Cement clinker breaking roller surface heating repair device

A cement clinker and crushing roller technology, which is applied in metal processing equipment, welding equipment, gas flame welding equipment, etc., can solve the problems of large volume and weight of crushing rollers, hidden safety hazards, etc., to reduce production safety and ensure safety , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

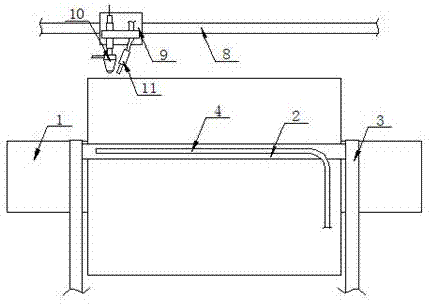

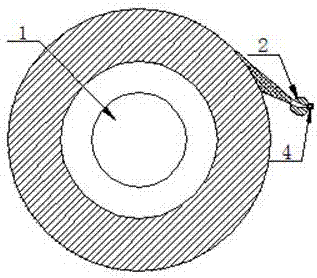

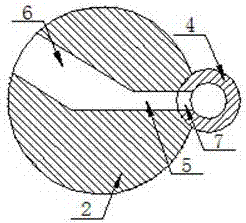

[0016] refer to Figure 1 to Figure 3 , Figure 1 to Figure 3 It is a structural schematic diagram of a specific embodiment of the present invention.

[0017] Such as Figure 1 to Figure 3 As shown, a cement clinker crushing roller surface heating and repairing device includes a crushing roller rotating support column 1 for passing through the crushing roller axis to support the crushing roller, and a roller arranged above the crushing roller rotating support column 1 surface repair surfacing mechanism, and a roller surface repair heating mechanism arranged on one side of the crushing roller rotating support column 1, the crushing roller rotating supporting column 1 is horizontally arranged; the roller surface repair heating mechanism includes a roller surface heating flame spraying mechanism Rod 2, the roller surface heating flame spray rod 2 is parallel to the crushing roller rotating support column 1, the roller surface heating flame spray rod 2 is provided with a roller ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com