Patents

Literature

52results about How to "Reduce production safety" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

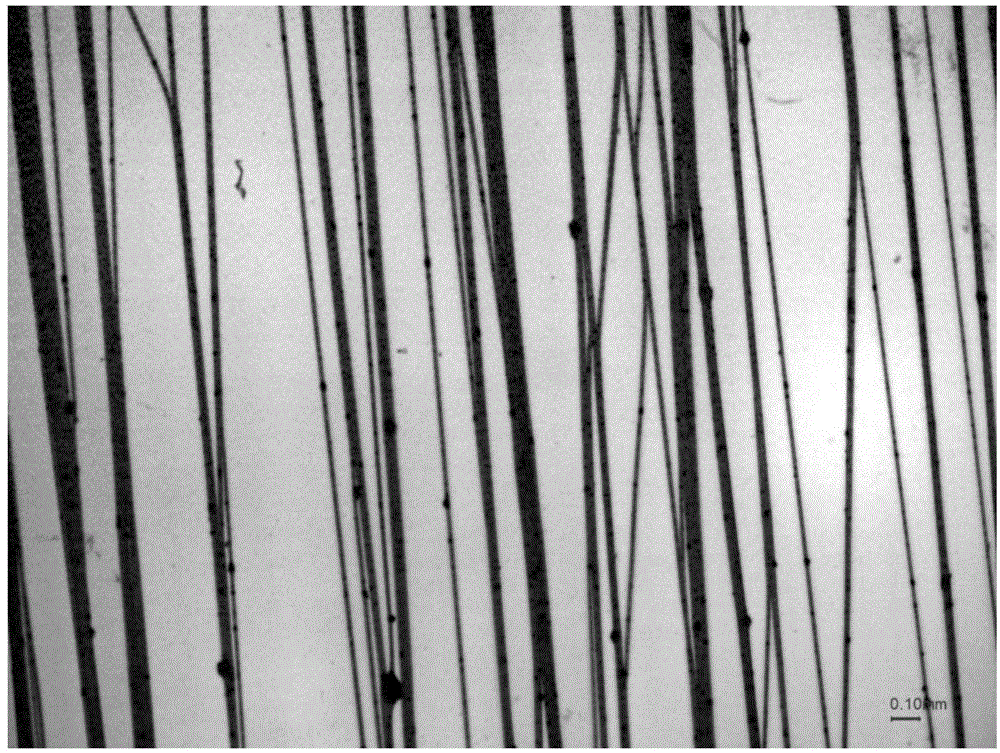

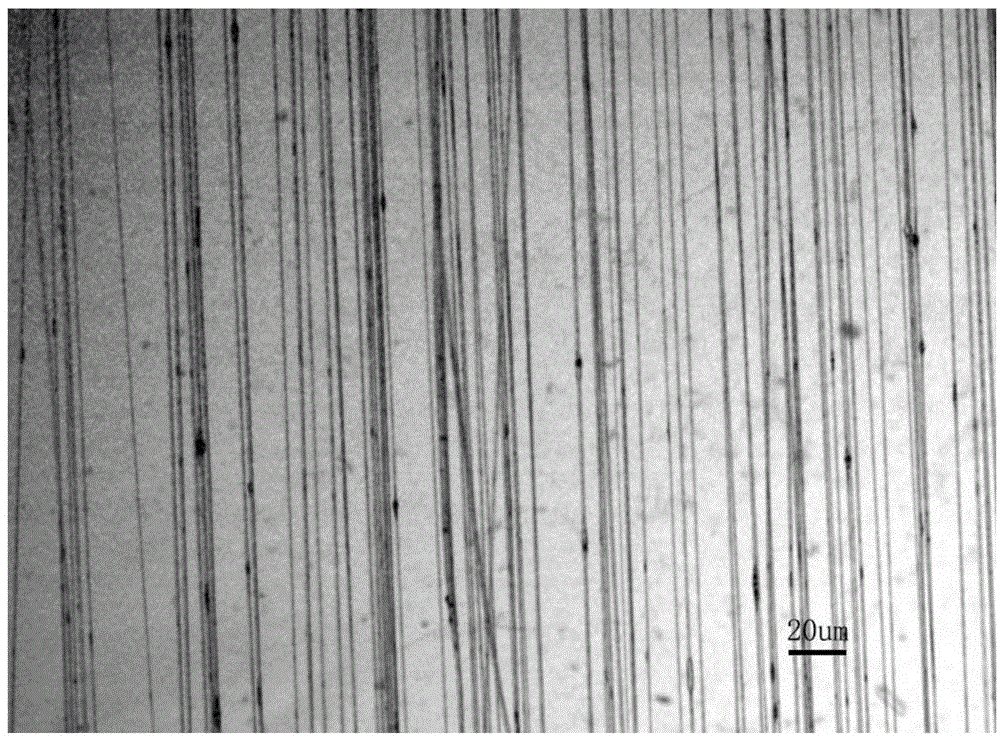

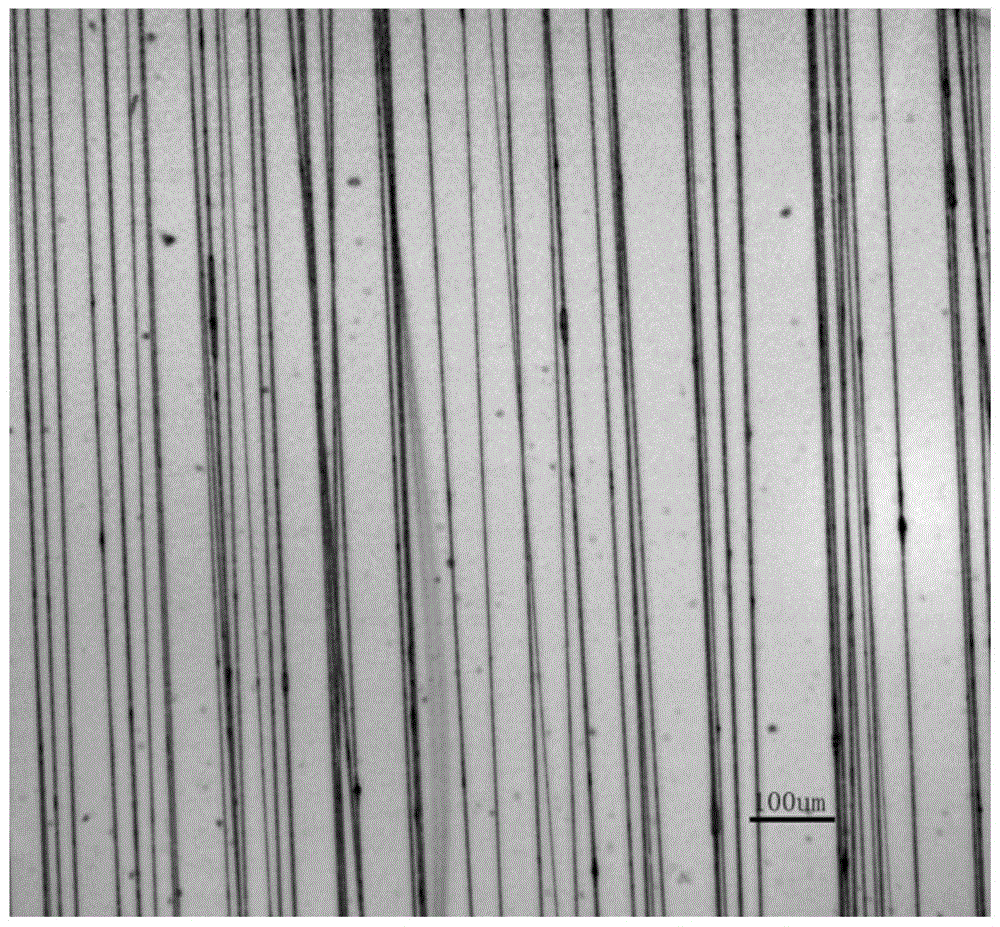

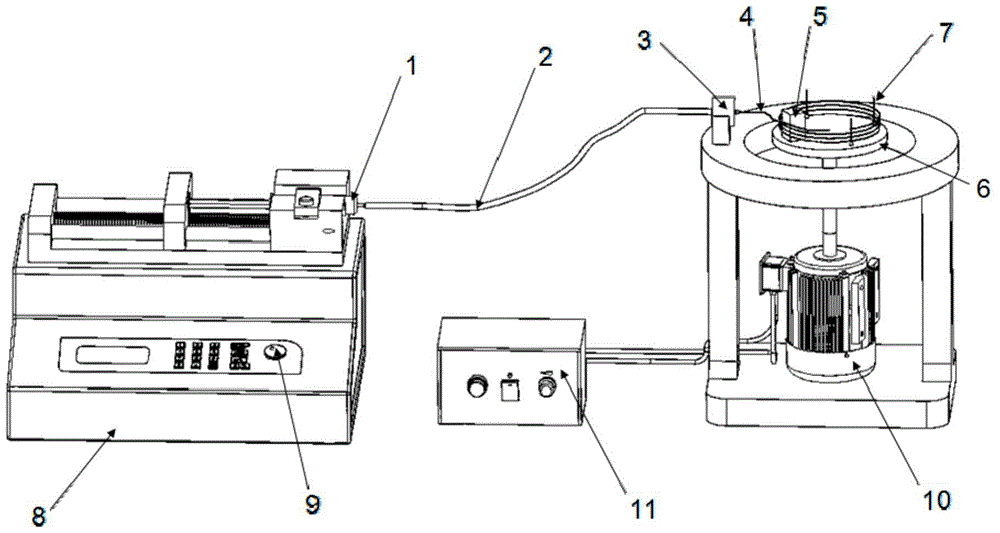

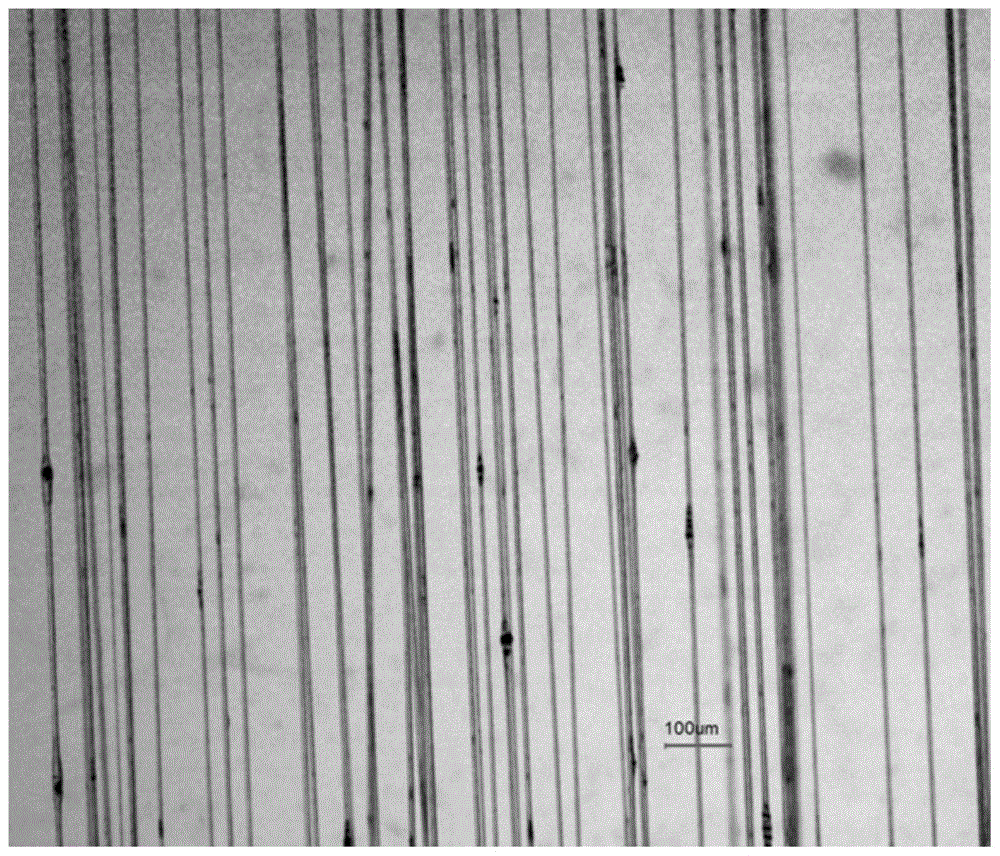

Method for preparing conducting polymer micro-nanofibers in magnetic spinning mode

ActiveCN104911719AArranged in an orderly mannerIncrease productionElectroconductive/antistatic filament manufactureFilament/thread formingMicro nanoFiber

The invention discloses a method for preparing conducting polymer micro-nanofibers in a magnetic spinning mode. The method comprises the steps that 1, a magnetic spinning device is built, wherein the magnetic spinning device comprises a rotary collection disc with a permanent magnet; 2, a spinning precursor solution is prepared, wherein magnetic nano particles, high-molecular polymer and conducting polymer are mixed and dissolved in an organic solvent solution; 3, the magnetic spinning device is utilized for preparing conducting polymer micro-nano complex fibers, wherein the spinning precursor solution is injected into a feeding device, the feeding device is started, liquid drops on an opening of a spinning nozzle forms a jet flow under the effect of magnetic field force to be connected with the permanent magnet to be a bridge, a brushless direct-current motor is started to drive the collection disc to rotate, the ferrofluid jet flow is continuously pulled out under the effect of magnetic field force, and conducting polymer micro-nanofibers are wound and formed among vertical supporting columns of the collection disc. The method does not need the high voltage effect, reduces the production cost and potential safety hazards, is suitable for large-scale production and has the good application prospect, and the fibers are distributed in order.

Owner:QINGDAO UNIV

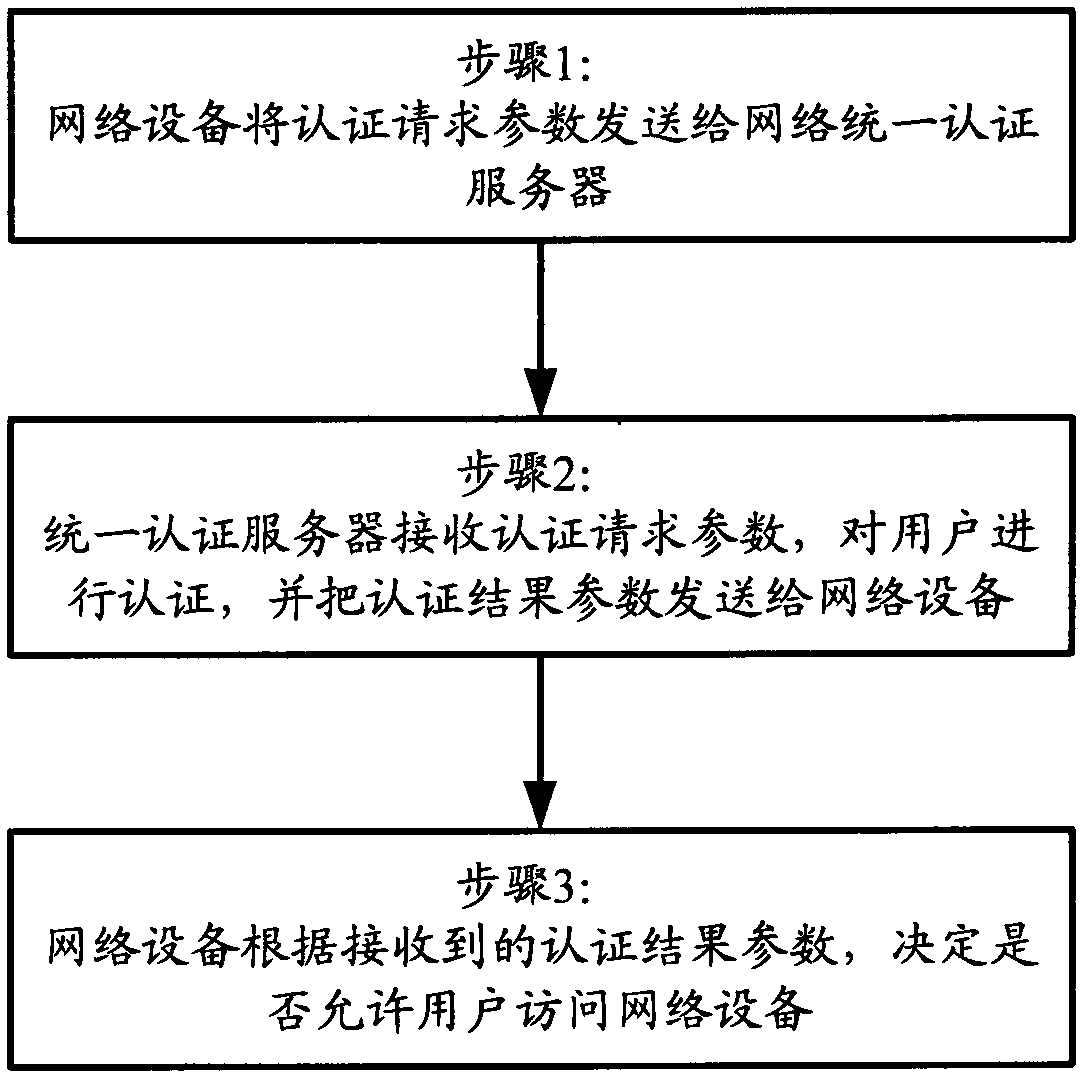

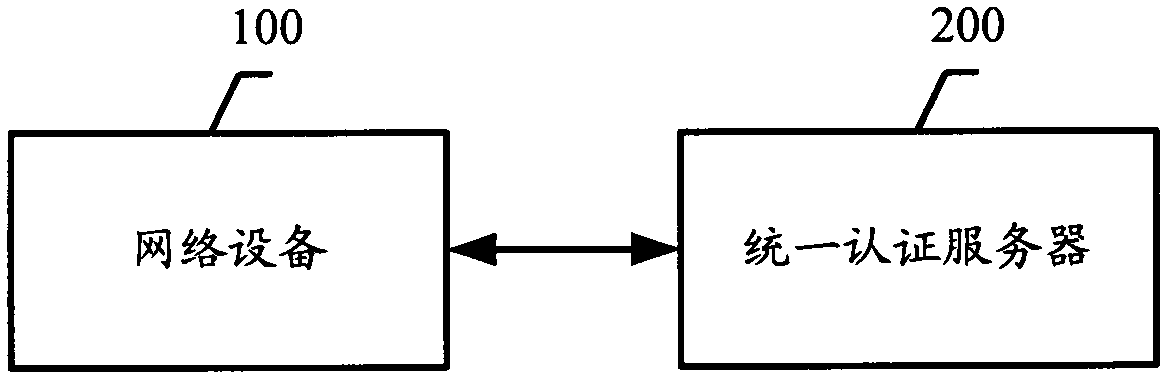

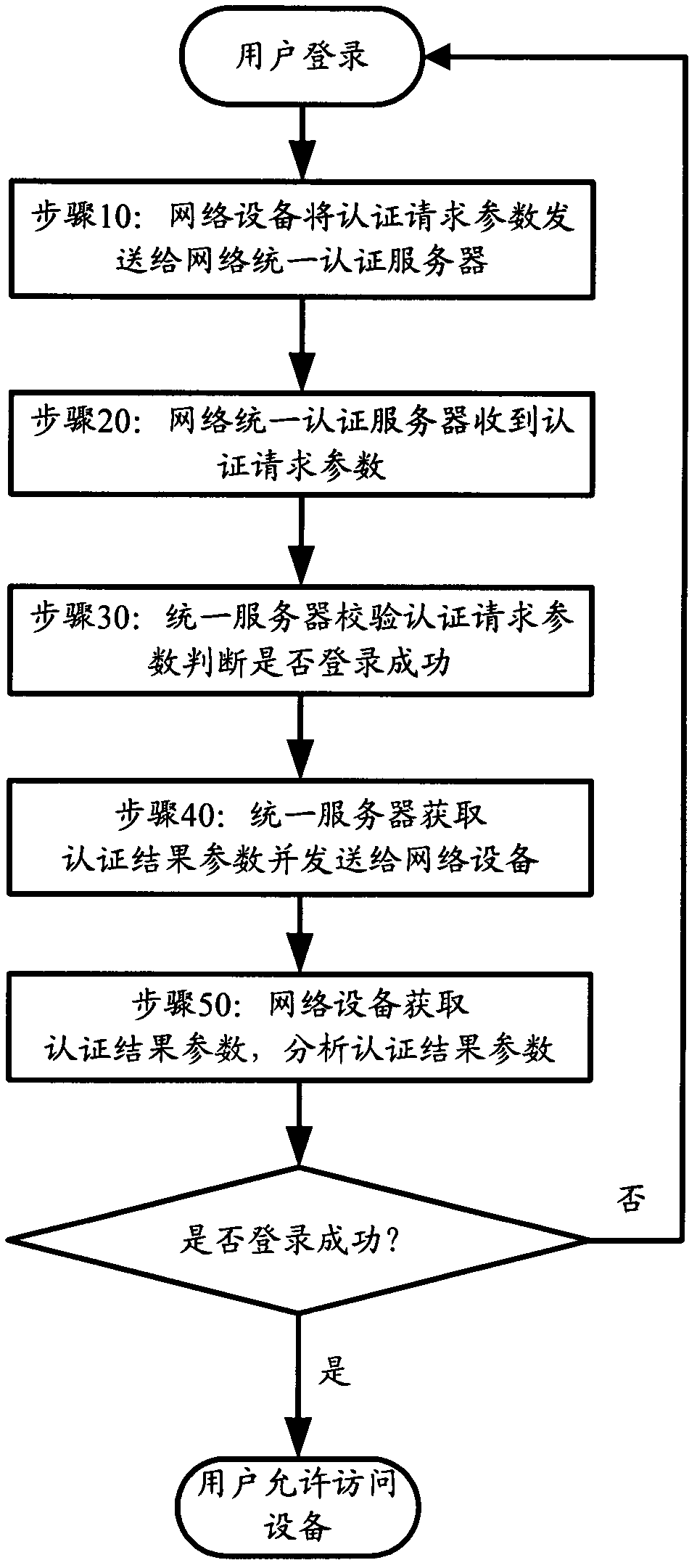

User identity authentication method and system

InactiveCN102307097ARealize centralized managementIncrease flexibilityUser identity/authority verificationUser authenticationAuthentication server

The invention provides a user identity authentication method, which comprises the following steps of: uniformly storing and recording authentication parameters of user identity into a unified authentication server, and uniformly authenticating the legality of the user identity by using the unified authentication server when a user logs in network equipment. The invention also provides a user identity authentication system. By the user identity authentication method and the user identity authentication system, security-policy-based unified user management and authentication can be realized, the unified authentication of a plurality of pieces of network equipment over the user identity is realized and the maintenance difficulties and complexity of a network equipment manager are reduced simultaneously, thereby reducing production cost and threats to information security.

Owner:ZICT TECH CO LTD

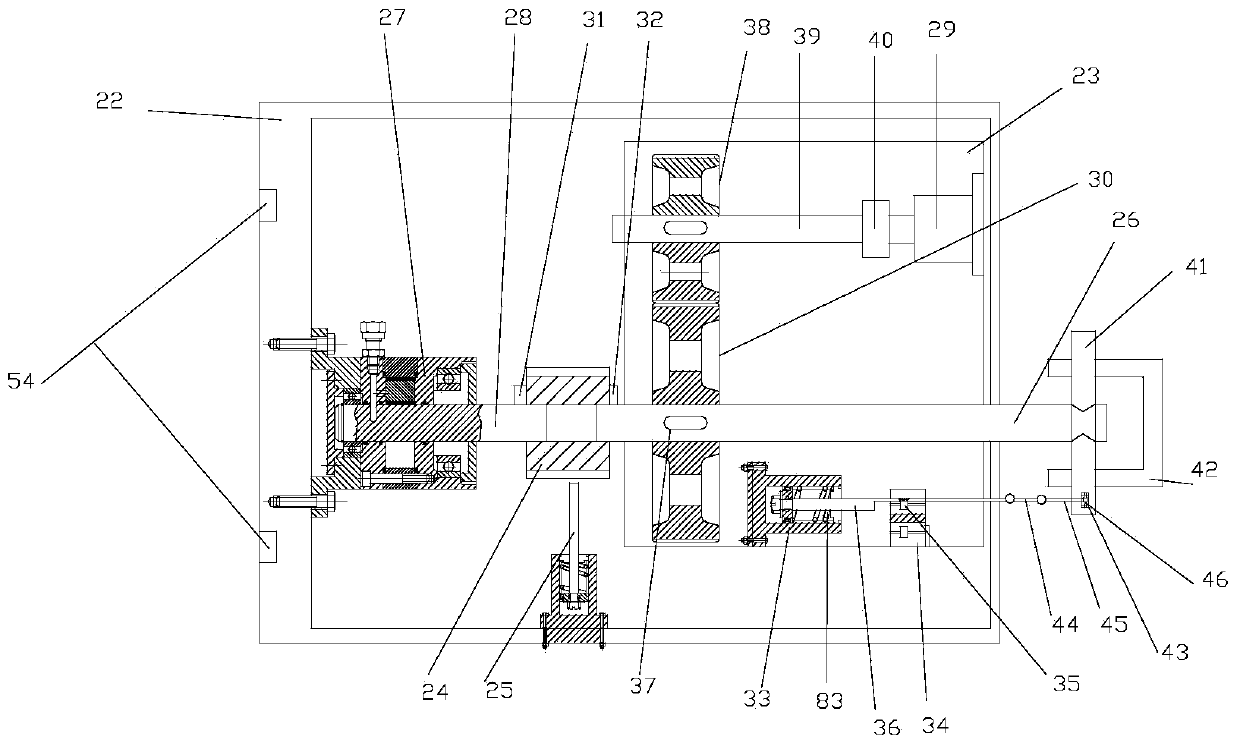

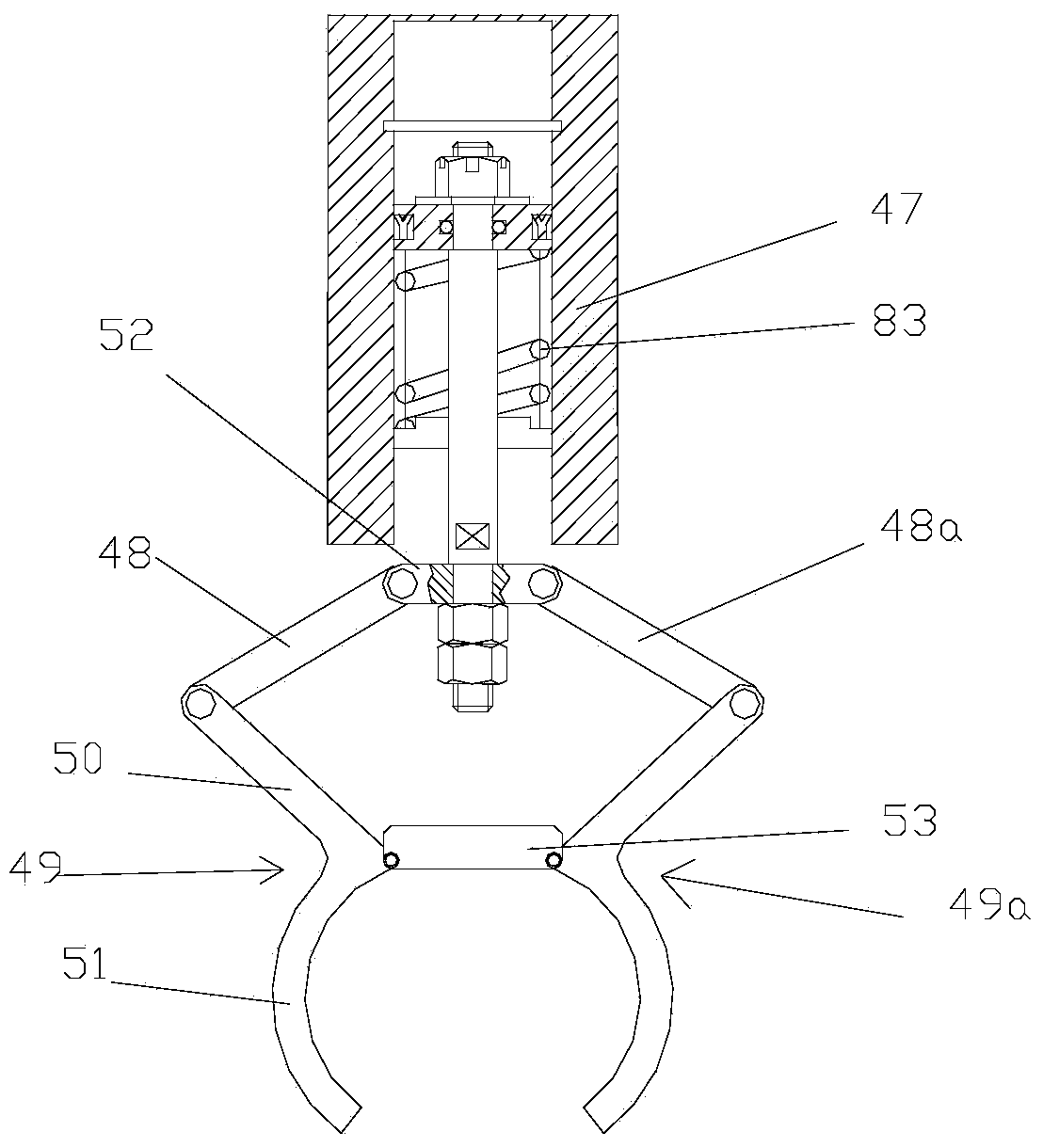

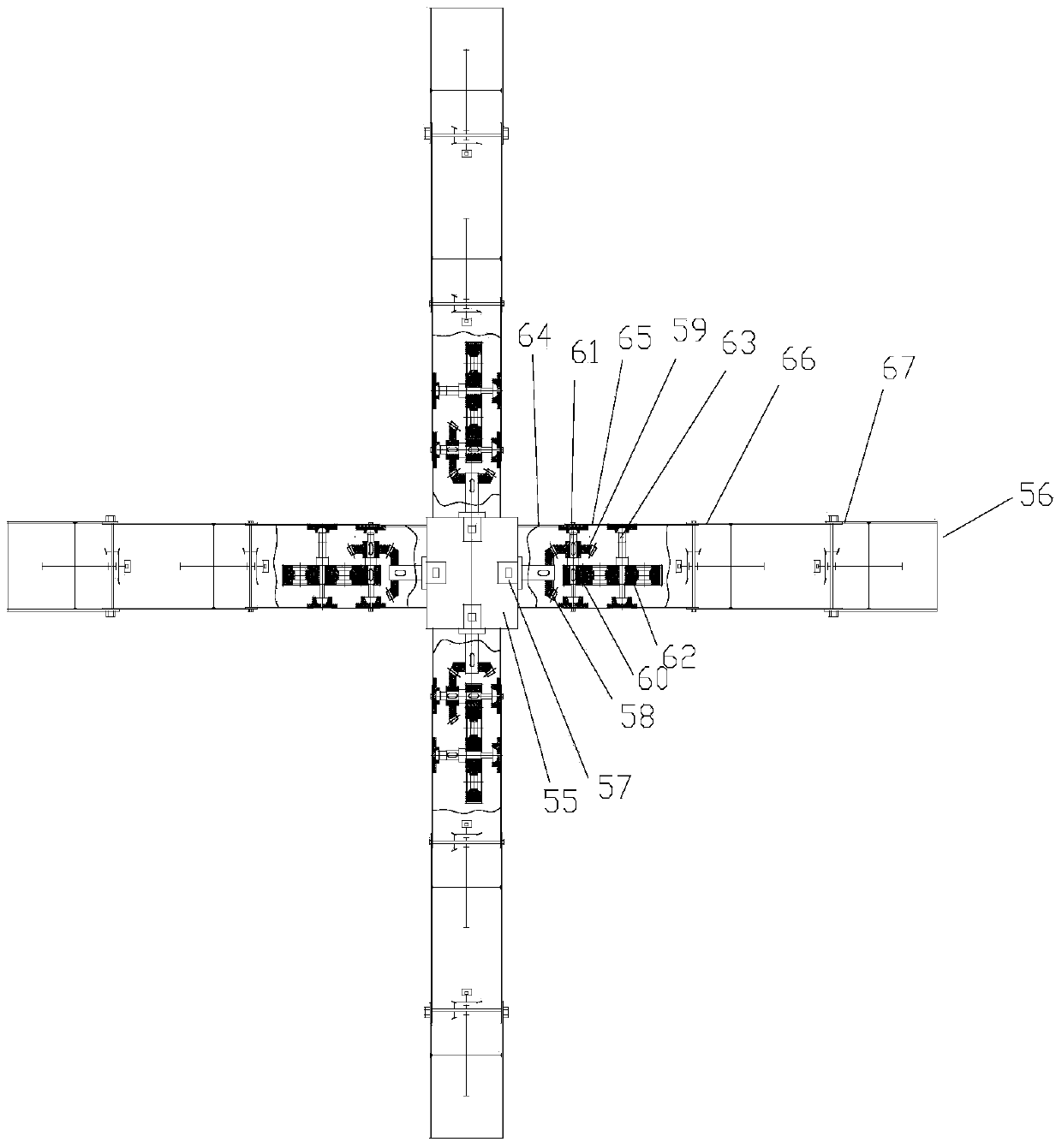

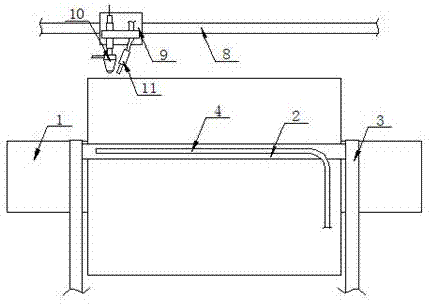

Heavy-load precision redundant three-arm mechanical hand based on traveling crane

ActiveCN104308859AHigh positioning accuracySolve the contradiction between overloading and precisionProgramme-controlled manipulatorJointsAutomatic controlManipulator

The invention discloses a heavy-load precision redundant three-arm mechanical hand based on a traveling crane. The three-arm mechanical hand comprises a base, a clamp assembly and an automatic control system, wherein the clamp assembly comprises a mounting seat used for mounting mechanical arms, a gripping mechanical hand used for gripping a workpiece, and a carrying mechanical hand used for carrying the gripped workpiece; the gripping mechanical hand comprises a heavy-load mechanical hand used for gripping a heavy workpiece, and a light-load mechanical hand used for gripping a light precision workpiece. According to the three-arm mechanical hand, the gripping mechanical hand adopts a redundant mechanical arm structure, the heavy-load mechanical hand is used for loading a heavy object, the light-load mechanical hand is used for carrying a precision device, and the two gripping mechanical hands can cooperatively carry and mount the workpiece in space, so that the problem of conflict between heavy load and precision in the field of mechanical hands is solved; in addition, due to the carrying mechanical hand, the disadvantage that a traveling crane needs to run a round trip for carrying a part at present is overcome, the labor intensity of workers is greatly reduced, the production efficiency of workshops is improved, and the energy consumption is greatly reduced.

Owner:CHONGQING JIAOTONG UNIVERSITY

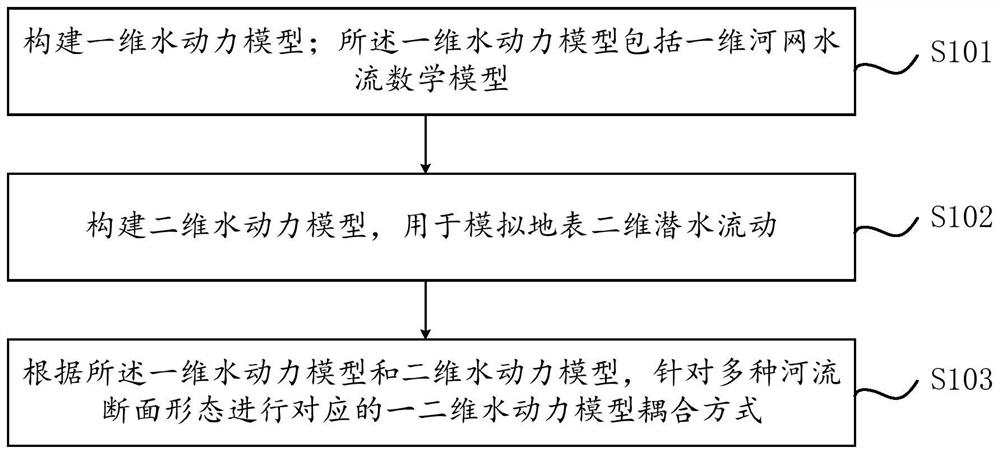

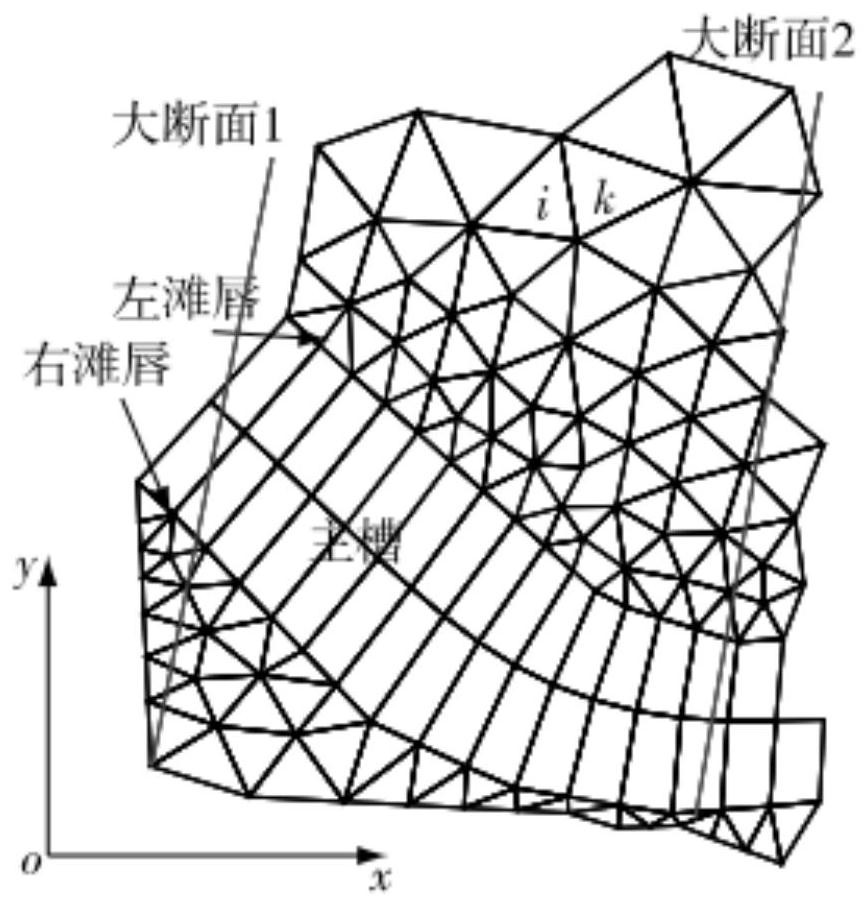

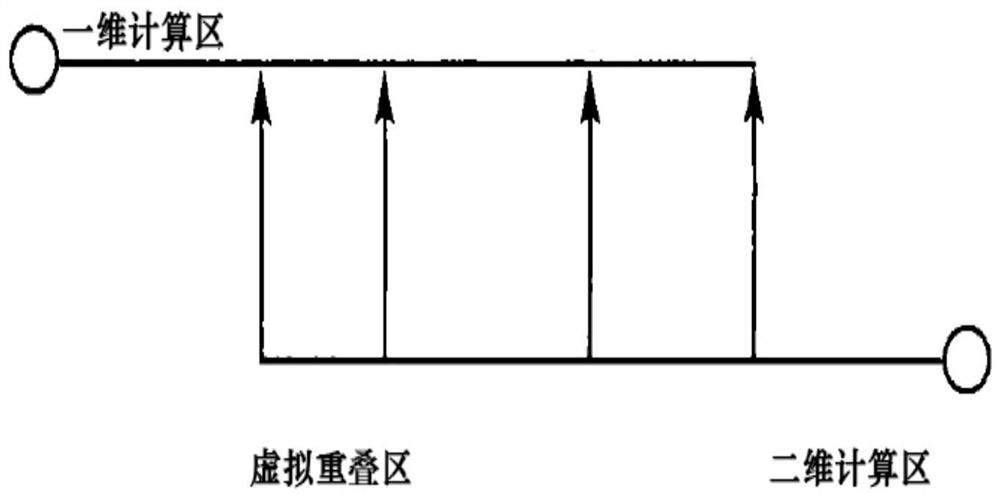

Coupling method and system for one-dimensional hydrodynamic model and two-dimensional hydrodynamic model

PendingCN112257352ARealize resourcesReduce the peak flow of the flood dischargeClimate change adaptationDesign optimisation/simulationRiver networkMathematical model

The invention relates to a coupling method and system for a one-dimensional hydrodynamic model and a two-dimensional hydrodynamic model. The method comprises steps that the one-dimensional hydrodynamic model is constructed; wherein the one-dimensional hydrodynamic model comprises a one-dimensional river network water flow mathematical model; a two-dimensional hydrodynamic model is constructed to simulate two-dimensional shallow water flow of an earth surface; and according to the one-dimensional hydrodynamic model and the two-dimensional hydrodynamic model, a corresponding one-dimensional andtwo-dimensional hydrodynamic model coupling mode is carried out for various river section forms. According to the method, a one-dimensional and two-dimensional coupled hydrodynamic model is adopted, the influence of urban buildings, trees and other plants on flood propagation can be fully considered, and hydrodynamic models of different scales and different dimensions are coupled according to theone-dimensional flow characteristics of a river channel and the two-dimensional flow characteristics of a lake; and flood influence degree and range simulation and prediction under different flood frequencies are carried out. The urban water regime situation can be perceived, the water level information is collected in combination with an upstream sensing instrument, and the aims of reducing the discharge peak flow and achieving flood recycling are achieved in combination with gate dam dispatching.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

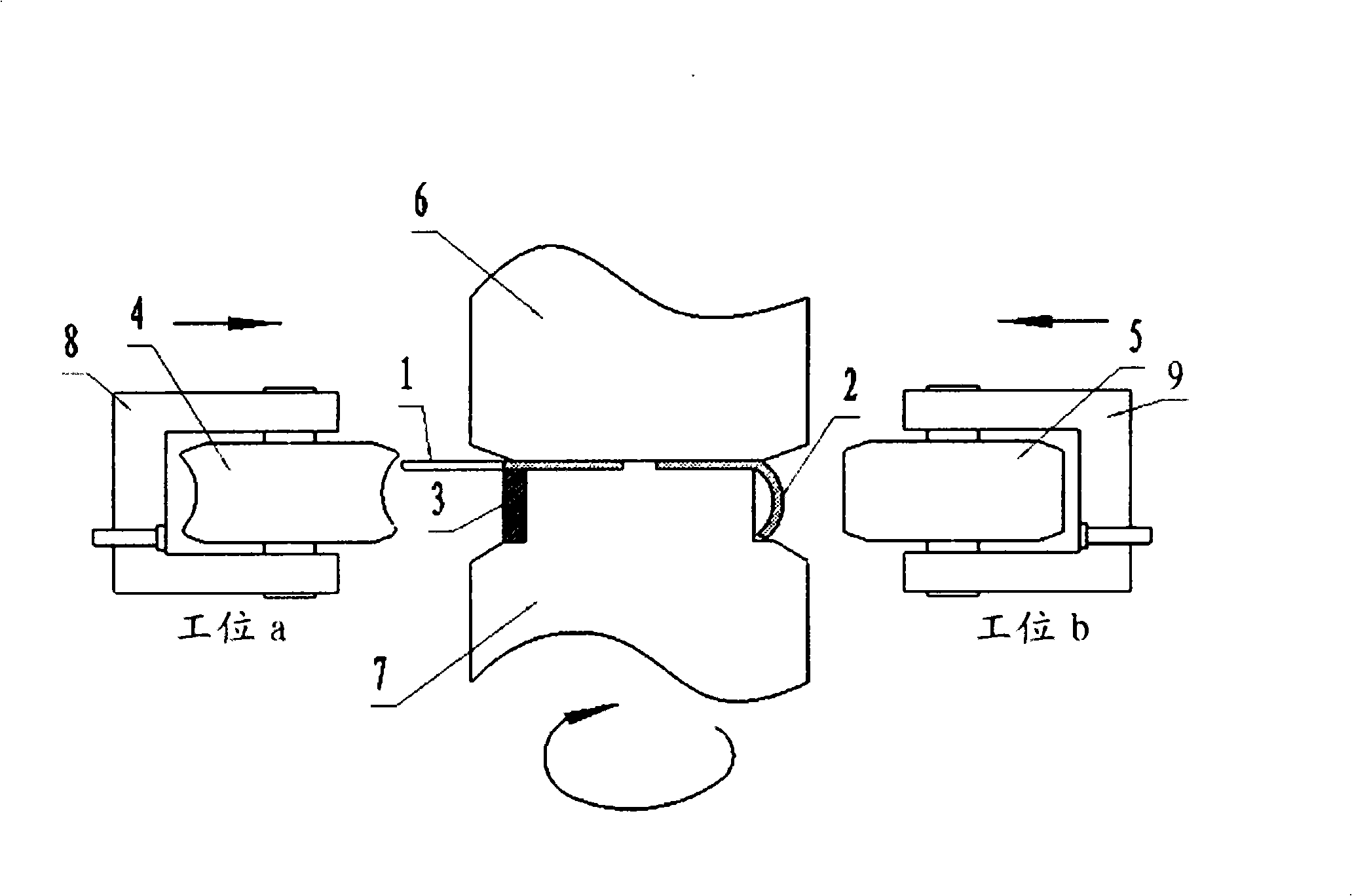

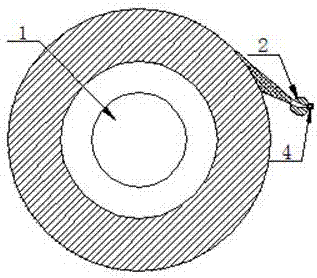

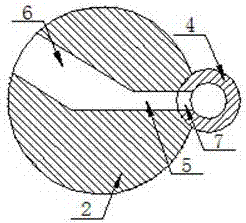

Technique for flow forming processing metal sheet into revolution body and thickening wall

The present invention relates to a process for processing a metal plate into a revolving body with a thick wall in rotary extrusion way, which belongs to the field of the mechanical manufacturing engineering, and in particular relates to the manufacturing of a plate processing device and a rotary extrusion mold, and consists of a metal circular plate 1 with a process hole, a rotary wheel 4, a rotary wheel 5, an upper die seat 6, a lower die seat 7, a wheel bracket 8 and a wheel bracket 9, wherein, the rotary wheel 4 is installed on the wheel bracket 8 through a rotary shaft to assemble a work station a; the rotary wheel 5 is installed on the wheel bracket 9 through a rotary shaft to assemble a work station b; the end surface of the rotary wheel 4 is a concave arc; the end surface of the rotary wheel 5 is a plane. The process of the present invention has the advantages such as simple structure, low energy consumption, material conservation, good production safety, convenient commissioning operation, good quality, low cost, etc., which not only changes the traditional processing method, but also thickens the wall of the product, and can be applied to different fields, and is an important process for the processing of the metal plate at present.

Owner:BEIJING DINGXUAN TECH

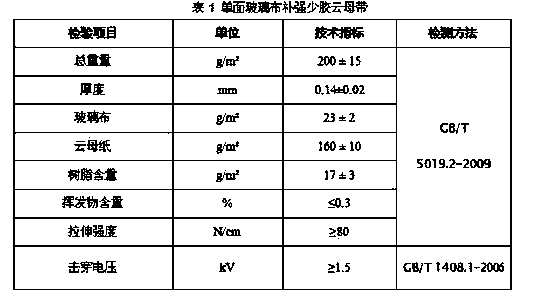

Mica tape production method without using organic solvent

The invention discloses a mica tape production method without using an organic solvent. The mica tape production method comprises the following steps of unwinding of a reinforced material; unwinding of mica paper and roller painting of an adhesive; hot-press compositing; winding; slitting. The novel mica tape production method is characterized in that any solvent is not used, and oven baking is not used; the roller painting of the adhesive adopts a hot roller for painting, and the adhesive painting amount can be controlled by heating a roller and controlling a gap between scraping rollers; the roller painting of the adhesive adopts a gluing roller of a sandwich layer structure, the scraping rollers and a glue groove, and the sandwich layer structure is internally filled with hot water or hot oil; the hot-press compositing adopts a mode of oppositely pressing a hot pressing roller and a cold pressing roller, the hot pressing roller is internally filled with hot oil, and the cold pressing roller is internally filled with cooling water. According to the mica tape production method disclosed by the invention, the organic solvent is not used, the baking is not needed, the using of the organic solvent in a production process is avoided, the production cost is greatly reduced, the emission of waste gas is reduced, the energy consumption of a baking process is reduced, and the production speed is increased; in respect of a device, the investment cost is low, the production safety is high, the gluing is uniform, and the gluing can be easily controlled.

Owner:ZHUZHOU TIMES ELECTRIC INSULATION

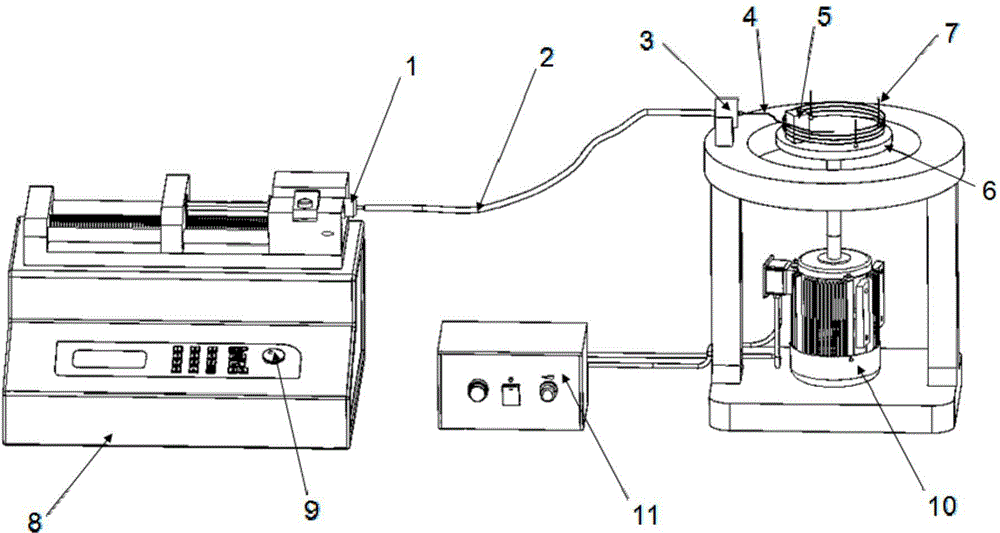

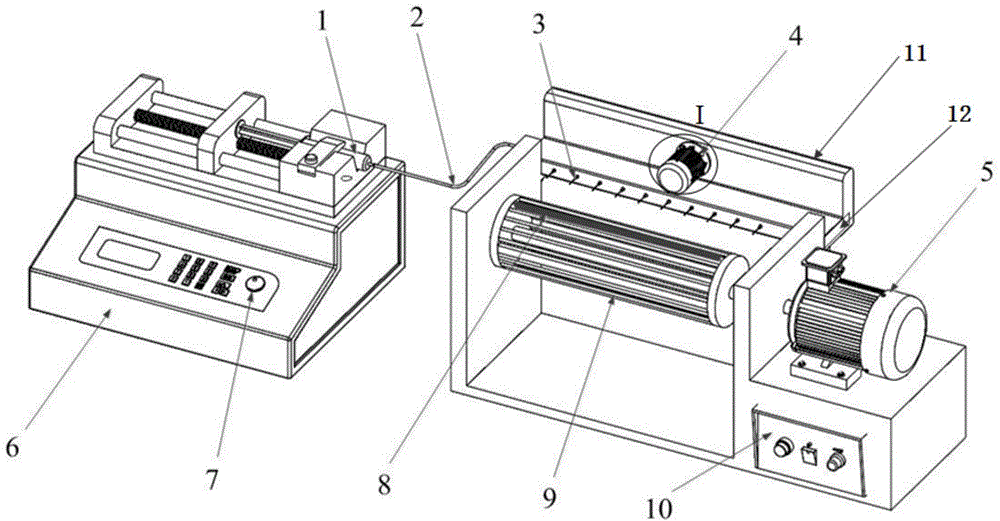

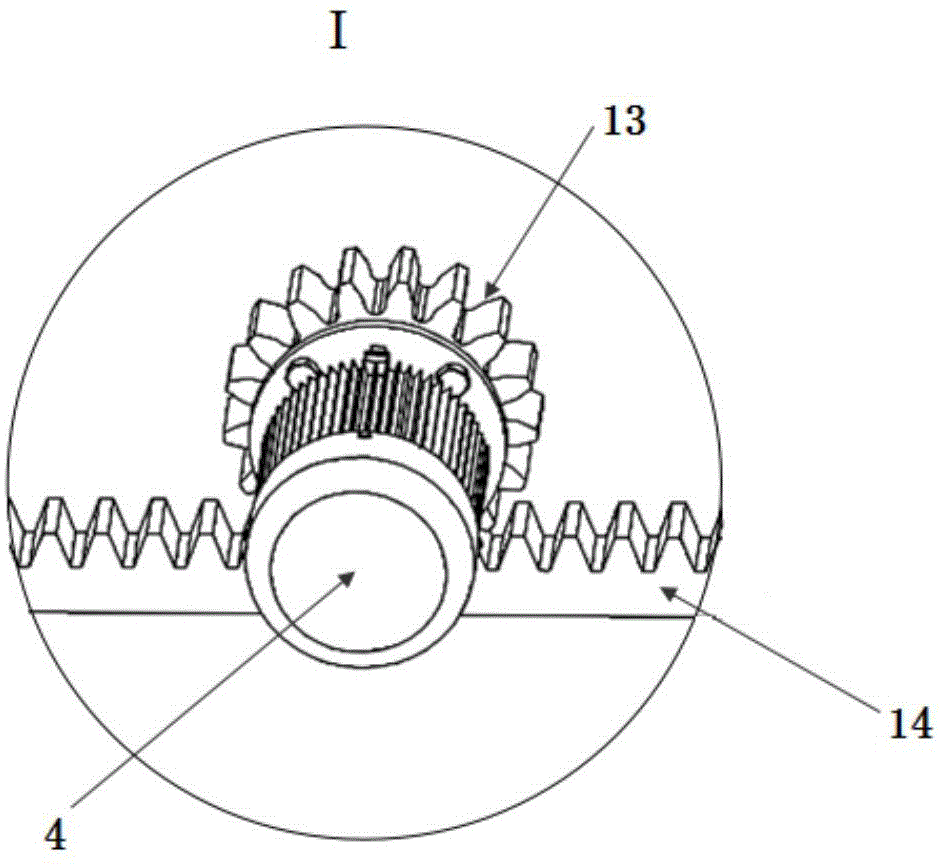

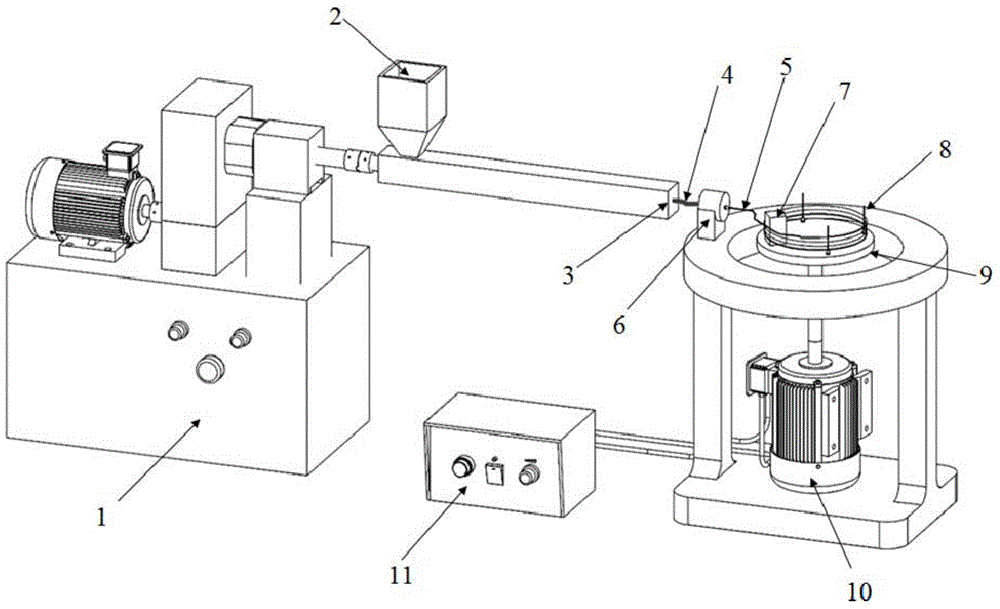

Large-scale magnetic spinning equipment and method using equipment for manufacturing micro-nano-meter fibers

ActiveCN104878461AArranged in an orderly mannerIncrease productionArtificial thread manufacturing machinesFilament/thread formingMicro nanoFiber

The invention discloses large-scale magnetic spinning equipment and a method using the equipment for manufacturing micro-nano-meter fibers. The equipment comprises a support, a feeding device, a spinning spraying device and a roller type collecting device horizontally arranged. Bar-shaped permanent magnets for providing a magnetic field are fixed to the surface of a collecting roller of the roller type collecting device. The spinning spraying device is provided with a plurality of spinning spraying heads which are uniformly arranged in a column. Injection orifices of the spinning spraying heads point to the bar-shaped permanents of the surface of the collecting roller. The spinning spraying device further comprises a spraying head drive mechanism which can drive the spinning spraying heads to do reciprocating motion in the center axis direction of the collecting roller. According to the equipment, magnetic field force replaces electric field force, under the effect of the alternating magnetic field, ferrofluid is stretched to manufacture the magnetic micro-nano-meter fibers, the high-voltage effect is not needed in the whole process, the production cost and the potential safety hazards are reduced effectively, the micro-nano-meter fibers can be produced continuously in batches, the manufactured fibers are arranged orderly, the yield is high, and the magnetic spinning equipment is suitable for mass production.

Owner:QINGDAO UNIV

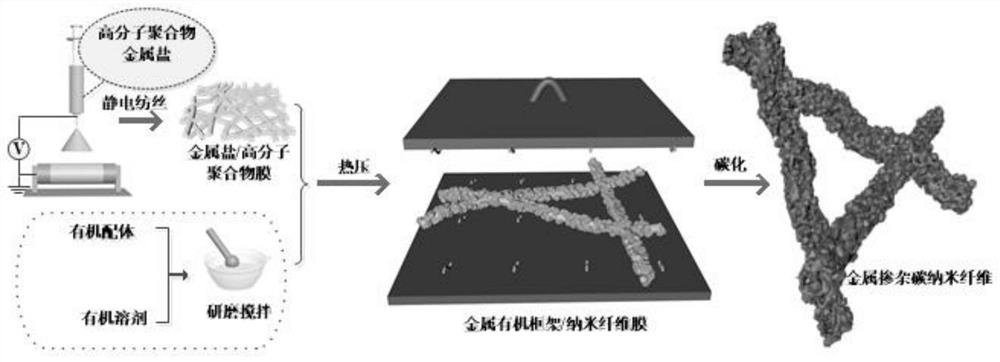

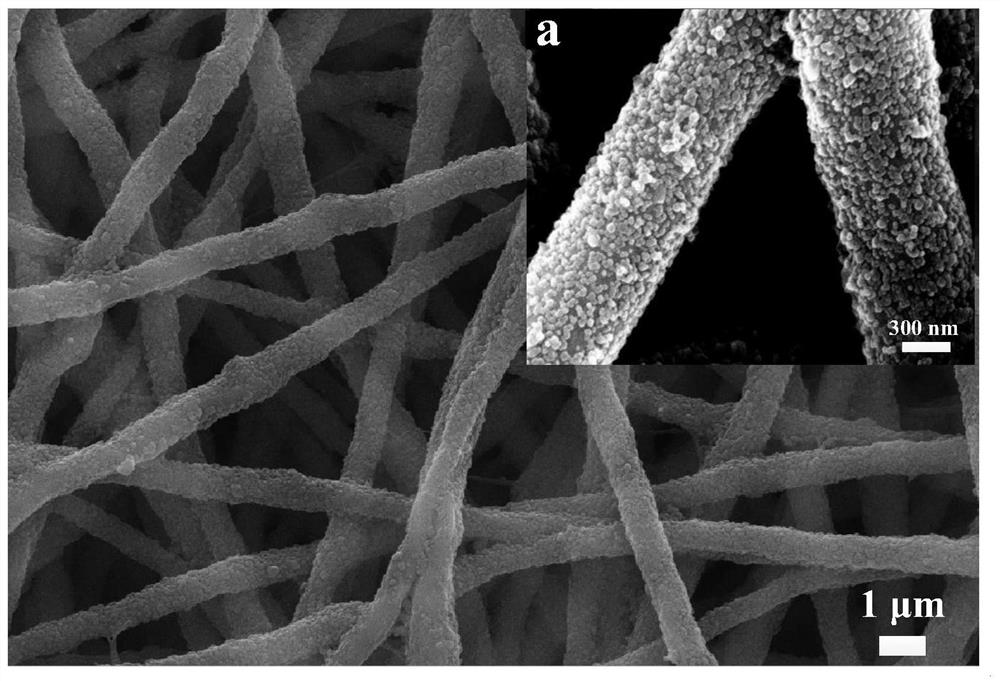

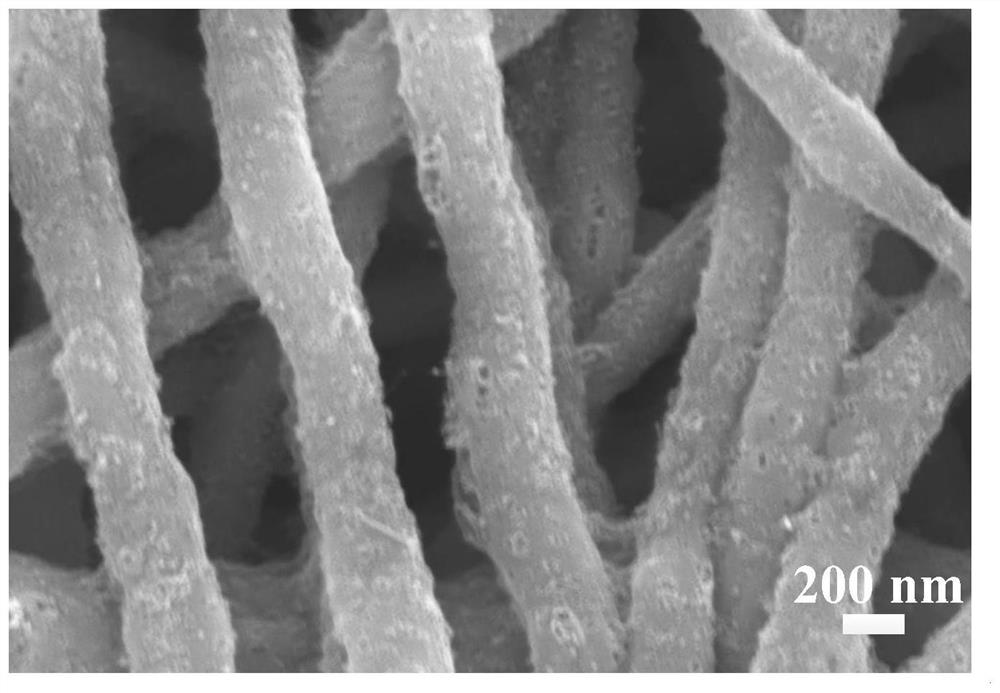

Preparation method for rapidly growing metal organic framework derivative with assistance of metal salt

ActiveCN113054207ATightly boundNot easy to fall offCell electrodesFibre typesOrganosolvMetal-organic framework

The invention provides a preparation method for rapidly growing a metal organic framework derivative with assistance of a metal salt, and belongs to the technical field of nano material preparation and fuel cell catalysis. The preparation method comprises the following steps of: firstly, adding the metal salt and a high-molecular polymer into an organic solvent, stirring to obtain a mixed solution, acquiring a metal salt / high-molecular nanofiber membrane by adopting an electrostatic spinning technology, and then uniformly coating the metal salt / high-molecular nanofiber membrane with an organic ligand solution required by the growth of the MOF; and secondly, achieving chemical bond combination of metal ions and ligands in nanofibers through adopting a hot pressing technology, so that the MOF material compactly and evenly grows on the nanofiber membrane, and the MOF / nanofiber membrane is calcined under inert gas to form the metal-embedded nitrogen-doped porous carbon nanofibers. According to the preparation method, solvents such as methanol, ethanol and water are not used in the preparation process, and the method is short in preparation time, simple in process, environment-friendly and suitable for large-scale production and has important application value in the fields of energy catalysis and environmental protection.

Owner:UNIV OF SCI & TECH BEIJING

HMB-Ca production process method

InactiveCN108129294AEasy to operateOptimizationOrganic compound preparationCarboxylic acid salt preparationFood additiveOrganic solvent

The invention discloses HMB-Ca production process method, which comprises the following steps that HMB is dissolved in water; calcium salt is added; stirring, filtering and concentration are performedto obtain an HMB-Ca crude product; the HMB-Ca crude product is added into an alcohol solvent; after stirring, filtering and concentration are performed, an organic solvent is added; stirring and filtering are performed; solid drying is performed to obtain an HMB-Ca product; during the filtering, the hole diameter is 1 to 100 micrometers. The HMB-Ca production process method has the advantages that the production operation and purification filtering conditions of the HMB-Ca product are optimized; the mechanical impurities and the metal ion residues in the HMB-Ca product are effectively reduced; the safety when the HMB-Ca product is used as a health care product and food additive is improved; the process conditions are mild; the operation is easy; the production operation safety degrade isreduced; green and environment-friendly effects are achieved; the industrialization is favorably realized.

Owner:穆云

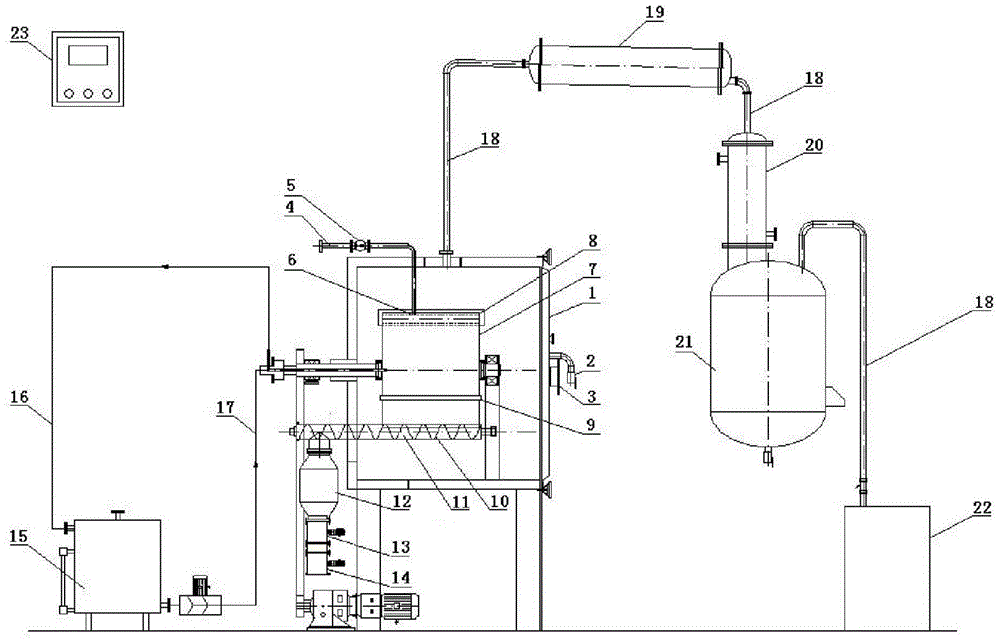

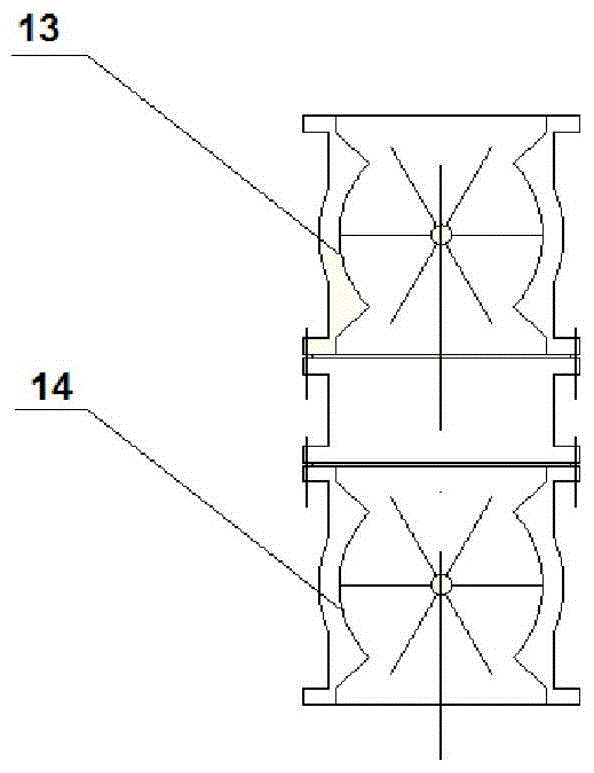

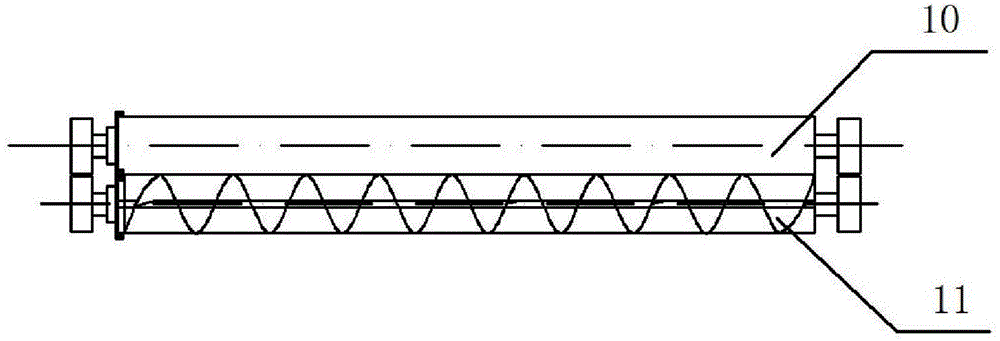

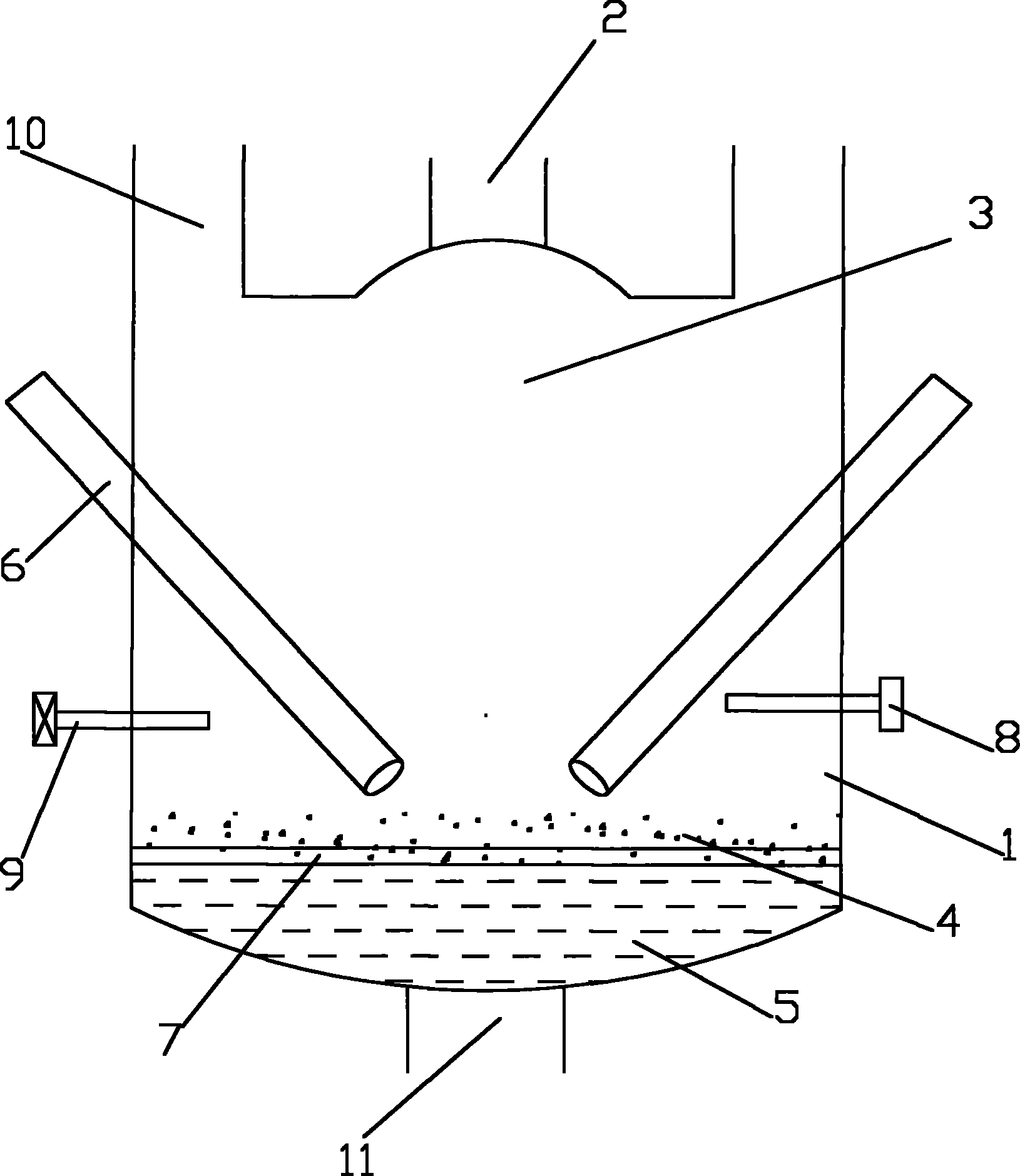

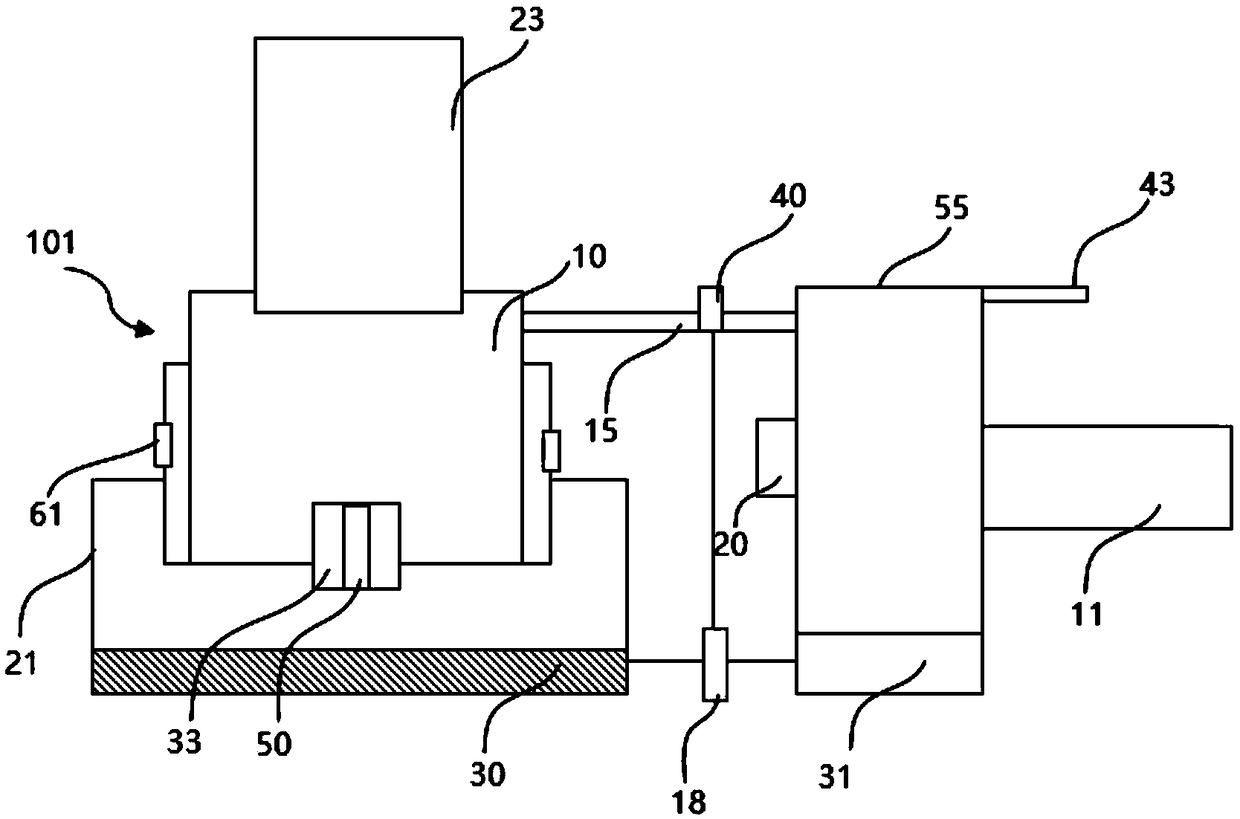

Continuous dry drum zein drying device and method

ActiveCN104642713AAvoid sex changeAchieve recyclingFood preservationControl systemAgricultural engineering

The invention provides a continuous dry drum zein drying device and method. The device comprises a main box body system, a feeding system, a drum scrapper blade drying system, a steam feeding system, a cooling discharging system, a condensing system, a water injection pump system and a control system; the cooling discharging system is used for discharging through a two-stage air closer, so that the air in the environment can be prevented from entering a main box body to the greatest extent, the constant vacuum degree of the main box body can be remained, and as a result, a vacuum system can be sealed; meanwhile, ethanol can be efficiently recovered, and the production cost and potential risk can be reduced.

Owner:高邮市日星药用辅料有限公司

Process and device for producing sodium silicate

InactiveCN104071800AReduce lossReduce energy consumptionAlkali metal silicatesTemperature controlLiquid state

The invention discloses a process for producing sodium silicate. The process comprises the following steps of: 1) mixing quartz sand and sodium carbonate in proportion and stirring to form a mixture; 2) uniformly conveying the mixture into an electrode furnace, heating to 1400-1500 DEG C and melting by an electric arc or a plasma arc generated by an electrode arranged in the electrode furnace to generate liquid-state sodium silicate and CO2; and 3) forming the finished product by using the liquid-state sodium silicate according to a water quenching method or a dry method. The invention further discloses a device for producing sodium silicate. According to the process and the device for producing sodium silicate disclosed by the invention, sodium carbonate and high-quality quartz sand are heated and melted by the electric arc or the plasma arc generated by the electrode to form a high-temperature liquid material, thus achieving the advantages of low energy consumption, accurate temperature control, good product quality, low raw material loss, low environmental pollution and high production safety.

Owner:重庆市大足区蓝盾水玻璃厂

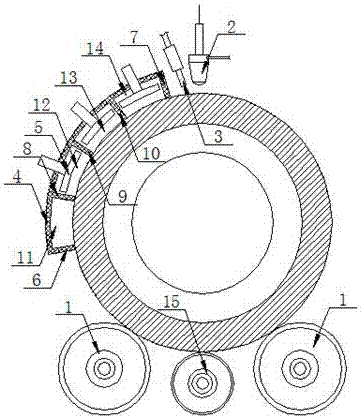

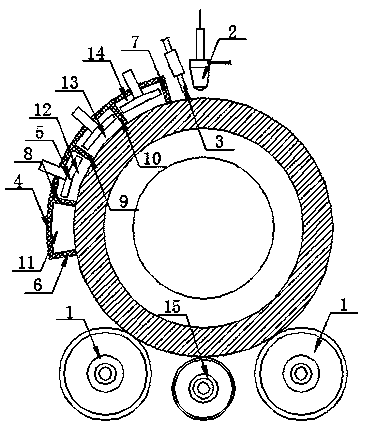

Preheating surfacing device for wear-resistant layer of limestone crushing roller

ActiveCN107457509AReduce operating energy consumptionReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesVertical planeWear resistant

The invention discloses a preheating and surfacing device for a wear-resistant layer of a limestone crushing roller. The preheating and surfacing device comprises two surfacing rotary supporting rollers, a wear-resistant layer surfacing welding gun, a surfacing welding powder spray pipe and a surfacing preheating arc-shaped cover plate, wherein the two surfacing rotary supporting rollers are arranged at the bottom of the crushing roller with the axis horizontally placed, the wear-resistant layer surfacing welding gun and the surfacing welding powder spray pipe are arranged above the top surface of the crushing roller, and the surfacing preheating arc-shaped cover plate is arranged on the roller surface of the crushing roller and is located on one side of the wear-resistant layer surfacing welding gun; the axes of the two surfacing rotary supporting rollers are all horizontal and are parallel to the axis of the crushing roller; the two surfacing rotary supporting rollers are symmetrically arranged relative to the vertical plane of the axis of the crushing roller; surfacing preheating heating blocks are arranged between the surfacing preheating arc-shaped cover plate and the roller surface of the crushing roller; and the surfacing welding powder spray pipe is located between the surfacing preheating arc-shaped cover plate and the wear-resistant layer surfacing welding gun. According to the preheating and surfacing device, the preheating and surfacing operation of the crushing roller can be continuously completed on one device, and therefore the labor intensity of operators can be reduced, and the production safety can be improved.

Owner:溧阳天山水泥有限公司

New synthesis process of naftifine drug intermediate N-methyl-1-naphthalenemethylamine

ActiveCN112552182AEasy to operateReduce solid wasteAmino compound purification/separationOrganic compound preparationDichloromethaneMethylated naphthalene

The invention discloses a new synthesis process of a naftifine drug intermediate N-methyl-1-naphthalenemethylamine. The process includes: adding phosphoric acid, concentrated hydrochloric acid, industrial naphthalene, paraformaldehyde and a catalyst, performing heating, introducing HCL gas, and carrying out reaction to obtain a 1-chloromethylnaphthalene crude product; performing cooling, dropwiseadding the 1-chloromethylnaphthalene crude product into a methanolamine solution, and carrying out reaction to obtain an N-methyl-1-naphthalenemethylamine crude product; performing evaporating to remove the redundant methanolamine solution, adjusting the alkali with a sodium hydroxide aqueous solution, conducting washing with water for layering, adding water and dichloromethane into an organic layer, adjusting the pH value with hydrochloric acid, performing layering, taking the water layer, and adjusting alkali with a sodium hydroxide solution to obtain a crude product, and carrying out reduced pressure rectification to obtain a finished product. According to the method, the N-methyl-1-naphthalenemethylamine finished product is successfully synthesized directly in a one-pot mode, the situation that the product yield is reduced due to the fact that a lot of residues are generated is avoided, meanwhile, the safety risk in the rectification process is avoided, the purity of the crude product is greatly improved, the cost is low, and the production safety is high.

Owner:杭州新桂实业有限公司

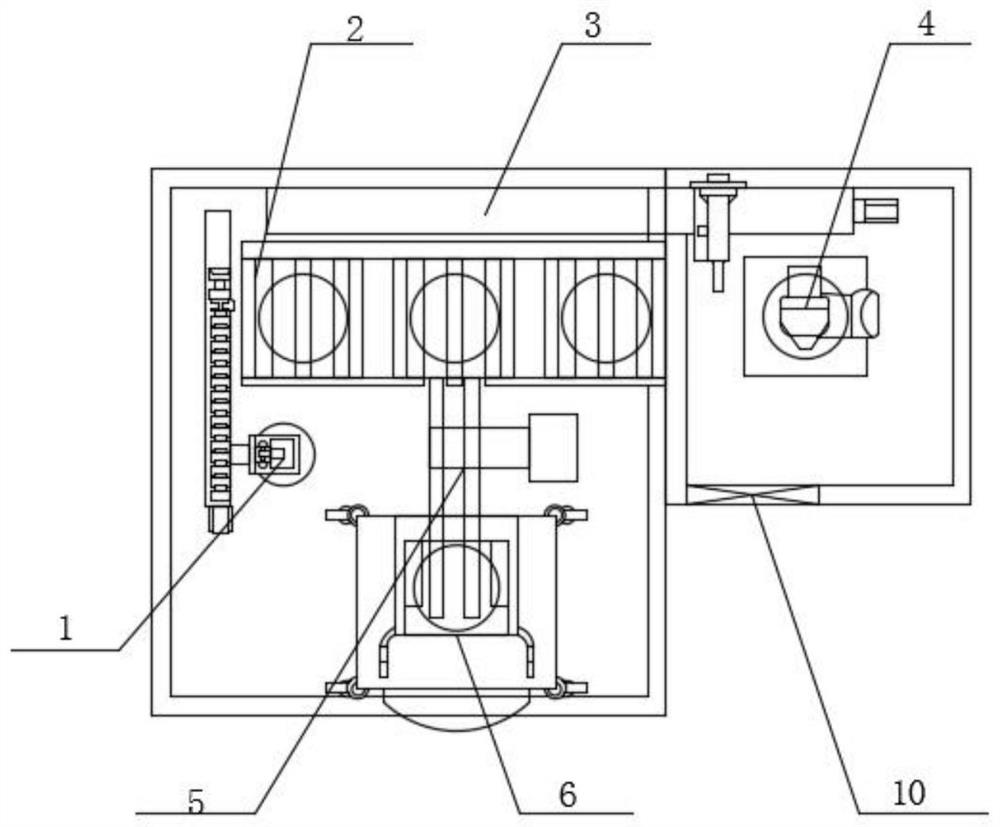

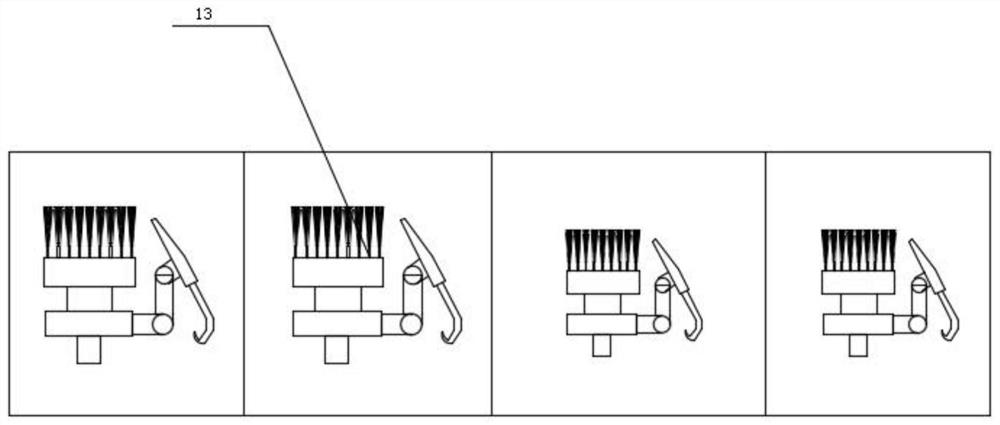

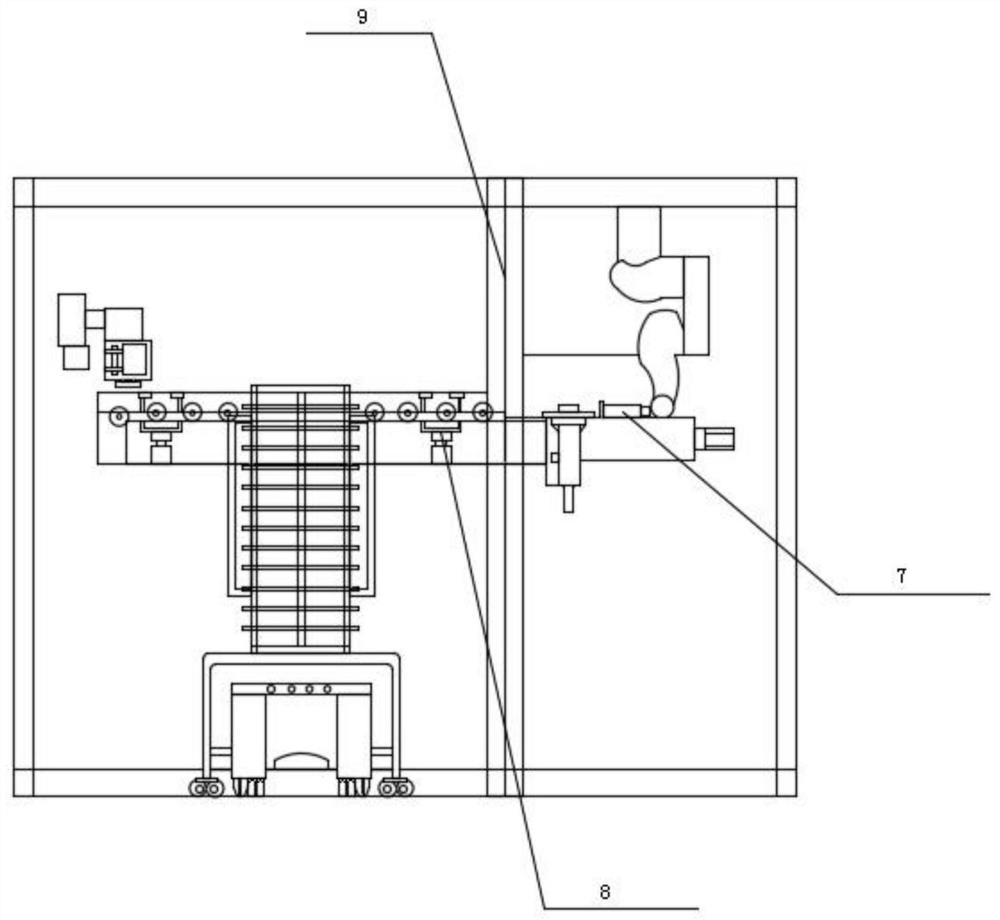

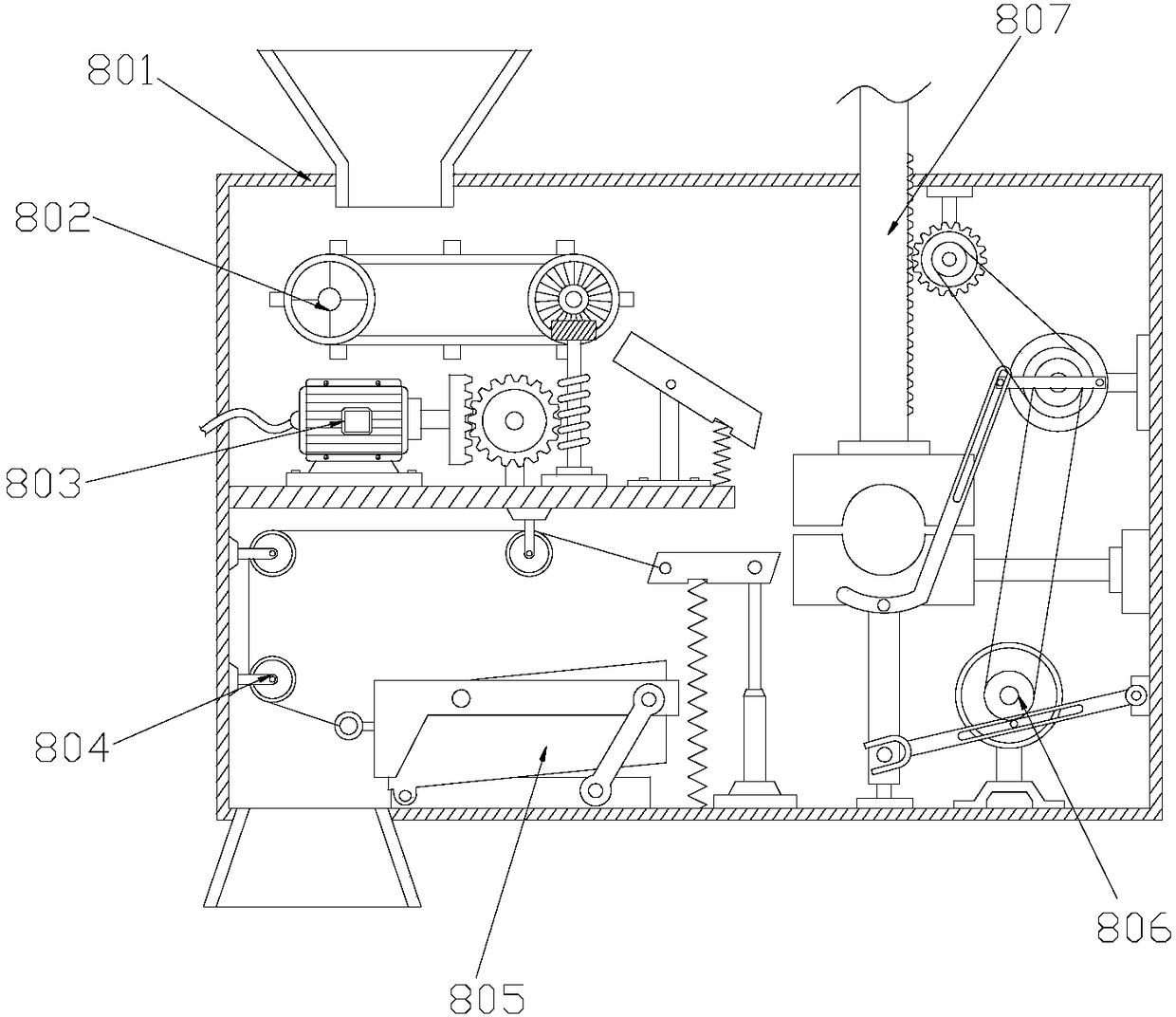

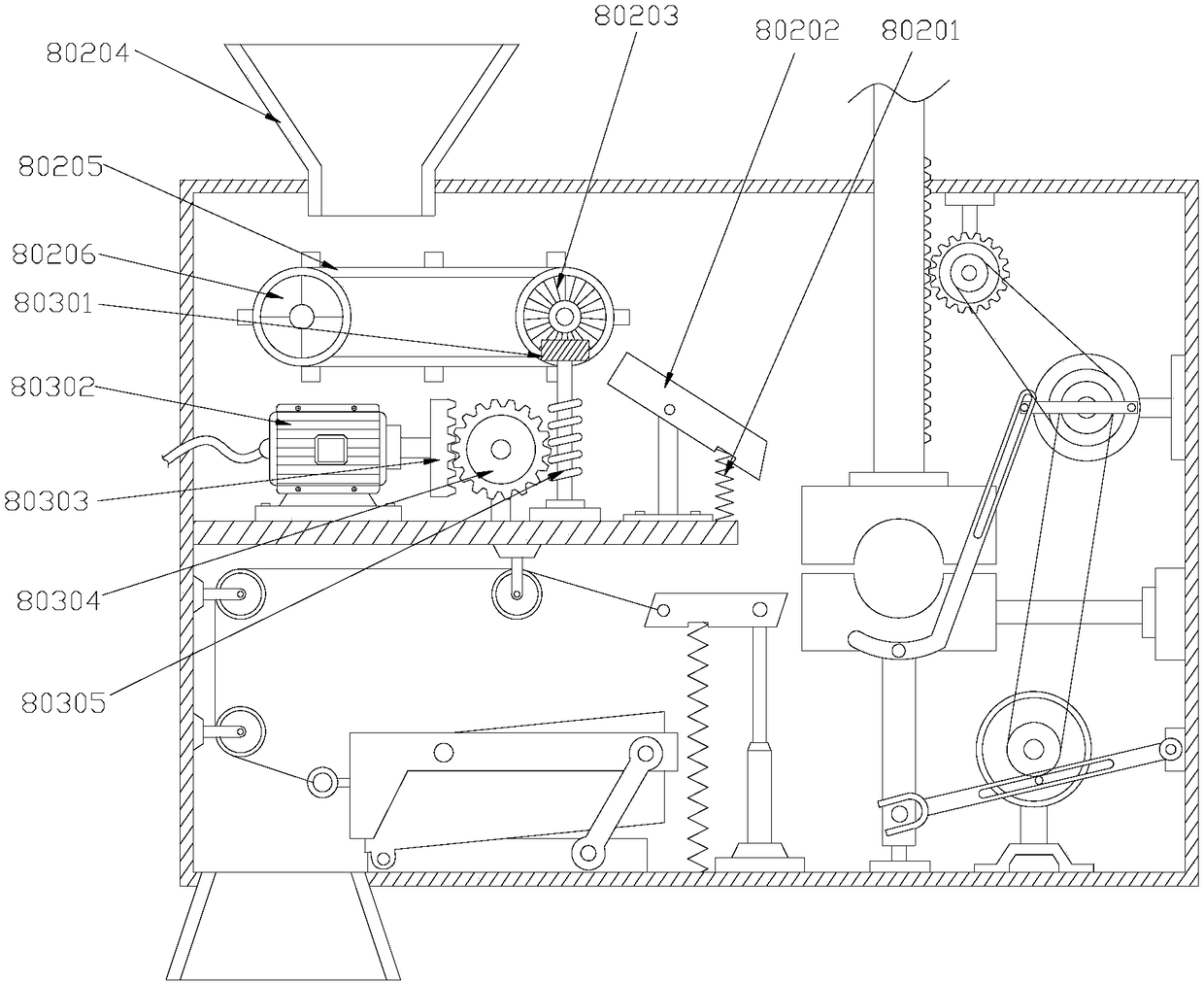

Full-automatic intelligent deburring machine

PendingCN111644928AProtect your healthReduce labor intensityEdge grinding machinesAutomatic grinding controlManufacturing engineeringRoboty

The invention relates to the technical field of powder removal metallurgical blank deburring, and discloses a full-automatic intelligent deburring machine. The full-automatic intelligent deburring machine comprises a machine frame, a feed conveying mechanism, a universal trolley, a machine body, an automatic tray feeding and discharging mechanism, a manipulator tray taking mechanism, a robot, a hairbrush mechanism, a tray fixing mechanism, a tray rotating mechanism and a digital control system; the universal trolley enters the machine frame and is positioned in the machine frame; the robot isa multi-joint robot; the hairbrush mechanism is installed on the multi-joint robot and provided with various hairbrushes, and accordingly, it is achieved that a product is pressed fixedly; and throughthe different hairbrushes and the technology, deburring of upper surfaces, peripheries or inner holes of various pressed products is completed, the efficient high-quality flexible deburring purpose is achieved, and the problems that at present, deburring is low in efficiency and poor in quality and cannot adapt to mass flexible automatic stable production are solved.

Owner:湖南汇创智造自动化科技有限公司

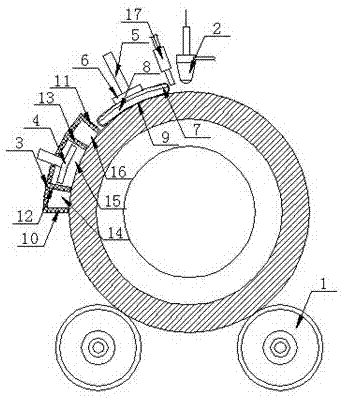

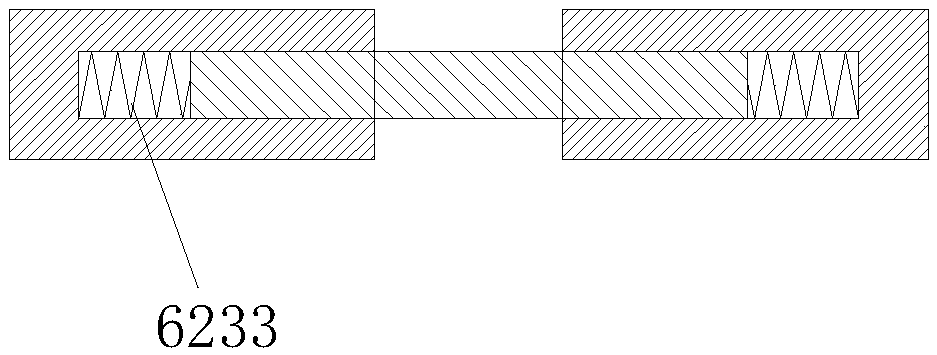

A melt magnetic spinning device and a method for preparing micro-nano fibers using the device

ActiveCN104878455BIncrease productionArranged in an orderly mannerArtificial thread manufacturing machinesFilament/thread formingEngineeringHigh pressure

The invention discloses a melt magnetic spinning device and a method for preparing micro-nano fibers by using the device. The device includes a heating feeding device with a controllable feeding rate, a spinning nozzle, a nozzle driving mechanism and a spinning receiving device , the spinning receiving device includes a horizontal collection disk, the center of the bottom of the collection disk is connected with the output shaft of the DC brushless motor for linkage, and the upper surface of the collection disk is symmetrically arranged with a plurality of vertical shafts with the central axis of the disk as the symmetrical axis. One of the vertical pillars is a permanent magnet, and the rest are metal needles. The spinning nozzle is arranged horizontally, and the injection port of the spinning nozzle points to the permanent magnet of the spinning receiving device. The connection of the spinning nozzle can drive its The nozzle drive mechanism that reciprocates in the vertical direction. The device does not need high-voltage action during use, effectively reduces production costs and potential safety hazards, and the prepared fibers are arranged in an orderly manner, with high output and suitable for large-scale production, and the obtained micro-nano fibers have good application prospects.

Owner:QINGDAO UNIV

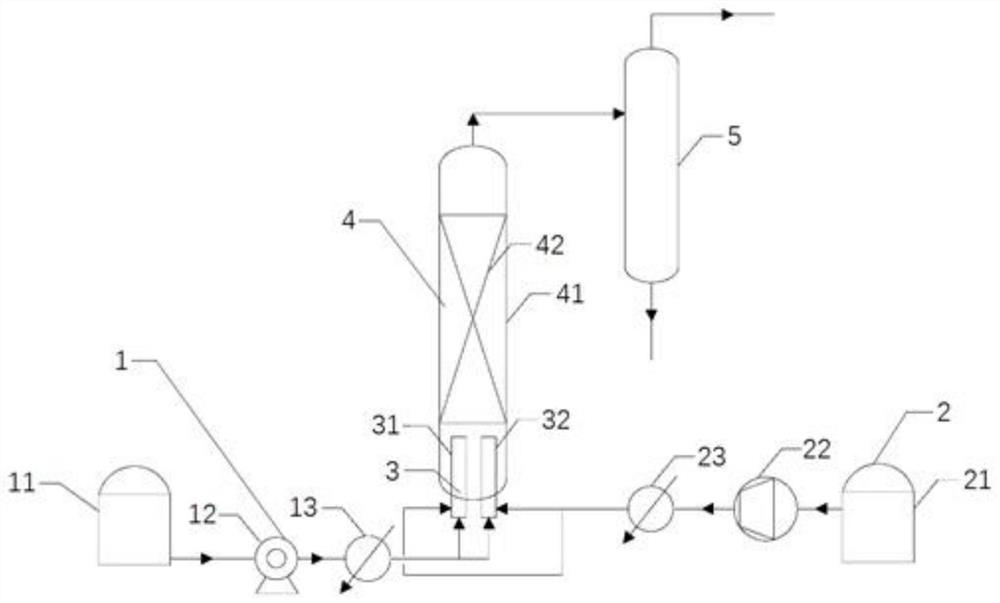

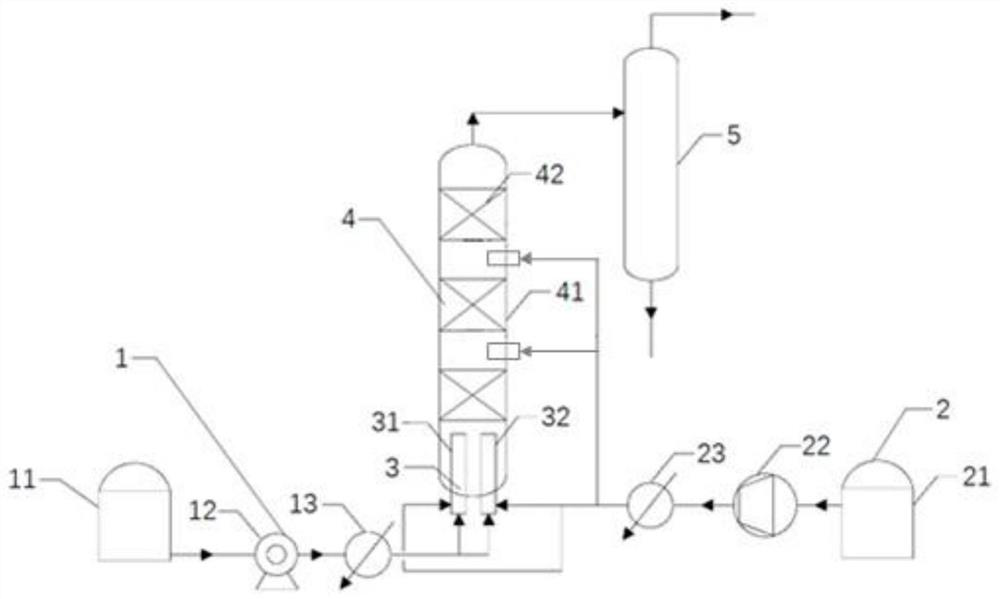

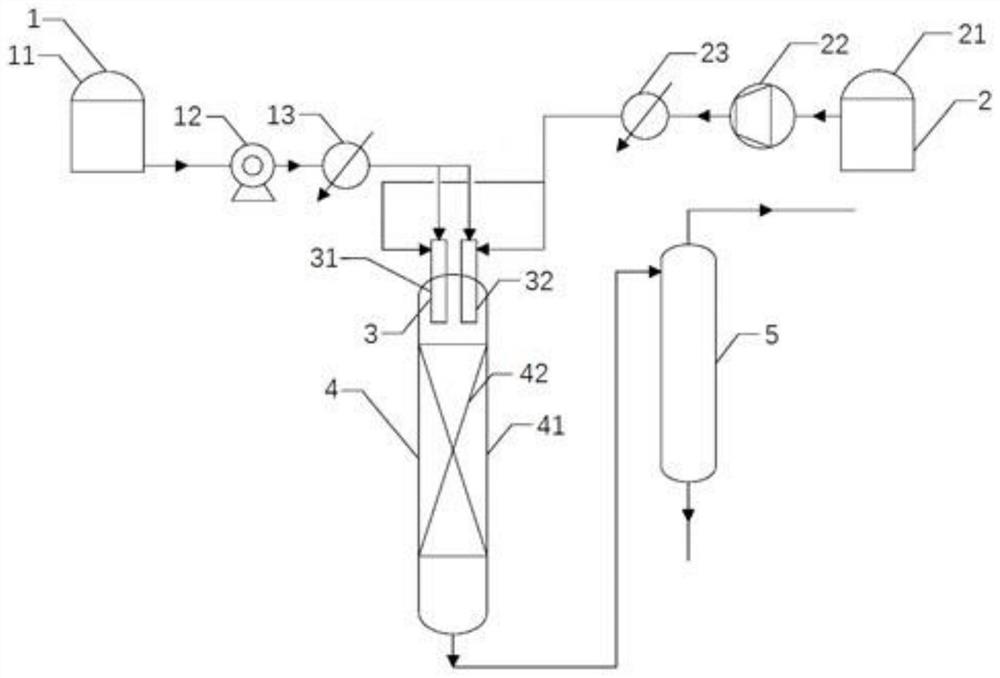

Mixed oil hydrogenation micro-interface enhanced reaction system and method

InactiveCN112175667AReduce material consumptionReduce energy consumptionHydrocarbon oil crackingChemical/physical processesFluid phaseEmulsion

The invention relates to a mixed oil hydrogenation micro-interface enhanced reaction system and method. The mixed oil hydrogenation micro-interface enhanced reaction system comprises a liquid phase feeding unit, a gas phase feeding unit, a micro-interface generator, a fixed bed reactor and a separation tank. Compared with a traditional fixed bed reactor, the micro-interface generator is arranged on the fixed bed reactor, and before reaction raw materials enter the reactor for reaction, pressure energy of gas and / or kinetic energy of liquid in the reaction process are / is converted into surfaceenergy of hydrogen bubbles, hydrogen bubbles are crushed into micro-bubbles with a diameter of more than or equal to 1 [mu] m and less than 1 mm, so the phase contact area between mixed oil and hydrogen in the hydrogenation reaction process is effectively increased, the mass transfer efficiency between the mixed oil and hydrogen is improved, and the mixed oil and the hydrogen micro-bubbles are mixed to form a gas-liquid emulsion after crushing, and furthermore, the reaction efficiency between the mixed oil and the hydrogen is enhanced within a relatively low preset pressure range.

Owner:NANJING YANCHANG REACTION TECH RES INST CO LTD

Cement clinker breaking roller surface heating repair device

ActiveCN107283020AAvoid damageEnsure safetyGas flame welding apparatusSpray nozzlePulp and paper industry

The invention discloses a cement clinker breaking roller surface heating repair device. The device comprises a breaking roller rotary supporting column used for penetrating through the axis of a breaking roller to support the breaking roller, a roller surface repair build up welding mechanism arranged above the breaking roller rotary supporting column, and a roller surface repair heating mechanism arranged on one side of the breaking roller rotary supporting column. The breaking roller rotary supporting column is horizontally arranged. The roller surface repair heating mechanism comprises a roller surface heating flame spray rod, the roller surface heating flame spray rod is parallel to the breaking roller rotary supporting column, a roller surface heating flame spray nozzle is formed in the roller surface heating flame spray rod, and the roller surface heating flame spray nozzle faces the roller surface of the breaking roller in an obliquely upward mode. According to the cement clinker breaking roller surface heating repair device, the roller surface of the breaking roller can be subjected to preheating and build up welding work through mechanical equipment, and therefore the labor intensity and production safety of workers are reduced.

Owner:江西银杉白水泥股份有限公司

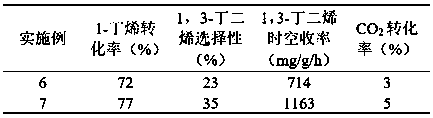

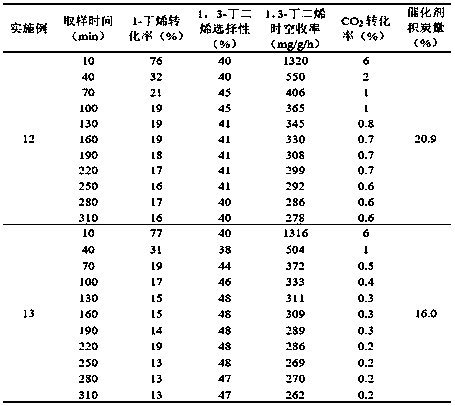

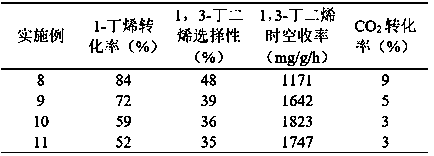

Reaction process for preparing 1, 3-butadiene by oxidizing and dehydrogenating 1-butene with carbon dioxide

ActiveCN111470932AEliminate "hot spots"Improve stabilityCatalystsHydrocarbon preparation catalystsButeneButadiene Dioxide

The invention provides a reaction process for preparing 1, 3-butadiene by oxidizing and dehydrogenating 1-butene with carbon dioxide. According to the reaction process, water vapor is introduced intoa reaction system so as to reduce the carbon deposition of a catalyst during the reaction process, such that the catalyst is regenerated, the reaction heat during the high temperature reaction is removed, the fine adjustment effect on the surface morphology of the catalyst is generated, and the carbon deposition resistance, the reaction activity and the stability of the catalyst are improved.

Owner:TIANJIN UNIV OF SCI & TECH

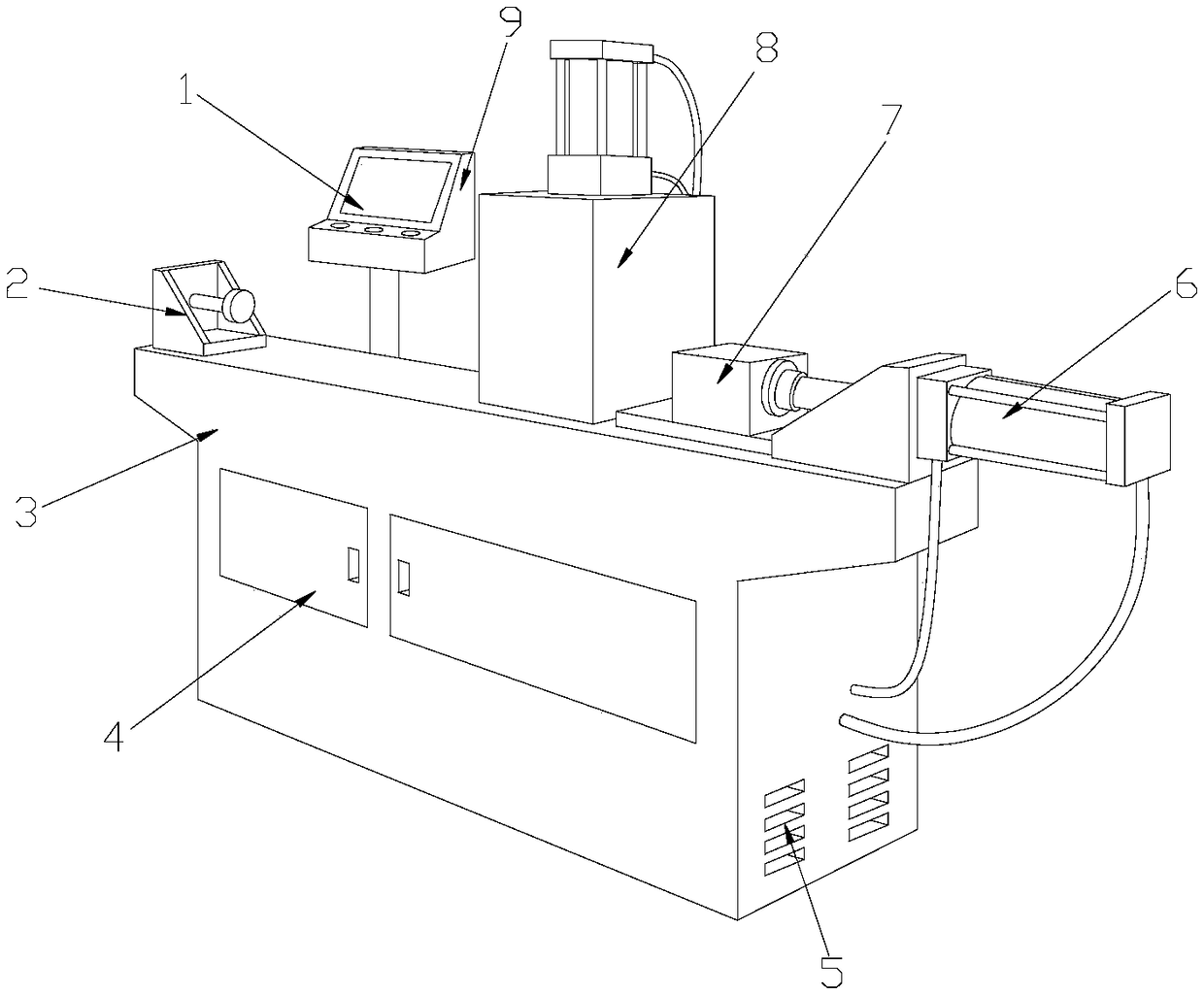

Pipe end hydraulic forming device for automobile exhaust pipe

InactiveCN108480494AIncrease productivityEnsure safetyMetal-working feeding devicesStripping-off devicesHydraulic cylinderLiquid-crystal display

The invention discloses a pipe end hydraulic forming device for an automobile exhaust pipe. The device structurally comprises a liquid crystal display panel, a pipe tail positioning and adjusting device, a forming machine fixing seat, an equipment overhaul door, an exhaust heat-dissipating hole, a hydraulic cylinder, a pipe end forming mold, a clamping and unloading device and an electric controller. As the pipe end hydraulic forming device for the automobile exhaust pipe is provided with the clamping and unloading device, the exhaust pipe can be automatically placed on a processing table to be clamped and processed and formed. After the exhaust pipe is processed, the exhaust pipe is unloaded automatically. The exhaust pipes need not to be placed on the equipment to process manually, so that the safety of operators in the working process is guaranteed while the production efficiency of the pipe end hydraulic forming equipment is improved effectively.

Owner:湖州高锐工贸有限公司

Planting technology for organic rice

InactiveCN105145219AIncrease weed contentReduce nutrientsExcrement fertilisersBioloigcal waste fertilisersNutrientWeed

The invention provides a planting technology for organic rice. The planting technology includes the following steps that land which is idle for at least two years is selected as an organic rice planting region, and a partition with the width of 30-80 m is arranged around the region; after the land is subjected to soil loosening, irrigation and application of specially-made organic fertilizer in spring and the paddy field is mashed through a land preparation machine, rice transplanting is conducted while film mulching is conducted through a mulch applicator; ultraviolet lamps and trichogramma beehives are arranged; during growth of the organic rice, weeds are pulled out in a manual weeding mode. Rice is harvested in autumn, dehusked, bagged, subjected to quality inspection and put in storage. In the planting process of the organic rice, only the farmyard manure is used, pollution is avoided, meanwhile, effective absorption of microelements and nutrient substances is guaranteed, and the nutrition performance and valuableness of the organic rice are guaranteed. The organic rice is high in yield, and the yield can reach 80% or above that of common rice; after sowing, manual participation is not needed basically, cost expenditure is reduced, and productivity is liberated.

Owner:沈阳久兴粮谷加工有限公司

Preparation method of nano kaolin for rubber filler

PendingCN113604076AReduce labor intensityNo pollution in the processGrain treatmentsPigment treatment with macromolecular organic compoundsPolymer scienceKaolin clay

The invention discloses a preparation method of nano kaolin for a rubber filler. The method is simple and environment-friendly in process and capable of fully stripping a kaolin lamellar structure, so that the particle size reaches 300-500 nanometers, the lamellar thickness reaches 20-50 nanometers, the nano effect of kaolin can be fully exerted in a rubber system, and the effects of high reinforcement and high filling are achieved.

Owner:山西中埃科技有限公司

Automatic impregnating thermal treatment mechanism

InactiveCN108787342ASimple structureNo manualLiquid surface applicatorsCoatingsEngineeringHigh pressure

The invention discloses an automatic impregnating thermal treatment mechanism. The automatic impregnating thermal treatment mechanism comprises a convex impregnating device which is composed of an impregnating body and a liquid supply slot, an automatic discharge device which is arranged at the upper end of the impregnating body, a valve mechanism and an inverse device which are arranged at a joint of the impregnating body and the inner cavity of the liquid supply slot, a variable-frequency pressure controller which is arranged on the bottom of the liquid supply slot, a thermal treatment device which is fixedly arranged at the right side of the impregnating body through a conveyor belt with a conveying start up, an controller and an automatic unloading channel which are separately arrangedat left and right sides of the thermal treatment device; and left and right sides of the impregnating body are equipped with constant apparatuses; the bottom of the thermal treatment device is equipped with a high-pressure heater; a trigger is arranged between the variable-frequency pressure controller and the high-pressure controller; the trigger is connected with the conveying start valve; andboth the impregnating body and the thermal treatment device realize functions of liquid supply, hydraulic impregnating and high-pressure heating and drying through the variable-frequency pressure controller.

Owner:ZHANGJIAGANG SHUANGCHENG ELECTRICIAN EQUIP CO LTD

Bromochlorohydantoin continuous production method

ActiveCN111675656BReduce production stepsReduce manufacturing costProductsOrganic chemistryWater chlorinationCyanohydrin

Owner:河北利仕化学科技有限公司

Process for extracting pectin by using sisal hemp residue

InactiveCN107629143AGuarantee product qualityGuarantee production safetyInorganic saltsOrganic solvent

The invention discloses a process for extracting pectin by using sisal hemp residue. The process comprises: S1, raw material pretreatment; S2, enzyme inactivation through cooking; S3, near neutral extraction with an inorganic salt; S4, decolorization and impurity removal; S5, pressure reducing concentration; S6, crystallization; S7, three treatment combination; and S8, drying screening and pectinfinished product obtaining. According to the present invention, the solid technical basis is provided for the large-scale production of pectin and the ensuring of the normal pectin product supply through the rich raw material resources; the pectin is extracted by using the neutral inorganic salt as the auxiliary agent, such that the investment on the production equipment can be save about 30%; theproduced pectin is the natural low-fat pectin, such that the performance of the product is further improved, and the process has advantages of simpleness, effectiveness, safety, low cost and good benefits; and with the process, the volatilization of organic solvents and the unnecessary loss are effectively prevented, the pectin production safety achieves the relatively improved assurance, the loss of organic solvents is substantially reduced, the production cost is reduced, and the profit of pectin enterprises can be increased.

Owner:杭州舒诚生物科技有限公司

A method for preparing graphene/polymer ordered micro-nano composite fibers by magnetic spinning

InactiveCN104862799BArranged in an orderly mannerIncrease productionArtificial thread manufacturing machinesMonocomponent synthetic polymer artificial filamentBrushless motorsCircular disc

The invention discloses a method for preparing graphene / polymer micro-nano fibers by magnetic spinning, which comprises the following steps: (1) building a magnetic spinning device: the magnetic spinning device includes a rotating collection disc with a permanent magnet; (2) ) Preparation of precursor spinning solution: magnetic nanoparticles, high molecular polymer and graphene dispersion are mixed and dissolved in an organic solvent to prepare a solution; (3) graphene / polymer micro-nano composite fiber is prepared by using a magnetic spinning device: the precursor The spinning solution is injected into the feeding device, and the feeding device is turned on. The liquid droplets at the nozzle of the spinning nozzle form a jet flow and bridge the permanent magnet under the action of the magnetic field force, and the DC brushless motor is turned on to drive the collecting disc to rotate. Under the action of the magnetic field force, the ferrofluid jet is continuously pulled out and entangled between the vertical pillars of the collecting disc to form micro-nano fibers. The method does not require high-voltage action, reduces production costs and safety hazards, has orderly fiber arrangement, is suitable for large-scale production, and has good application prospects.

Owner:QINGDAO UNIV

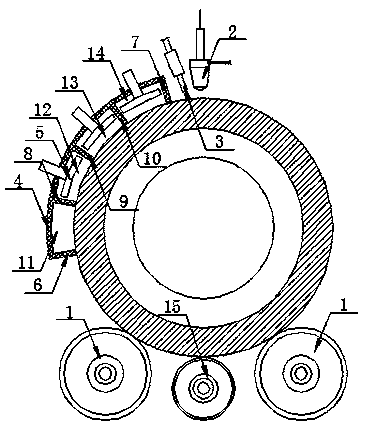

High-stability grinding roller surface overlaying welding repair equipment

ActiveCN107457510AReduce labor intensityReduce production safetyWelding/cutting auxillary devicesAuxillary welding devicesRestoration deviceEngineering

The invention discloses high-stability grinding roller surface overlaying welding repair equipment which comprises two overlaying welding rotary supporting rollers, an abrasion-resistant layer overlaying welding gun, an overlaying welding preheat arc-shaped cover plate and a heat-preservation fixing press block, wherein the two overlaying welding rotary supporting rollers are arranged at the bottom of a grinding roller; the grinding roller is horizontally placed along an axis; the abrasion-resistant layer overlaying welding gun is arranged above the top surface of the grinding roller; the overlaying welding preheat arc-shaped cover plate is arranged on the roller surface of the grinding roller and positioned on one side of the abrasion-resistant layer overlaying welding gun; the heat-preservation fixing press block is arranged on the roller surface of the grinding roller and positioned between the abrasion-resistant layer overlaying welding gun and the overlaying welding preheat arc-shaped cover plate; the axes of the two overlaying welding rotary supporting rollers are both horizontal and parallel to the grinding roller; the two overlaying welding rotary supporting rollers are symmetrically arranged relative to the vertical surface penetrating through the axis of the grinding roller; and an overlaying welding preheat heating block is arranged between the overlaying welding preheat arc-shaped cover plate and the roller surface of the grinding roller. By adoption of the high-stability grinding roller surface overlaying welding repair equipment, the grinding roller can be kept stable in an abrasion-resistant layer overlaying welding operation process; besides, the roller surface of the grinding roller for crushing can be automatically preheated; and the labor intensity and the production safety of operators can be reduced.

Owner:贵港捷盛机械有限公司

Preparation process of clofarabine intermediate

PendingCN112062795ALow priceFacilitate subsequent processingEsterified saccharide compoundsSugar derivativesBeakerAcetic anhydride

The invention discloses a preparation process of a clofarabine intermediate. The preparation process comprises the following steps of a) preparing the following raw materials including 5-8 g of D-ribose, 20-30 ml of a hydrogen chloride gas-methanol solution, 15-25 ml of pyridine, 50-70 ml of chloroform, 40-55 ml of glacial acetic acid, 5-8 ml of acetic anhydride, 20-30 ml of barium chloride, 3-5 ml of concentrated sulfuric acid, 80-100 ml of 95% ethyl alcohol, 6-10 ml of dinitrobenzotrifluoride, and 200-300 ml of ice water; and b) preparing following instruments of a low-temperature cooling circulating pump, a reduced pressure distillation kettle, a 250 ml beaker, a stirrer and a mixed reaction kettle. The D-ribose, hydrogen chloride gas-methanol solution, pyridine, chloroform, glacial acetic acid, acetic anhydride and other raw materials are all common chemical raw materials with low price, and the production cost is low; and besides, guanosine which is difficult to remove thoroughlyis not adopted as a raw material, the subsequent processing of the finished product of the clofarabine intermediate is convenient while low cost is achieved, and the potential safety hazard is small.

Owner:TIANJIN QUANHECHENG TECH

An integrated machine for hair planting and packaging after the toothbrush handle is formed

ActiveCN108887865BReduce labor intensityReduce production safetyBrush bodiesWrappingBristleEngineering

Owner:广东三椒口腔健康产业研究院有限公司

A preheating and surfacing device for wear-resistant layer of limestone crushing roller

ActiveCN107457509BReduce operating energy consumptionReduce labor intensityWelding/cutting auxillary devicesAuxillary welding devicesVertical planeWear resistant

Owner:溧阳天山水泥有限公司

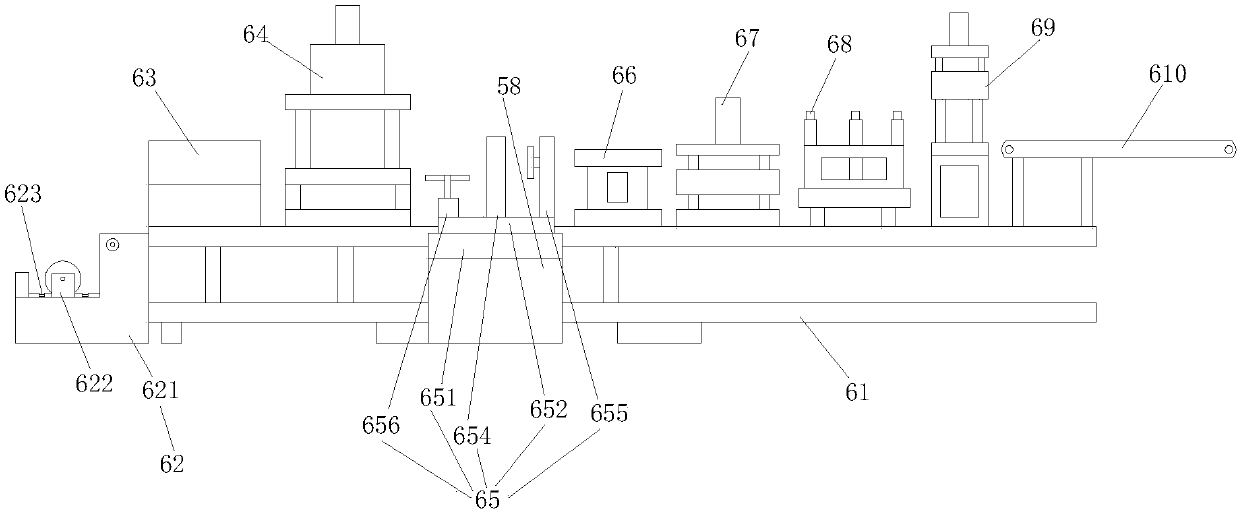

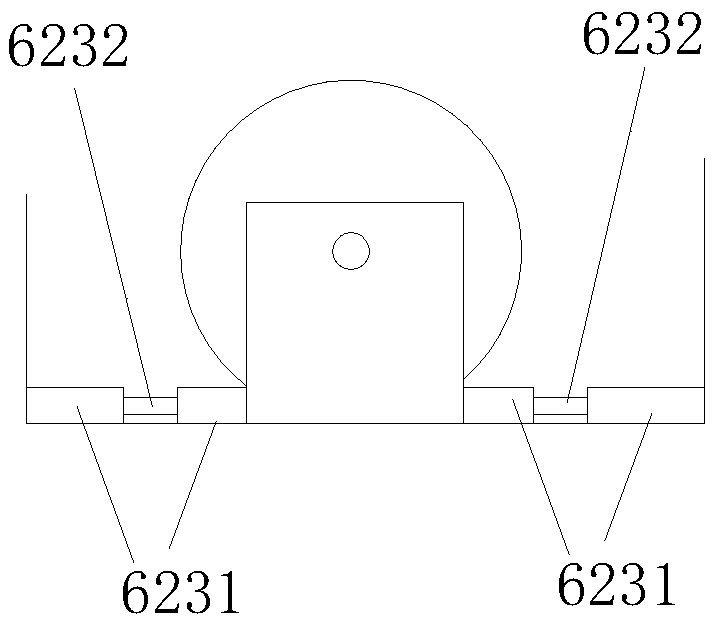

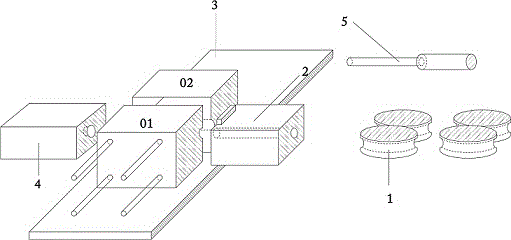

Solid car hook automatic pier equipment

ActiveCN103522066BGuaranteed accuracyReduce production safetyOther manufacturing equipments/toolsHandling devicesHead shapeMechanical engineering

The invention discloses automatic solid head shaping equipment of an automobile lifting hook. The automatic solid head shaping equipment of the automobile lifting hook serves as an automobile lifting hook production device which is small in occupied space, accurate in cutting and capable of achieving automatic feeding and automatic discharging. The automatic solid head shaping equipment of the automobile lifting hook comprises drawing circles, a guiding and cutting male mold, a clamping box A, a clamping box B, a sliding rail, a positioning pier head and a discharging ejector pin, round steel can be made straight and round through a plurality of sets of drawing circles and can be sent into a groove in the middle of the clamping box A and into a groove in the middle of the clamping box B through a hole of the guiding and cutting male mold, a hydraulic device pushes the clamping box A and the clamping box B to clamp the round steel when the round steel touches the positioning pier head, the round steel is cut off by a cutting device on the left side of the guiding and cutting male mold, then the positioning pier head starts to squeeze the left end of the round steel to obtain a needed shape, the clamping box A and the clamping box B move on the sliding rail, the well shaped right end of the round steel aims at the discharging ejector pin, the hydraulic device loosens the clamping boxes, and then the round steel is pushed out of the clamping boxes by the discharging ejector pin.

Owner:安徽振华汽车部件有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com