Preparation method for biomass-based nitrogen-doped thin layer graphitized carbon material

A thin-layer graphite, nitrogen-doped technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve the problems of uncontrollable surface structure, low degree of graphitization, and thick graphitic carbon-carbon layer, and achieve thin graphite. layer, the synthesis method is simple, and the effect of good graphitization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) First put 1g of lignin into a round bottom bottle, add 10mL of 0.1mol / L acetic anhydride solution and 10ml of 0.1mol / L nitric acid, stir at room temperature for 5h, then add 1mol / L sodium hydroxide solution Adjust the pH to neutral, and finally extract with tetrahydrofuran to obtain nitrated lignin;

[0023] (2) Take 0.5g of nitrolignin obtained in step 1) and dissolve it in 50% ethanol solution, add a little iron powder, drop in 2ml of hydrochloric acid, heat up to 130°C, react for 6h, then add dropwise sodium hydroxide solution (1mol / L) adjusting the pH to alkaline, centrifuging, washing, and drying to obtain nitrogen-doped lignin;

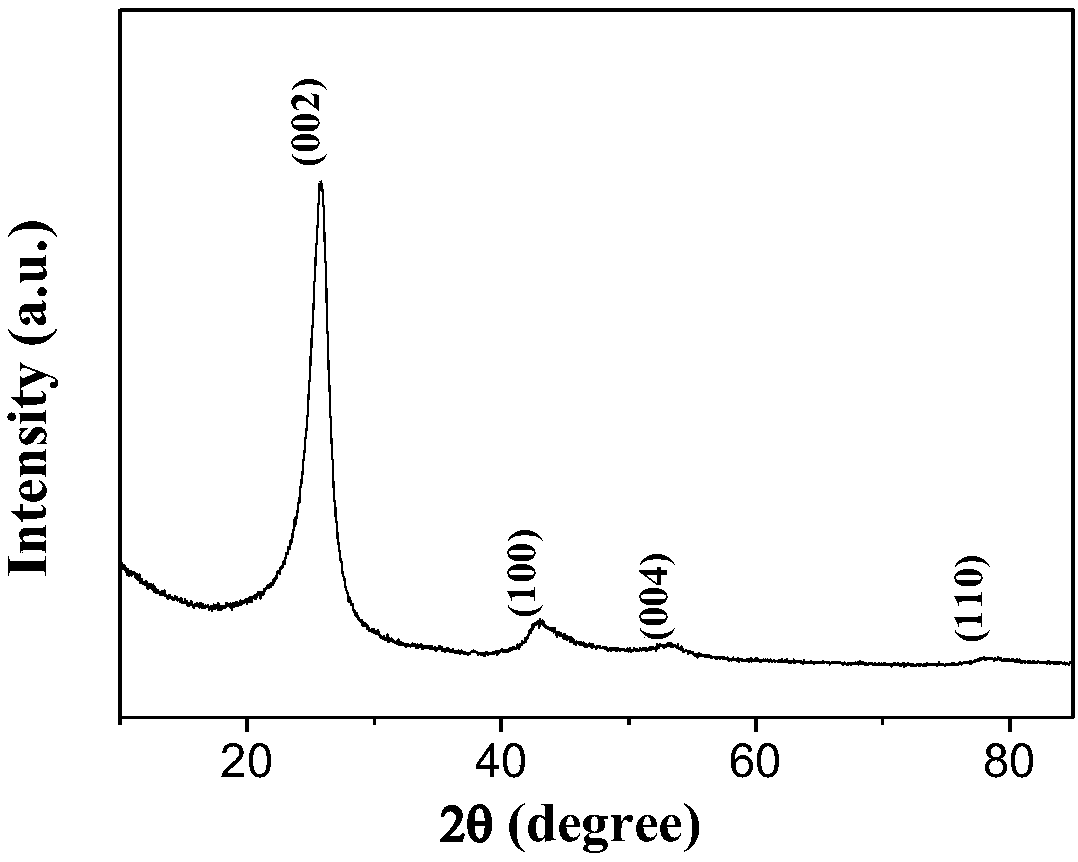

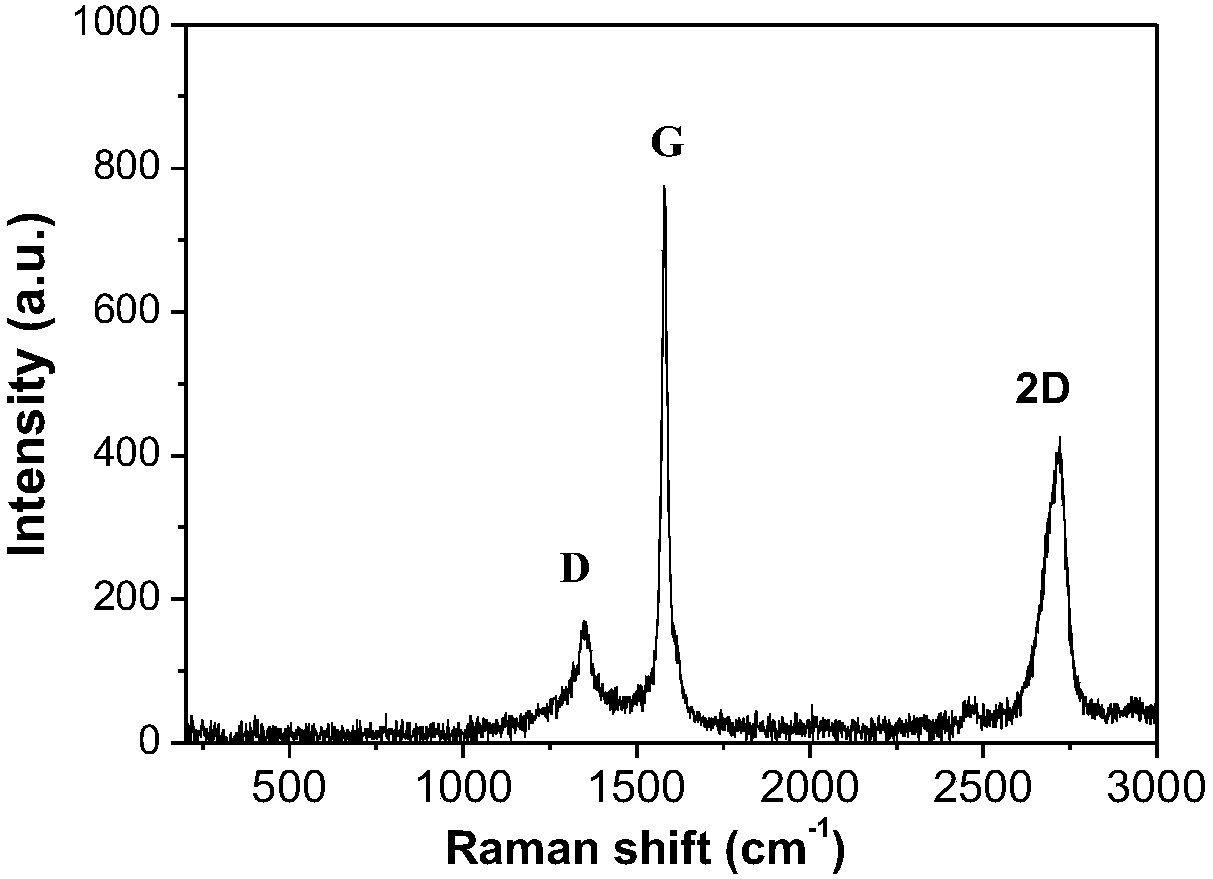

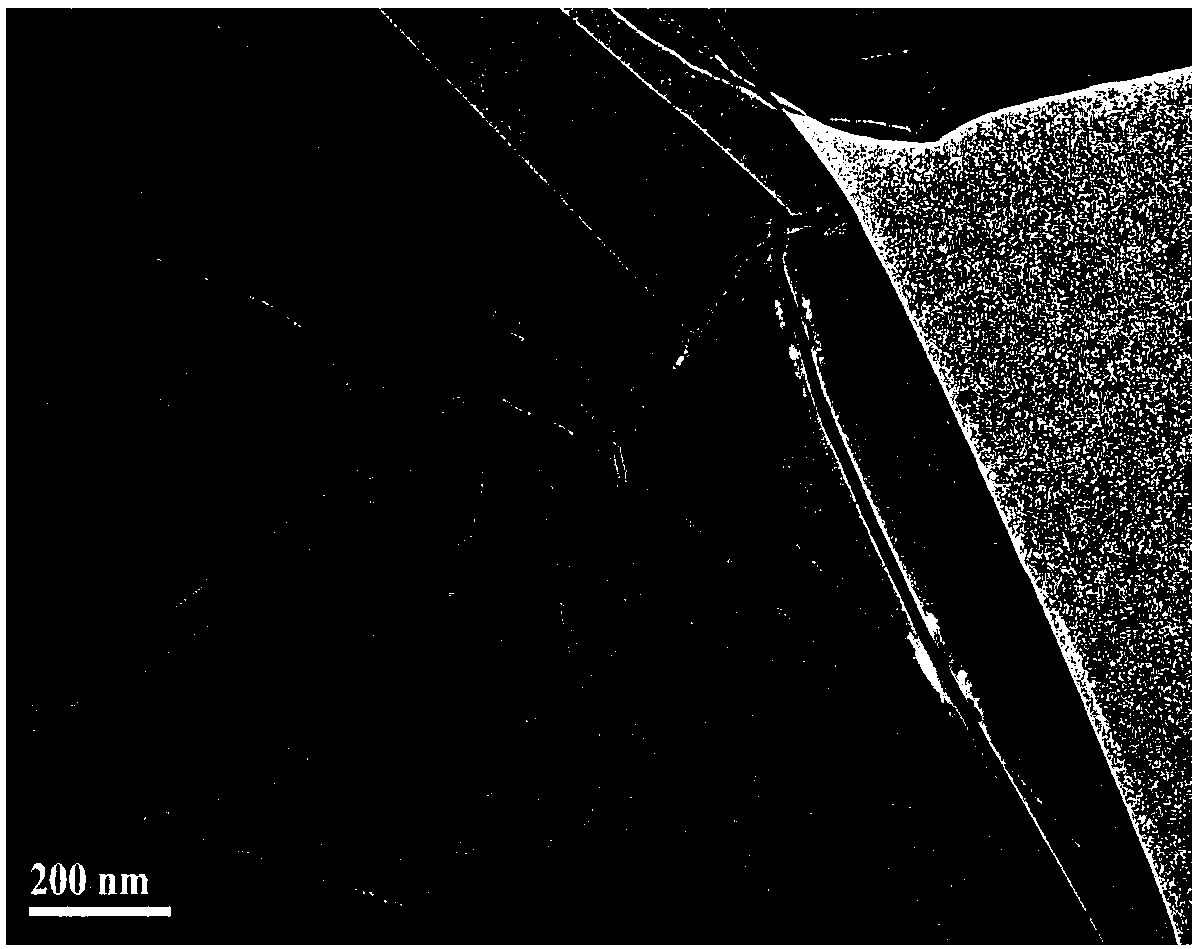

[0024] (3) The nitrogen-doped lignin precursor obtained in step 2) was placed in a high-temperature furnace, and the temperature was raised to 1200 °C at a rate of 2 °C / min in an argon atmosphere, and the flow rate of the inert gas was 50 mL / min. After carbonizing at 1200° C. for 3 hours, cool naturally to room temperature to obtain...

Embodiment 2

[0027] (1) First put 1g of lignin into a round bottom bottle, add 10mL of 0.1mol / L acetic anhydride solution and 10ml of 0.1mol / L nitric acid, stir at room temperature for 5h, then add 1mol / L sodium hydroxide solution Adjust the pH to neutral, and finally extract it with tetrachloromethane to obtain nitrified lignin;

[0028] (2) Take 0.5g of nitrated lignin obtained in step 1) and dissolve it in 50% ethanol solution, add a little iron powder, drop in 2ml of hydrochloric acid, heat up to 130°C, react for 6h, and then add dropwise sodium hydroxide solution (1mol / L) adjusting the pH to alkaline, centrifuging, washing and drying to obtain nitrogen-doped lignin.

[0029] (3) The nitrogen-doped lignin precursor obtained in step 2) was placed in a high-temperature furnace, and the temperature was raised to 1200 °C at a rate of 2 °C / min in an argon atmosphere, and the flow rate of the inert gas was 50 mL / min. After carbonization at 1000° C. for 3 h, it was naturally cooled to room ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com