Method for preparing conducting polymer micro-nanofibers in magnetic spinning mode

A conductive polymer, micro-nano fiber technology, applied in the direction of conjugated synthetic polymer rayon, fiber processing, fiber chemical characteristics, etc., can solve the problems of morphology, size controllability and regularity, template removal trouble, Solvent volatilization waste and other problems, to achieve the effect of reducing production costs and safety hazards, low production equipment requirements, and orderly arrangement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for preparing conductive polymer micro-nano fibers by magnetic spinning, comprising the following steps:

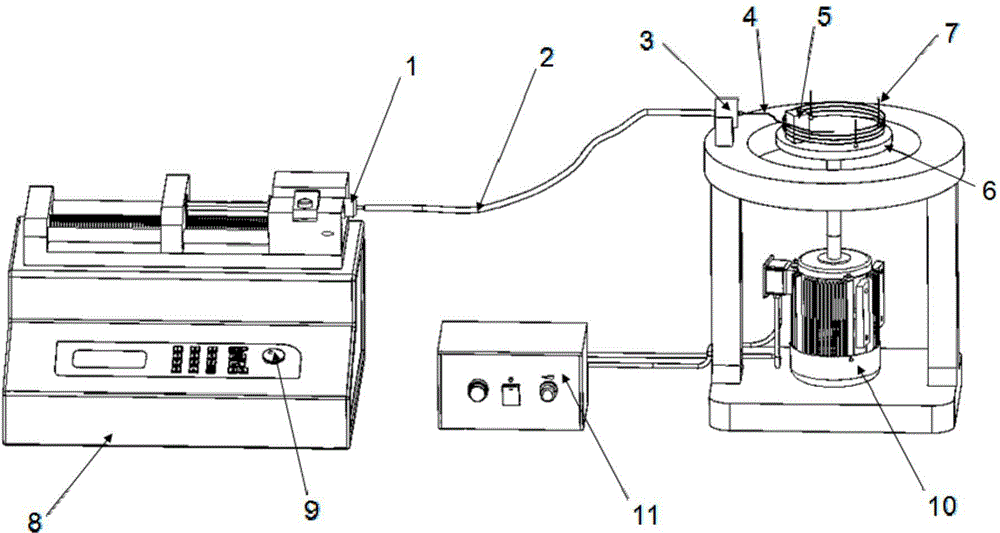

[0027] (1) The construction of the magnetic spinning device: the magnetic spinning device is as follows: figure 1As shown, it includes a feeding device that can control the feeding rate, a spinning nozzle 4, a nozzle driving mechanism and a spinning receiving device, and the spinning receiving device includes a horizontally arranged collecting disc 6, and the collecting disc 6 The center of the bottom circle is connected with the output shaft of the DC brushless motor 10, and the DC brushless motor 10 is electrically connected to the power supply and the motor controller 11 for controlling the motor speed. The upper surface of the collecting disc 6 is symmetrical about the central axis of the disc. A plurality of vertical pillars are set, and the vertical pillars are 4, of which 1 is a permanent magnet 5, and 3 are metal fine needles 7, and the spinning no...

Embodiment 2

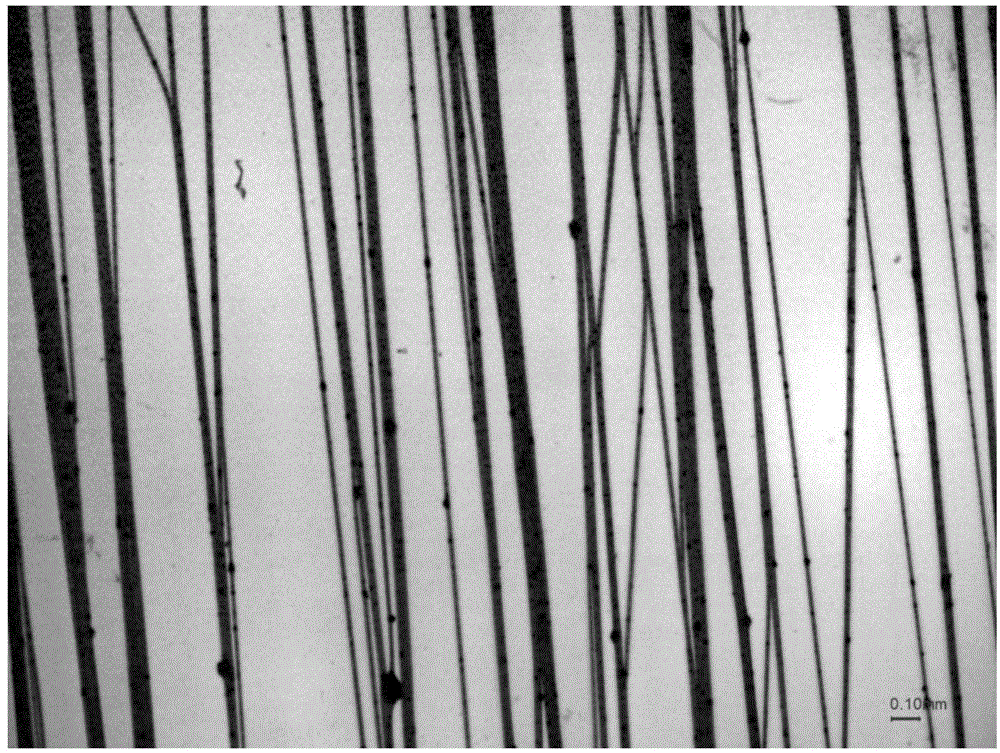

[0031] Post-treatment is carried out to the conductive polymer micro-nanofibers obtained in Example 1: the conductive polymer micro-nanofibers (PEDOT / γ-Fe) obtained in step (3) of Example 1 2 o 3 Composite micro-nanofibers) were soaked and oxidized in a mixed solution of sulfuric acid and nitric acid with a volume ratio of 3:1, the oxidation temperature was 80°C, and the time was 48 hours, then the micro-nanofibers were taken out and washed with deionized water and alcohol for 6 times Dry in vacuum at 110°C. The conductive polymer micro-nanowire without magnetic particles can be obtained.

Embodiment 3

[0033] A method for preparing conductive polymer micro-nano fibers by magnetic spinning, its steps are similar to embodiment 1, the difference is: step (2) preparation of spinning precursor solution: select sodium dodecylbenzene sulfonate as surfactant, Gamma-Fe with a diameter of 20 nm 2 o 3 Disperse the magnetic nanoparticles into chloroform, add surfactants with the same quality as the magnetic nanoparticles, and prepare γ-Fe 2 o 3 A magnetic fluid solution with a mass fraction of 11.5% of magnetic nanoparticles; 2.2 grams of polyvinylidene fluoride with a molecular weight of 270,000 was added to a mixed solution of 3.8 grams of N,N-dimethylformamide and 3.8 grams of acetone, heated in a water bath at 40°C and magnetically stirred for 3 After 1 hour, add 2.2 grams of polyaniline to prepare a polyaniline solution, heat in a water bath at 40°C and stir magnetically for 12 hours to mix the solution evenly to obtain a conductive polymer solution; the conductive polymer soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com