Full-automatic intelligent deburring machine

A deburring machine, fully automatic technology, applied in the direction of grinding automatic control device, grinding feed movement, grinding machine parts, etc., to achieve the effect of protecting physical health, reducing production safety, and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

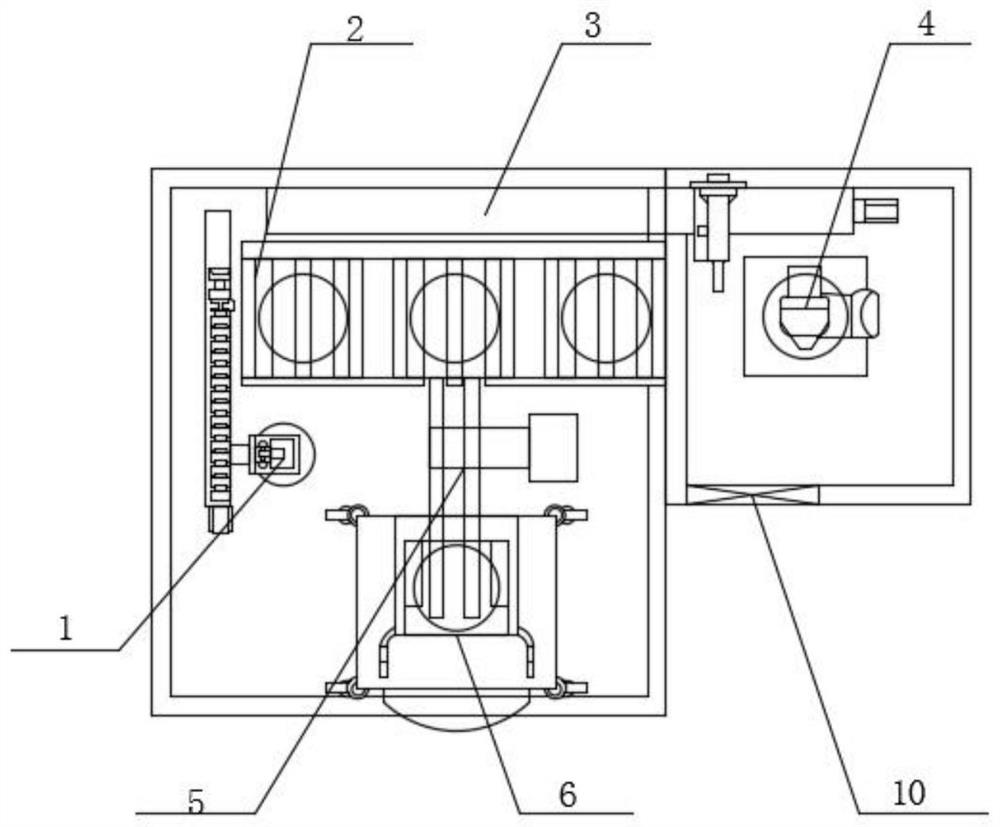

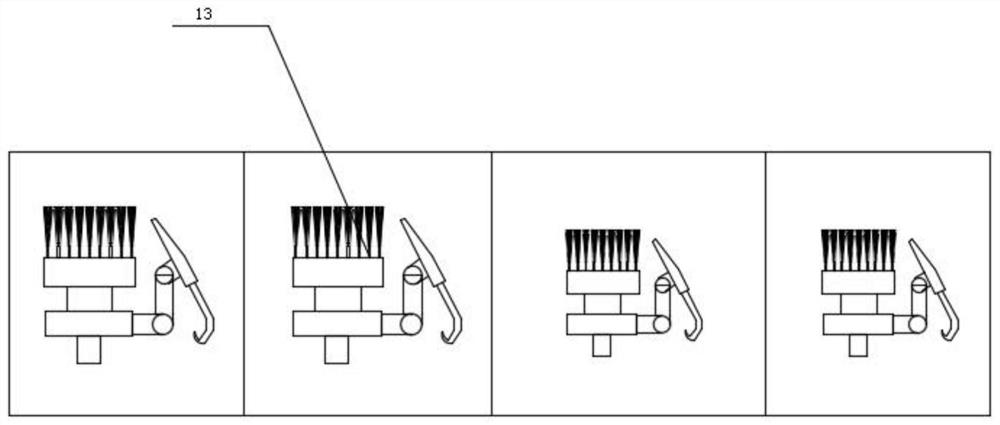

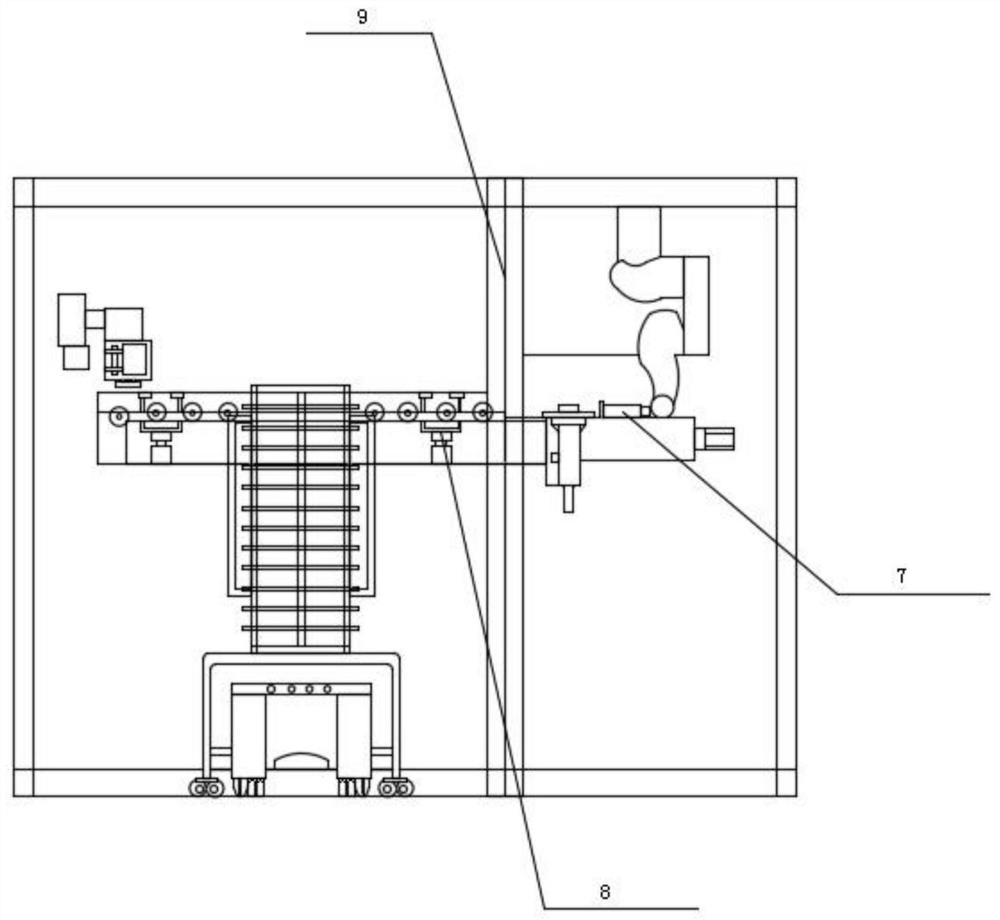

[0035] The present invention provides a fully automatic intelligent deburring machine, comprising: a frame 9, a universal trolley 6, a body, an automatic loading and unloading tray mechanism, a manipulator taking tray mechanism, a robot, an integrated brush 13, a tray fixing mechanism, a tray Disc rotation mechanism, digital control system; it is characterized in that: the general-purpose trolley 6 is installed on the frame 9; the robot is a multi-joint robot 4; the integrated brush 13 is installed on the multi-joint robot 4; the integrated The hair brush 13 is equipped with at least one set of integrated hair brushes.

[0036] Preferably, the general-purpose trolley 6 is a manual or AGV, which is used to turn over the sintering trays of the baked products.

[0037] Preferably, the centers of the power roller 2, the multi-joint robot 4 and the rotating tray 7 are on the same horizontal axis.

[0038] Preferably, at least one set of integrated hair brushes is installed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com