Preparation method for rapidly growing metal organic framework derivative with assistance of metal salt

A metal-organic framework, metal salt technology, applied in rayon manufacturing, fiber chemical characteristics, electrical components, etc., can solve the obstacles that hinder the large-scale production and industrial application of MOF materials, large-scale commercial application limitations, and expensive layer deposition methods. To achieve the effect of enriching high active sites, reducing production costs and safety hazards, and improving electrocatalytic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

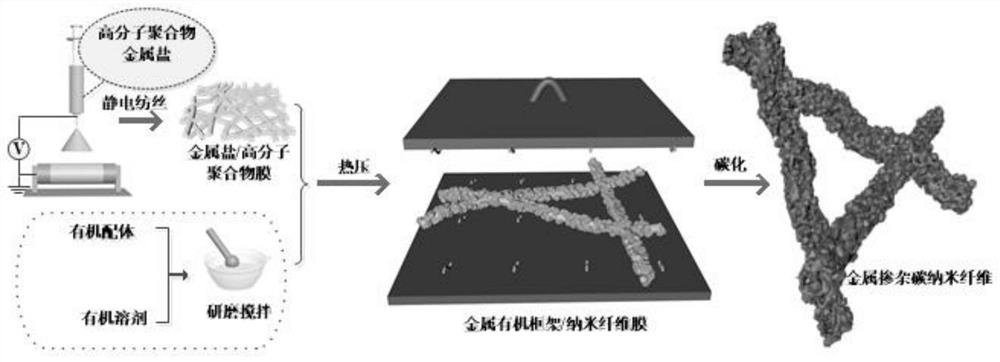

[0028] The invention provides a preparation method of a metal salt assisted rapid growth metal organic framework derivative.

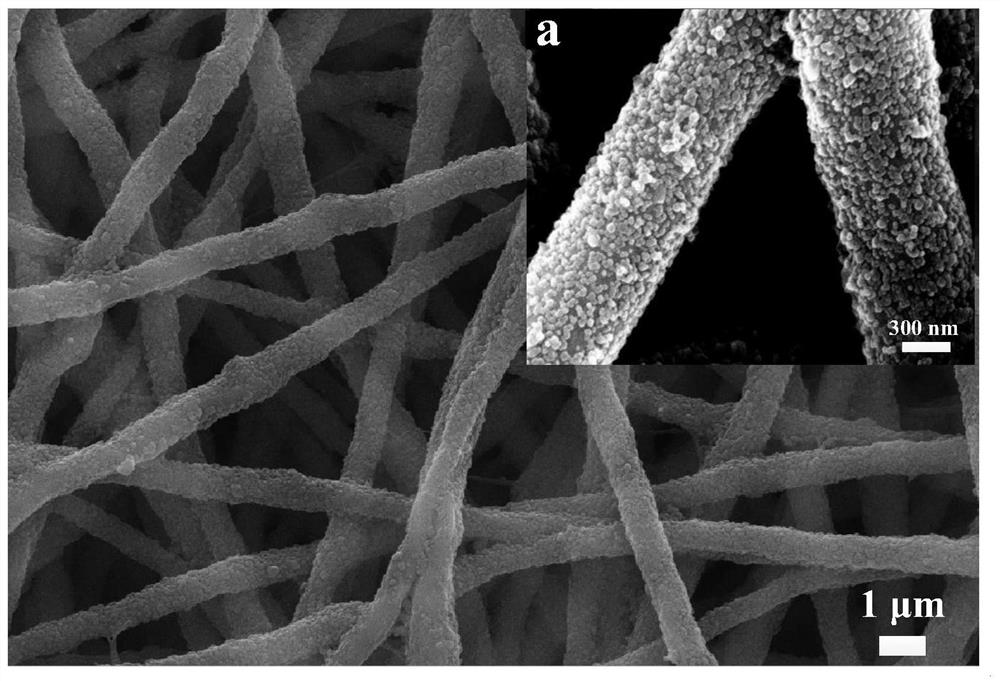

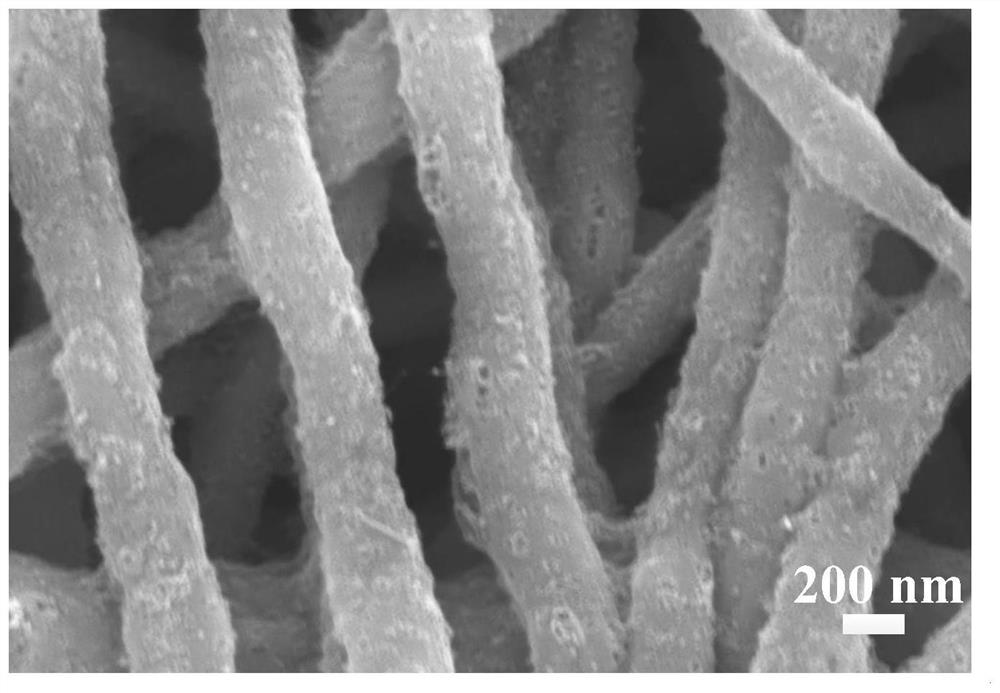

[0029] In this method, metal salts and high molecular polymers are first added to organic solvents, and the mixed solution is obtained by thorough stirring, and the metal salt / polymer nanofiber membrane is obtained by electrospinning technology, and then the organic ligands required for the growth of MOFs containing metal organic frameworks are mixed. The body solution is evenly coated on the metal salt / polymer nanofiber membrane, and then the chemical bond between the metal ion and the ligand in the nanofiber is realized by hot pressing technology, so that the MOF material grows densely and uniformly on the nanofiber membrane, and the MOF / nano Metal-embedded nitrogen-doped porous carbon nanofibers were formed after the fiber membrane was calcined under inert gas.

[0030] Such as figure 1 As shown, the specific steps are as follows:

[0031] (1) Add...

Embodiment 1

[0036] The first step, preparation of metal salt / polyacrylonitrile (PAN) nanofiber membrane

[0037] Add 1.0 g of polyacrylonitrile (PAN) and 1.0 g of cobalt acetate into 10 mL of dimethylformamide solution, and magnetically stir for 10 h at room temperature to form a uniform spinning solution. The above spinning solution was transferred to a 10mL syringe and placed on a syringe pump, and a cobalt acetate / polyacrylonitrile (PAN) nanofiber membrane was obtained by electrospinning technology. The applied voltage for spinning is 12-20kV, the feed rate of the syringe pump is 0.6mL / h, the distance between the needle and the roller receiver is 20cm, and the needle of the syringe is 19#.

[0038] The second step, preparation of ZIF-8 / PAN nanofiber membrane

[0039] Such as figure 1 As shown, 0.35g dimethylimidazole (2-MeIm) and 5mL polyethylene glycol (PEG200) were placed in a mortar and ground evenly, and then coated on the cobalt acetate / polyacrylonitrile (PAN) nanofiber membrane...

Embodiment 2

[0043] The first step is to prepare bimetallic salt / polyacrylonitrile (PAN) nanofiber membrane:

[0044] Add 1.0 g of polyacrylonitrile, 0.47 g of cobalt acetate, and 0.53 g of zinc acetate into 10 mL of dimethylformamide solution, and magnetically stir for 10 h at room temperature to form a uniform spinning solution. The above spinning solution was transferred into a 10mL syringe and placed on a syringe pump, and cobalt acetate-zinc acetate / PAN nanofiber membrane was obtained by electrospinning technology. The applied voltage for spinning is 12-20kV, the feed rate of the syringe pump is 0.6mL / h, the distance between the needle and the roller receiver is 20cm, and the needle of the syringe is 19#.

[0045] The second step, preparation of bimetallic organic framework (BMZIF) / PAN nanofibrous membrane

[0046] The polyethylene glycol (PEG200) of 0.35g dimethylimidazole (2-MeIm) and 5ml is placed in mortar and grinds evenly, is then coated on zinc acetate / cobalt acetate / polyacrylon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com