Lanthanum doped monometallic catalyst for preparing carbon nano tube with uniform diameter and preparing process thereof

A technology of carbon nanotubes and single metals, applied in the field of catalysts for preparing carbon nanotubes, achieving high catalytic efficiency, uniform distribution, and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

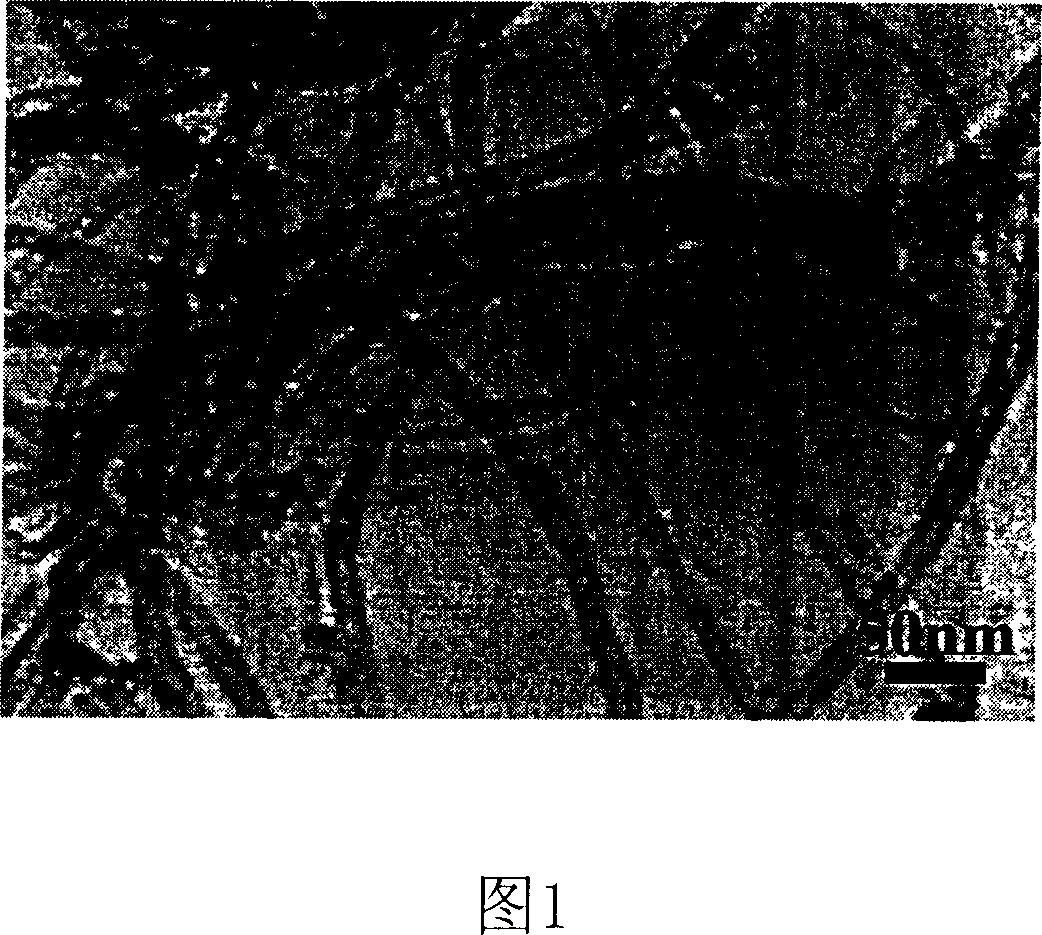

Image

Examples

Embodiment 1

[0018] A lanthanum-doped single metal oxide catalyst for preparing carbon nanotubes with uniform diameter, which uses magnesium oxide as a carrier, and the carrier is loaded with a nickel metal oxide component, a lanthanum-doped component and a catalytic component, the four The molar ratio is 50:10:1:50.

Embodiment 2

[0020] A lanthanum-doped single metal oxide catalyst for preparing carbon nanotubes with uniform diameter, which uses magnesium oxide as a carrier, and the carrier is loaded with a nickel metal oxide component, a lanthanum metal doped component and a catalytic component, four The molar ratio of those is 25:10:1:25.

Embodiment 3

[0022] A method for preparing a lanthanum-doped monometallic catalyst of uniform diameter carbon nanotubes, according to the molar ratio Co:La:Mo:Mg=5:5:75:125, weigh cobalt chloride, lanthanum carbonate, molybdenum acid For ammonium and magnesium chloride, first dissolve magnesium chloride in an appropriate amount of distilled water, then add cobalt chloride, lanthanum carbonate and ammonium molybdate in sequence, and wait until they are completely dissolved, then dry the solution at 160°C for 4 hours. Calcining the obtained product in air at 700° C. for 20 minutes and then pulverizing it to obtain a catalyst that can be used to prepare carbon nanotubes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com