Preparation method and application of novel carbon and silicon-based composite material

A technology of silicon composite materials and composite materials, applied in nanotechnology for materials and surface science, active material electrodes, electrical components, etc., can solve the problems of unrealized commercial production, high difficulty, low output, etc., and achieve excellent The degree of graphitization, the increase of added value, and the effects of a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

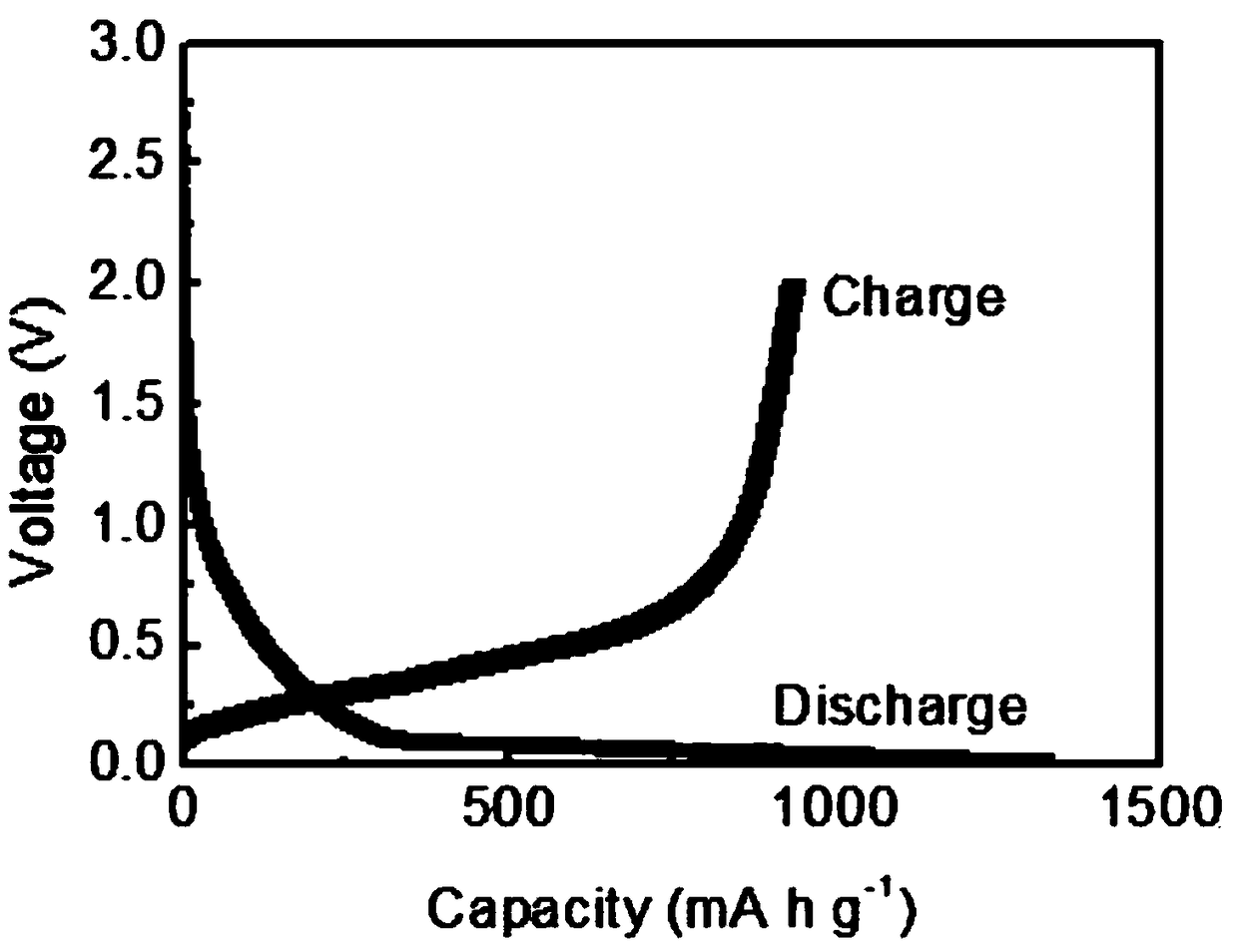

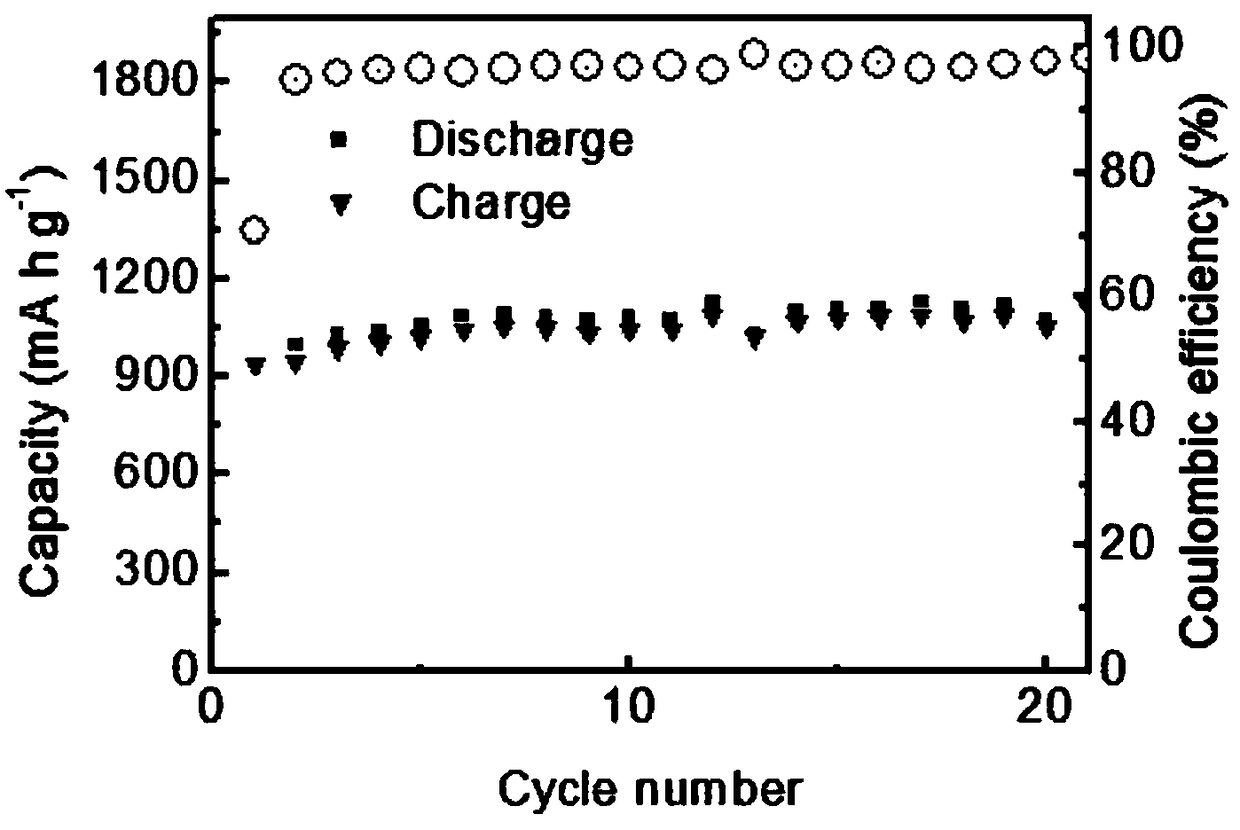

Examples

Embodiment 1

[0030] A preparation method of a novel carbon-silicon-based composite material, the specific steps are as follows:

[0031] S1. Add 8 g of sucrose to 200 mL of distilled water to obtain an aqueous sucrose solution with a concentration of 0.04 g / mL;

[0032] S2. Add 0.1 g of silicon powder to 20 mL of the sucrose aqueous solution obtained in S1, and disperse evenly by ultrasonic waves. Place the dispersed solution in a porcelain boat, stir for 12 h, and preliminarily dry at room temperature for 8 h to obtain a reactant;

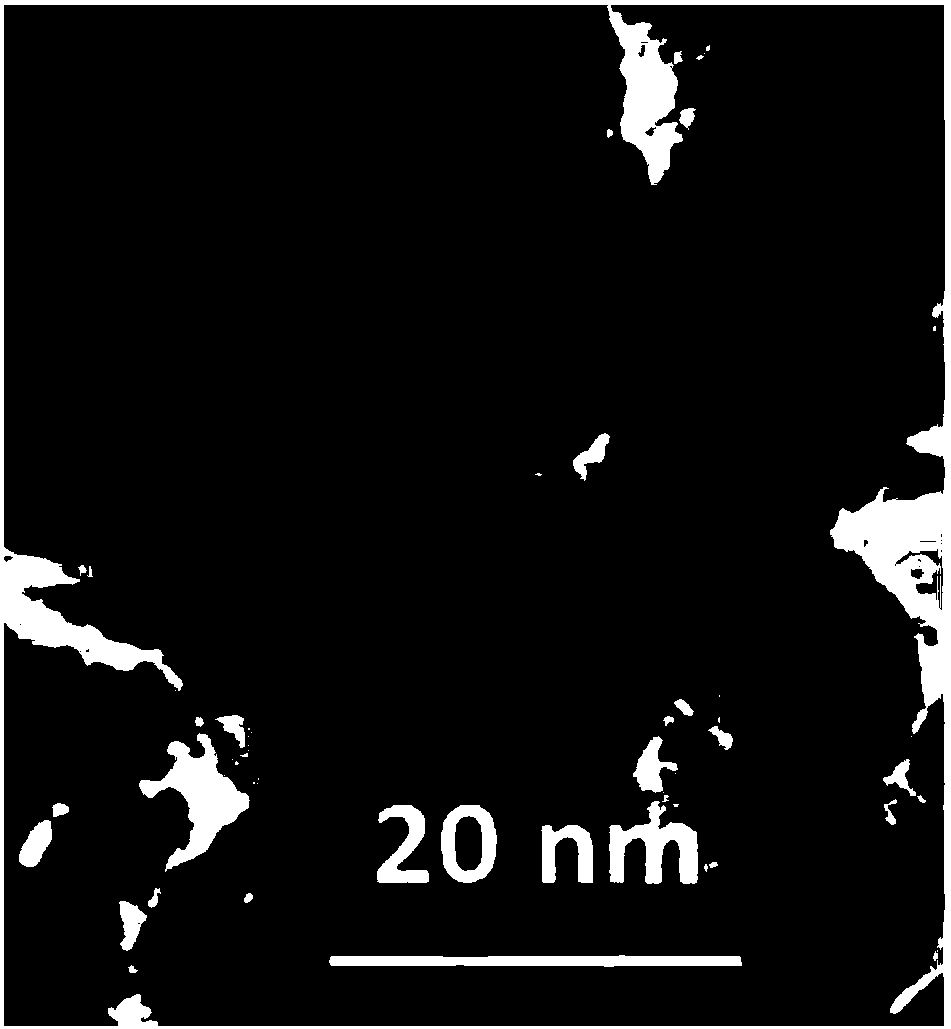

[0033] S3. Calcining the reactant obtained in S2 in a tube furnace at 1173K for 2 hours in a high-purity nitrogen atmosphere, after washing and centrifuging, drying in a vacuum oven at 373K for 8 hours to obtain a primary carbon-silicon composite material;

[0034] S4. Add 0.1 g of graphite fibers to 0.1 g of primary carbon-silicon composite material obtained in S3, disperse uniformly in an ethanol solution by ultrasonic, stir for 4 h, and dry at room temperat...

Embodiment 2

[0036] A preparation method of a novel carbon-silicon-based composite material, the specific steps are as follows:

[0037] S1. Add 3.2 g of sucrose to 200 mL of distilled water to obtain an aqueous sucrose solution with a concentration of 0.016 g / mL;

[0038] S2. Add 0.1 g of silicon powder to 50 mL of the sucrose aqueous solution obtained in S1, disperse evenly by ultrasonic, place the dispersed solution in a porcelain boat, stir for 15 h, and preliminarily dry at room temperature for 12 h to obtain a reactant;

[0039] S3. Calcining the reactant obtained in S2 in a tube furnace at 1123K for 2.5 hours in a high-purity nitrogen atmosphere, after washing and centrifuging, drying in a vacuum oven at 373K for 10 hours to obtain a primary carbon-silicon composite material;

[0040] S4. Add 0.12g of graphite fibers to 0.24g of the primary carbon-silicon composite material obtained in S3, disperse uniformly in an ethanol solution by ultrasonic, stir for 11 hours, and dry at room te...

Embodiment 3

[0042] A preparation method of a novel carbon-silicon-based composite material, the specific steps are as follows:

[0043] S1. Add 6 g of sucrose to 300 ml of distilled water to obtain an aqueous solution of sucrose with a concentration of 0.02 g / mL;

[0044] S2. Add 0.1g of silicon powder to 80mL of the sucrose aqueous solution obtained in S1, and disperse evenly in the ethanol solution by ultrasonic, put the dispersed solution in a porcelain boat, stir for 12h, and preliminarily dry at room temperature for 8h to obtain the reactant ;

[0045] S3. Calcining the reactant obtained in S2 in a tube furnace at 1273K for 2 hours in a high-purity nitrogen atmosphere, after washing and centrifuging, drying in a vacuum oven at 363K for 12 hours to obtain a primary carbon-silicon composite material;

[0046]S4. Add 0.6 g of graphite fibers to 0.3 g of the primary carbon-silicon composite material obtained in S3, disperse uniformly by ultrasonic, stir for 10 h, and dry at room tempera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com