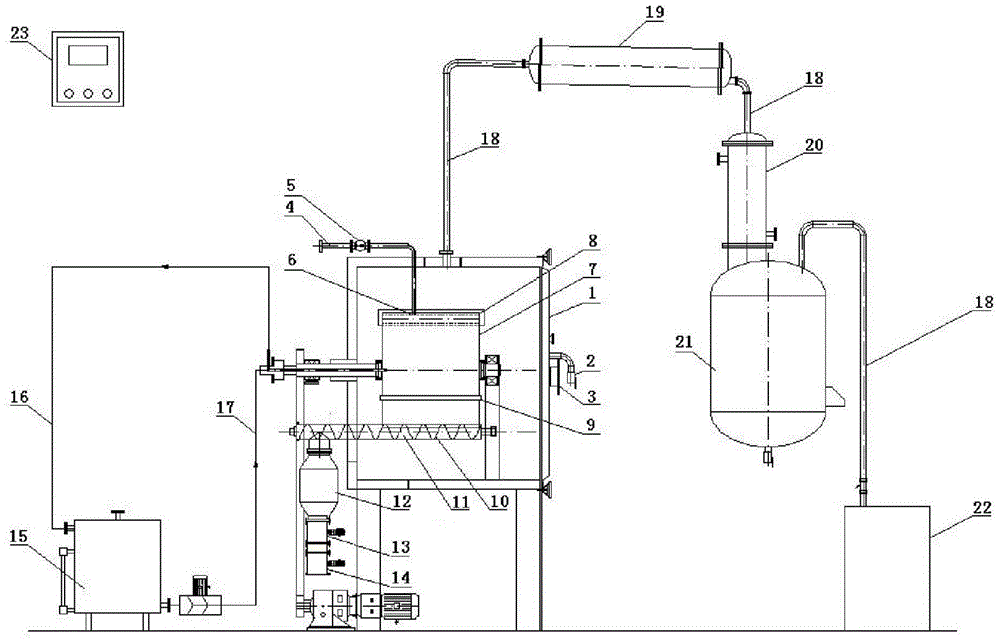

Continuous dry drum zein drying device and method

A vacuum drum and drying equipment technology, applied in food preservation, food science, application, etc., can solve the problems of difficult solvent recovery, high production cost, low production efficiency, etc., to reduce production cost and potential safety hazards, efficiently recycle, prevent sex change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

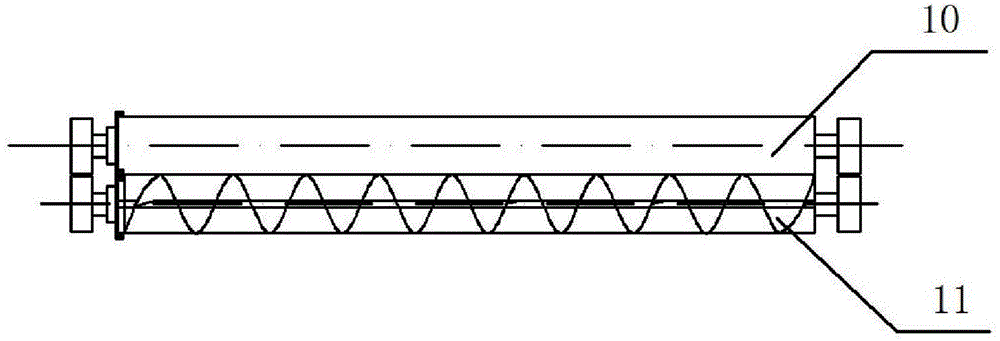

Embodiment 1

[0044] First start the drum scraper drying equipment and adjust the speed to 0.8r / min. Start the steam supply equipment, adjust the steam pressure to 0.20MPa, and preheat the main box. Secondly, start the water jet pump equipment and adjust the vacuum degree of the box to 0.001MPa. Open the liquid inlet system and adjust the flow rate to 0.8L / min. The volume percentage concentration of the corn protein extract is 22%, and the extract enters the distribution groove 8 obliquely above the back of the main cylinder 7 through the feed pipe 4, and is evenly distributed on the surface of the rotating main cylinder 7 after flowing out from the distribution groove 8 . The circulating steam generated by the steam supply system 15 is transported to the inner wall of the main cylinder 7 through the hot steam inlet pipe 16, and then flows back to the steam supply system 15 through the cold steam discharge pipe 17; the corn protein extract rotates with the main cylinder 7 and is evenly dr...

Embodiment 2

[0047] First start the drum scraper drying equipment and adjust the speed to 1.2r / min. Start the steam supply equipment, adjust the steam pressure to 0.25MPa, and preheat the main box. Secondly, start the water jet pump equipment and adjust the vacuum degree of the box to 0.002MPa. Open the liquid inlet system and adjust the flow rate to 1.3L / min. The volume percentage concentration of the corn protein extract is 20%. The extract enters the distribution groove 8 obliquely above the back of the main cylinder 7 through the feed pipe 4, and is evenly distributed on the surface of the rotating main cylinder 7 after flowing out from the distribution groove 8. . The circulating steam generated by the steam supply system 15 is transported to the inner wall of the main cylinder 7 through the hot steam inlet pipe 16, and then flows back to the steam supply system 15 through the cold steam discharge pipe 17; the corn protein extract rotates with the main cylinder 7 and is evenly dried...

Embodiment 3

[0050] First start the drum scraper drying equipment and adjust the speed to 1.5r / min. Start the steam supply equipment, adjust the steam pressure to 0.30MPa, and preheat the main box. Secondly, start the water jet pump equipment and adjust the vacuum degree of the box to 0.002MPa. Open the liquid inlet system and adjust the flow rate to 1.8L / min. The volume percentage concentration of the corn protein extract is 25%, and the extract enters the distributing groove 8 obliquely above the back of the main cylinder 7 through the feed pipe 4, and is evenly distributed on the surface of the rotating main cylinder 7 after flowing out from the distributing groove 8 . The circulating steam generated by the steam supply system 15 is transported to the inner wall of the main cylinder 7 through the hot steam inlet pipe 16, and then flows back to the steam supply system 15 through the cold steam discharge pipe 17; the corn protein extract rotates with the main cylinder 7 and is evenly dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com