Method for preparing graded mesoporous carbon nanocomposite nickel oxide material

A nanocomposite, mesoporous carbon technology, applied in the direction of nickel oxide/nickel hydroxide, nano carbon, etc., can solve the problems of low conductivity, low cycle stability, hindering commercial application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

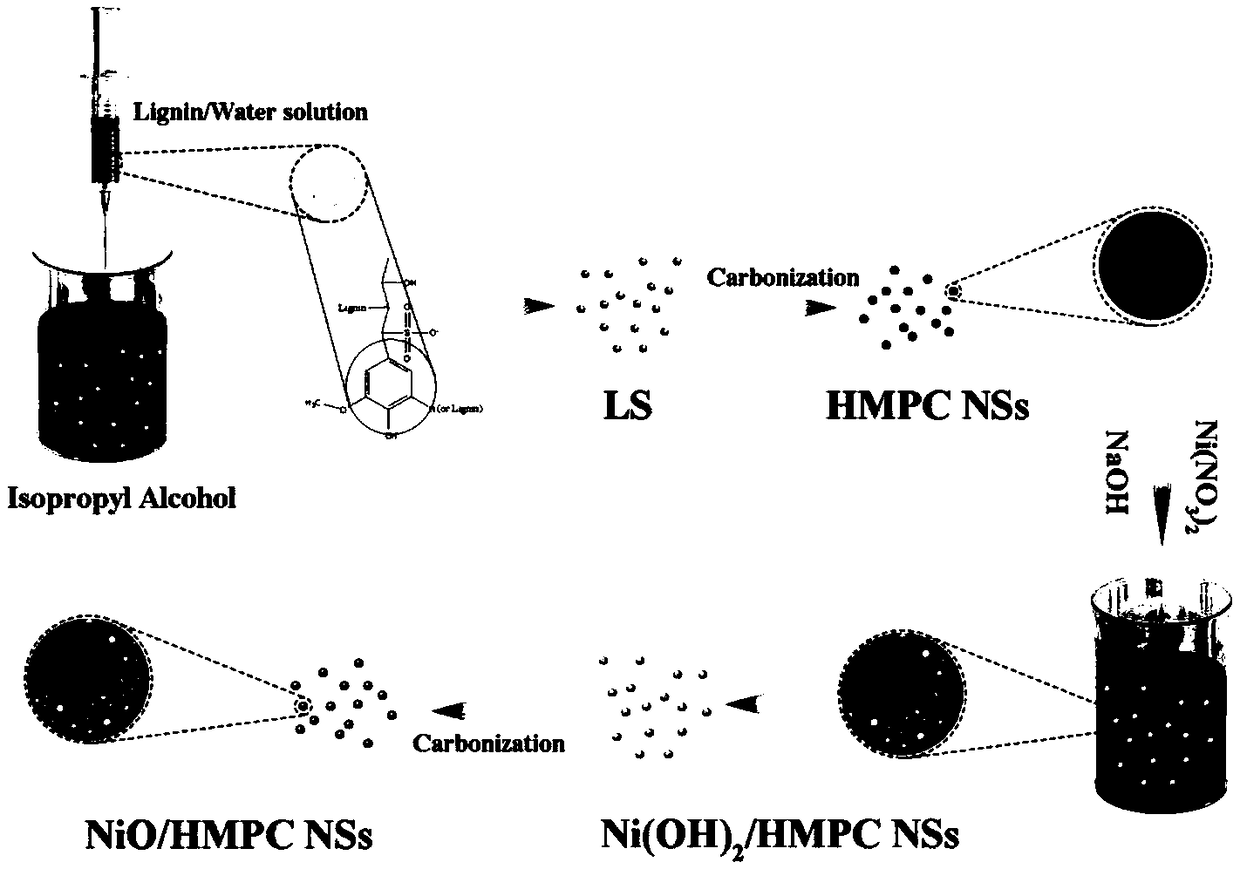

[0025] refer to Figure 1 to Figure 7 , a preparation method of hierarchical mesoporous carbon nanocomposite nickel oxide material, comprising the following steps:

[0026] (1) Sodium lignosulfonate is dissolved in deionized water and ultrasonically dissolved;

[0027] (2) Take isopropanol and place it in an ultrasonic water bath, and inject the solution obtained in step (1) into the isopropanol by means of an autosampler to obtain a suspension of lignin microspheres. The product is centrifuged and vacuum-dried to obtain lignin nanosphere powder (LS);

[0028] (3) the dried lignin nanosphere powder that step (2) obtains is placed in N 2 Calcined in a tube furnace in atmosphere to obtain hierarchical mesoporous carbon nanospheres (HMPC NSs).

[0029] (4) Put the HMPC NSs obtained in step (3) in sodium hydroxide and nickel nitrate solution to react to obtain HMPC NSs (Ni(OH) 2 / HMPC NSs).

[0030] (5) Ni(OH) obtained by step (4) 2 / HMPC NSs put N 2 The nickel oxide carbon...

example 1

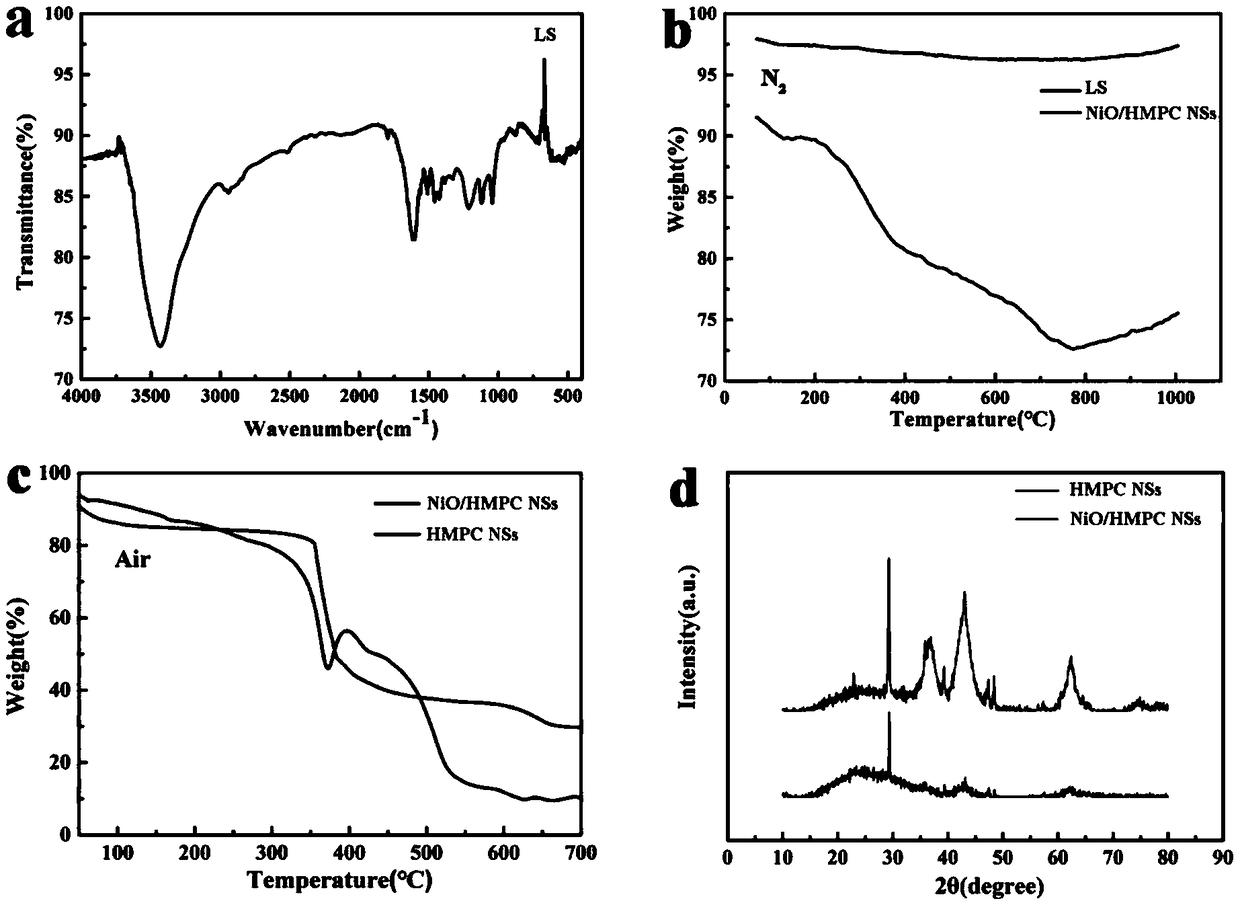

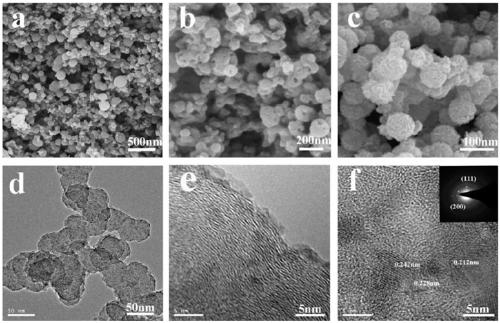

[0032] Example 1: if figure 1 shown. Dissolve 0.5g of sodium lignosulfonate in 20ml of deionized water, and ultrasonically dissolve. Take 40ml of isopropanol and place it in a 150w ultrasonic water bath, use a 30ml syringe to inject the sodium lignosulfonate aqueous solution into the isopropanol at a speed of 20ml / h by means of an automatic injector. A suspension of lignin microspheres was obtained. The reactant was centrifuged at 6000rpm for 5min, and dried in a vacuum oven at 60°C for 24h to obtain lignin microsphere powder (LS). Place the dry lignin nanosphere powder in N 2 Calcined in a tube furnace in atmosphere to obtain hierarchical mesoporous carbon nanospheres (HMPC NSs). Using HMPC NSs (0.5g) as a template, it was dispersed in 1mol / L NaOH solution for 2 hours. Add 1mol / L nickel nitrate solution and stir for 10min, then seal it in a 30ml autoclave with polytetrafluoroethylene, store at 180°C for 10h, centrifuge at 3000rpm for 10min, wash with water and ethanol th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com