Method for preparing high-ratio graphite-type nitrogen-doped graphene tube in template-free one-step method

A graphite-type nitrogen and graphene tube technology, applied in the field of nanomaterials, can solve the problems of complex nitrogen-doped graphene tube process, low proportion of graphite-type nitrogen doping content, and low purity of graphene tubes, etc., to achieve easy control, Ease of mass production and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

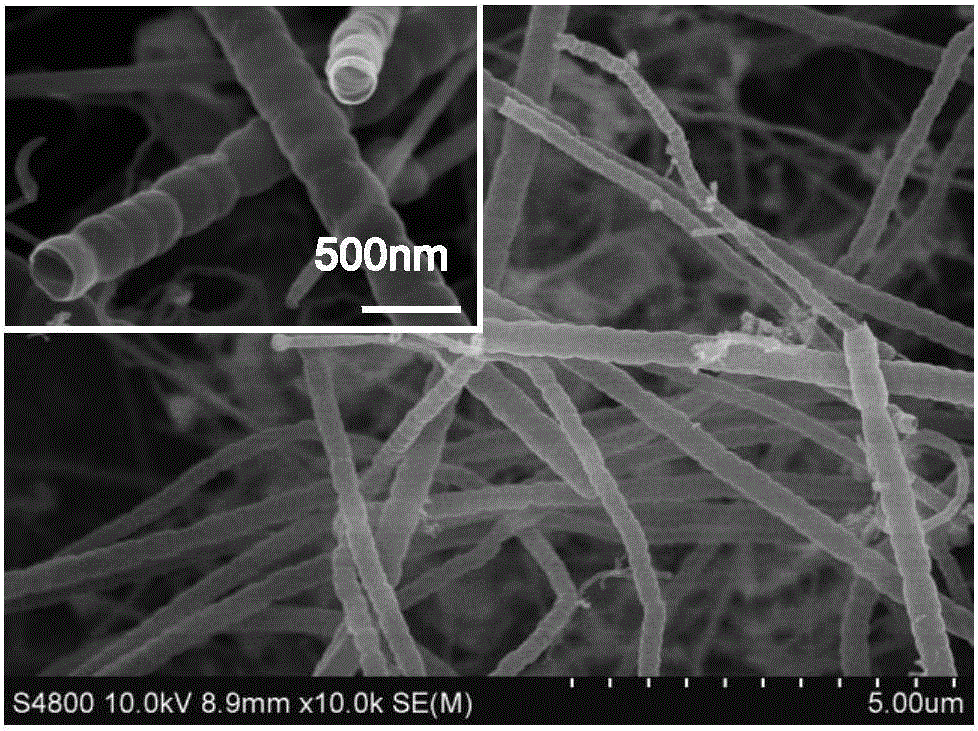

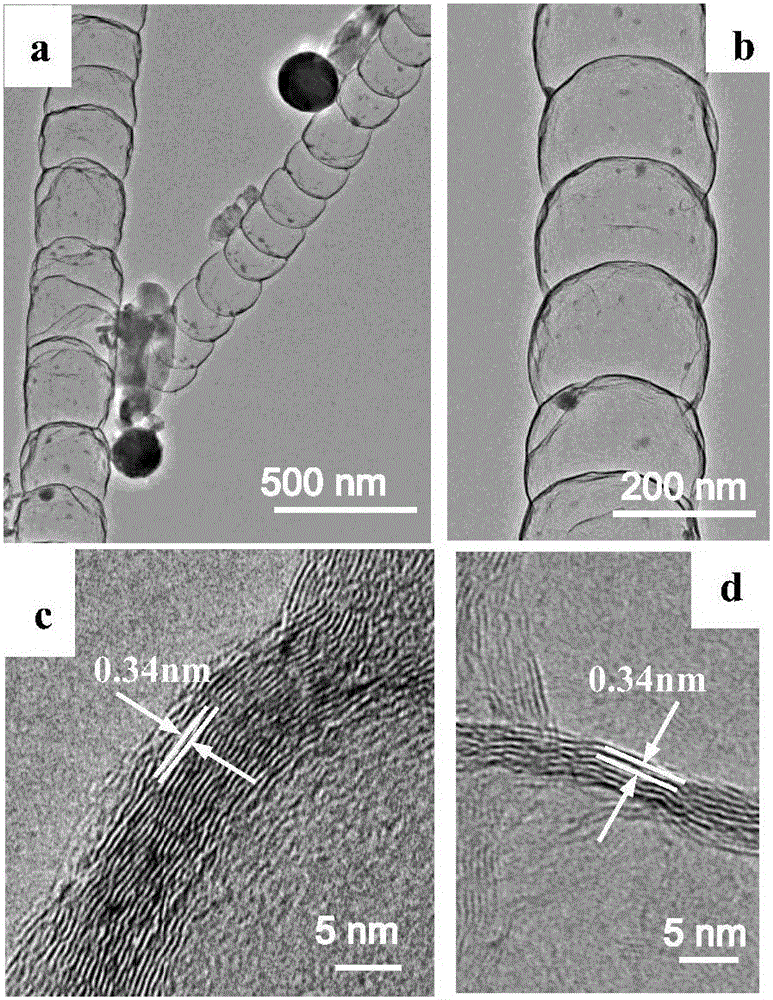

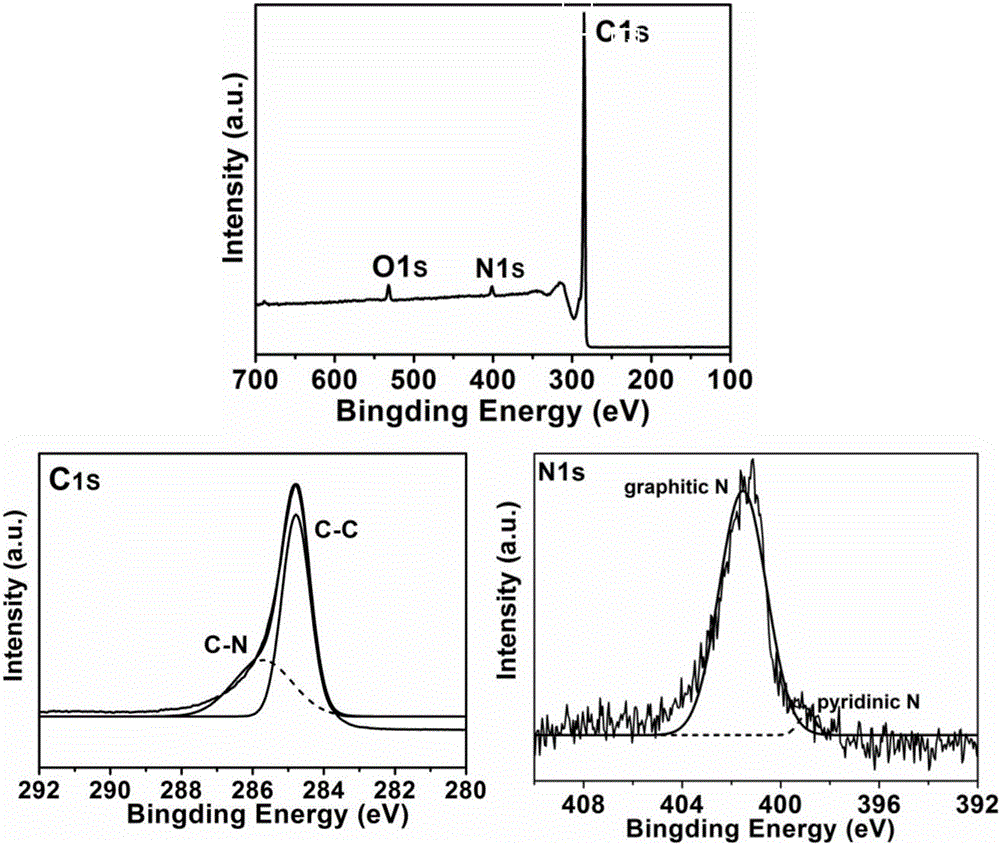

[0020]Select commercially available analytically pure melamine as the reaction raw material, Si powder with a purity of 99.5% as the auxiliary material, weigh 4.725g of melamine and 0.7g of the Si powder auxiliary material, put them into an agate mortar and grind for 40min; The smooth circular graphite sheet was used as the reaction substrate. After the graphite substrate was cleaned and dried in an ultrasonic cleaner, it was immersed in a pre-prepared Ni(NO 3 ) 2 Ethanol solution for 5 minutes, take it out and dry it in the air for later use; place the mixed raw material obtained by grinding on the carbon cloth, place the graphite substrate impregnated with the catalyst on the top of the mixed raw material, and place it in the graphite reaction chamber at a distance of 3-5mm from the raw material , and then put the graphite reaction chamber into the vacuum controllable atmosphere furnace; start the vacuum system, evacuate the vacuum controllable atmosphere furnace to 50-80Pa,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com