Method for reducing carbon dioxide into porous carbon material, and porous carbon material and application thereof

A porous carbon material, carbon dioxide technology, applied in the direction of nano-carbon, carbon preparation/purification, graphene, etc., to achieve high electrical conductivity, good crystallization performance, and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Preparation of dense porous carbon materials: Taking pure magnesium as an example, 15 g of Mg powder was placed in Al 2 o 3 vessel, in gentle CO 2 Under air flow (flow rate: 60 Sccm), heat in a tube furnace at 680° C. for 6 h. After the reaction, the black product was collected and stirred in 2.0M HCl solution for 10 h at room temperature to remove MgO. The mixture was then filtered and rinsed several times with deionized water until the pH of the filtrate reached around neutral. Finally, the separated solid carbon product was rinsed with ethanol and dried overnight at room temperature. The resulting product is called C-Ms.

Embodiment 2

[0040] Change pure magnesium into the mixture of magnesium and zinc, repeat the operation process of embodiment 1, the product obtained is called C-MZ-n, when the Zn / Mg ratio is greater than or equal to 3, the product is called C-MZ-3, measure The analysis results are as follows:

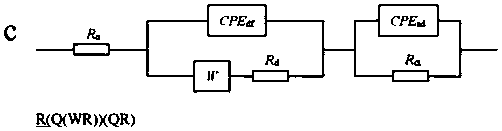

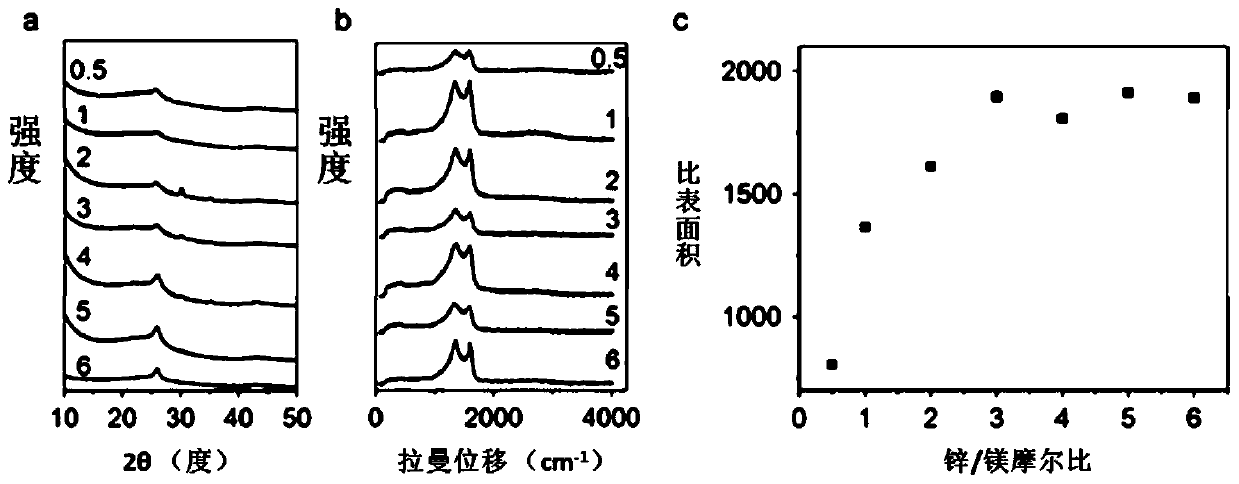

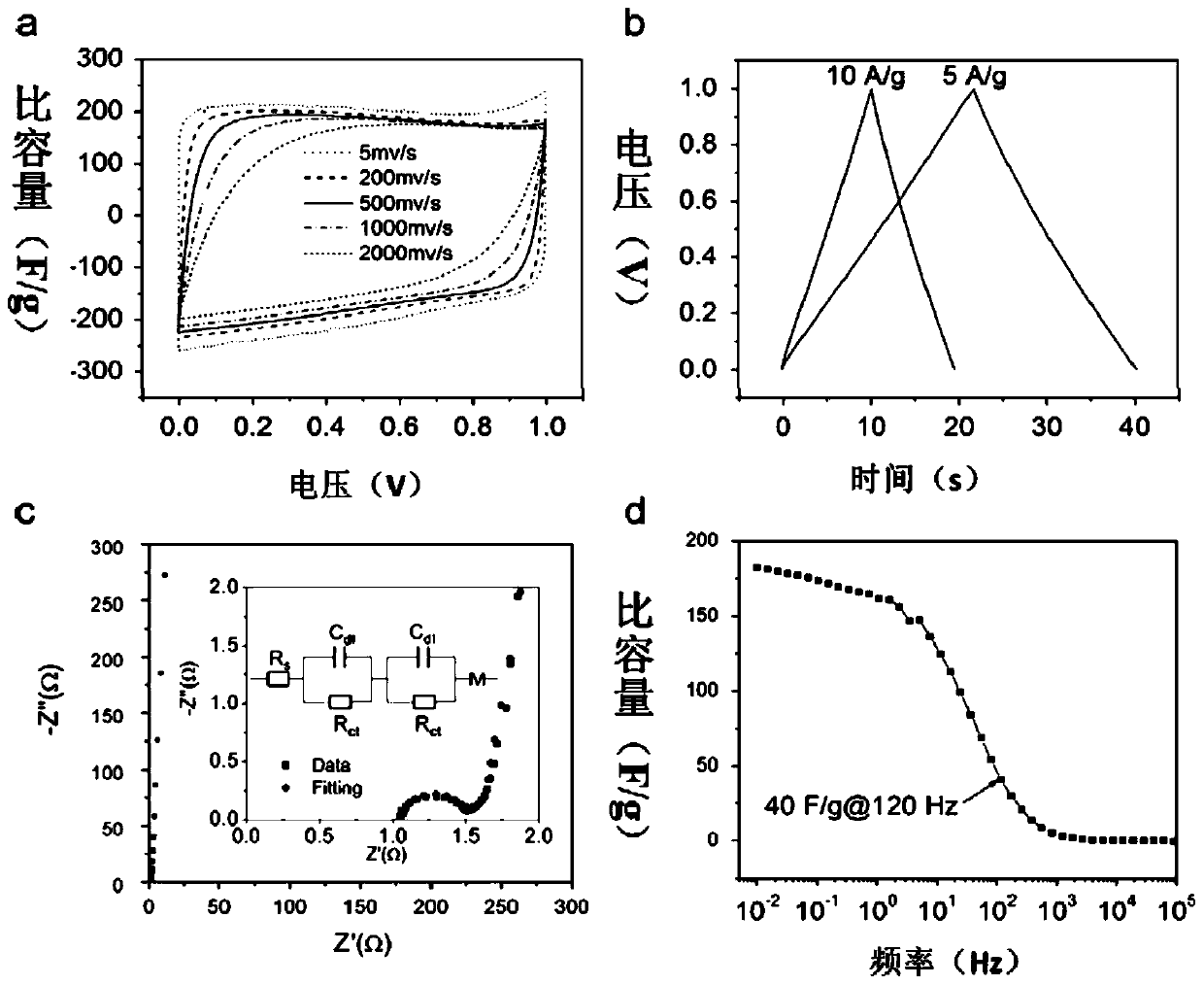

[0041] Compared with C-Ms, the specific surface area of C-MZ-n is indeed significantly increased, when the Zn / Mg ratio is greater than or equal to 3, it is 1900m 2 ( figure 1 c). When pure Zn is used as reducing agent for CO 2 During the reduction of Zn, although Zn was oxidized to ZnO, no carbon black was formed after the simple visual reaction. Furthermore, compared with C-Ms, the graphitic crystal features of all C-MZ-n are obviously weakened, which can be seen from the lower resolution XRD peaks and higher ID / IG ratio in Raman spectra ( figure 1 a, figure 1 b).

[0042] The nanoporosity of C-MZ-n, C-MZ-3 was observed by transmission electron microscopy (TEM). C-MZ-3 consists of densely ...

Embodiment 3

[0046] Replace pure magnesium with a mixture of magnesium and copper, and use a mixture of Mg and Cu powders with an equal ratio of substances, at 60SCCMCO 2 Heating at 680°C for 12h under airflow. After the product is cooled, stir it with 2mol / L HCl solution for 12 hours to remove MgO, remove Cu with concentrated ammonia water and oxygen, then filter and wash the mixture several times with deionized water and ethanol, and finally, dry the product at 80 degrees Celsius overnight . The resulting carbon product C-Mg / Cu. As a comparison, the carbon product using Mg alone is called C-Ms, and the measurement and analysis results are as follows:

[0047] By comparing the XRD patterns of C-Mg and C-Mg / Cu, it can be seen that the addition of copper greatly improves the crystallinity of the material. Electron microscopy (HRTEM) images confirmed the highly graphitized structure of C-Mg / Cu, where graphene layers are ordered stacked tens of nanometers in C-Mg / Cu and less than 20 nm in ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com