Carbon micro-tube epoxy resin wave-absorbing composite material and preparation method thereof

A technology of carbon microtubes and epoxy resin, applied in nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of poor strength of composite radar absorbing materials, low elastic modulus of hollow fibers, and cumbersome preparation process, etc., to achieve The effect of good graphitization degree, large lumen and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific Embodiment 1: A carbon microtube epoxy resin wave-absorbing composite material in this embodiment is made of 0.1%~1.0% carbon microtube and 99.0%~99.9% epoxy resin glue by mass percentage; Among them, carbon microtubes are made of urea and ethylene glycol at a mass ratio of 50 to 100:1; epoxy resin glue is made of 100 parts of bisphenol A epoxy resin, 5 parts to 10 parts It is composed of acetone and 8-12 parts of diethylenetriamine.

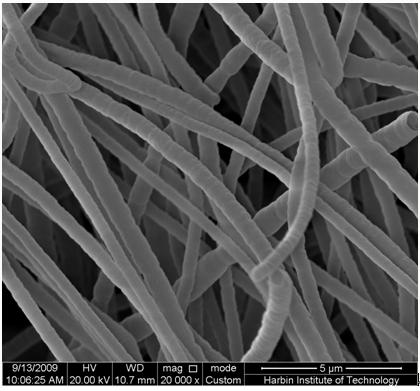

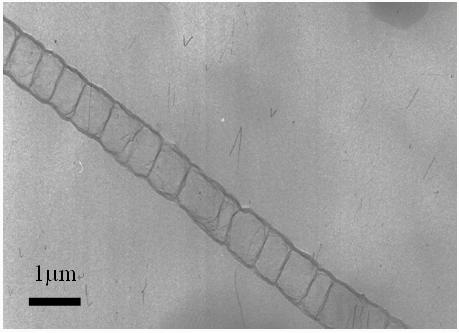

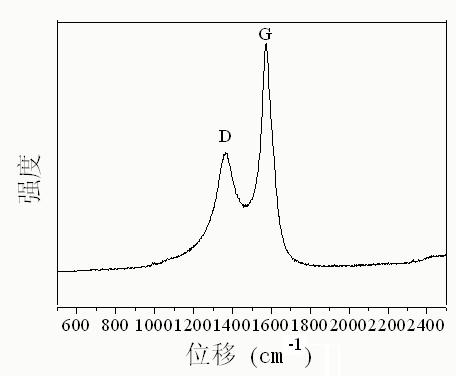

[0010] The carbon microtubes of this embodiment are bamboo-shaped carbon microtubes with a diameter of 0.5 μm to 1 μm and a wall thickness of about 10 nm. The carbon microtubes are synthesized in situ at low temperature, have a good degree of graphitization, and are During the process, the amino group is grafted on the surface of the hollow carbon fiber, which significantly improves the combination with the epoxy resin matrix, and does not require any surface treatment during the preparation of the composite material. The elasti...

specific Embodiment approach 2

[0011] Embodiment 2: The difference between this embodiment and Embodiment 1 is that a carbon microtube epoxy resin wave-absorbing composite material is composed of 0.2%~0.9% carbon microtubes and 99.1%~99.8% carbon microtubes by mass percentage. Made of epoxy glue. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0012] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: a carbon microtube epoxy resin wave-absorbing composite material is composed of 0.5% carbon microtubes and 99.5% epoxy resin glue by mass percentage made. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com