 10 o C / min heating rate from room temperature to 950 o C, keep warm for 15min, and then rapidly cool down to room temperature to obtain a calcined product. The obtained calcined product is collected and set aside.

Embodiment 3

[0037] Measure 150mLH respectively 2 SO 4 and 100mLH 3 PO 4 Place in a round bottom flask with a volume of 500mL, stir for 10min and mix well. Weigh 5 g of graphitized mesocarbon microspheres, add them into the mixed acid, and ultrasonicate for 20 min. Then add 2gCrO to the mixture 3 , at 60 oC Stirring at temperature for 24h. After the reaction was completed, it was cooled to room temperature and filtered to obtain a black solid. Use 10% hydrochloric acid solution to wash five times, then wash repeatedly with distilled water until neutral, and in a vacuum environment, 80 oC drying temperature. The dried black solid was then placed in a quartz tube furnace. Introduce helium as a protective gas, the gas flow rate is 150mL / min, with 15 o C / min heating rate from room temperature to 1000 o C, keep warm for 10min, and then rapidly cool down to room temperature, so as to obtain a calcined product. The obtained calcined product is collected and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com