High thermal conductivity of graphite material and preparation method and application thereof

A technology of high thermal conductivity graphite and graphite materials, applied in the field of carbon materials, can solve environmental pollution and other problems, and achieve the effects of lower overall cost, lower production cost, and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

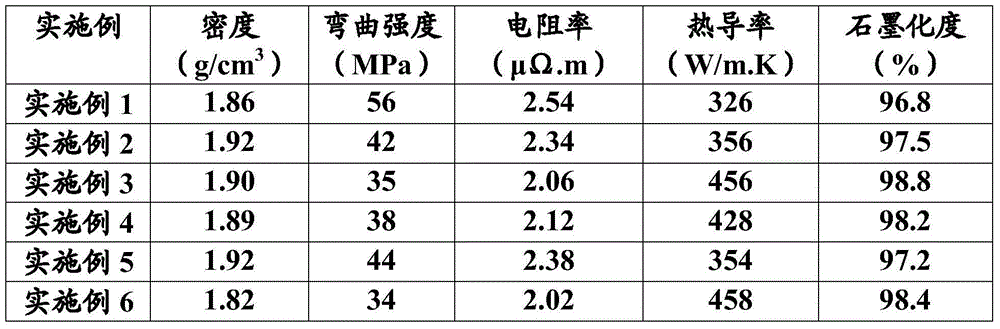

Embodiment 1

[0060] First, the natural flake graphite tailings, mesocarbon microspheres and TiB 2 Weigh in a weight ratio of 32:63:5 and mix in a high-speed mixer for 2 hours. Then take a certain amount of mixed material and put it into a steel mold, form it on a flat vulcanizer with a pressure of 100 MPa, hold the pressure for 10 minutes and demould to obtain a green body. Put the green body in a graphitization furnace, under the protection of nitrogen, first raise the temperature to 900°C at a heating rate of 2°C / min, and keep it for 30 minutes; then raise it to 1300°C at a heating rate of 5°C / min, and hold 20 minutes; finally, the temperature was raised to 2000°C at a heating rate of 10°C / min, kept at a temperature of 60 minutes, and naturally cooled to 100°C to obtain the high thermal conductivity graphite material of the present invention. Its physical properties are shown in Table 1.

Embodiment 2

[0062] First, artificial graphite tailings, mesocarbon microspheres and TiC were weighed in a weight ratio of 50:46:4, and mixed in a high-speed mixer for 1 hour. Then take a certain amount of mixed material and put it into a steel mold, form it on a flat vulcanizer with a pressure of 200 MPa, hold the pressure for 5 minutes and demould to obtain a green body. Put the green body in a graphitization furnace, under the protection of nitrogen, first raise the temperature to 900°C at a rate of 2°C / min, and keep it for 20 minutes; then raise the temperature to 1300°C at a rate of 3°C / min, keep it 30 minutes; finally, the temperature was raised to 2200° C. at a heating rate of 15° C. / min, kept for 40 minutes, and naturally cooled to 100° C. to obtain the high thermal conductivity graphite material of the present invention. Its physical properties are shown in Table 1.

Embodiment 3

[0064] First, the natural flake graphite tailings, mesocarbon microspheres and B 4 C is weighed at a weight ratio of 64:33:3, and mixed in a high-speed mixer for 3 hours. Then take a certain amount of mixed material and put it into a steel mold, form it on a flat vulcanizer with a pressure of 240 MPa, hold the pressure for 1 minute and demould to obtain a green body. Put the green body in a graphitization furnace, under the protection of nitrogen, first raise the temperature to 900°C at a rate of 1°C / min, and keep it for 20 minutes; then raise the temperature to 1300°C at a rate of 5°C / min, and keep it 20 minutes; finally, the temperature was raised to 2000° C. at a heating rate of 20° C. / min, kept for 40 minutes, and naturally cooled to 100° C. to obtain the high thermal conductivity graphite material of the present invention. Its physical properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com