Solid car hook automatic pier equipment

A technology of automobile crane and pier head, which is applied in the direction of metal processing equipment, other manufacturing equipment/tools, manufacturing tools, etc. It can solve problems such as errors and insufficient manual cutting length of round steel, so as to ensure accuracy, reduce production safety, The effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

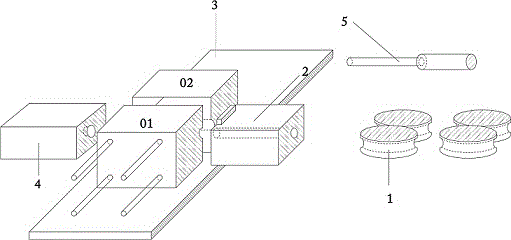

[0012] Solid car hook automatic pier equipment, such as figure 1 As shown, there is a semicircular groove on the side of the drawing circle 1, and every two drawing circles 1 form a group, a total of 6-7 groups of drawing circles, put the round steel into the groove of the drawing circle 1, Pulling circle 1 is driven and rotated by the motor, and the curved round steel is straightened and rounded. Through the rotation of pulling circle 1, the straightened round steel is guided to cut off the round hole of punch 2, and then sent into the clamping box A and clamping box A. When the top of the round steel hits the positioning pier head 4, the hydraulic device pushes the clamping box A and the clamping box B to clamp the round steel in the groove, and guides and cuts the left side of the punch 2. The cutting device cuts off the round steel, and the positioning pier head 4 squeezes out the desired shape from the clamped round steel pier head, the clamping box A and the clamping box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com